Could cruise ships eventually run off nuclear power? This company is working on it

Nuclear-powered ships could be coming to the world of cruising — but with a twist.

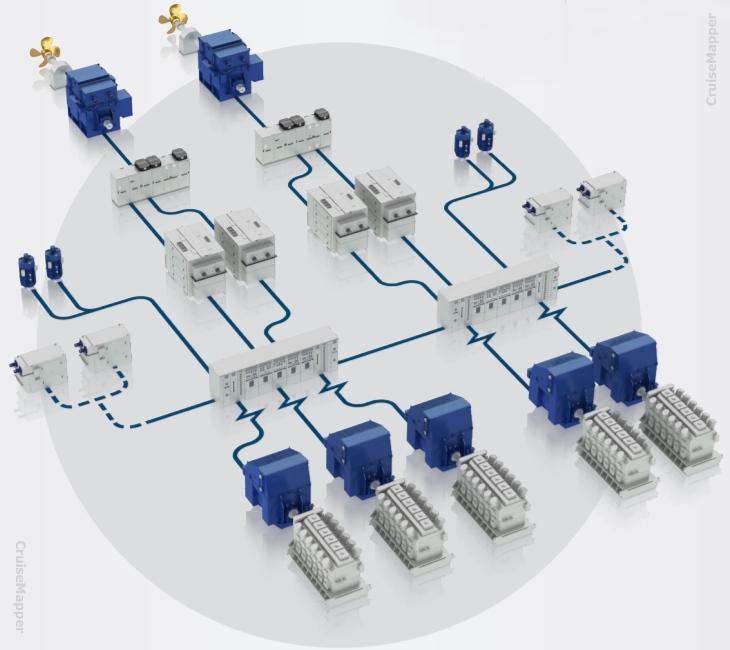

Norwegian shipbuilder Ulstein this week unveiled a new concept for a cruise vessel that would run on electricity generated at sea using a nuclear reactor.

The twist is that the reactor wouldn't be located on the cruise ship itself, but on a separate service vessel. The service vessel would recharge electric batteries on the cruise ship every few days.

For more cruise news, guides and tips, sign up for TPG's cruise newsletter .

If the idea moves forward (something that will require both regulators as well as cruise lines to get on board), it will result in the arrival of what has long been something of a Holy Grail for the cruise industry – cruise vessels that are entirely emission-free.

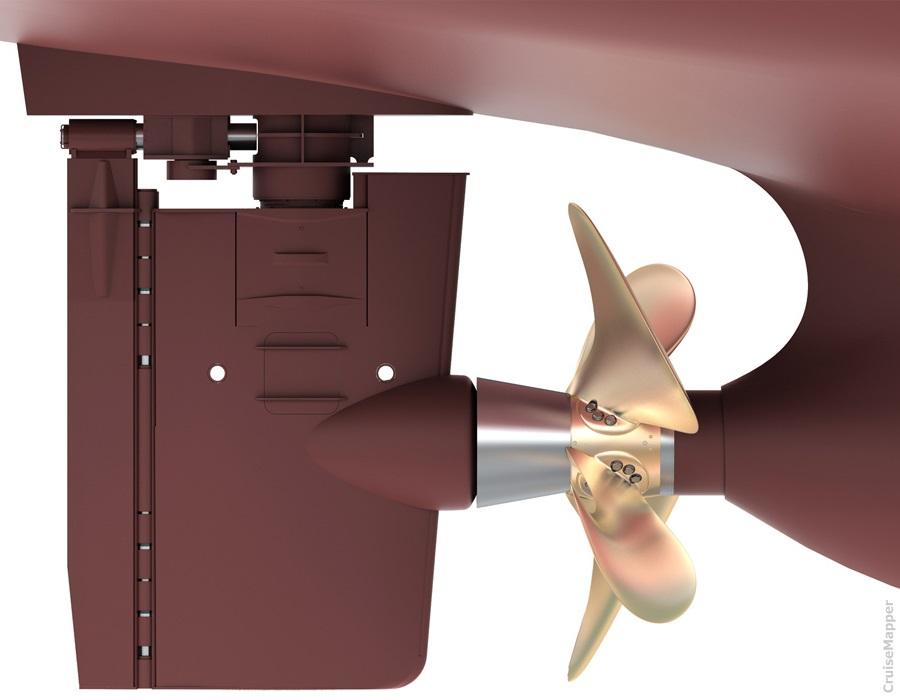

Cruise ships have traditionally been powered with bunker oil, also known as heavy fuel oil, or another grade of oil called marine gasoil. Additionally, some ships in recent years have been designed to run on Liquefied Natural Gas, which is touted as a cleaner fuel than traditional marine-grade oils. However, using all such fuels results in emissions.

"Where you are going very long distances [with a cruise ship], you will never be able to be zero emissions with the fuel we have today," Ulstein senior naval architect Torill Muren told TPG on Tuesday at Seatrade Cruise Global, the cruise industry's annual meetup in Miami. "We want to start a discussion [about using nuclear power]."

Muren spoke one-on-one with TPG moments after Ulstein revealed the concept at the company's booth at Seatrade Cruise Global, which is taking place this week at the Miami Beach Convention Center.

The company unveiled an outline of its concept for both an all-electric cruise vessel and the nuclear power-generating service vessel that would keep the all-electric cruise vessel charged. It also showed off artist's renderings of what the two vessels would look like.

As depicted in the renderings, the cruise ship the line is proposing would be a small, hardy vessel of the sort that is used for expedition cruising — a type of cruising that involves traveling to hard-to-reach and often environmentally sensitive places such as Antarctica and the Arctic. It's a type of vessel that is a specialty for Ulstein.

The company recently built two new expedition ships for Lindblad Expeditions that are considered among the most advanced expedition ships currently at sea.

Related: Is this the ultimate Antarctica cruise ship? Our take on Lindblad's new vessel

Muren said Ulstein's idea is that one service vessel with a small nuclear reactor could serve as a floating power station for up to four small, all-electric expedition ships sailing in a region such as Antarctica.

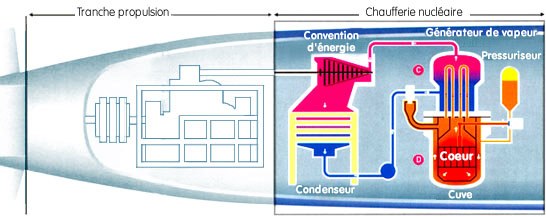

As Ulstein conceives it, the service ship would feature a rarely built type of nuclear reactor that uses a thorium molten salt mixture. Such reactors are considered safer than conventional nuclear reactors because they operate with fuel in a molten state. In the event of an emergency, the fuel would drain into a containment vessel and solidify, preventing the sort of uncontrolled nuclear meltdown that can happen with a more traditional uranium-fueled reactor.

Norway-based Ulstein is calling its concept for the service ship Ulstein Thor — a nod to the thorium fuel that will be used in the vessel's electricity-producing reactor that also evokes the power of the Norse god of the same name.

Muren told TPG the concept could become a reality within 10 years if the industry and politicians signed on to the idea.

She said rapid advancements in battery storage happening now could mean that electric batteries with a high-enough capacity to run a small cruise ship for many days will be available in "five or six years." Add in electricity generated by a thorium-fueled reactor, and there could be a revolution in how ships are powered, she suggested.

"A very small amount of thorium can power a ship for 25 years," Muren said.

The all-electric cruise vessel that Ulstein proposes would be about 328 feet long and carry up to 80 passengers and 80 crew. It would be built extra tough to operate in polar areas with ice (it would have a 1C ice class rating).

The power-generating service ship would also be built as a rescue ship that could aid vessels in distress in remote areas such as Antarctica, the company said.

"Thor enables replenishment of energy and supplies on site, while also boasting the technology to facilitate rescue operations, as well as conducting research tasks," the line said in a press release issued at the time of the announcement. "It is, in effect, a crucial piece of infrastructure to support sustainable and safer operations. Thor literally has the power to change our entire industry."

The service ship would have helicopter pads, firefighting equipment, rescue booms, workboats, autonomous surface vehicles and airborne drones, cranes, laboratories and a lecture lounge, the company said.

Muren noted that thorium has relatively low radioactivity and produces radioactive waste that is easier to manage than the radioactive waste from more traditional uranium reactors.

"Thorium is a much nicer substance, and it produces very little waste compared to uranium [used in other reactors]," she said. "With uranium, you have a lot of waste that you have to take care of for ... thousands of years. For thorium, it is a couple of hundred years."

Nuclear power plants have been used on military ships but almost never on passenger ships. A single nuclear-powered cargo vessel that also carried a small number of passengers, the NS Savannah, debuted in 1959 and operated for several years. It was built as a demonstration project with funding from the U.S. government.

Muren acknowledged that it could take some time to get cruise operators and political authorities comfortable with the idea of using nuclear power for cruise ship-related operations. However, she expects the cruise world will eventually embrace the idea of battery-run vessels charged with nuclear-generated energy.

"I think you will at some point see that we will go to batteries [for cruise ships], as we did with cars," she said. She added that it's important for the industry and authorities to begin talking about it now, even as the technology that could make it happen is still being developed.

"It's so important to start now, because the more we wait, the longer it will [take] before we are there," Muren said.

Planning a cruise? Start with these stories:

- The 5 most desirable cabin locations on any cruise ship

- The 8 worst cabin locations on any cruise ship

- A quick guide to the most popular cruise lines

- 21 tips and tricks that will make your cruise go smoothly

- 15 ways cruisers waste money

- 12 best cruises for people who never want to grow up

- What to pack for your first cruise

Here's what our members say

"I live in D.C. and want local news."

"I believe in local journalism."

"Y'all are doing real local D.C. journalism."

" Washington City Paper has made me feel like I am part of the D.C. community."

If you agree with our members, will you support our work and keep City Paper going?

Washington City Paper

Why Not Nuclear-Powered Cruise Ships?

Share this story:

- Click to share on Facebook (Opens in new window)

- Click to share on X (Opens in new window)

- Click to share on Reddit (Opens in new window)

We know D.C. Get our free newsletter to stay in the know.

Unsubscribe any time.

Modern ships run on fuel—a lot of fuel. Why not make large ships, like cruise ships and cargo transports, nuclear-powered? —Xodiac

Good news, Xodiac: The future is now. As soon as this weekend, you yourself can set sail on the Russian craft 50 Years of Victory , the largest nuclear-powered icebreaker in the world, which, as a side gig, takes passengers cruising over the sunny North Pole. A stateroom’s yours for a cool $26,995, and the two-week package includes an open bar, hot-air balloon rides, and the chance to see firsthand just how quickly climate change is rendering icebreakers obsolete. No wonder they’re turning to tourism.

There is indeed something of a global existential need for technological advancement in this arena. And admittedly the non-Russian, non-icebreaking pickings are a little slim, as far as civilian nuclear-powered ships go, but there’s reason to think that’s about to change.

Of course, there’s been reason to think it’s about to change since the 1950s, when the idea made its public debut, courtesy of President Dwight D. Eisenhower. World War II was over. Having let the nuclear horse out of the barn, the United States was now trying to keep the reins as tight as possible. To that end, Ike introduced his Atoms for Peace program, the aim of which was to spread globally the promise of a kinder, gentler split nucleus. We note here that Atoms for Peace has since been appropriated as the name of an alt-rock supergroup led by Radiohead’s Thom Yorke.

Atoms for Peace was also propaganda—the Eisenhower initiative, that is, not the band. Ike hoped that by offering countries assistance in developing their nuclear-energy capabilities, the U.S. might keep their sympathies firmly on the side of the West. He made recipient countries pinky-swear they wouldn’t use the technology to develop a nuclear weapon, a geopolitical strategy that worked out about as well as you’d expect: the assistance set Iran down the weapons path, and also helped Israel, India, and Pakistan cook up bombs of their own.

But I digress. Ike was also keen to prove the myriad ways nuclear could benefit everyday Americans. Thus one stateside AFP project was the NS Savannah , a civilian nuclear ship launched in 1959 as a harbinger of America’s rosy atomic future.

Well, sort of, but honestly more like a preview of how slow the whole nuclear-merchant-marine concept would be to gain any kind of traction. Currently the Savannah is gathering dust in Baltimore, having remained in useful service for only ten years. The vessel did fine technologywise, but, configured as a hybrid of passenger ship and cargo ship, it fell short in both capacities—not really providing a model worth replicating.

What’s been holding back nuclear merchant ships? There’s a matter of, for instance, customer queasiness. Talking to the magazine Maritime Executive in 2015, one industry consultant said, “When you ask educated, professional groups whether they believe we should become more reliant on nuclear power, 30-40 percent are positive. When you ask the same group if they would be prepared to take their family on holiday on a nuclear-powered cruise ship, the number drops to below 10 percent.” Crew members on military nuclear ships, safe though they may be, wear dosimeters at all times, just in case—hardly a reassuring sight for your typical Caribbean vacationers, I’d imagine.

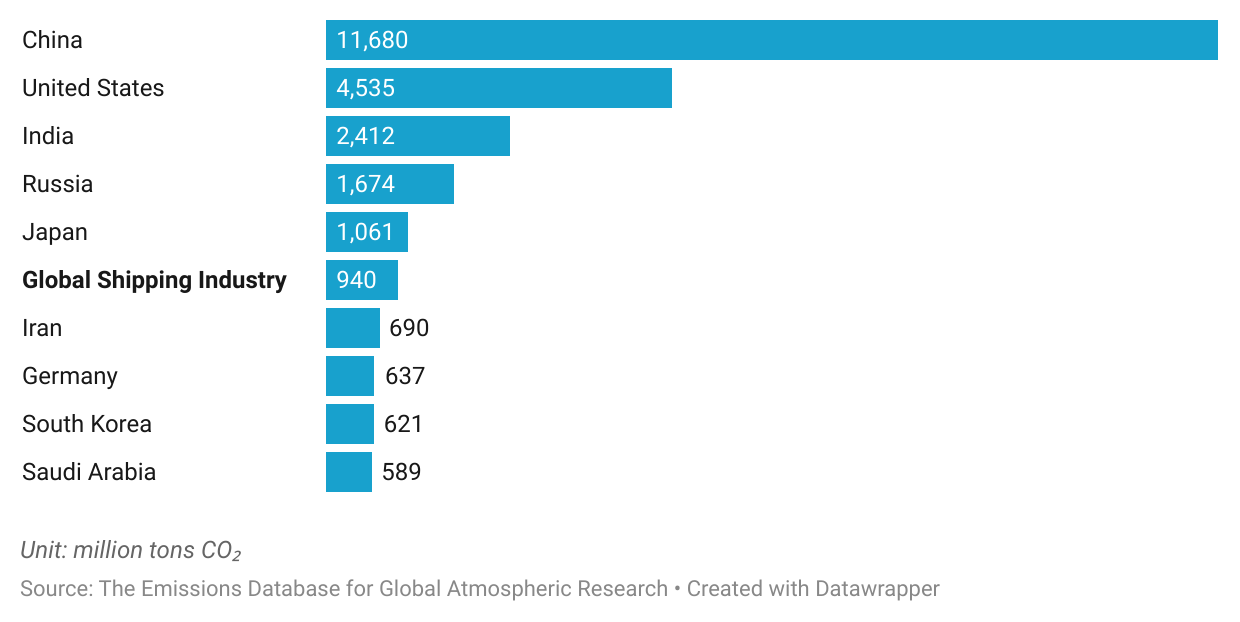

Otherwise, the challenges look logistically complex but certainly not insurmountable: rejiggering regulatory regimes, retrofitting ships, trying to figure out what to do with the nuclear waste (a problem, of course, not specific to shipping). And the benefits are significant:

- Ship owners nowadays have resisted switching to cleaner-burning natural gas because of a lack of in-port infrastructure for refueling, and so commercial craft continue to burn the dirtier fossil fuels. Nuclear avoids the issue altogether: not only zero emissions, but no refueling for five to seven years at a time.

- The startup costs of nuclear aren’t nothing—besides the reactor itself, there’s security, insurance, etc—but Nuclear Engineering International estimates that, factoring in lower fuel costs, a given ship could break even within 10 to 20 years. The economics should continue to improve, too, as the world sees heavier regulation of fossil fuels, in the form of carbon taxes and the like.

- Cheaper fuel means ships can travel faster—a boon in ways obvious (getting goods to market) and subtle (less susceptibility to pirate attacks).

The technology is basically there, too. As I pointed out in a 2009 column, the bite-size nuclear reactors that may one day revolutionize power generation are still in early stages on land, but not at sea—the U.S. Navy’s been successfully powering submarines with small nukes for decades. And though there have been plenty of maritime accidents over those years, no leakage has ever resulted from a sunk nuclear reactor. We’ve seen increasing interest in the possibility of nuclear propulsion over the last several years, and one imagines companies will feel a further push from the Paris climate accord of 2015, which encouraged the development of nuclear technologies. So maybe hold on to that 27 grand for now, Xodiac—I suspect you’ll see your options expand, and cheapen, after not too long. —Cecil Adams

Have something you need to get straight? Take it up with Cecil at straightdope.com .

Recommended Stories

Featured local savings.

Cruise FAQs

Why aren’t cruise ships nuclear powered.

Standing on the expansive deck of a vast cruise ship, in awe of its immense scale and cutting-edge technology, I find myself pondering the reason such colossal vessels do not utilize nuclear energy. The stark contrast between their luxuriousness and the dependence on conventional fuels strikes me as odd in an era where nuclear power has been established as a reliable, effective, and environmentally friendly energy option.

This article aims to delve into the reasons behind the absence of nuclear-powered cruise ships, examining the safety concerns and risks associated with nuclear energy, the public perception and fear surrounding it, as well as the logistical challenges and infrastructure requirements. Additionally, we will explore alternative energy sources for cruise ships, consider the economic implications, and delve into the regulatory and legal hurdles that must be overcome.

By analyzing case studies, historical context, and future possibilities, we hope to shed light on the potential for nuclear-powered cruise ships and the technological advancements that may make them a reality in the future.

Table of Contents

Key Takeaways

- Safety concerns and risks associated with nuclear power have contributed to the reluctance to use nuclear power in cruise ships.

- Public acceptance of nuclear power is a significant factor in the decision to not use nuclear power in cruise ships.

- Alternative energy sources such as liquefied natural gas (LNG) and advanced hybrid systems are considered more feasible options for cruise ships.

- Financial considerations, including high upfront costs and uncertainty of fuel prices, make nuclear power less financially viable for cruise ships.

Safety Concerns and Risks Associated with Nuclear Energy

Nuclear-powered cruise ships aren’t used due to the safety concerns and risks associated with nuclear energy. Public acceptance of nuclear power is a major factor in the decision-making process, and the potential dangers outweigh the benefits.

One major concern is nuclear waste disposal. The long-term storage and management of radioactive waste pose significant challenges, both in terms of technical feasibility and public perception.

The fear of potential accidents and the release of radiation into the environment is another reason why cruise ships have not adopted nuclear power. The public’s perception of nuclear energy is largely shaped by historical events such as the Chernobyl and Fukushima disasters. These incidents have left a lasting impression on society, creating a deep-rooted fear that cannot be easily overcome.

Therefore, cruise ships continue to rely on other forms of energy, prioritizing safety and public preference.

Public Perception and Fear of Nuclear Energy

In discussing the subtopic of public perception and fear of nuclear energy, it’s important to address the stigma and negative public opinion that surrounds this form of power generation.

There is a lack of trust in nuclear technology, primarily due to the high-profile accidents and disasters that have occurred in the past.

Additionally, the fear of radiation and its potential health risks plays a significant role in shaping public opinion and attitudes towards nuclear energy.

Stigma and Negative Public Opinion

Imagine the public’s reaction if cruise ships were powered by nuclear energy – it’s no wonder they haven’t gone down that route! The stigma and negative public opinion surrounding nuclear power have created significant barriers for its implementation in various industries, including the cruise ship industry.

Here are four reasons why the public is hesitant to embrace nuclear-powered cruise ships:

Safety concerns: The potential for accidents and radiation leaks creates fear and anxiety among the public.

Environmental impact: Many people associate nuclear power with the production of hazardous waste and worry about the long-term consequences for marine ecosystems.

Lack of trust in nuclear technology: Past incidents, such as the Chernobyl and Fukushima disasters, have eroded public trust in the safety and reliability of nuclear energy.

Perception of risk: People tend to overestimate the risks associated with nuclear power, making it difficult to change their perception and accept it as a viable alternative.

Considering these factors, it’s crucial to address the lack of trust in nuclear technology to explore alternative fuels and evaluate the economic viability of nuclear-powered cruise ships.

Lack of Trust in Nuclear Technology

Addressing the lack of trust in nuclear technology is crucial for evaluating alternative fuels and the economic viability of using nuclear energy for cruise ships. The public opinion shift towards nuclear energy acceptance has been slow and hesitant due to historical incidents such as Chernobyl and Fukushima. These incidents have left a lasting impression on people’s minds, fueling fear and skepticism regarding the safety of nuclear power.

However, it’s important to note that advancements in technology and stricter regulations have significantly improved the safety measures in place for nuclear reactors. Public education and transparency about the benefits and risks of nuclear power can help alleviate concerns and build trust. By highlighting the advancements in safety protocols and the potential for clean and efficient energy production, the cruise industry can pave the way for a more sustainable future.

Transitioning into the subsequent section about the ‘fear of radiation and health risks’, it’s imperative to address these concerns head-on and provide evidence-based information to dispel any misconceptions.

Fear of Radiation and Health Risks

Confront your fears head-on and embrace the truth about the potential health risks and radiation associated with nuclear energy.

When it comes to cruise ships, one of the main concerns is radiation exposure and its long-term health effects. Many people worry that being on a nuclear-powered ship could lead to higher levels of radiation exposure, which could have detrimental effects on their well-being. However, it’s important to understand that modern nuclear technology is highly regulated and designed to minimize these risks.

Stringent safety measures are in place to ensure that radiation exposure is kept at a safe level for both passengers and crew members. Additionally, studies have shown that the long-term health effects of radiation exposure from nuclear-powered ships are minimal.

As we delve into the subsequent section about logistical challenges and infrastructure requirements, it becomes clear that the fear of radiation should not be a barrier to exploring the potential benefits of nuclear-powered cruise ships.

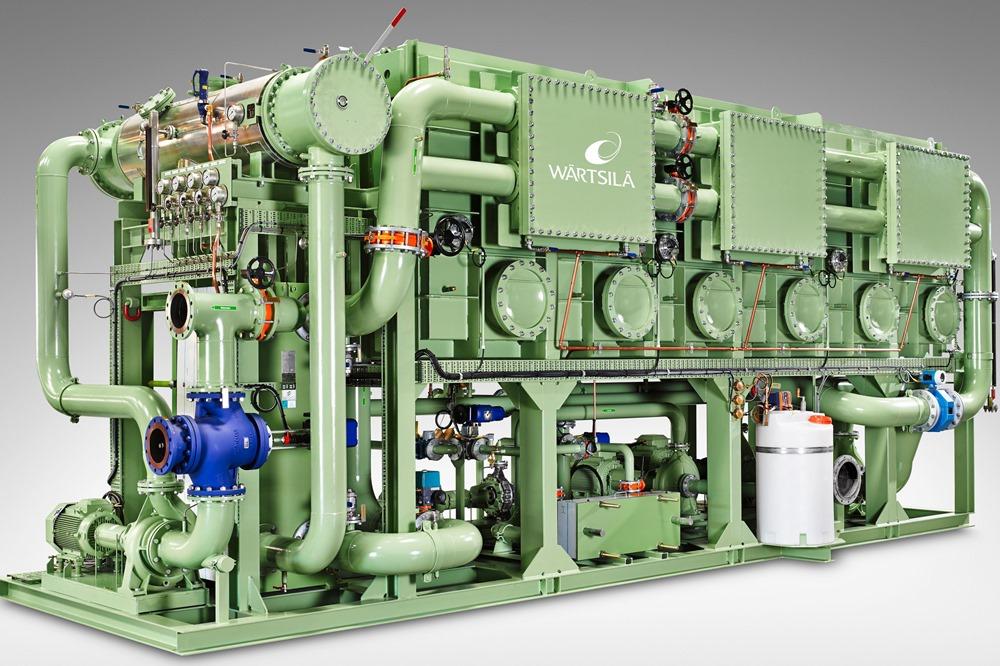

Logistical Challenges and Infrastructure Requirements

One of the main reasons cruise ships aren’t nuclear powered is because the logistical challenges and infrastructure requirements would be incredibly complex. The installation and maintenance of a nuclear power system on a cruise ship would require specialized facilities and expertise that aren’t currently available in the industry.

The size and weight of nuclear reactors would also pose significant challenges for the design and construction of cruise ships. Additionally, the transportation, storage, and disposal of nuclear fuel and waste would require extensive safety measures and regulatory oversight.

These logistical challenges and infrastructure requirements would result in significant costs and time delays, making it impractical for cruise ship companies to adopt nuclear power. Therefore, alternative sources of energy, such as liquefied natural gas or advanced hybrid systems, are being explored as more feasible options.

Transitioning into the subsequent section about ‘regulatory and legal hurdles’, it’s important to consider the additional complexities and considerations that arise in the nuclear power industry.

Regulatory and Legal Hurdles

When considering the use of nuclear power on cruise ships, it’s important to address the regulatory and legal hurdles that come with it.

International and national regulations for nuclear-powered vessels must be taken into account to ensure compliance and safety.

Additionally, liability and insurance concerns, as well as compliance with environmental standards and treaties, need to be carefully considered and addressed.

International and National Regulations for Nuclear-Powered Vessels

Although there are international and national regulations in place for nuclear-powered vessels, cruise ships haven’t adopted this technology. Compliance challenges and the need for comprehensive environmental impact assessments are some of the reasons behind this decision.

Nuclear-powered ships require strict adherence to safety protocols, including regular inspections, extensive training for crew members, and potential risks associated with nuclear waste disposal. Additionally, the potential liability and insurance concerns associated with nuclear accidents may deter cruise ship operators from pursuing this technology.

Transitioning into the subsequent section, the focus shifts to exploring the implications of liability and insurance concerns in further understanding why cruise ships haven’t embraced nuclear power as a viable option.

Liability and Insurance Concerns

If you’re considering the use of nuclear power in vessels, it’s important to be aware that liability and insurance concerns play a significant role in the decision-making process. Studies show that the potential cost of a nuclear accident could reach billions of dollars.

When it comes to liability coverage for nuclear-powered ships, the insurance industry faces unique challenges due to the high risks associated with nuclear energy. Insurers must carefully assess the potential consequences of a nuclear accident and the resulting damage to both human life and the environment. As a result, insurance premiums for nuclear-powered vessels are significantly higher compared to conventional ships.

Additionally, obtaining liability coverage for nuclear accidents can be difficult due to the limited number of insurers willing to provide adequate protection. These concerns contribute to the decision to opt for conventional power sources in cruise ships.

Moving on to the next section about compliance with environmental standards and treaties, it is important to consider the impact of conventional fuel consumption on the environment.

Compliance with Environmental Standards and Treaties

The liability and insurance concerns surrounding nuclear-powered cruise ships have been a significant barrier to their adoption. However, another crucial factor that needs to be considered is compliance with international regulations and environmental standards.

Cruise ships operate in various regions worldwide, and they must adhere to stringent guidelines set by international bodies such as the International Maritime Organization (IMO) and the International Convention for the Prevention of Pollution from Ships (MARPOL). These regulations aim to minimize the environmental impact of maritime activities, including emissions and waste disposal.

Nuclear power, although a low-carbon alternative, presents challenges in meeting these standards due to concerns about the disposal of radioactive waste. Additionally, economic considerations play a role in the decision-making process. The high upfront costs associated with building nuclear-powered cruise ships, coupled with the uncertainty of long-term fuel prices, may make it less financially viable compared to other alternatives.

Moving forward, exploring alternative energy sources for cruise ships becomes imperative to meet both environmental and economic requirements.

Alternative Energy Sources for Cruise Ships

When it comes to alternative energy sources for cruise ships, there are several key options to consider.

First, the use of low-sulfur marine diesel fuel has gained popularity as a cleaner fuel option, reducing emissions and environmental impact.

Second, LNG (Liquefied Natural Gas) has emerged as an attractive alternative, offering lower carbon emissions and better air quality.

Lastly, the exploration of hybrid and electric propulsion systems is underway, aiming to further reduce greenhouse gas emissions and improve sustainability in the cruise industry.

These advancements in alternative energy sources are crucial in addressing environmental concerns and meeting regulatory requirements in the maritime sector.

Use of Low-Sulfur Marine Diesel Fuel

Imagine cruising on a luxurious ship powered by low-sulfur marine diesel fuel, ensuring a cleaner and more environmentally-friendly voyage. The use of low-sulfur marine diesel fuel has become increasingly popular in the cruise industry due to its reduced sulfur content, which helps to minimize air pollution and improve air quality.

Here are four key reasons why cruise ships are embracing this alternative fuel option:

Compliance with regulations: Low-sulfur marine diesel fuel meets the stringent emission requirements set by international regulations, such as the International Maritime Organization’s (IMO) sulfur cap of 0.5%.

Health and environmental benefits: By reducing sulfur emissions, low-sulfur marine diesel fuel helps to mitigate the negative impacts on human health and the environment, including respiratory diseases and acid rain.

Cost-effectiveness: While low-sulfur marine diesel fuel may be slightly more expensive than traditional fuels, the long-term benefits outweigh the initial costs, as it reduces the risk of fines and penalties for non-compliance with emission regulations.

Compatibility with existing infrastructure: Cruise ships can easily transition to low-sulfur marine diesel fuel without major modifications to their existing engines and fuel systems, making it a practical and convenient option.

Transitioning into the subsequent section about ‘lng (liquefied natural gas) as a cleaner fuel option’, we can explore further alternatives that cruise ships are considering to reduce their environmental impact.

LNG (Liquefied Natural Gas) as a Cleaner Fuel Option

If you’re looking for a cleaner fuel option, consider LNG (Liquefied Natural Gas) for your cruise ship. LNG, which is a cleaner-burning fuel compared to traditional marine diesel, has gained attention as a potential alternative for powering cruise ships.

The environmental impact of LNG is significantly lower, with reduced emissions of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. By utilizing LNG, cruise ships can contribute to a healthier and more sustainable maritime environment. Moreover, LNG has the potential to enhance energy efficiency and reduce greenhouse gas emissions, further reducing the carbon footprint of cruise ships.

Transitioning to LNG as a fuel option aligns with the industry’s commitment to reducing environmental impacts. Looking ahead, the exploration of hybrid and electric propulsion systems will continue to drive advancements in sustainable cruise ship operations.

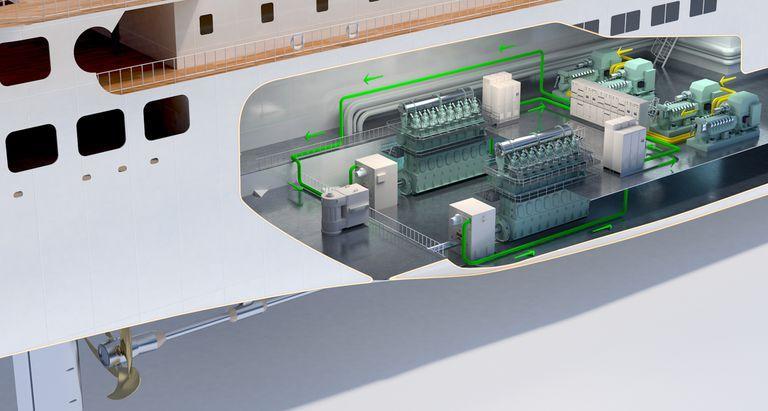

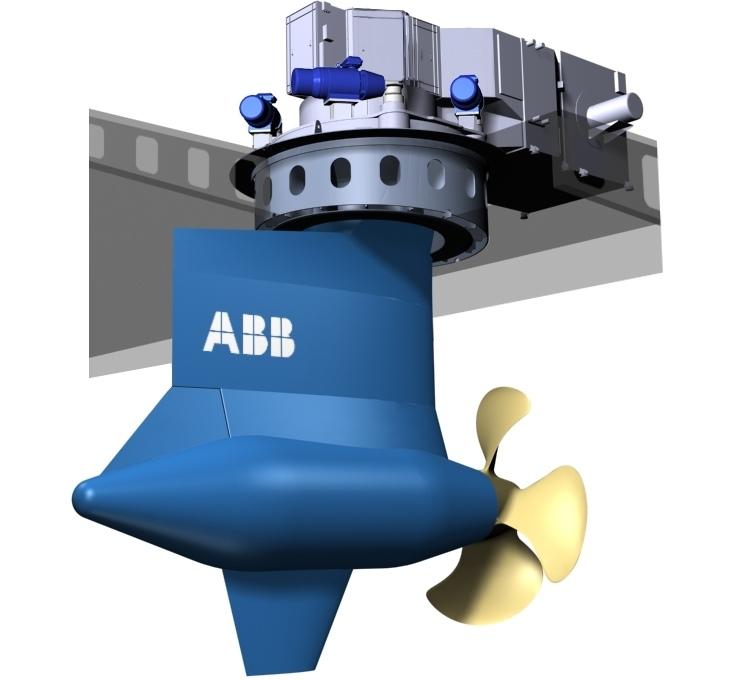

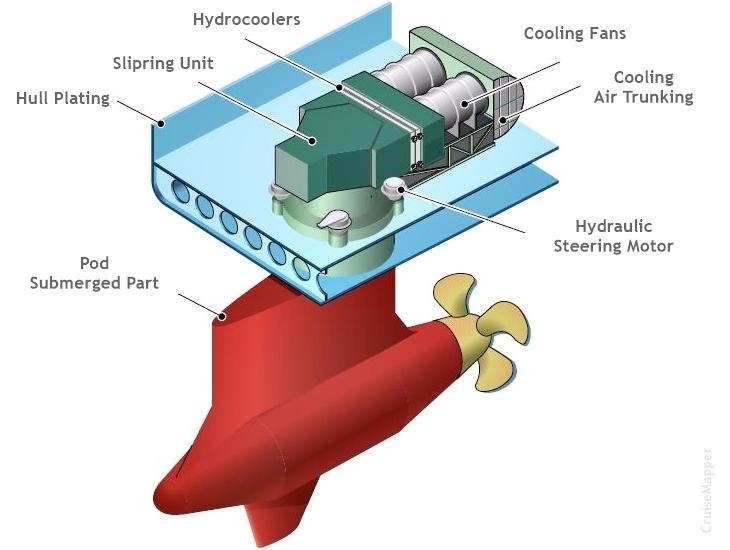

Exploration of Hybrid and Electric Propulsion Systems

The exploration of hybrid and electric propulsion systems has opened up new possibilities for the future of cruise ship operations, creating opportunities for greater energy efficiency and reduced environmental impact. Hybrid propulsion systems combine traditional fuel sources with electric power, allowing for more flexibility and optimization of energy usage. Electric propulsion technology, on the other hand, relies solely on electricity to power the ship, eliminating the need for fossil fuels altogether. This shift towards cleaner and more sustainable propulsion systems is driven by the industry’s commitment to reducing greenhouse gas emissions and improving air quality. By incorporating these advanced technologies, cruise ships can significantly reduce their carbon footprint and contribute to a more sustainable future for the maritime industry. Moving forward, it is essential to further explore and develop these hybrid and electric propulsion systems to address the growing concerns about environmental impact and sustainability in the cruise ship industry.

Environmental Impact and Sustainability

Although cruise ships contribute significantly to environmental pollution, there’s a pressing need to explore sustainable alternatives to conventional fuel sources. In order to address this issue, the cruise industry is increasingly turning to low carbon alternatives for propulsion systems.

Sustainable tourism is a growing trend, and cruise companies are under pressure to reduce their carbon footprint. One potential solution is the use of electric propulsion systems, which can significantly reduce emissions compared to traditional diesel engines. These systems utilize batteries or fuel cells to power the ship, resulting in reduced greenhouse gas emissions and improved air quality.

Additionally, the use of renewable energy sources such as solar or wind power can further enhance the sustainability of cruise ships. By adopting these low carbon alternatives, the cruise industry can contribute to a cleaner and more environmentally friendly future.

Transitioning into the subsequent section about economic considerations and cost-benefit analysis, it’s important to evaluate the financial implications of implementing these sustainable technologies.

Economic Considerations and Cost-Benefit Analysis

When considering the economic considerations and cost-benefit analysis of cruise ships, there are several key points to examine.

First and foremost, the initial investment and construction costs of a cruise ship can be substantial, with billions of dollars required to build a new vessel.

Additionally, operational expenses and maintenance can also be significant, as cruise ships require constant upkeep and fuel costs can be high.

Lastly, return on investment and profitability are important factors to consider, as cruise lines must generate enough revenue to cover their expenses and make a profit in order to remain sustainable in the long term.

Initial Investment and Construction Costs

You could save a significant amount of money by considering alternative propulsion systems for cruise ships. When it comes to initial investment and construction costs, nuclear-powered cruise ships face several logistical challenges and regulatory hurdles.

The construction of a nuclear-powered vessel requires specialized infrastructure and expertise, which can significantly drive up costs. The installation of the necessary safety measures and containment systems further adds to the expenses. Additionally, strict regulatory requirements and inspections are necessary to ensure the safe operation of nuclear reactors on board. These factors contribute to the higher construction costs associated with nuclear-powered cruise ships.

However, it’s important to consider that while the initial investment may be higher, the long-term operational expenses and maintenance costs of nuclear-powered ships can be significantly lower compared to traditional propulsion systems. This transition into the subsequent section about operational expenses and maintenance highlights the financial benefits of alternative propulsion systems.

Operational Expenses and Maintenance

To keep the alternative propulsion systems running smoothly, regular maintenance and operational expenses can be a drop in the bucket compared to the initial investment. Cruise ships are complex machines that require constant upkeep and adherence to environmental standards. Logistical challenges arise when it comes to sourcing fuel and ensuring compliance with environmental regulations. This includes managing the disposal of waste and emissions control. The table below highlights some of the key operational expenses and maintenance tasks involved in running a cruise ship powered by alternative propulsion systems:

Ensuring smooth operations and meeting environmental standards requires significant investment, both in terms of time and resources. However, these expenses are necessary to ensure the long-term viability of alternative propulsion systems in cruise ships. The next section will explore the return on investment and profitability of nuclear-powered cruise ships.

Return on Investment and Profitability

Investing in alternative propulsion systems for cruise ships can lead to significant returns and ensure profitability in the long run. By exploring alternative fuels, such as nuclear power, cruise ship operators can reduce their dependency on expensive and polluting fossil fuels. This shift towards cleaner energy sources not only benefits the environment but also has a positive impact on local economies.

Reduced fuel costs: Nuclear-powered cruise ships would eliminate the need for traditional marine fuels, which can be a major expense for operators. This cost savings can contribute to higher profitability in the long term.

Increased operational efficiency: Nuclear propulsion systems offer higher energy efficiency and longer operating ranges compared to conventional engines. This allows cruise ships to travel longer distances without refueling, opening up new routes and expanding their customer base.

Positive image and market demand: Embracing nuclear power would position cruise ship operators as environmentally responsible and attract environmentally conscious travelers. This can lead to increased demand and higher ticket prices, further driving profitability.

Transitioning to the subsequent section about ‘international regulations and agreements’, it’s essential to understand the impact of these factors on the decision-making process.

International Regulations and Agreements

Imagine cruising the open seas on a massive ship, powered by nuclear energy, but unfortunately, due to international regulations and agreements, cruise ships aren’t currently allowed to be nuclear powered.

This restriction is primarily due to liability implications and concerns about the environmental impact. Nuclear power plants require strict safety measures to prevent accidents and potential radiation leaks. The liability associated with such accidents would be immense, as cruise ships carry thousands of passengers and crew members.

Additionally, the environmental impact of nuclear power is a significant concern. While nuclear energy itself is a clean and efficient source of power, the storage and disposal of nuclear waste pose long-term environmental risks.

As a result, international regulations prioritize the use of alternative energy sources for cruise ships.

Transitioning to the next section, exploring case studies and historical context, provides insight into the challenges faced by the industry.

Case Studies and Historical Context

When discussing the topic of nuclear-powered naval vessels, it’s crucial to mention the USS Nautilus as a significant case study. This submarine holds a prominent place in history as the first operational nuclear-powered vessel.

Additionally, exploring past proposals and feasibility studies for nuclear cruise ships offers valuable insights into the challenges and considerations involved in adopting this technology.

Finally, it’s important to examine the lessons learned from nuclear accidents and disasters to understand the potential risks and safety measures associated with nuclear-powered vessels.

The USS Nautilus and Nuclear-Powered Naval Vessels

Although you might think that nuclear-powered naval vessels would be the norm, the USS Nautilus was the first of its kind, paving the way for future innovations in maritime propulsion. This groundbreaking submarine, commissioned in 1954, introduced the world to the immense potential of nuclear propulsion technology. It revolutionized naval warfare, thanks to its ability to remain submerged for extended periods without the need for frequent refueling.

The USS Nautilus was a game-changer for several reasons:

- It was the first submarine to complete a submerged transit of the North Pole.

- It set numerous speed and endurance records, demonstrating the superiority of nuclear power over conventional propulsion.

- Its success sparked a global race to develop similar nuclear-powered vessels.

- The USS Nautilus showcased the immense power and versatility of nuclear propulsion technology, proving its value in military operations.

- It laid the foundation for the development of future nuclear-powered naval vessels.

With the successful deployment of the USS Nautilus, the stage was set for exploring the possibility of nuclear-powered cruise ships, as we’ll explore in the subsequent section on past proposals and feasibility studies.

Past Proposals and Feasibility Studies for Nuclear Cruise Ships

The exploration of nuclear propulsion technology for maritime transportation has included past proposals and feasibility studies for incorporating this innovative technology into cruise vessels. Feasibility assessments have been conducted to evaluate the potential benefits and risks of nuclear-powered cruise ships. Technological advancements have been made in reactor design and safety measures, which have increased the viability of nuclear propulsion systems for cruise vessels. However, there are several factors that have hindered the implementation of nuclear power in the cruise industry. These include concerns about public perception and safety, the high initial cost of nuclear propulsion systems, and the limited availability of infrastructure to support nuclear-powered cruise ships. Despite the potential advantages of nuclear propulsion, these challenges have led to the continued reliance on conventional fuel sources in the cruise industry. Moving forward, it is important to consider the lessons learned from nuclear accidents and disasters to ensure the safe and responsible use of nuclear technology in maritime transportation. [SUBTOPIC TRANSITION]

Lessons Learned from Nuclear Accidents and Disasters

Take a moment to reflect on the valuable lessons you can learn from past nuclear accidents and disasters, which can help ensure the safe and responsible use of this technology in maritime transportation. Some of the lessons learned include:

Chernobyl and Fukushima disasters highlighted the importance of robust safety protocols and emergency response plans.

Public perception of nuclear power can greatly influence its acceptance and implementation.

Environmental impact of nuclear accidents can be long-lasting, with effects on ecosystems and human health.

Proper waste management and disposal are crucial to prevent contamination and minimize long-term environmental damage.

The need for continuous monitoring and maintenance to detect and prevent any potential issues.

Looking ahead, future possibilities and technological advancements in nuclear power generation can pave the way for a more sustainable and efficient maritime industry.

Future Possibilities and Technological Advancements

One exciting possibility for the future of cruise ships is the potential for nuclear power. With future innovations and technological advancements, it may become feasible to harness nuclear energy to propel these massive vessels.

The use of nuclear power on cruise ships could offer numerous benefits, including increased efficiency and reduced reliance on fossil fuels. Nuclear reactors can generate large amounts of power with minimal fuel consumption, making them a sustainable option for long-distance travel. Additionally, the compact size of nuclear reactors could allow for more space onboard, potentially leading to enhanced amenities and passenger comfort.

However, there are several challenges to overcome, such as ensuring the safety of nuclear technology and addressing public concerns. Nonetheless, exploring the possibilities of nuclear-powered cruise ships could lead to groundbreaking advancements in the future of maritime transportation.

Frequently Asked Questions

Are there any existing nuclear-powered cruise ships in operation.

No, there are no existing nuclear-powered cruise ships in operation. However, nuclear power offers several benefits for cruise ships, including greater fuel efficiency, longer cruising range, and reduced greenhouse gas emissions.

How do alternative energy sources compare to nuclear power for cruise ships?

When comparing alternative energy sources for cruise ships, it’s like weighing the efficiency and cost of different engines. Nuclear power offers high efficiency, but its high cost and safety concerns make it less attractive for cruise ships.

What are the potential environmental benefits of using nuclear power in cruise ships?

Using nuclear power in cruise ships has several potential environmental benefits, such as reducing greenhouse gas emissions and dependence on fossil fuels. However, it also comes with drawbacks and risks, including the disposal of radioactive waste and the potential for accidents. Compared to traditional fuel sources, nuclear power offers a more sustainable and efficient option.

Are there any international regulations or agreements that restrict the use of nuclear power in cruise ships?

There are no international regulations or agreements specifically prohibiting the use of nuclear power in cruise ships. However, concerns about safety, waste management, and public perception have deterred the adoption of nuclear power in this industry.

What are some potential future technological advancements that could make nuclear power more feasible for cruise ships?

Advancements in nuclear technology, such as compact and safer reactor designs, as well as improved waste management systems, may address safety concerns associated with nuclear power. These advancements could make nuclear power more feasible for cruise ships in the future.

In conclusion, the decision to not utilize nuclear power on cruise ships stems from a myriad of factors. Safety concerns, public perception, logistical challenges, regulatory hurdles, and economic considerations all play a significant role in shaping this decision.

While alternative energy sources are being explored, the potential for future advancements in technology may pave the way for nuclear-powered cruise ships. However, it’s essential to acknowledge the historical context and international regulations that influence this industry.

By carefully weighing the risks and benefits, we can continue to navigate towards a sustainable and efficient future for cruise ship travel.

Meet Asra, a talented and adventurous writer who infuses her passion for exploration into every word she writes. Asra’s love for storytelling and her insatiable curiosity about the world make her an invaluable asset to the Voyager Info team.

From a young age, Asra was drawn to the power of words and their ability to transport readers to far-off lands and magical realms. Her fascination with travel and cultures from around the globe fueled her desire to become a travel writer, and she set out on a journey to turn her dreams into reality.

Why Do Cruise Ships Have To Stop In Canada

Which Of The Following Best Describes Pollution Discharged By Cruise Ships?

Meet Asra, a talented and adventurous writer who infuses her passion for exploration into every word she writes. Asra’s love for storytelling and her insatiable curiosity about the world make her an invaluable asset to the Voyager Info team. From a young age, Asra was drawn to the power of words and their ability to transport readers to far-off lands and magical realms. Her fascination with travel and cultures from around the globe fueled her desire to become a travel writer, and she set out on a journey to turn her dreams into reality.

You may like

What fresh seafood collaborations does rudi's catch offer?.

Yearning for a seafood experience like no other?

In the realm of new seafood partnerships, Rudi’s Catch has decidedly elevated standards. The complex interplay between area fishers and the kitchen crew culminates in a flavor experience that is absolutely remarkable.

But what sets their offerings apart goes beyond the catch itself. Stay tuned to discover the secret ingredient that makes Rudi's Catch a must-visit for seafood enthusiasts and culinary connoisseurs alike.

- Rudi's Catch collaborates closely with local fishermen for fresh seafood sourcing.

- The partnership ensures sustainable and authentic dining experiences.

- Chef Rudi Sodamin showcases his culinary prowess through innovative seafood dishes.

- Global influences are infused into the menu for an elevated dining experience.

Rudi's Catch and Local Fishermen Partnership

Collaborating closely with local fishermen, Rudi's Catch consistently sources the freshest seafood from nearby ports of call to ensure a sustainable and authentic dining experience for our guests. Our partnership with these fishermen isn't just about procuring ingredients; it's a commitment to supporting local communities and promoting responsible fishing practices. By prioritizing sustainable sourcing, we guarantee that every dish served at Rudi's Catch not only meets the highest quality standards but also contributes to the well-being of our oceans.

This collaboration goes beyond just business; it's a shared passion for preserving marine ecosystems and providing our guests with an unparalleled freshness that can only come from seafood caught just hours before reaching their plates. The direct relationship we've with local fishermen allows us to hand-select the best catches of the day, ensuring that each bite is a testament to the dedication and hard work of those who make our unique dining experience possible.

Join us at Rudi's Catch and taste the difference that supporting local fishermen can make in every savory bite.

Innovative Seafood Fusion Creations

Crafting an exquisite symphony of flavors, our innovative seafood fusion creations at Rudi's Catch redefine culinary boundaries with each delectable bite. Our menu showcases contemporary interpretations of classic dishes with international influences, reflecting Chef Rudi Sodamin's creativity and expertise.

Guests can indulge in a variety of options, from signature beef classics to sustainably sourced seafood delights. The interactive dining experience is elevated with the seafood trolley, offering fresh lobster, shrimp, oysters, and more for a personalized touch.

Throughout the meal, diners can anticipate surprises like unique desserts and special gifts, adding an element of excitement to their culinary journey. Vegetarian options are also available, ensuring that all preferences are catered to.

At Rudi's Catch, we aim to provide not just a meal but an unforgettable experience where every bite tells a story of innovation and passion.

Celebrity Chef Collaborations at Rudi's Catch

Excitingly showcasing the culinary prowess of renowned Culinary Chef Rudi Sodamin, Rudi's Catch offers a tantalizing array of fresh seafood collaborations that redefine the dining experience. The menu, curated through a celebrity chef collaboration, replaces mundane seafood offerings with contemporary interpretations and innovative dishes. Drawing from global influences, Chef Rudi Sodamin infuses each dish with a touch of his expertise, providing guests with a truly elevated dining experience. These collaborations bring fresh perspectives to the table, allowing diners to savor seafood in ways they may have never imagined.

The fusion of Princess Seafood and Catch by Rudi results in a menu that showcases the best of both worlds, where traditional meets contemporary, and flavors from around the globe harmonize to create an unforgettable dining experience.

Sustainable Seafood Sourcing Practices

In sourcing our seafood, Rudi's Catch prioritizes sustainability by carefully selecting fresh offerings from local ports of call to uphold our commitment to quality and environmental responsibility.

- Sustainable Seafood: We're dedicated to sourcing seafood in a sustainable manner to ensure the long-term health of marine ecosystems.

- Local Ports: By sourcing from local ports, we support nearby communities and reduce our carbon footprint by minimizing transportation distances.

- Freshness: Our focus on freshness guarantees that the seafood dishes we offer are of the highest quality and flavor.

- Responsible Sourcing: We take pride in responsibly sourcing our seafood, aligning with Chef Rudi Sodamin's values and Princess Cruises' commitment to ethical practices.

- Environmentally Conscious: Supporting environmentally conscious fishing practices isn't just a choice for us; it's a responsibility we embrace to protect our oceans for future generations.

Exclusive Seafood Pairings Menu

With an unwavering dedication to excellence, our exclusive seafood pairings menu at Rudi's Catch epitomizes a harmonious blend of fresh, sustainably sourced ingredients meticulously crafted to delight the senses. Chef Rudi Sodamin's innovative touch shines through in dishes like Asian-fried calamari and lobsters with garlic butter, offering a symphony of flavors.

Alongside these seafood delights, guests can savor vegetarian options and signature beef classics, ensuring a diverse and flavorful dining experience for all preferences. Our menu aims to provide a fresh perspective on seafood dining, emphasizing quality and taste in every dish presented.

Each creation is a testament to our commitment to providing a culinary journey that excites the palate and leaves a lasting impression. At Rudi's Catch, we invite you to indulge in our exclusive seafood pairings menu, where every bite tells a story of passion and dedication to the art of fine dining.

What Is the New Seafood Restaurant on Princess Cruises?

'The Catch by Rudi' is the new seafood restaurant on Princess Cruises, showcasing contemporary interpretations of classic dishes and international fusion influences. Priced at $39 per person, it's part of the Princess Premier package.

Which Princess Ships Have the Catch Restaurant?

On Princess ships, The Catch by Rudi sets sail, gracing Enchanted, Majestic, Sky, and Discovery. It's a seafood delight, with innovative dishes like Tower of Taste and Beauty on the Plate. Join us for an oceanic feast!

Why Is Sky Princess Going Into Dry Dock?

We're excited about Sky Princess heading to dry dock for routine maintenance and upgrades. This downtime allows us to enhance amenities, ensure top performance, and guarantee an exceptional guest experience. Technical inspections and necessary repairs will be conducted to maintain our high standards.

What Is the New Restaurant on Sky Princess?

The new restaurant on Sky Princess is 'The Catch by Rudi,' offering a three-course meal experience at $39 per person. Curated by Chef Rudi Sodamin, the menu showcases fresh seafood like lobster and oysters.

In conclusion, Rudi's Catch offers a tantalizing array of fresh seafood collaborations that truly elevate the dining experience at sea.

From the innovative fusion creations to the exclusive pairings menu, every dish showcases the dedication to quality and sustainability that sets Rudi's Catch apart.

In the world of seafood dining, Rudi's Catch truly hits the nail on the head, providing a culinary journey that's both exciting and satisfying.

Claire, a creative soul with an unquenchable thirst for storytelling, is an integral part of the Voyager Info team. As a dedicated writer, she weaves captivating narratives that transport readers to enchanting cruise destinations and beyond.

Claire’s love affair with writing began at an early age when she discovered the magic of words and their ability to craft worlds and emotions. Her innate curiosity led her to explore various literary genres, but it was travel writing that truly captured her heart. Drawing inspiration from her own globetrotting adventures and encounters with diverse cultures, Claire embarked on a journey to become a travel writer par excellence.

The Impact of Hurricane Dorian on Bahamas' Famous Swimming Pigs: Before and After

Discover the resilience of the Bahamas' iconic swimming pigs post-Hurricane Dorian, uncovering a tale of survival and hope amidst devastation.

As we move closer to understanding the consequences of Hurricane Dorian for the Bahamas’ renowned swimming pigs, it feels like we’re revealing a story of endurance in the face of devastation. The effect of the hurricane on these cherished animals has led to widespread speculation about their outcome.

Stay tuned as we explore the challenges faced by the swimming pigs before and after the catastrophic event, shedding light on their survival, rehabilitation efforts, and the future of this iconic population in the Bahamas.

- Catastrophic impact on habitats led to widespread devastation on Pig Beach.

- Local volunteers and global donations crucial for rescue and recovery efforts.

- Rehabilitation efforts focus on collaborative care, aided by global support.

- Long-term plans prioritize establishing resilient habitats to protect the swimming pigs.

Hurricane Dorian's Devastation on Swimming Pigs

Hurricane Dorian's impact on the swimming pigs of the Bahamas was catastrophic, leading to widespread devastation in their habitats across the islands. Particularly on Pig Beach, a popular spot for the famous swimming pigs, the Category 5 storm wreaked havoc. The storm surge resulted in the loss of many pigs in areas like Grand Bahama and the Abaco Islands. Concerns quickly arose regarding the welfare of the surviving pigs as they struggled to cope with the aftermath of the extreme weather conditions. Tragically, some of the pigs perished due to the harsh conditions brought on by Hurricane Dorian.

The situation was further compounded by the disappearance of Reginald Curry, who was responsible for caring for a colony of pigs. His absence added to the distressing circumstances faced by the already vulnerable swimming pigs. The impact of Hurricane Dorian on the swimming pigs of the Bahamas was profound, necessitating urgent rescue and recovery efforts to address the devastation caused to their habitats.

Rescue and Recovery Efforts

Following the devastating impact of Hurricane Dorian on the Bahamas' swimming pigs, the focus has shifted towards implementing comprehensive rescue and recovery efforts to safeguard the surviving pig population and rebuild their habitats.

Local volunteers played a crucial role in rescuing the surviving swimming pigs post-Hurricane Dorian, providing essential care, food, and temporary shelters. Additionally, global donations poured in to support the recovery efforts for the swimming pigs in the aftermath of the hurricane.

The swimming pigs aren't only beloved by locals but are also considered vital for The Bahamas' economic recovery, symbolizing resilience for the Bahamian people. Long-term plans include rebuilding a more resilient habitat for the swimming pigs, implementing safety measures, and collaborating with experts to protect them.

Lessons learned from Hurricane Dorian emphasize the importance of better disaster preparedness for animals, community support during crises, awareness of climate change effects, and the global impact of natural disasters.

Rehabilitation of the Pigs

In the ongoing efforts to rehabilitate the swimming pigs in the Bahamas post-Hurricane Dorian, a collaborative approach involving local volunteers, global support, and expert consultation is crucial for ensuring the long-term well-being and safety of these beloved animals. Workers tirelessly served the surviving pigs, providing essential care and temporary shelters. Donations from around the world poured in, aiding in the rehabilitation process. Efforts are underway to rebuild a more resilient habitat for the pigs, incorporating expert advice to protect them from future natural disasters. To highlight the significance of this rehabilitation, a table showcasing the progress made so far is provided below:

The collaborative efforts demonstrate a united front in ensuring the well-being of these unique animals, vital not only for their sake but also for the economic recovery and tourism industry of The Bahamas.

Impact on Tourism Industry

Amidst the aftermath of Hurricane Dorian, the impact on the Bahamas' tourism industry, particularly the allure of the Exuma's swimming pigs, stands as a critical focal point for economic recovery and visitor engagement. The devastation caused by the hurricane has disrupted the tourism landscape, affecting the famous swimming pigs and their contribution to the local economy. Here's a closer look at the impact:

- Abortion of Tourist Arrivals : The hurricane's aftermath led to a significant decrease in tourist arrivals to the Exumas, with many visitors rerouting their travel plans to less affected areas.

- Disruptor of Cruise Line Donations : While cruise lines have been supportive of recovery efforts post-Dorian, the disruption in the tourism sector has influenced the allocation of these funds, potentially impacting the preservation of attractions like the swimming pigs.

- Serving an Eviction Notice to Economic Growth : The temporary decline in tourism activities post-hurricane served as an eviction notice to the anticipated economic growth, underscoring the vulnerability of the tourism industry in the face of natural disasters.

Long-term Outlook for the Pigs

The recovery efforts post-Hurricane Dorian are focusing on establishing a more resilient habitat for the swimming pigs on Big Major Cay, emphasizing collaborations with experts to ensure long-term protection and safety measures for these iconic animals.

The rebuilding process includes enhancing the swimming pigs' habitat to better withstand future natural disasters, such as hurricanes. Implementing safety measures like reinforced shelters, early warning systems, and emergency evacuation plans are key components of the long-term outlook for the pigs.

Disaster preparedness is a crucial lesson learned from the impact of Hurricane Dorian, highlighting the importance of proactive measures to safeguard the well-being of the swimming pigs and other wildlife in the region.

What Happened to the Swimming Pigs in the Bahamas?

We observed the fate of the swimming pigs in the Bahamas post-Hurricane Dorian. Some pigs survived, but many perished due to the storm surge. Efforts were made to rescue survivors and rebuild their habitat for safety and economic recovery.

How Was the Bahamas Affected by Hurricane Dorian?

We experienced extensive devastation in The Bahamas from Hurricane Dorian. The storm, a Category 5 with 185 mph winds, brought a storm surge over 25 feet in areas like Grand Bahama and the Abaco Islands, causing severe flooding and destruction.

Who Helped the Bahamas After Hurricane Dorian?

We all helped the Bahamas after Hurricane Dorian. Donations poured in from cruise lines and international organizations. Local volunteers and NGOs worked tirelessly. Nations and agencies assisted in recovery efforts. The global community united to support the Bahamas.

How Do the Pigs in the Bahamas Survive?

We believe the pigs in the Bahamas survive by relying on natural instincts and group dynamics. Their feral nature and family bonds help them weather storms successfully. Adult pigs protect piglets, showcasing their resilience and ability to endure harsh conditions.

In conclusion, the impact of Hurricane Dorian on the Bahamas' famous swimming pigs was devastating, with many perishing and their habitat suffering severe damage. However, efforts to rescue and rehabilitate the surviving pigs have been successful, highlighting their resilience and importance to the country's tourism industry.

One interesting statistic is that the swimming pigs contribute an estimated $20 million annually to the Bahamas' economy, emphasizing their significance for the country's long-term recovery and future prosperity.

The Ultimate Red Sox Experience: Luxurious Air Travel With Crystal Skye

Embark on the Red Sox's opulent journey aboard Crystal Skye, where extravagant luxury meets unparalleled service – a lavish experience like no other awaits.

As we embark on the lavish Crystal Skye, we are immersed in an unparalleled realm of luxury and comfort, offering a unique travel experience.

The Red Sox's choice to opt for this lavish mode of transportation not only speaks to their commitment to excellence but also sets the stage for a journey filled with unparalleled luxury and sophistication.

From the exquisite interiors to the bespoke services, every detail on this extraordinary aircraft promises an experience that transcends the ordinary, leaving us eager to discover more about this ultimate Red Sox adventure.

- Red Sox chartered a Boeing 777 with Crystal Skye for a London trip, offering exclusive luxury travel.

- Crystal Skye's amenities include Michelin-star dining, spacious lounges, and attentive service for comfort.

- Passengers enjoyed 88 flat first-class seats, gourmet meals, and top-notch entertainment on the luxurious aircraft.

- The journey showcased unparalleled luxury with a dedicated butler, executive chef, and exquisite bathroom facilities.

Red Sox Chartered Crystal Skye Details

Chartering the Crystal Skye Boeing 777, the Red Sox indulged in a luxurious airborne experience unlike any other for their London excursion. The sheer opulence of the Boeing 777, with its 88 flat first-class seats, full bar, dining room, and individual 24-inch entertainment screens, set the stage for an unforgettable journey.

At a price tag of approximately $500,000 for a mere six-hour flight, the Red Sox spared no expense to ensure their comfort and satisfaction. Passengers were pampered with top-notch amenities, including the services of an executive chef providing Michelin-star quality dining, a dedicated butler catering to their every need, and luxurious bathroom facilities rivaling those of a high-end hotel.

The exclusivity and grandeur of the Crystal Skye jet exemplify the epitome of luxury travel, with air cruises often costing up to $159,000 per person for global trips, offering a truly lavish and exclusive experience that only a select few can savor.

Luxury Amenities on Crystal Skye

Indulging in the opulent realm of luxury travel, Crystal Skye's lavish amenities redefine the airborne experience for passengers seeking unparalleled comfort and extravagance. With 88 flatbed seats that convert into 70.5-inch beds, ultimate comfort is guaranteed throughout the flight. Each seat features a 24-inch touchscreen display for entertainment, allowing passengers to immerse themselves in a world of movies, music, and games.

The butler service and full-time executive chef elevate the dining experience to new heights, promising Michelin-star quality meals that satisfy even the most discerning palates. From complimentary wifi to a fully stocked bar and a spacious lounge with dining tables, Crystal Skye ensures that every aspect of the journey is tailored to provide the ultimate comfort and luxury. The promise of luxurious bathroom facilities further enhances the overall travel experience, setting a new standard for opulence in the skies.

With Crystal Skye, every moment spent aboard is a testament to the epitome of luxury travel.

Crystal Skye's Michelin-Star Dining Experience

Embarking on a culinary journey of unparalleled excellence, Crystal Skye's Michelin-star dining experience elevates luxury air travel to new heights. On this luxurious jet, passengers are treated to a gastronomic delight curated by a full-time executive chef, ensuring gourmet meals that rival those of top-rated restaurants. The high-end dining on Crystal Skye isn't just about sustenance; it's a symphony of flavors, textures, and presentations that showcase the finest ingredients and culinary expertise.

Each dish served onboard reflects a commitment to excellence, offering passengers top-notch cuisine that's both visually stunning and palate-pleasing. The culinary offerings go beyond mere sustenance; they're a celebration of the art of food, meticulously prepared to tantalize the taste buds of even the most discerning connoisseurs.

The dining experience on Crystal Skye isn't just a meal—it's an event, a luxurious indulgence that enhances the overall luxury travel experience. From the first bite to the last, every aspect of the dining experience reflects the commitment to providing passengers with a truly unforgettable journey through the world of high-end dining.

Red Sox London Series Travel Highlights

Experiencing the opulence of Crystal Skye's luxurious amenities, the Red Sox embarked on a journey to London for the MLB games, setting the stage for unforgettable travel highlights. The Boston Red Sox arrived in style aboard the Crystal Skye Boeing 777, indulging in the epitome of luxury travel. The flight provided a remarkable experience with 88 flat first-class seats, a full bar, and a dining room, ensuring the team's comfort throughout the journey. Passengers were treated to 24-inch entertainment screens, top-notch dining curated by an executive chef, and the impeccable service of a dedicated butler. With a reported cost of $500,000, this exclusive charter elevated the Red Sox's travel to London, adding an extra layer of extravagance to their trip. The combination of exceptional service, luxurious amenities, and a sophisticated atmosphere on the Crystal Skye jet truly made this journey a remarkable highlight for the team.

Behind the Scenes: Crystal Skye Aircraft

Glimpsing into the inner workings of the Crystal Skye aircraft reveals a world of unparalleled luxury and sophistication. Here's why we believe the Crystal Skye stands out:

- Boeing 777-200LR Jet : This aircraft from Crystal AirCruises is a symbol of elegance and comfort, providing a smooth and opulent flying experience.

- Luxurious Interior : Transformed into a stylish luxury oasis, the Crystal Skye boasts a roomy lounge, dining tables, and 88 flatbed seats for maximum relaxation during the journey.

- Cutting-Edge Features : Each seat is equipped with a 24-inch entertainment screen, ensuring passengers are entertained throughout the flight. Additionally, complimentary wifi is available to keep everyone connected.

- Michelin-Star Quality Dining : With access to a full-time executive chef and a promise of Michelin-star quality dining, passengers on the Crystal Skye are treated to a culinary experience that surpasses expectations.

The Crystal Skye isn't just a means of transport; it's a gateway to a world where luxury, comfort, and exceptional service converge to create an unforgettable travel experience.

What Is the Red Sox Plane on Jetblue?

We fly on JetBlue's official plane, which provides comfort and convenience. The journey is always smooth, and the service is top-notch. It's a great way for us to travel to our games with ease.

What's so Special About Fenway Park?

We adore Fenway Park for its storied past and the legendary Green Monster. The intimate atmosphere, rich history, and iconic moments make it a shrine for baseball fans. Fenway embodies the soul of baseball.

How Tall Is the Green Monster?

The Green Monster at Fenway Park stands 37 feet tall. Its imposing presence challenges hitters to aim for the skies. The wall's iconic color and proximity to home plate create a unique aspect of baseball history and lore.

How Much Did Fenway Park Cost to Build?

Like a treasure chest of history, Fenway Park, our beloved home, was built in 1912 for $650,000. Its enduring charm and iconic status in Major League Baseball make it a testament to timeless beauty.

As we soared through the skies in unparalleled luxury, it was clear that the Red Sox spared no expense in ensuring our comfort.

Yet, amidst the opulence and extravagance, it became apparent that true success lies not in the plush seats or gourmet meals, but in the unity and determination of a team striving for greatness.

In the end, it's not the crystal skies above us, but the unwavering spirit within us that defines our ultimate journey.

Affiliate disclaimer

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

Ted Lange's Isaac Love Boat Inspired Cocktail How-To Guide

10 Epic Rivers in Asia to Explore by Bike

Which Celebrity Cruise Ships Have Been Refurbished

What Drinks Can You Bring On Princess Cruise

How To Turn On Cruise Control Tesla Model 3

How To Set Cruise Control Tesla Model Y

What Is The Weather Like On A Transatlantic Cruise In April

Azamara Onward: Origins, Renovation, and Future Plans

Anthony Bourdain: Unconventional Culinary Icon and Global Influencer

Arctic Adventure: Uncharted Destinations With Le Commandant Charcot

Atlas Ocean Voyages Welcomes World Traveller: A New Chapter Begins!

Are Luxury Cruises Worth the Price? Comparing Amenities, Staff Services, Gratuities, Beverages, Dining, Itineraries, Shore Excursions, and Special Memories

How To Check Weather For A Cruise

How To Get From Venice To Chioggia Cruise Terminal

How Do You Qualify For An Ultra Cruise On Carnival

Retrotechtacular: The Nuclear Cruise Ship Of The Future Earns Glowing Reviews

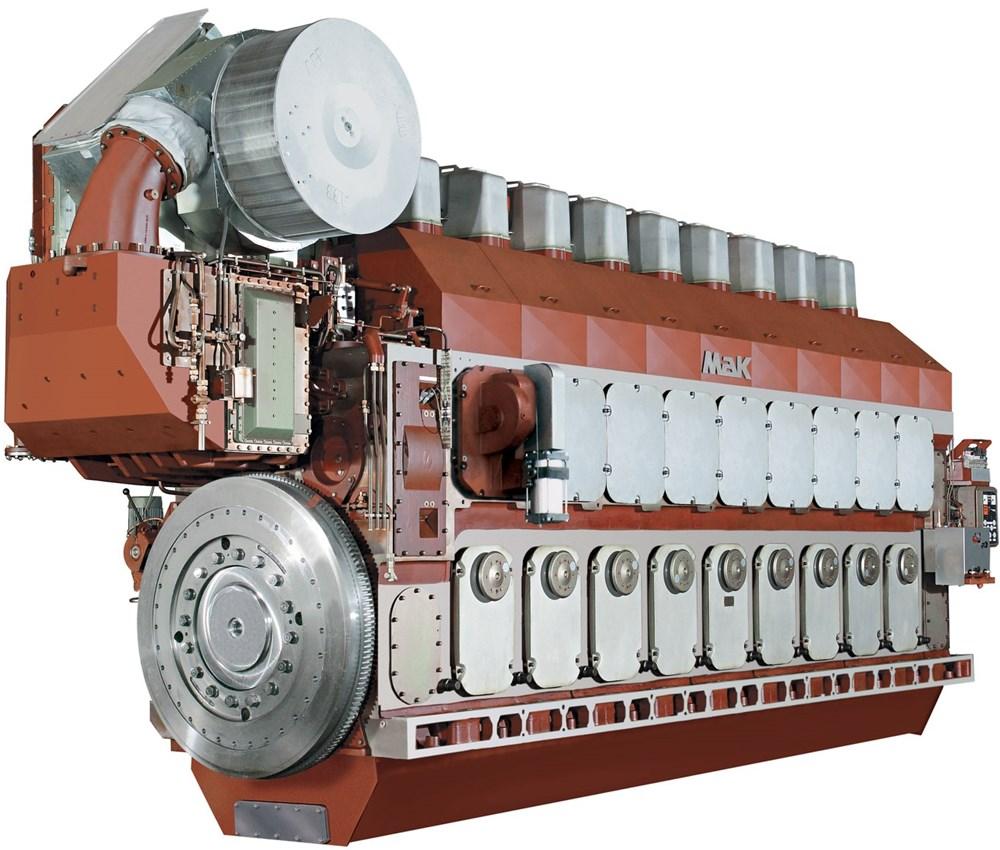

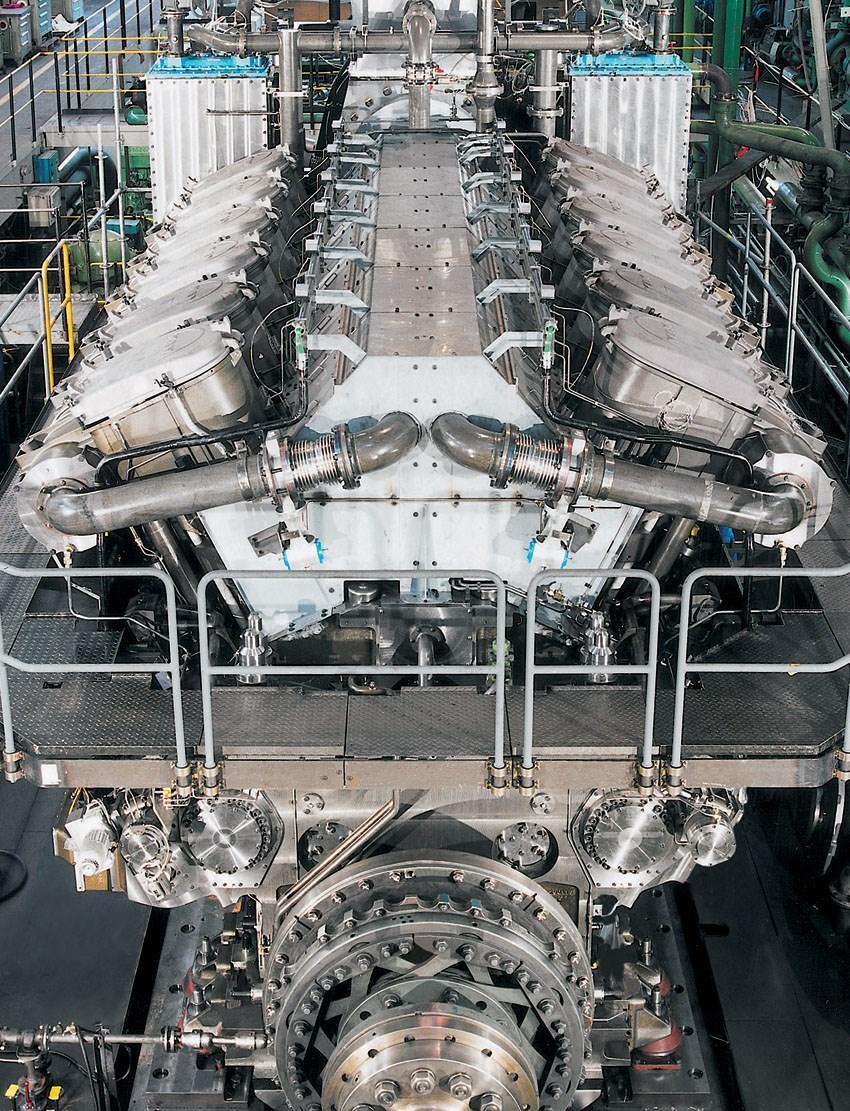

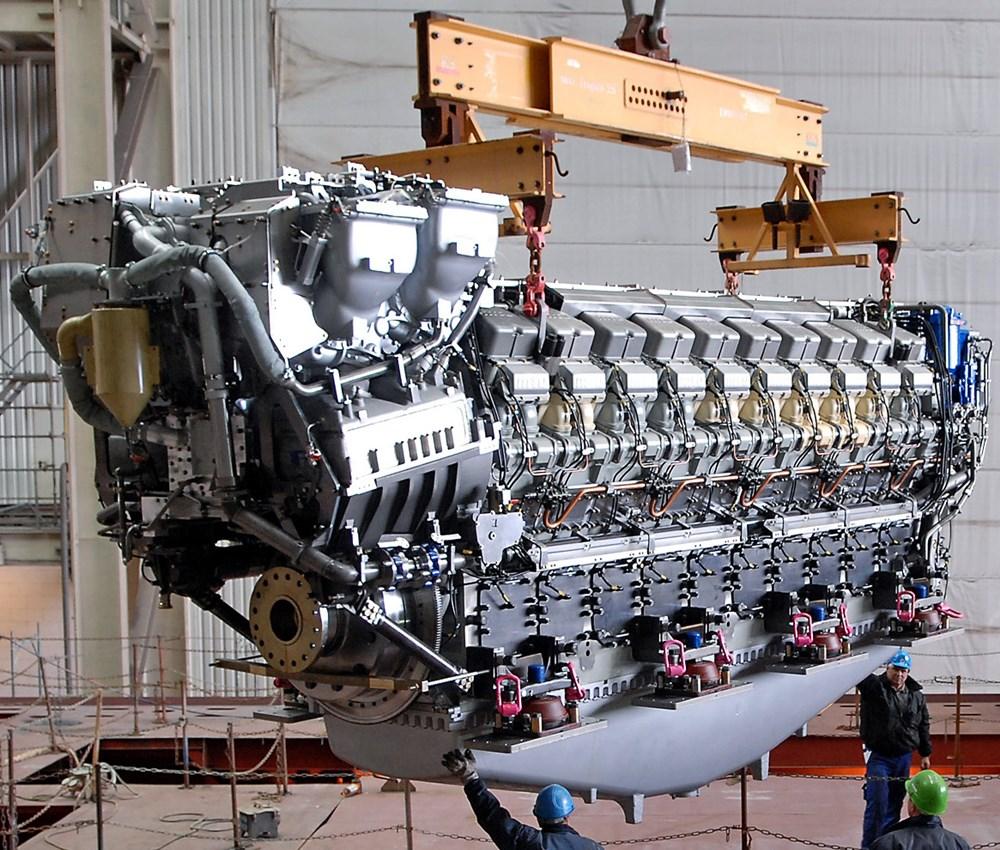

The average modern cruise ship takes about 250 tons or 80,000 gallons of fuel daily. But can you imagine a cruise ship capable of circling the globe fourteen times before it needed to top off? That was the claim for the NS Savannah , a nuclear-powered cruise ship born out of President Eisenhower’s “Atoms for Peace” initiative.

The ship was a joint project of several government agencies, including the US Maritime Administration. With a maiden cruise in 1962, the vessel cost a little more than $18 million to build, but the 74-megawatt nuclear reactor added nearly $30 million to the price tag. The ship could carry 60 passengers, 124 crew, and over 14,000 tons of cargo around 300,000 nautical miles using one set of 32 fuel elements. What was it like onboard? The video below gives a glimpse of nuclear cruising in the 1960s.

If you want some more modern views of the vessel, NPR recently toured it at its current home in Baltimore and they have great photos.

Nuclear propulsion for warships is nothing new, of course. But the Savannah is one of only a handful of civilian ships to carry a reactor, and most of those were either Russian icebreakers or cargo ships. Unlike a military reactor, Savannah’s power plant was not made to be especially compact or shock resistant but had safety and serviceability in mind.

The reactor compartment was near the center of the vessel. It was possible to refuel the reactor from access above the compartment. The reactor was a tall cylinder inside a 50-foot-long containment vessel that was 35 feet in diameter. The steel vessel was up to 4 inches thick and could handle up to 186 PSI. Shielding included four feet of concrete, six inches of lead, and six inches of polyethylene. There was also 24 inches of collision shielding built from steel and redwood.

The fuel was low-enriched uranium. Each of the 32 fuel elements had 164 uranium oxide pellets contained in helium. The elements around the edge of the array were enriched to 4.6%, but the central elements were at 4.2%. A set of 21 control rods could fully insert into the core with electric motors in less than two seconds. The entire thing was 17 feet high.

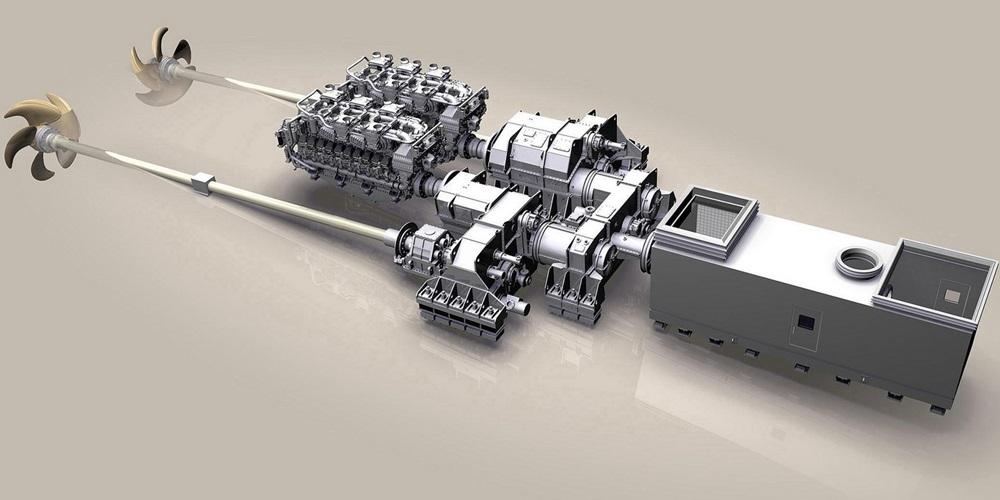

The ship’s screw runs on steam generated by the heat from the nuclear reactor. A 35 ton gear that drives the screw is a precision-machined beast you can see in the video below. Watching the ship being built in that same video, you’d hardly know the ship had a nuclear reactor onboard.

The ship had 30 staterooms for passengers. That seems small by today’s super ship standards, but at the time, that was a respectable number for a luxury cruise ship. The dining room could seat 100 passengers, and many rooms, like the library, could convert to a movie theater or pool. The ship was a demonstration and was heavy on style but short on cargo capacity.

One of the problems with the ship is that it required a larger crew, many with unusual special training. In fact, the normal deck officers became unhappy that the nuclear engineering staff were paid better, and a strike stopped the ship for a while in Galveston. This caused the Maritime Administration to select a new operator, leading to further delays as they had to train a new crew.

The ship was named after the SS Savannah , the first steamship to cross the Atlantic. Both ships were not commercially successful but paved the way for new technology. In fact, as the world seeks to reduce carbon emissions, there is talk of civilian ships using nuclear power again .

Where Is It Now?

The Savannah traveled about 450,000 nautical miles during its lifetime. By 1965, passenger service ended after carrying a total of 848 passengers. For three more years, the ship carried cargo, being refueled once in Galveston, Texas. Once the ship was removed from service in 1972, it bounced around a bit. The city of Savannah was going to make it into a hotel. When that fell through, the ship rested in Galveston for a bit before winding up a museum ship in South Carolina. Eventually, the ship would need nearly a million dollars of renovation and wound up in Baltimore.

The fuel pellets left the ship in 1975, and the reactor found a final resting spot in Utah in 2022. Indeed, disposing of fuel and the power plant may be the largest expense of operating a ship like this.

Was the ship a success or a failure? It depends on your criteria. As a goodwill ambassador, it was a success. As a technology demonstrator, we think it worked well. It hasn’t ushered in the atomic age of shipping, but that may be just because it was a little too early. New smaller and safer reactors may well bring Savannah a lot of technological cousins in the future.

33 thoughts on “ Retrotechtacular: The Nuclear Cruise Ship Of The Future Earns Glowing Reviews ”

There were 2 nuclear powered Arktika-class vessels that took passengers until recently. These were icebreakers used for scientific exploration and later for high-paying passengers who wanted to go to the north pole. ex. https://www.quarkexpeditions.com/expedition-ships/50-years-of-victory

Not sure why these are no longer available for trips… lots of potential reasons, some of which this article brings to mind.

Couldn’t be Putin’s misadventure in Ukraine…

I recall the promise that nook lee yar was going to make power generation so cheap it would be almost free while being perfectly safe. Must have missed it playing army in ‘Nam

nook you lar, shirley

Let’s make it happen. It can just undock and forever cruise the world, founding a new civilization. When everything else collapses, it can be used as a base for pirate-raider descendants in search of Mount Everest.

They open it up for tours each year for National Maritime day. I’ve been a few times and it’s very interesting.

“Unlike a military reactor, Savannah’s power plant was not made to be especially compact or shock resistant but had safety and serviceability in mind”

I think Admiral Hyman Rickover would viscerally disagree with you !

Not to say USN’s reactors are not safe. But they are small and from what I understand not as easy to service. And certainly made to take more of a beating which is, of course, safe for its purpose.

It takes some major cutting to open up US military nuclear ships for refueling. CVNs (nuclear aircraft carriers) were being designed for a 50 year lifetime with one mid-life refueling. But advancing technology used in the Ford class will be seeing off the Nimitz class ships before they get to 50 years old.

Some wanted the first CVN, Enterprise, preserved as a museum ship since it was the first CVN. It had been refueled once and there shouldn’t have been any reason the reactor section couldn’t have been opened up the same way then given a cosmetic closing up after all the reactor parts had been pulled. But nope. Had to be scrapped. Enterprise was also a victim of advancing technology. Intended to be the first of a class of ships it ended up being a one-off with 8 small reactors when the next CVN, Nimitz, established a new class (that ultimately grew to 10 ships) with two, larger reactors. Nimitz was retired in 2017 and has begun the scrapping process.

It seems unlikely that the Navy will allow any CVN to be made into a museum ship. :(

The “Big-E” was at Newport News Shipbuilding a few months ago. She was moored next to CVN-79 (new Ford class under construction). No one there (Navy reps included) really wanted to go aboard her since several areas are still reportedly “hot”.

Would’ve been nice to preserve her for posterity (given her storied history going back over half a century).