What to Do When a Well Pump Keeps Tripping Breaker?

Well pump is a lifesaver for some families. Most rural families use an alternative source of water supply to fulfill their water demands. Although a well pump is a great alternative, an issue with the machine can make your life miserable.

Among the problems, tripping is one of the most common and, at the same time, irritating problems. Don’t be surprised when you see the well pump keeps tripping breaker all of a sudden. It’s a normal situation when something like overload, pressure switch problem, breaker problem, etc. happens.

This article will cover everything regarding the issue. Don’t worry. Stay till the end.

- 1.1 1. Overloading The Circuit

- 1.2 2. Fault In The Wiring

- 1.3 3. Weak Breaker

- 1.4 4. Well Pump Motor Defect

- 1.5 5. Clogged Impeller

- 1.6 6. Bad Seals

- 1.7 7. Pressure Switch

- 2 Video of Well Pump Tripping Breaker

- 3.1 Inspect The Pressure Switch

- 3.2 Disconnect The Motor

- 3.3 Inspect The Pump Motor

- 3.4 Fix The Blockages

- 3.5 Check The Pipes, Pump Boxes, Bearings, And Shafts

- 4 Tips To Follow While Working With The Well Pump Tripping Breaker Issue

- 5.1 How can you tell if your well pump is bad?

- 5.2 Can a well pressure switch cause breaker to trip?

- 5.3 What causes the pump to trip?

- 6 Conclusion

Why Does A Well Pump Keeps Tripping Breaker?

The situation can be frustrating when a well pump or submersible water pump keeps tripping the breaker. Before replacing the well pump, it’s always better to find out the reasons behind the issue.

These are the 7 most common reasons for a well pump to keep tripping its breaker –

1. Overloading The Circuit

One of the main reasons for the breaker tripping issue is overloading. Overload normally means more power input than the device can handle.

When the circuit is overloaded, the circuit breaker may start to act weirdly. In such circumstances, tripping is a common outcome.

Solution: When the overloading issue happens, you have to do something to make it go away. Removing the clogs in the circuit is the way to get the job done here.

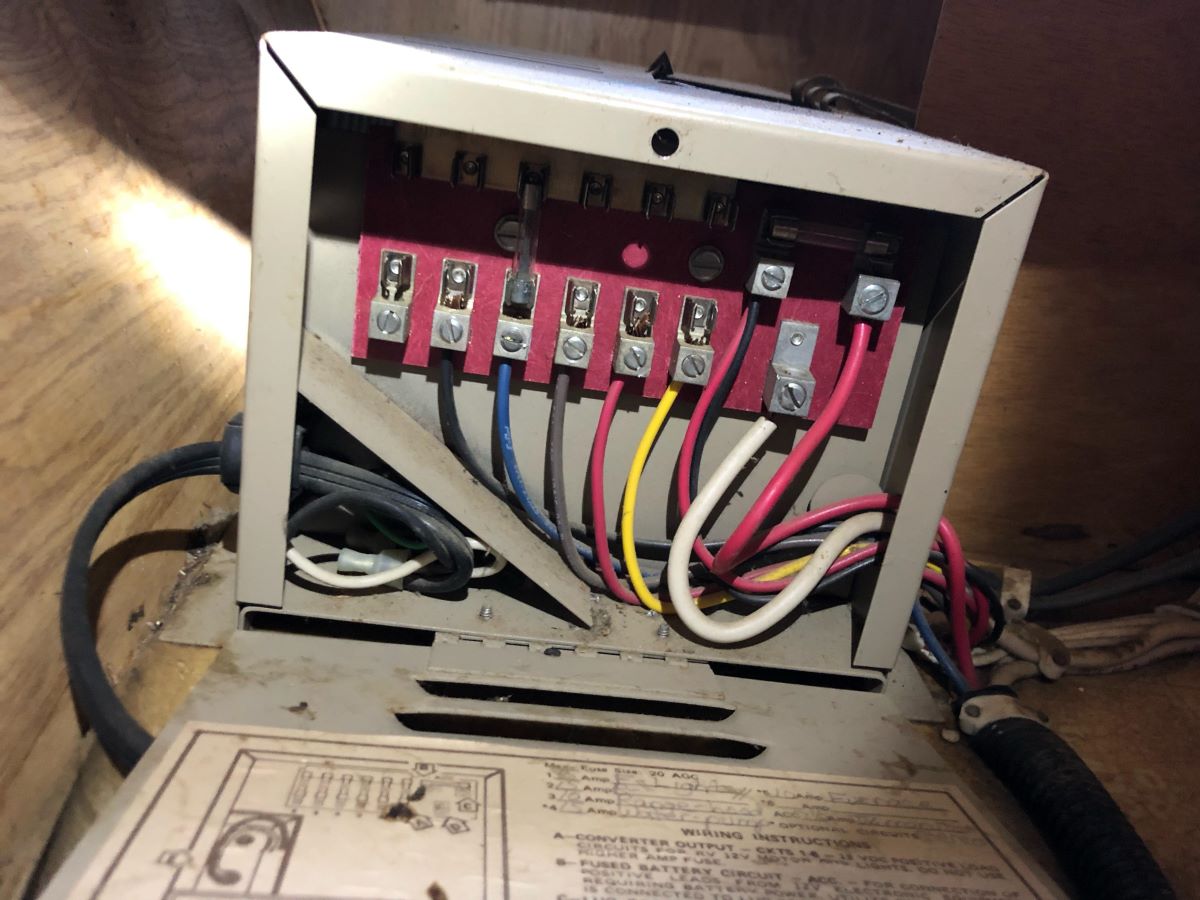

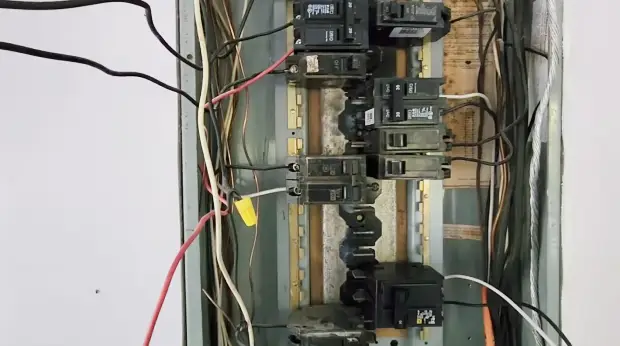

2. Fault In The Wiring

Another reason for the tripping problem is faulty wiring. The wires may be short or damaged. In such cases, you may find the tripping issue as an outcome of the wiring fault.

There may be a loose connection in the electrical box too. You may find a similar outcome in this situation also.

Solution: Check the entire wiring of the well pump. If you don’t think you will be able to inspect, hire a professional. After that, fix the damage to the wiring.

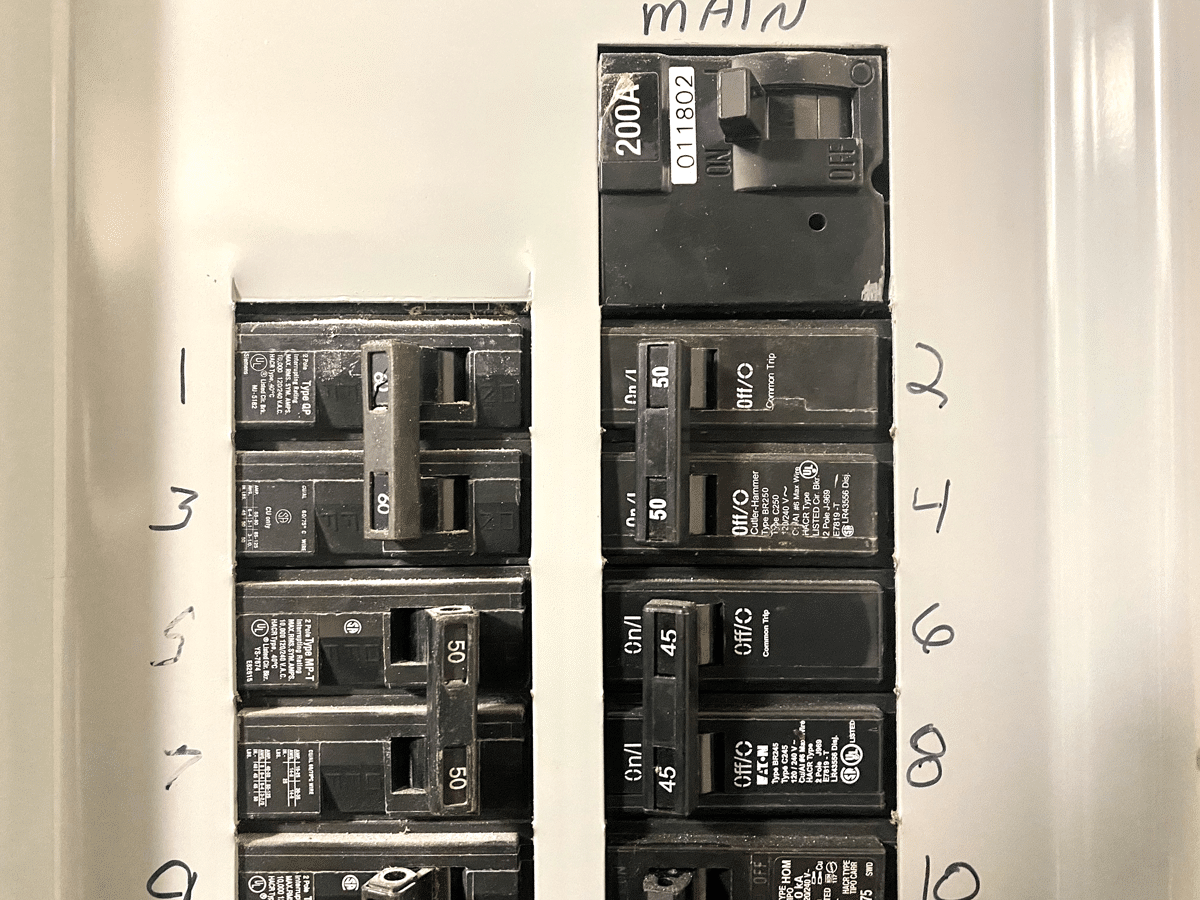

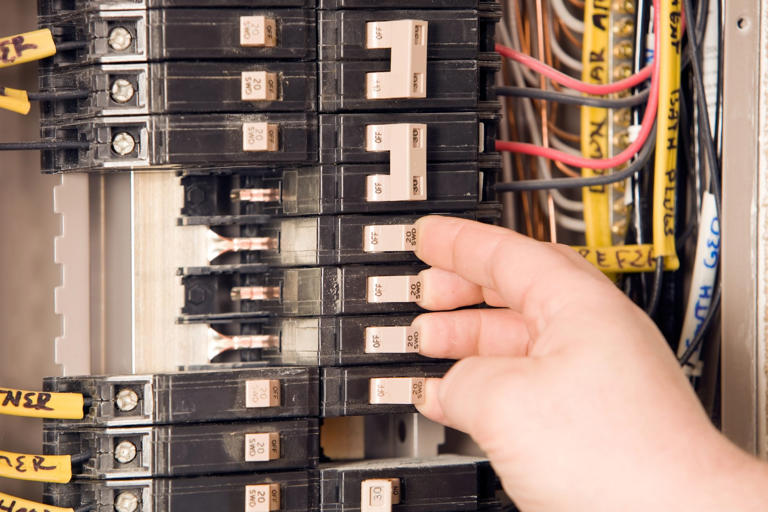

3. Weak Breaker

The breaker may also trip when the breaker itself is faulty. It’s a common instance that appliances get older and lose their temperament. If that’s the case, the breaker won’t be able to perform its function as it’s supposed to.

Solution: When the breaker itself is weak or faulty, you won’t have any option but to replace the breaker. Try buying a premium breaker. Otherwise, you may face issues again with it.

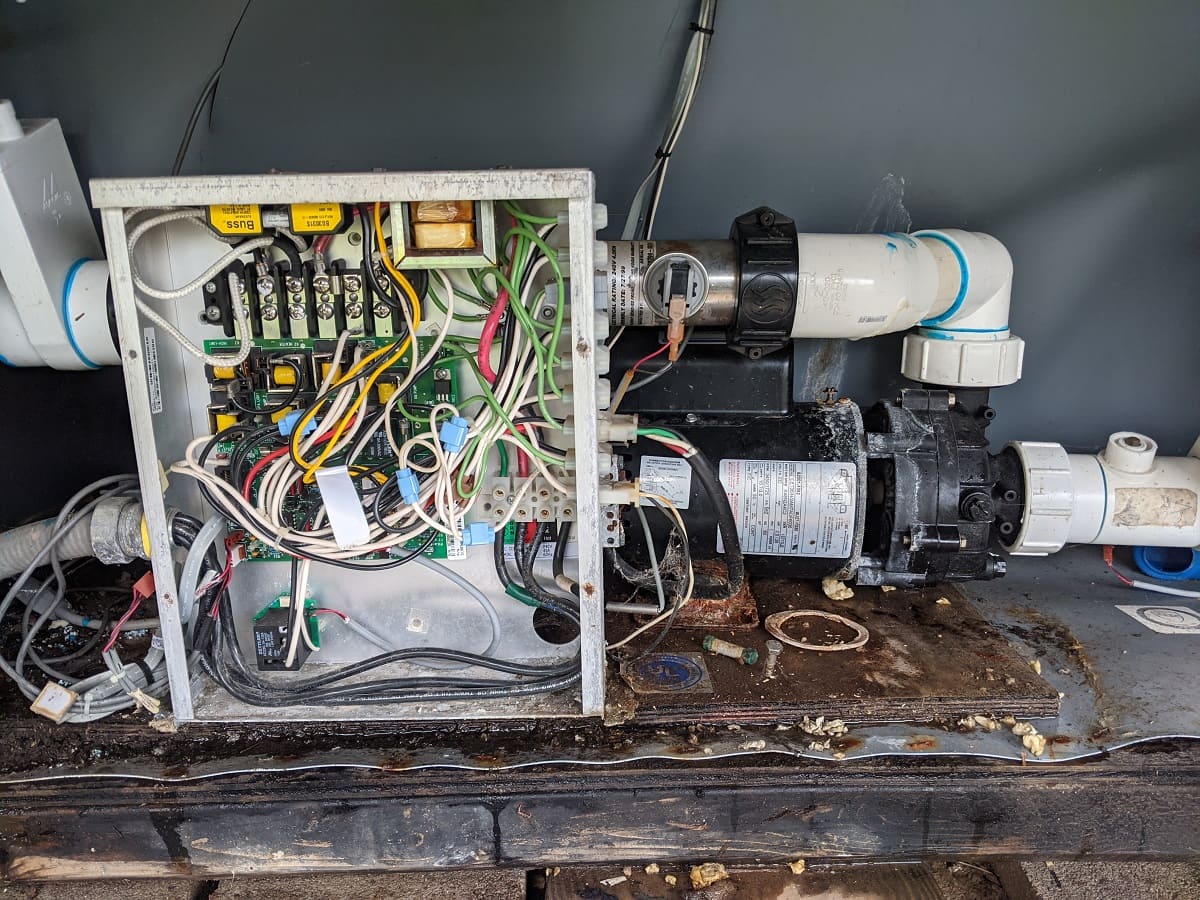

4. Well Pump Motor Defect

Don’t be surprised. A well pump may keep tripping when there’s a defect in the well pump motor. Sometimes the well pump performs poorly due to a problem with the pump’s motor.

So, the pump tripping problem isn’t impossible to fix when there’s a problem with the motor. That’s why checking the pump motor is another crucial step to finding the root of the tripping problem.

Solution: Replacing or changing the pump motor is the only option here. Similar to the breaker, try to get a good-quality pump motor as a replacement.

5. Clogged Impeller

Sometimes the impeller may get clogged. As the impeller is a major component of a well pump, the clogging of it’s a big concern. You may face problems like continuous breaker tripping until the clog is fixed.

Solution: Try to remove all the clogs within the impeller. To do that, you have to take the cover or seal of the casing first. Then, you will see the impeller. Remove it from the machine and then clean the impeller properly.

6. Bad Seals

The seals of the well pump may also be why your well pump keeps tripping its breaker.

When the breaker is in a position where the mechanical seal has failed, you may face the tripping issue. Things like this become common since a failed seal allows water to enter the pump parts.

Solution: When the seal problem is the main issue, you will have to work with the seal. Try changing the seal or fixing the leak in the seal.

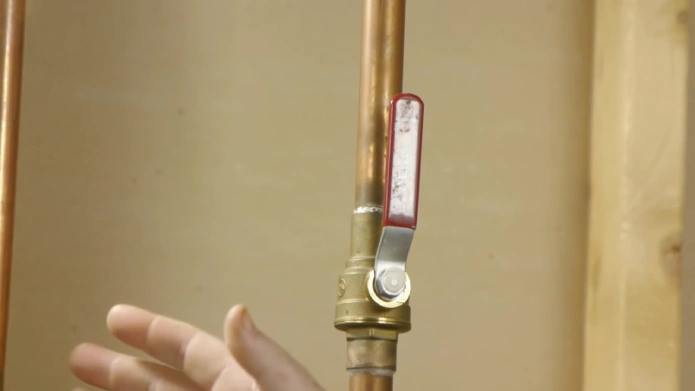

7. Pressure Switch

Sometimes you may think, will a bad pressure switch trip the breaker ? Yes, a bad pressure switch may also be the reason for a well pump to trip its breaker.

A pressure switch can become weak or bad due to the burnt or bad contacts on the pressure switch. If that happens, it can lead to a situation like tripping the breaker.

Solution: When there is an issue with the pressure switch, try replacing the bad contacts. They are the main culprit in this situation.

- How to reset the well pump pressure switch without a lever?

- Can you burn out a well pump?

- Well pump is running but not building pressure.

Video of Well Pump Tripping Breaker

To get a more simplified visualization of the reasons for the issue, check out this video.

How To Diagnose The Well Pump When It Keeps Tripping Breaker

Sometimes you may find a new well pump tripping breaker . Old or new, it is important to get to the root of the issue. Besides inspecting the individual symptoms or studying the reasons, a thorough diagnosis of the well pump is also a useful way to get rid of the issue. Follow the next steps to get the job done smoothly.

Inspect The Pressure Switch

The first step in diagnosing the well pump will be to inspect the pump’s pressure switch. Since a bad pressure switch is one of the main reasons that cause the breaker to trip, it’s important to see whether it is okay or not. If you find the pressure switch is faulty, replace it as soon as possible.

Disconnect The Motor

After you are done with the pressure switch, it’s time to work with the pump motor. Sometimes, issues with the pump motor can lead to face problems with the well pump. That’s why you have to disconnect the motor from the pump so that you can surely know what the culprit is.

To disconnect the motor from the pump, turn off the power source first. Then, remove the bolts or turn the clamp to disconnect the motor.

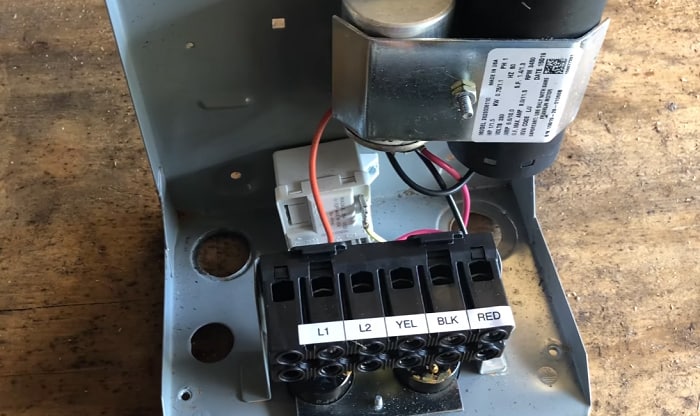

Inspect The Pump Motor

When splitting off the pump motor from the pump is over, you have to inspect the motor to know if it’s okay. You have to measure the motor’s resistance to know the answer.

To do this, taking the help of a digital multimeter is a must. When the reading of the multimeter is below 1 Ohm, the pump motor is not good. You have to replace it.

Fix The Blockages

Fixing the blockages is the next step when you are done with the motor. You have to free the pump from any sort of blockage so that there is no overload issue. Checking the box baskets and pipes of the pump is an important step to clear off the blockages.

Check The Pipes, Pump Boxes, Bearings, And Shafts

When the mentioned four steps are done, you can also check the pipes, the pump box, bearings, and the shafts to see if they’re okay.

Checking these parts is also important as any fault within them may lead to the tripping of the breaker.

Tips To Follow While Working With The Well Pump Tripping Breaker Issue

In most cases, working with the well pump may seem difficult as most of the people doing DIY are not experts. the following tips may help you more-

- Diagnose the well pump thoroughly. You may try to skip one or two parts of the diagnosis if you see them as not important. Do not do that. Even faults within the minor parts of a well pump may lead to a major problem.

- Use a premium pump motor as a replacement. Going for some cheap alternatives is tempting. But if you go for it, you may face a lot of issues with your pump in the future.

- Don’t go for cheap alternatives while replacing bearings or shafts. Just like the motor, cheap bearings or shafts may also cause problems in the future.

- Wear protective gear to ensure the best safety. For instance, use rubber gloves while inspecting the motor of the pump with a multimeter.

- Don’t hesitate to hire a professional when you are out of moves. It’s very much possible to become clueless while working with a well pump. Don’t try to experiment with something. Hire an expert right away.

- Well pump overheats and shuts off?

- Pros and cons of constant pressure well pumps

- Can you use a pool pump for a well pump?

How can you tell if your well pump is bad?

There are a lot of symptoms to give the verdict that your well pump is bad. If you find the symptoms like –

- Muddy or murky water coming out from the tap,

- The tap sputtering water,

- The taste of the water is way off than usual, or

- Loud noises coming out from the pump,

They all indicate the pump has gone bad.

Can a well pressure switch cause breaker to trip?

A well-pressure switch can also cause the breaker to trip. It happens especially when the pressure switch becomes weak or bad to perform properly.

What causes the pump to trip?

The reasons for a pump to trip are a lot. Among them, the main causes are overloading, motor defects, bad circuit breakers, clogged impellers, bad seals, and bad pressure switches.

The issue we’ve tried to cover here is an irritating and frustrating one. It’s never a pleasing scene to see your well pump keeps tripping breaker.

However, don’t go for the prompt replacement of the pump without diagnosing. Finding the root of the problem will help a lot to solve the problem efficiently and with much less money.

As an Amazon Associate, I earn from qualifying purchases.

Professional Plumber and Blogger

James is passionate about plumbing and is also a Professional Plumbing Course Tutor. He has experience of over 15+ years of as a plumber in San Diego, California. He completed many plumbing projects in commercial and residential areas. James cooperated and shared his on-field plumbing experience with the writing team to make the guides helpful.

Similar Posts

Harbor Freight Shallow Well Pump Problems: How to Fix?

Sooner or later, your shallow well pump is bound to present you with some defects, even if it’s from a renowned brand like Harbor Freight. The most common Harbor Freight Shallow well pump problems include pulsing water, murky or smelly water, or sometimes, no water at all! Inflated utility bills are also a matter of…

How Long Can A Well Pump Run Before Burning Out?

If you have a well pump system in your house, you’ve stressed at one point about how long a well pump can run before burning out. A top-quality well pump can run for almost 24 hours without any interruptions. Average-quality well pumps last for about 12-18 hours. If the pump is run continuously without any…

Well Pump Running But Not Building Pressure: How To Fix It?

A well pump creates pressure to force water from the source deep into the ground where it can be used. Your pump can break if it gets too much pressure, but what to do when your well pump is running but not building pressure? It’s a widespread problem for every pump user. Several factors can…

![well pump trips circuit breaker Can You Burn Out A Well Pump? [Reasons & Quick Solutions]](https://pumpingpies.com/wp-content/uploads/2022/08/Can-You-Burn-Out-A-Well-Pump-Reasons-Quick-Solutions-768x432.png)

Can You Burn Out A Well Pump? [Reasons & Quick Solutions]

A good quality well pump generally lasts longer; you can say, more than 10 years. But the fact is true that you need to constantly take care of the well pump in case it shows any problems. But the question is: can you burn out a well pump? The answer is YES. Your well pump…

Pros And Cons Of Constant Pressure Well Pump: Is It A Right Choice?

Can you find a sector where we aren’t using technology nowadays? Probably not. Technology has become a part of our everyday life. And it’s updating continuously. That’s why people choose constant pressure pumps over traditional ones. But what makes it better than a standard pump? What are the pros and cons of constant pressure well…

Well Pump Overheats Shuts Off: 10 Possible Reasons & Solutions

A well pump overheats when the water demand exceeds what the pump can provide. When this happens, your pump shuts off automatically to prevent an electrical fire or power surge that could damage your entire system. So, what to do when the well pump overheats and shuts off? Check the pressure tank and breaker box for…

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

(352) 316-4088

- Our Warranties

- Employment Opportunities

- City & Municipal Water Testing

- Water Pressure & Water Storage Tank Systems

- Hard Water Treatment

- Reverse Osmosis System

- Water Purification & Water Filters

- Water Softener Installation & Repairs

- Well Camera Surveys

- Solar Powered Well Pumps

- Water & Well System Inspections

- Well Drilling Services

- Well Pump Maintenance

- Well Pump Installation

- Well Pump Repair

- Well Water Testing

- Service Areas

Why Does My Well Pump Keep Tripping the Breaker?

You go to turn on your water only for nothing to come out. Confused, you decide to go check your breaker box, and, sure enough, the circuit breaker on your water pump has tripped. With so many possibilities of what could have happened, it can be hard to determine which one is the culprit. We at Perry’s Pump Repair will go over the five most common reasons your water pump is tripping your breaker and how to fix it.

5 Reasons Your Water Pump Is Tripping Your Circuit Breaker

Overloaded circuit.

This is one of the leading causes your submersible water pump will trip your breaker. Overloading is a phenomenon that happens when more energy than the circuit can handle passes through the device. The breaker prevents an overload of amperage from harming your pump or anything connected to it. If your water pump is pulling more energy than it should, this can cause the breaker to trip.

Solution : This is something you’ll want to leave to professionals. Electricity can be extremely dangerous to mess with if you aren’t professionally trained. We suggest you call your local electrician or reach out to us to see if it’s time for a new water pump .

Rain and Lightning

Here in Gainesville, you know we get almost daily summer thunderstorms and plenty of rain. While these weather conditions are just considered a part of everyday life in Florida, they can occasionally cause problems for your water pump.

A direct lightning strike can cause your water pump breaker to trip. Much like an overloaded circuit, this is due to the sudden surge of voltage all at once. Rain, on the other hand, can also cause a trip in your circuit breaker. This can be a sign of deeper problems such as deteriorating seals or even FLooding in your pump.

Solution : If your circuit breaker trips immediately after a lightning strike, you should be able to switch back on fine with no issue. If it pops again, the lightning may have caused damage to your wires, and you’ll want to call in a professional to prevent hazards like an electrical fire. If you believe rain may be the culprit, reach out to us so we can inspect and repair any damaged seals or FLooding.

Leaks in Pump

Sometimes, your water pump or its outer shell (called the water pump housing) can develop a leak. This can be caused by several different factors such as faulty sealant or using the incorrect coolant. If a leak has developed, it may get water on its wires or inside the pump itself, causing them to short-circuit and trip the breaker.

Solution : Since it may be hard to determine where the leak is or if it’s safe for an untrained hand to repair, leaks are best left to a professional water pump repair service like Perry’s Pump Repair. One of the best ways to solve this is to keep it from happening in the first place by having a preventative maintenance plan.

Wiring Issues

If you’re finding your breaker is tripping as soon as you turn it back on, it may not be an issue with the pump itself but its wiring. The wires could be fried, short-circuited, or simply not connected securely to an electrical source. Occasionally, wire damage can be caused by rodents or other pests that may have chewed through them.

Solution : Since this is dealing with electricity, you’ll want to have an electrician check your wiring and fix any issues they may see.

Clogged Impeller

One of the key components of your submersible water pump is its impeller. The impeller uses the energy from the motor to actually pump your water. Through normal use and wear, the impeller may become clogged, causing your circuit breaker to trip. If you’re noticing a frequently tripping breaker and a grinding noise from your water pump, a clogged impeller is likely the issue.

Solution : Often, this is an easy fix to do at home. Identify where your water pump’s impeller is and simply remove any debris from the area.

Call in the Professionals at Perry’s Pump Repair for All Your Water Pump Maintenance Needs

A tripped water pump circuit breaker can be quite frustrating. Not only does it indicate a problem, but it keeps water from flowing into your home. While we may not be electricians, we are well pump experts, and we can tell you what needs to happen next. We’ll help you identify what the issue is, how to fix it, and treat it to last with our warranty guarantee if we can help. Call us today to see how we can help keep your water pump properly functioning and maintained.

“Looking for a upright man to work on all your well problems? Perry’s Pump Repair is the place to call. They can help you over the phone or be on-site. We see that they are first looking out for YOU! I had some bad times with other companies selling all to me, but all I needed was one or two things. (up and running)”

Timothy Moore

“We hired Perry’s Pump Repair to install a new 4″ submersible well a few weeks back. Mr. Chris and his sweet wife answered all of our many questions … we had plenty! The communication before, during, and after the process exceeded our expectations. We appreciated that he used 100% USA parts.”

Kristina Walker

“These are guys who stayed until 10 pm in the rain and mugginess to get my well pump replaced. They might not be the cheapest outfit around but they warranty their work and their pumps. The one I had replaced was only 3 years old and not under warranty so Perry’s 5-year coverage on my new pump is comforting.”

Brad MacDonald

Anytime I have a problem with my well, I call these guys. Even in Jacksonville, they get me on the schedule as soon as they can. Always within 2 days. Each time they are courteous and quick.

Our company motto is “ Expect to be Impressed! ” Schedule your water consultation appointment today. We service all types of water needs from residential to commercial. We look forward to earning your business. Proudly serving the North Central Florida area.

ADVERTISEMENT

- POST a QUESTION or COMMENT about checking electrical wiring to diagnose well pump problems such as tripping breakers, blown fuses, weak pump performance or no water delivery from a well water pump

We also provide a more comprehensive INDEX to RELATED ARTICLES for this topic, but we recommend that you use the page top or bottom SEARCH BOX as a quick way to find information you need.

Questions & answers about how to fix problems in well pump wiring, posted originally at WATER PUMP WIRING REPAIR - be sure to review the help given in that original article.

On 2022-03-28 by Inspectapedia Com Moderator - water in submersible well pump motor needs replacement

@Ryan j wheeler, I would replace the entire pump.

On 2022-03-28 by Ryan j wheeler

I have water inside my submersible pump motor.

On 2022-01-26 by Inspectapedia Com Moderator

- well flow rate is inadequate + a pump protection switch turns off the pump to protect it from damage should the pump be run "dry"

- pump pressure control switch pressure sensor port OR the small pipe nipple or tube bringing water pressure to the pump switch is debris clogged

On 2022-01-26 by Rob

I have new 3wire 1/2 hp pump new pressure tank new pressure switch new wiring to well head . Checked continuity on wires from well head to motor.

Well runs and cycles fine intermittently looses pressure to 0 and stops for 2-3 minutes then starts again . There is power when not running??? Starts again after 2 1/2 mins consistently

Pressure switch points are closed when this happens

On 2022-01-17 by Inspectapedia Com Moderator - what to do if the pump won't start

@Anonymous, In the Index to Related Articles you will find an article titled "Pump will not start". It contains some good diagnostic steps to help you out.

On 2022-01-17 by Anonymous

the pump switch will not cycle on. I replaced the switch and I had a service tech come out and found one leg of the well pump wiring at 15 amps and the other at 3 amps changed controller and switch with no change.

The switch will not turn itself on and must be manually turned on. Is the motor on the submersible pump bad. they are coming tomorrow to change it but seem unsure of the issure

On 2021-11-27 by Inspectapedia Com Moderator - long-electrical-wire run question

@Guy Priano, I don't think the problem is bleed-over; the problem is running a too-small wire size over a very long run that causes an excessive voltage drop. Please find your question repeated along with a detailed reply and our suggestions for wire sizes and an alternative, now found at SE CABLE & WIRE SIZES FOR LONG RUNS Be sure to read those notes as we've written in considerable detail to give a careful answer and explanation in reply to your question.

On 2021-11-24 by Guy Priano

When I replace the wire it will be in conduit. Maybe I need three separate wires that are direct burial so there is no bleed over? Just need to know what kind and size of wire that will perform without problems.

On 2021-11-02 by Inspectapedia Com Moderator - pump failed after a heavy rain storm

@Aaron, It sounds like an electrician is needed to trace the circuit to find the break or open connection. Watch out : a broken, live electrical wire can be a serious shock or even electrocution hazard.

On 2021-11-02 by Aaron

My water stoped after a bad rain storm I changed the pressure switch and got new control box. I am getting power in and out pressure switch but the control box is far away down by the road.

When I check the power coming to control box L1 the white wire reads 0 and the black wire reads 120. I need 230

does this mean I have a break in the wire from pressure switch to control box or have I don’t something wrong? Any help greatly appreciated been going on a week without water !!

On 2021-10-28 by Inspectapedia Com Moderator - shocked when touching well casing

@Anonymous, Watch out : Turn off the well circuit immediately to avoid dangerous or fatal electric shock. Someone could be killed!

Your electrician or pump installer will perhaps test the pump circuit and may find shorted wires.

On 2021-10-28 by Anonymous

When I touch well casing I feel electric current but pump will not run

On 2021-09-22 by inspectapedia.com.moderator (mod) - pump protection device operation

@Eddie, Just some vague guesses: consider how the pump protection device works. Usually it's monitoring current draw or Amps as an indicator that a pump may be running dry (and thus subject to damage). So we could have low voltage, or a failing sensor in the pump protection device itself, or even a constriction in the piping system (you've checked for this).

(this reader's question, our reply, and the complete discussion is now found at AMPS MEASUREMENT METHODS )

On 2021-09-22 by Eddie

I have a submersible well pump that fills a 5000 gal. storage tank. Pump motor is controlled by a pump motor control with protection device inside, and a Pumpmaster float switch.

My problem, that is now present from original installation, seems to be control of the power to the pump. When float switch activates pump motor, it fills normally for about 10 minutes and then clicks off and immediately back on, and keeps pumping as if nothing happened. A few minutes later it repeats.

On 2021-09-19 by inspectapedia.com.moderator (mod)

@Tshuma, Lightning strike Short circuit Jammed impeller Ran dry Damaged wire Jammed pressure control Other

On 2021-09-19 by Tshuma

Causes of burning of a cable of a submissible pump

On 2021-09-07 by inspectapedia.com.moderator (mod) - use of the orange wire at a pressure control switch

@Harriet Blain, Sorry I don't see an orange wire, but I do see

two red and a

yellow and a

Two wires are power in to the switch and two are power out to the pump.

The terminals are labeled at least inside the switch cover showing which two connections are LINE (incoming power) and the other two will be LOAD (to the pump). Watch out: At least one of your wires, the yellow one, is burned and overheated. The problem could be a bad switch (have it replaced) or the pump itself could be bad. Watch out: there is live voltage at those terminals. Touching them with power -on you could be shocked or killed.

On 2021-09-07 by Harriet Blain

What is the orange wire to a pressure tank switch for? Woke up this morning to no water

On 2021-07-29 by inspectapedia.com.moderator (mod) - temporarily bypass the Pumptec pump safer switch

@Dave, I would start by checking that the pump works properly by running it directly, BRIEFLY, temporarily bypassing the Pumptec pump saver. https://inspectapedia.com/water/Water-Pump-Control-Switch-Manuals.php WATER PUMP PRESSURE SWITCH MANUALS gives us Franklin Electric, PUMPTEC-PLUS PUMP CONTROL & PROTECTION SYSTEM INSTALLATION GUIDE [PDF] (2013) Franklin Electric, op. ci at https://inspectapedia.com/water/Pumptec-Plus-Manual-Franklin.pdf that has some nice wiring illustrations. Also for other readers we provide: https://inspectapedia.com/water/Water-Pump-Repair-Manuals.php WATER PUMP & TANK I&O & REPAIR MANUALS

On 2021-07-29 by Dave - how to wire my pumptec to my control box

I just installed a new 1 hp submersible pump with a Franklin control box it turns out I have a low flow well one half to one gal. Per minute so I bought a pumptec pump saver.

I need to know how to wire my pumptec to my control box and my float switch.the way I have it wired now there is still one twenty going to the pump in all three wires even though the pumptec turned off the pump there is no water coming out of the well. Any help would be greatly appreciated thank you in advance.

On 2021-07-04 by inspectapedia.com.moderator (mod) - how is a 240V circuit measured?

@Don, In a typical 240 volt electrical circuit you will find half that amount when measuring between each of the individual wires and neutral or ground.

On 2021-07-04 by Don

Trying to test the wires going power to the pump and I'm only getting 130 from one wire and it's a 230 pump at the pressure switch of this deep well submersible pump I am getting two 1:30 readings from two separate screws what should the reading be at the pump I believe it should be 1:30 * 2

On 2021-05-22 by danjoefriedman (mod) - easy tests for a pump wire shorted to ground

@Joe, Sometimes some simple electrical tests using a VOM or DMM can tell you whether it is a short to ground or a hot neutral short or an open wire. But ultimately you'll need to follow the wiring to find the damage.

On 2021-05-22 y Joe

Hi my connection between well pump and irrigation panel is failing , there is power but does not relay from well to box, any ideas? Thank you

On 2021-05-15 by (mod) - air leaks in well piping

@Anonymous, Check for any air leaks in the piping which you can tell by the pump changing noise or sound as it runs and check for a damaged or clogged impeller in the pump

On 2021-05-14 by Anonymous

Pump is primed but will not pump water

On 2021-05-12 - by (mod) - electrical shorts or low voltage can damage a submersible well pump

@Cliff, I think that a submersible well pump could be damaged or put out of commission by electrical shorts or low voltage or other problems in the electrical supply.

On 2021-05-12 by Cliff

Is it possible that a submissive pump die of poor wiring

On 2021-05-07 - by (mod) - no voltage found on wires to pump

@Sam Smith, To answer with confidence I would need to know more about how and where you made your tests and also whether or not you have one simple pressure control switch or a switch that is in turn operating a 240 volt relay control showing at the top of this page. In general you would not expect to see voltage on the wires to the pump unless the pressure control switch was in the closed position. At that point if you're not seeing voltage at the pressure control switch on the pump wires and then I suspect the problem is the switch or relay.

On 2021-05-07 by Sam Smith

I'm showing 240 on the 2 wires of the relay coming from the power box. However, I'm not showing any voltage on the wires coming from the pump. I know I need to go towards the pump to see if there is another junction box and if so if it's showing 240 there. However, if the wires are ok is it likely that the water pump has gone bad?

On 2021-05-02 - by (mod) - where do we measure 220V?

@Tom, with two wires and 220 volts I would expect you would get 220 volts between the two wires coming from your electric panel. Are we on the same page here?

On 2021-05-02 by Tom

This is a big world water pump 220 volts 2 wire

With the closed circuit on the pressure switch the voltage reads 250 volts on one leg and 0 voltage on the other leg

I checked the voltage on the line and load on the pressure switch one side is 250 and the other side is 0

On 2021-02-08 - by (mod) - wiring a 120V pump up to 240V is likely to damage the pu,p

Edwin Unfortunately, sending 220VAC to a motor wired for 120VAC may damage the motor if in fact you fed it 220 volts; if you just fed one leg and thus 120V to the pump it may be ok, but you want to use the proper pressure control switch too.

On 2021-02-08 by Edwin J Ferrari

I hooked up new pump and forgot to change the switch from 220 to 110, will this hurt the pump capacity?

On 2021-01-24 by (mod) - unbalanced voltage on 2 legs of a 240VAC pump circuit

That sounds odd indeed, Jarry; I'd expect around 120VAC on each leg of a 240V circuit when tested from leg to ground, and around 240VAC when tested leg-to-leg. You could have a damaged wire enroute to the pump or a pump motor winding that's shorting. Sorry to say you may need to pull the pump to check wiring and pump motor Do keep me posted; what you find will help others.

On 2021-01-24 by jarry

ok the deep well pump i installed 2 years ago quit,,, its a 220 v 3 hp about 100 foot deep,,,,

well i had replaced the gauge and pressure switch when i put it in,,, its a 2 wire pump........

ok so i thought i tested circuits,, it sits like many below ground and the manual shut off was a fused box ......

so after i tested them and no breakers were tripped ,,,, i checked voltage and the voltage with wires on supply to fuse box disconnected show 120 on each,,, then i connected them and coming from the new breaker box they show 120 each side,,,, and good solid ground,,,,

but when i connect them to the pressure switch and pump and turn them on the one leg on the pressure switch goes to 168 and the other is like 78 v so the pump isnt working, i did unhook wires from the pressure switch and the continuity tester shows one leg and ground making continuity the other is ope.n. this pump being a 2 wire only has the pressure switch no control box my email is [email protected]

On 2021-01-18 - by (mod) - is the problem the pump or a leak in piping?

Are you certain that the problem is that the pump isn't running as opposed to a running pump but a leak or piping problem?

On 2021-01-17 by Greg

So I bypassed my pressure switch and starter box to test the 11 year old pump at my parents place. It had proper voltage and didn't kick on. So I replaced the pump with a brand new one. When I powered the system up nothing happened so I started trouble shooting the system as I always have. Everything tested just fine but still nothing. So I once again ran a jumper wire from the supply at the emergency shut off straight to the pump and still it did nothing.

I know for a fact it's getting proper voltage to the pump at all times no matter what. I'm returning the new pump tomorrow. Am I wrong thinking that the new pump is bad too? ( It's a 1/2 hp 2 wire 230V submersible deep well pump)

On 2020-12-22 - by (mod) - some water system component isn't working: which one?

What's not working, Amit: Water tank Water pump Water meter? I'll be glad to help but I need a clue about what we're discussing.

On 2020-12-22 by Amit Bijalwan

water tank pump meter... is not working...

On 2020-12-19 - by (mod) -

Gil Please tell me the "unit" brand and model

On 2020-12-19 by Gilbert Suazo jr

The unit was beeping. Now green light is flashing. What does it mean

On 2020-11-12 by (mod) - pump is tripping the circuit breaker th

June If your pump is tripping the circuit breaker the usual causes are a failing pump motor or possibly damaged electrical wiring.

On 2020-11-12 by june

our sumersable pump starts but a few minutes it trips

On 2020-10-28 - by (mod) - cause of repeated breaker tripping for your pump

Stephen The most common cause of repeated breaker tripping for your pump would be a failing pump motor; that may be due to a bad bearing, running the pump dry, or less common, low voltage or damaged wiring.

On 2020-10-28 by Chiboka Stephen

What are the causes of continue tripping off of over load switch on residential submersible pump

On 2020-07-29 by Robert

When my well pump comes on my line voltage goes down. I notice this as dimmed lights will dim even more. What would fix this symptom?

Do I need to run a larger wire size? My pump is probably 150' from the holding tank.

On 2020-07-12 - by (mod) - detect problem of well running out of water

Probably not, Jose. I may have been hasty (trying to answer too many questions too fast - apologies). The symptom you describe occurs usually when there is low flow rate of water into the well combined with a pump protection switch or device (designed to shut off the pump to prevent it from running "dry" and thus being damaged). A diagnostic step is to stop using water for as long as you can - several hours or more - to let the well recover (if it can). IF then you find that the pump delivers water normally, the problem is probably poor or low flow rate. Let me know and we can take it from there.

On 2020-07-12 by Jose

Thanks for the response Dan. Could the problem be a leaky foot valve if the pump doesn’t lose prime? The pump is able to immediately pump water every time it turns on but it only stays on for a few seconds. This happens even if I’m holding the pressure control “fill” lever.

On 2020-07-11 - by (mod) - signs of a leaky foot valve

Jose The no. 1 most common cause of loss of water after a power loss, provided the well or electrical system didn't itself take a direct lighting strike, is that the well had a pre-existing leaky foot valve. During the power outage the pump lost prime as water drained back into the well. Try re-priming the pump, but ultimately you'll need to replace the leaky foot valve or other check valve in the system.

On 2020-07-11 by Jose

BTW, I forgot to add that when the pump shuts off after running for a few seconds it won’t run again until about 20-30 seconds later, even if manually holding the pressure switch “fill” lever

We had a storm a few days ago and lighting (sounded fairly close) that cut our power off until the utility company fixed things a few hours later. We continued using water while power was out but had no water pressure when power came back. I replaced the old pressure switch with a new one that has the little lever to manually switch on the pump to refill the tank when pressure drops too low.

The pump only runs for a few seconds and then shuts off. I have to manually hold lever (over and over) until I finally get enough pressure in the tank where the switch takes over, but even then the pump only runs in 2-5 second increments until it reaches max pressure (60 PSI). Pump is about 5 years old without problems prior to this. What could be causing this issue??

On 2020-06-25 - by (mod) - is the pump 120V or 240V?

Really The pump may be a 220V motor unit - do you know? Do you have the pump IO manual? Is there a data tag on the pump giving its brand and model?

On 2020-06-22 by Really only2wires

How do I wire a old well pump . It doesn't have a ground wire ? There no place for one .

On 2020-04-30 - by (mod) - anytime I put on my water pump, the cucuit breaker Trips

Dave Two common causes of a circuit breaker tripping when the pump turns on are - a short circuit anywhere in the well pump wiring - those issues are discussed above on this page - a seized or frozen pump motor - details are at ELECTRIC MOTOR DIAGNOSTIC GUIDE inspectapedia.com/electric/Electric_Motor_Diagnosis.php but Watch out : if you're not familiar with safe electrical wiring and practices, don't fool with these tests yourself as you could be shocked or killed. Your electrician can do some simple tests, measuring resistance, to get a clue about what's happening. If the pump is a submersible unit, in the well, it may have to be pulled in any case, as the problem is either the wiring or the pump or its control switch.

On 2020-04-30 by Dave

Hi, i need help, anytime I put on my water pump, the cucuit breaker Trips, what could be the problem?

On 2020-03-20 - by (mod) - What would cause a main power fault indicator on my main system board?

Stuart I can but make a feeble guess as you don't give the name of equipment, model no. etc. that would permit consulting the installation and operation manual for your well pump (or other equipment unspecified) But typically a power fault means low voltage or loss of voltage or, less likely, reversed polarity. Knowing the context is diagnostic: is this a new indication on equipment previously installed and working properly or has the indicator always been on since installation?

On 2020-03-20 by Stuart Howroyd

What would cause a main power fault indicator on my main system board?

Question: what caused my well pump pressure control switch to burn up like this?

Wire on well pump charred. Water shut off and when restarted saw a spark. Can I just insulate? How do I fix this please?

(See picture. It’s the burnt wire on the right)

Wire fried on well pump. Water stopped working. Then wire sparked when turned back on. How can I fix it please?(far right wire see image) --> - Valerie

Moderator reply: burned wiring probably means shorted wires or damaged / failed water pump

The burned wiring tells us that there was (probably) a short circuit in the wiring and/or a seized pump motor.

It is of course unsafe.

I worry as well that no fuse blew nor circuit breaker tripped.

Do not just insulate and turn power back on.

Leave the circuit off to avoid a fire and shock hazard - sorry I know that's not exactly convenient.

Your repair tech or electrician will do some tests to find out if the problem is a seized pump motor or shorted wires - that's when we will know what repair is needed.

You will need at least a new pressure control switch (notice the overheated, burned contacts not just the wires), and perhaps some new wire and most trouble, perhaps a new pump).

If the pump motor is seized (or overheated and failed) that in turn can be caused by a variety of problems such as well running dry or pump running constantly.

Do keep me posted.

Reader follow-up: my pump was cycling on and off alot

Thank you so much for your quick response Daniel. My water pump cycles a lot.

Do you think the two are related. Over used/overworked system?

Just curious. Hope to have a specialist come out today. Will definitely keep you posted. Thanks again.

Moderator reply: pump short cycling can cause well pump damage and / or pressure switch burn-up

Yes - if you search InspectApedia.com with the on page search box you will find our articles on WATER PUMP SHORT CYCLING - home

Often the cause is a water-logged pressure tank.

But prolonged rapid on-off cycling might indeed burn up a pressure control switch. If that was the cause you will be so lucky because the fix is pretty easy and all above ground.

Replace the switch and any burned wiring and correct the air charge in your pressure tank.

Search InspectApedia.com for

WATER TANK AIR, HOW TO ADD

and also see

WATER TANK AIR HOW MUCH TO ADD

Your pressure control switch is damaged and should be replaced. More details are

at WATER PUMP CONTROLS & SWITCHES - home

WATER PUMP SWITCH INSTALLATION MANUALS

Watch out : don't try electrical wiring yourself if you're not trained as you could be shocked or killed.

On 2020-01-19 by (mod) - low-voltage problem at the well pump

Bobby That certainly sounds like a low-voltage problem. Often when a pump motor itself is failing it can draw high current and dim lights, but as you have a new pump I suspect the problem is in the wiring or panel or electrical service itself. An electrician would 1. check supply voltage right at the electrical panel

2. check every wiring connection for looseness, overheating, arcing, corrosion, etc.

3. check circuit fusing and wire sizes and lengths Watch out : if you are not trained in safe electrical work you could be shocked or killed. Don't fool with it.

On 2020-01-19 by Bobby

There's low voltages going to my pump when the points are open when I close the points it gets higher voltage I have a light in well house so I can see when pump is running its dim with points open gets bright whe there closed what should I be looking for short or miss wiring I've change the pump all doing the same

On 2019-04-08 1 by (mod) - intermittent loss of water pressure

Tonya Most likely yes there is a central underlying issue - either a very low flow rate well or simply a loss of well prime.

On 2019-04-08 by Tonya Crabtree

The problem we are having after a period of a couple of months of no use of the property we arrive with no water. The 1st time the delay box was replaced,2 nd time the pump was replaced now the same issue. During last stay at property during heavy usage the water would recover slowly. Is there a main issue that could be causing these other issues to fail?

On 2019-03-28 1 by (mod) - Where do the black and white wire go on a well pump?

Aaron I cannot bet your life or the fire-safety of your building by making a guess at exactly what wiring you're trying to connect - I've got just no information about what your pump and control wires are. Typically in electrical wiring Black = hot and White = neutral, particularly on 120VAC circuits. However if your pump is a 240V pump someone could have run a two wire circuit to it and both wires could be hot. So sorry but I can't give an answer to what wires go where on an unknown switch for an unknown pump. It's just too dangerous. Watch out : Please keep in mind that if you are not trained and familiar with proper and safe electrical wiring, making a mistake can kill someone or burn down the building.

On 2019-03-20 by Aaron

Where do the black and white wire go on a well pump that has a regulator switch

On 2019-03-05 by (mod) - damaged pump wiring - wires keep breaking

Anon: Please see your question and my detail reply at

WELL PUMP WIRING DAMAGE

On 2019-03-05 by Anonymous

Why would the wires in my well keep breaking

On 2019-01-17 by (mod) - testing a submersible pump

Yes, an experienced electrician or pump installer can get an idea if the pump motor is working properly by measuring its current draw when the pump is turned-on.

On 2019-01-17 by Ronnie Neathery is there any way I can test pump

I bought some new property that has a deep well pump which is 375' to 400', it is a old homestead when the previous owners left they cut all the wires in well casing and at concrete slab,why is beyond me.

It's 3 wire, is there any way I can test pump before I sink money in a control box,new wire and pressure tank or do I just need to pull pump and replace?

On 2019-11-08 by (mod) - why your well pump keeps tripping the circuit breaker:

Bush: Let's diagnose this problem of why your well pump keeps tripping the circuit breaker: 1. What is the ampacity or AMPS number on the circuit breaker? Is it 15A, 20A or something larger, and is the breaker a single pole (one switch 120V) or double pole (two switch 240V) 2. Now take a look at the data tag on your water pump; is the pump 120V or 240V (some pumps can be wire to either voltage so if that's the case, how is your pump wired? and what is the AMPS rating of the pump - from the data tag Now if the pump AMPS is greater than the circuit amps, that alone would trip the circuit breaker; 3. About the prior pump motor seizing: that may occur if the pump is allowed to run "dry" for an extended period; IN turn that would mean that your well is out of water or nearly out of water and has a terrible recovery rate. If that's the case then running out of water happens even faster with a new bigger more-powerful well pump; Now if the new pump includes a pump protection feature, that could be turning off the pump. SO unless there is a wiring or ampacity error you need a plumber or well service company to open the well and inspect its condition and its water level and perhaps its flow rate. In the ARTICLE INDEX you'll find articles on how to test the well's flow rate or recovery rate.

On 2019-11-08 by Bush

My pump seized. I was advised to buy a much bigger pump. Installed the bigger pump to my old motor both with 0.75kw.when I turn on power, it pumps water for 3minutes,then the relay switch breaks, it automatically turns on after a minute, then breaks again in 2minutes.is it a motor problem or I need a much bigger circuit break?

On 2019-02-25 by (mod) - we have no water

Ed You should find the pump circuit in the main electrical panel and follow it from there. There may be another switch right at the location of your water pressure tank and pump controller.

Watch out : if you make a mistake and you're not familiar with safe electrical wiring you could be shocked or killed.

In the ARTICLE INDEX see NO WATER for a list of diagnostic steps

On 2019-02-25 by Ed

Have no water switched pressure switch and upgrade to 40/60 pumped air pressure to 38 psi volt metter saying no amperage from pump and 240 from house cant find a switch to turn pump system on

On 2019-01-05 - by (mod) - pump stops after just adding 2-3 psi to the pressure system

Anon When a pump stops after just adding 2-3 psi to the pressure system my first guess is that it is significantly mis-adjusted - perhaps on the differential screw or nut. But if you bought and installed a brand new 30/50 pressure controller And if you cleared or replaced the tubing or pipe that brings water pressure to the control from the pump or piping or tank, then yes, I'm stumped too. Can I assume that you've checked the water pressure with a reliable, independent pressure gauge to confirm that you're only seeing 2-3 psi? What happens if the pump is forced to keep running independently of the switch? If the pump can't develop more than 2-3 psi in that case there's either no water available or a gross water pipe leak or a pump that is itself damaged - say a bad impeller, low voltage, etc. Watch out : forcing the pump to run on without the pressure control is dangerous: if you exceed the tank and piping rated pressure you can blow out a pipe or tank, risking injury or death to anyone nearby as well as, of course, flooding the area. In sum I want enough diagnostic steps to figure out where the problem really lies: - in the pressure control switch - in the pump itself - in the piping - in the well's water level and flow rate - in an ancillary pump protection device

On 2019-01-05 by Anonymous

Nothing compare to my situation.., pressure switch contact stay on and pump go for 2-3 psi then stop 15-20 sec and start again numeros time with contact always on "ON" position.. My plumber have no answer to this trouble and will ask others plumbers for troublesoothiing

On 2019-01-01 - by (mod) - best diagnostics for the short cycling well pump

Anon The best diagnostics for the short cycling well pump that you described are in the article index that you will find a live link for near the top or bottom of this page. Look through that list of Articles to find short cycling and you will see the diagnostic and repair routine.

On 2018-12-24 by (mod) - only 120 V at a 240V pump hook-up

Darryl I'd like to help but am a bit scared of you getting electrocuted (killed) on Christmas Eve. If the pump uses 220 and only one line has power (120 or 110V) then the other line is open, and dangerous. If you can't find the break in the wiring it'd be safest to leave power off until you have an electrician on site. I'm not sure what the water valve switch is. The water pump ought to be completely independent from the septic lift pump.

On 2018-12-24 by Darryl

I have a 220 volt submersible pump for domestic water. It stopped working. Only 110 volt at the switch. Checking breaker, I have 220. However I noticed a wire labelled water valve switch inline with one leg of pump supply. It would appear this is open.

What is this water valve switch. Note , I have above ground septic bed with lift pump. Merry xmas. Help

On 2018-11-15 by (mod) - lost all water pressure, manually re-set the pump - repair people hot wired the pump and burned things up

That sounds as if a pump protection switch OR a circuit breaker was shutting off the pump circuit due to a problem that could be with the well itself (running out of water) or with the pump (drawing excessive current).

The bad news is that when keep forcing a pump to run when its protection equipment keeps turning it off, we risk creating a more-costly repair: the pump motor overheats and is damaged and perhaps ruined, or other pump parts like an impeller are ruined by running dry.

A pump can also be damaged if it's a 240 volt pump getting power on just one leg (120V) of the circuit - if you keep forcing it to "run".

Whoever was helping you was NOT in my OPINION the most-expert person in the box.

If a pump is damaged and won't run, replacing the water pressure tank won't fix the pump. So I'm thrilled that the onsite tech concluded "the water pressure tank was not the issue"

The technician was better than your first onsite guy in tracing the pump problem to a loss of power on one of the two 120V legs of what sounds like a 240V pump.

Now we read that there's a fuse panel problem that needs to be repaired

Watch out : that's an unsafe condition - you need help from a licensed electrician.

And yes, it sounds as if the pump may need to be replaced.

An experienced technician should know how to measure the current draw of the pump before pulling it out of the well - that can tell us if the pump is working properly or not.

Watch out : bypassing fuses or circuit breakers to "test" an electrical circuit is something that some nervy and in my OPINION under-trained service people might do, but in my view it's a serious error that risks starting a building fire or shocking somebody or worse.

So yeah, your pump people don't sound like they're innocent here, but unfortunately, you, as a "non-expert" probably had already damaged if not ruined your pump by continually forcing it to run when it was trying to shut itself off to avoid damage.

So you share some of the blame. The unfortunate compounding of trouble here is that the people you called

- went ahead with expensive repairs that were probably not needed

- caused additional damage that increases the total job cost

On 2018-11-15 by Brad

My well problems began with total loss of water throughout my home. We could regain functionality by manually resetting the switch. This lasted for about two days, and then we had to do it again. The third time it happened, we were unable to manually reset the switch. We are a family of four that scrapes by on my income.....

so, if manually resetting the switch gave us a temporary solution while trying to figure out a long term solution, that was our goal. So, we called a plumber out for an estimate. He immediately noticed we had a blown fuse in our service box.

He used a piece of wire to jump the blown fuse and we still had spark at the switch, but in his words, not enough voltage to actually turn the pump on because the wire was too small. So he surmised that the tank was bad and that was making the switch over work and that's why the fuse popped. He did no electrical testing before coming to this conclusion....

.the price he quoted was nearly $800.....we contacted some family members and scraped together enough to cover the repair. The tech came out the next day and upon looking over the situation determined that the tank was not the issue....

that it was probably something to do with the absence of a check valve, or the switch itself.....

again, with zero electrical testing.....he told me that he couldn't simply add a check valve to the existing system or simply replace the switch because the plumbing was in disrepair and he'd probably break some things off when trying to do those things......

since we had already secured the funds to cover the repair I decided that replacing the tank as well as all components involved was a good idea since everything would be new and would ease my mind that it was all set.

Plus, since the old tank was still holding air pressure I could maybe sell it for $100 or something. So the tech went about replacing the tank and all components. When finished, he tested it....

he told me all of the following only after he had finished.....

he was only getting half of the 240 volts necessary at the switch with both fuses in place....so he took both fuses out and hard wired the fuse box. After doing so, he turned the breaker back on and something popped in the fuse box leaving a scorch mark inside of the fuse box and at that point he determined that the pump wasn't running.....

so, essentially we paid them $800 for a repair that didn't fix the problem and now are saying that our pump is bad, that they will need to pull and replace it and that will cost me an additional $1000....

my questions are numerous....is hardwiring and bypassing fuses standard practice?

Could the electrical spike that popped inside the box and scorched it have also fried my pump? They are telling me that the event that happened in the fuse box would definitely not have burned up my pump....

but they have been wrong and or shifty in general the whole time....are they trying to get me to pay them more to fix a problem that they created? And was that problem created by them due to incompetence and unsafe practices?

I really don't know what to do and I would love some insight from a different source than the one who has misdiagnosed, potentially damaged my property, and denied wrongdoing at every turn. Thank you

On 2018-12-31 by Anonymous

Hi there, 1/2 hp pump at 85', pressure switch (30-50) start at low pressure to fill tank but pump stop and start every 2-3 psi increase with contact on pressure switch "ON" all the time, ....tks

On 2018-12-26 by Anonymous - the 20amp pump circuit breaker keeps being thrown

It may run all day or it might trip in 5 mins. How do I check the wires to see if there's a short between house and well or if the short is in the well itself? The wire from the house is buried really deep.

On 2018-04-23 by (mod) - what percentage of the wire is damaged if a pump burns up?

Replacing all of the wire is surely less costly than replacing half of it and then having to pay the installer to pull the pump and wire again to replace more.

On 2018-04-23 by renee

Cause of destroyed pump was that the main water supply line was frozen. It was determined that the water supply line was buried 8" to 15". Plumbing code for buried water supply lines is 36" deep at min. Not sure how long the pump ran, approx 10 days.

On 2018-01-05 by Anonymous - Check the pressure tank air pre charge

On 2018-01-05 by Cody

When I was out there working on it I plugged in a space heater and that turned my pump on, that I previously tested for power and it did. The contacts on the switch were even closed so my pump should have been running but wasn’t until I plugged in the heater.

On 2018-01-05 by (mod) - Ran the pump but now have no power to it

And now I don’t have power from the breaker to the switch. It did get really wet out in my pump house do to burst pipe twice in the last 6 months. I changed the wire that runs from the breaker to the switch and the pump kicked on again but it shut off early again and now it reads dead again. I’m pulling my hair out please help

The new lines can be snaked through the larger diameter plastic line. But I can't know for sure what you've got with no other description than your note. Take a look at the fittings, wiring, and water piping involved.

Tom The situation you describe makes me nervous. A FRN type fuse is a delayed response fuse intended to tolerate a very brief moment of high current draw that some electrical equipment uses, like compressor motors or large milling machines. If you use a non FRN the fuse might indeed blow at equipment startup even if otherwise it could carry the running load of the equipment it serves. But when you get repeated fuse blows including the FRN-R-20 fuse that you moved to the troublemaking side of the panel it sounds to me as if there is a short or defect in the equipment. I would have left such equipment OFF, have an electrician inspect the equipment and measure its current draw for proper and safe operation before trying to get it going with the right time-delay fuses. A wrong fuse that is "wrong" only in missing a required time delay to tolerate a startup load might luckily (or because it's defective and unsafe) survive for a few motor starts in a panel. But that would not explain a pump motor that wouldn't start. What would explain it would be

- one side of a 240V circuit is dead or its fuse blown, so the pump is getting just half its voltage

- a seizing or failing pump motor

- a bad pump start/run capacitor

Could the wrong 20amp fuse keep the pressure switch from turning on the pump? I picked up the correct fuses today but I was just curious. Thoughts?

Continue reading at WATER PUMP WIRING REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX .

Recommended Articles

- WATER PUMP ELECTRICAL SWITCHES

- WATER PRESSURE CONTROL SWITCH ADJUSTMENTS

- WATER PUMP PRESSURE CONTROL SWITCH

- WATER PUMP PROTECTION SWITCH

- WATER PUMP RELAY SWITCH

- WATER PUMP WIRING DAMAGE

- WATER PUMP WIRING REPAIR

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator . Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like. You will not receive a notification when a response to your question has been posted. Please bookmark this page to make it easy for you to check back for our response. Our Comment Box is provided by Countable Web Productions countable.ca

- Pumptrol® Pressure Switch Adjustment, Square D, Schneider Electric Corporation , 8001 Knightdale Blvd., Knightdale< NC 27545 1-888-778-2733 - Square D Technical Library, web search 07/24/2010 original source: http://ecatalog.squared.com/techlib/docdetail.cfm?oid=09008926800a93be

- 9013 Pumptrol® Commercial Pressure Switches Type F and 9013 Commercial Pressure Switches Type G, Catalog, SquareD, Schneider Electric Industries SAS, Schneider Electric Industries SAS, web search 02/23/2011, original source: http://ecatalog.squared.com/pubs/Machine Control/ Pressure-Float-Vacuum Switches/Pressure Switches-Water and Air/9013CT9701.pdf Square D is a brand of Schneider Electric.

- The Type FSG is the standard water pump switch, suitable for all types of pumps: jets, submersible, reciprocating, etc.

- The Type FYG is designed to meet higher horsepower and pressure requirements.

- The Type FRG is reverse acting: the contacts open on falling pressure. All are diaphragm actuated.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore . Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested CONTINUE READING or RECOMMENDED ARTICLES .

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: [email protected] . Alan Carson is a past president of ASHI, the American Society of Home Inspectors. Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME . Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.

Serving South Carolina Since 1960

Why Does The Breaker On My Well Pump Keep Tripping?

One of the most common reasons why the breaker on your well pump might keep tripping is due to an overloaded circuit. This typically happens when too many devices or appliances are simultaneously drawing power from the same circuit. For instance, if your well pump shares a circuit with other high-powered appliances, the combined energy requirement may exceed the circuit’s capacity, causing the breaker to trip as a safety measure.

As the owner of Austin Drilling & Well Repair Inc, a licensed well pump repair company in Columbia, SC, I understand the importance of a reliable well pump for a consistent water supply. However, a tripping circuit breaker can disrupt your well’s performance, leaving you without water and in need of prompt solutions. In this comprehensive guide, we’ll explore common reasons why the breaker to your well pump may trip and offer practical tips to address the issue effectively.

Reason 1: Overloading of the Circuit An overloaded circuit is one of the most common reasons why the breaker to your well pump may trip. When the well pump draws more current than the circuit can handle, the breaker automatically shuts off the power to prevent electrical hazards.

Solution: Reduce the electrical load on the circuit by disconnecting or turning off any other electrical appliances or devices connected to the same circuit. Consider redistributing electrical loads across different circuits to ensure balanced power distribution.

Reason 2: Motor Issues Issues with the well pump motor can also lead to breaker tripping. Motor problems, such as a short circuit or damaged windings, can cause excessive current draw, triggering the breaker’s protection mechanism.

Solution: If you suspect motor issues, it’s best to seek professional assistance from Austin Drilling & Well Repair Inc. Our experienced well pump technicians can inspect and diagnose the motor for any damage or malfunction. Depending on the severity of the problem, we can recommend motor repairs or replacements.

Reason 3: Waterlogged Well Pump A waterlogged well pump is a common issue in wells with a submersible pump. When the pump’s motor becomes flooded with water, it can cause the breaker to trip due to electrical short circuits.

Solution: A waterlogged well pump requires immediate attention from a professional well contractor. Contact Austin Drilling & Well Repair Inc to inspect the well and determine the cause of the waterlogging. Proper sealing and wellhead maintenance can prevent this issue from recurring.

Reason 4: Faulty Wiring or Connections Loose or damaged wiring and connections within the well pump system can lead to increased resistance and heat buildup. This can trip the breaker as a protective measure.

Solution: Regularly inspect the wiring and connections of your well pump system. If you notice any loose or damaged components, contact Austin Drilling & Well Repair Inc to perform necessary repairs or replacements. Ensure all connections are securely tightened to prevent future issues.

Reason 5: Ground Faults Ground faults occur when an electrical current flows through an unintended path, bypassing the intended circuit. This can cause the breaker to trip.

Solution: Addressing ground faults requires expertise and specialized equipment. Contact Austin Drilling & Well Repair Inc to perform a thorough well inspection and identify any ground faults in your well pump system. Proper grounding of electrical components is crucial for preventing future tripping.

Well Pump Breaker Keeps Tripping: Call Today

A tripping breaker can be frustrating and disruptive to your well’s performance. By understanding the common reasons why breakers trip and implementing the recommended solutions from Austin Drilling & Well Repair Inc , you can address the issue effectively and ensure a reliable water supply from your well. Regular maintenance and professional inspections are essential for preventing future breaker trips and maintaining the optimal performance of your well pump system . If you encounter repeated breaker tripping or require expert assistance, our dedicated team of well professionals is here to provide reliable solutions and exceptional service to keep your well operating smoothly.

Free Water Analysis

Installations.

803-926-5402

Monday – Friday 8am – 5pm

Information

Accreditation.

© AUSTIN DRILLING INC | All Rights Reserved

NOTICE. This Website Uses Cookies And Third Party Services to provide necessary website functionality, improve your experience and analyze our traffic. By using our website, you acknowledge and agree to our Terms of Use , Privacy Policy , Cookie Policy , and Accessibility Statement .

Well Pump Overload Keeps Tripping

For situations where we need water from a certain elevation to another, well pumps come in quite handy. These devices can transport water through areas that would otherwise be difficult to guide. However, we may run into issues with a well pump, especially one where our well pump overload keeps tripping.

Why does my water pump keep tripping the breaker?

To run a water pump needs to have a constant influx of electricity. In a situation where that electricity is cut, the water pump will cease to function. While there are a lot of outside dangers that can come our way when electricity outages are concerned, the pump itself can cause them. This situation will most often occur when said pump trips the breaker. Why does this happen? Let’s find out.

The pump is leaking

If our water pump leaks, the cases where the breaker is tipped can easily happen. The leaks most frequently occur from cracks in our water pump’s housing. When the housing is cracked, we’ll see water seep through said cracks. Reach to the pump’s electrical part, causing a short circuit.

This is not only a distracting situation that can slow down any work we are doing at the moment but also a hazard. Not treating these situations could pose a significant electrical hazard to our household and us. Despite starting off as a simple case of circuit breaker tipping, it can swiftly evolve into far more, especially if the water pump is near other electrical devices.

There’s an overload in the system

Yet another reason we may see circuit breakers being tipped frequently is overcharge. The overcharge occurs in a situation where the pump is drawing more power than the breaker is capable of handling. As a result, the breaker will end up tipping in order to prevent an overwhelming amount of electricity from being pulled. [ 1 ]

While the larger water pumps will require that energy, we’ll need to replace the breaker to allow electricity to flow. The issue of overcharge can often be avoided by purchasing the correct pump in the first place or the right breaker. There shouldn’t be more energy than the breaker can handle flowing through the connection if we want to avoid the situation where tipping happens.

Clogged impeller

An important part of a pump is an impeller. An impeller works the opposite of a propeller. Sucking in items rather than releasing them. Its performance can, potentially, lead to clogs happening. A clogged impeller will affect the water pump.

Having it try to dislodge the clog by seeking more electrical energy and then tipping the breaker as a result. If this occurs, inspect the impeller and remove debris that may be stuck in. [ 2 ]

Pressure switch

The pressure switch may be the issue in some situations. The switch could be worn out or malfunctioning. If that’s the case we find ourselves in, we could end up having more power being drawn into the pump. That surge of energy will lead to the eventual tipping of the circuit breaker. Take proper care of the pressure switch and make sure to check on it eventually. [ 3 ]

Pump tripping problem

We should consider these potential issues to resolve issues of a pump tripping the breaker. Fixing them will usually lead to a functional well pump that doesn’t trip the breaker and operates without a hitch. However, it is possible to end up with more complex issues in which situation professionals should be called.

Well breaker trips intermittently

Well pumps are mandatory to manage and maintain our well’s water level . However, their utility is only functional in situations where our pumps aren’t overwhelmed by some problem or where the flow of electricity is constant. The easiest way our flow of electricity can be through our breaker being tripped. If this frequently happens and becomes intermittent, we will have to deal with it.

These occasional cuts to our power will cause multiple issues to the overall system. The first and most obvious is that our well pump will not function the whole time, rendering it useless.

When a pump is constantly stopped and started, its internal workings of it can get messed up. What’s supposed to be reliable will get fried by the constant off-and-on situation that breaker being tripped causes.

Pump overload causes

Some configurations and specifications are tied to the parts of our pump that can impact its functionality too. The overload these can cause is dangerous, both as a hazard and as a danger to our pump.

Oversized impeller

An oversized impeller can be one such issue. The impeller will draw far more power which can be a quick way to end up overloading our pump. In situations such as this, we need to replace the impeller.

Additionally, this is a great reminder to consider your purchase. Do not buy overly powerful pump parts without being sure they can be accommodated.

Worn out parts

Another source of overcharge could stem simply from the pump being worn out or damaged. This is cause similar to that of standard cracks and leaks that may occur but usually assume age to be a factor too. In this situation, having consistent maintenance can prevent the problem before it happens.

Bad installation

Misalignment between the parts of the pump and the connections to the grid. When the installation of our pump isn’t properly done, we will frequently experience issues. One of these issues is overloading. It’s important to maintain the proper installation process to guarantee success. [ 4 ]

Well pump thermal overload

With pumps, we need protection from the potential electrical systems being shorted. One of the types of protection is thermal overload. Unfortunately, the thermal overload protection used on smaller pump motors often isn’t the best source of protection.

This malfunction of the thermal overload will often happen as a cause of other heat sources. Additionally, the sunlight could damage the pump likewise. Therefore, protecting the pump is key, whether from the sun or other sources of heat.

New well pump tripping breaker

A new well pump can cause issues with our circuit breaker the same way an old one can. However, the issues with the pump may stem from more than just our standard array of wear and tear or problematic parts. The new pump can suffer from an issue all on its own.

The most frequent problem we may face is simply that the item doesn’t fit with our electrical energy’s capacity. For example, we may have a pump that’s too powerful or doesn’t have all the required failsafe, leading to far more problems with said pump. This requires some extra inspection and planning when buying the pump to avoid.

What causes well pump to trip the breaker?

While we’ve seen what causes we may have for our well pump causing the problems, a few more should be considered. These problems can be as simple as incompatible parts or as complex as a major electrical malfunction.

Well Pump Motor

We can expect quite a few other issues with well pump motor malfunctioning. The problems are quickly going to crop up because electrical components can get quickly damaged by water.

Rodent or Pest Problem

The problem of small animals such as rats and cockroaches infesting our home can be extremely problematic. This is exceptionally troublesome for sump pumps as the pest can damage many pump parts. Additionally, pest infestations can damage our wiring, which can cause the breaker to trip. [ 5 ]

Well pump overload keeps tripping

When the issue persists, it’s usually best to get a detailed inspection of our system. Calling a professional to do a check on both electrical installation and our well pump is a good way to guarantee any outlying issues will be found. The problems could affect other devices without proper repairs, so getting a check done is universally useful.

- Pump, Deep Well Submersible Pump, 1Hp, 220V...

- 2 Wire Pump With Built In Control Box- Does...

- Country Of Origin : China

Well pumps are useful and, in some cases, key parts of transporting water from one area to the other. They are built to last and offer a simple operating procedure to boot. However, we could likely end up with a problem that affects the pump negatively.

To resolve the issue of breaker tripping, we should check all the potential causes of the problem. Additionally, monitoring the pump’s functionality can reassure us whether the problem we resolved was the only one. If it isn’t, and if none of the more basic malfunctions are to blame, professionals should be called in.

Michael Davis is a heating & plumbing expert who currently works as independent contractor in SC. He also writes for Plumbertip.

For almost 10 years he worked on various plumbing tasks across South Carolina.

Related Posts

How to Thaw Frozen Pipes Underground?

How to Fix Water Drainage Problems in Yard?

How to Replace Outdoor Faucet?

- Why Does My Well Pump Trip The Breaker?

If you have a well pump that keeps tripping the breaker, it can be a frustrating and inconvenient problem. When your well pump trips the breaker, it means that there is an issue causing the circuit to overload and the breaker to shut off the power supply. This can happen for several reasons, and it is important to identify the cause in order to fix the problem and prevent further issues in the future.

1. Overloading the Circuit

One common reason why a well pump may trip the breaker is that the circuit is being overloaded. This can happen if the well pump is drawing too much power, causing the breaker to shut off in order to prevent the wiring from overheating and potentially causing a fire. This can be caused by a malfunction in the well pump itself, such as a failing motor or a clogged filter that is causing the pump to work harder than usual. It can also be caused by other devices or appliances on the same circuit drawing too much power, such as a water heater or a sump pump.

2. Electrical Issues

Another common reason for a well pump to trip the breaker is due to electrical issues within the system. This can be caused by a short circuit, a ground fault, or a faulty electrical connection. When there is a short circuit, it means that there is a direct connection between the hot and neutral wires, causing a surge of electricity that can trip the breaker. A ground fault occurs when there is a connection between the hot wire and a ground wire, causing the electricity to flow through the ground instead of the intended circuit. A faulty electrical connection can also cause problems, such as loose or corroded wires, which can lead to overheating and tripping the breaker.

3. Motor Issues