Backing up with a Weight Distribution Hitch: A Comprehensive Guide.

- 1 What is a weight distribution hitch and how does it work?

- 2 Can you back up with a weight distribution hitch?

- 3 Can you back up with weight distribution bars?

- 4 Can you back up with sway control?

- 5 Can you back up with a Reese weight distribution hitch?

- 6 Do you have to remove sway bar when backing up?

- 7 Do you need a sway bar with a weight distribution hitch?

- 8 Can you back up with a husky weight distribution hitch?

- 9 Does a weight distribution hitch take weight off the tongue?

- 10 What happens if weight distribution hitch is too high?

- 11 At what weight should you use a weight distribution hitch?

- 12 Backing up with a Reese Weight Distribution Hitch

- 13 Backing up with a Blue Ox Weight Distribution Hitch

- 14 Backing up with a Curt Weight Distribution Hitch

- 15 Backing up with a Husky Weight Distribution Hitch

- 16 How sharp can you turn with a weight distribution hitch?

- 17 Can a weight distribution hitch damage a trailer?

- 18 Conclusion

Is backing up with a weight distribution hitch really possible? Yes, you can back up with a weight distribution hitch. Many weight distribution hitches, such as Husky and Equalizer, do not need to be removed before backing up, making it easy and convenient to maneuver your vehicle and trailer.

The weight distribution hitch helps distribute the weight of the trailer evenly across the vehicle and trailer axles, improving handling and stability. As a result, you can back up with confidence and enjoy a smoother and safer towing experience.

If you’re planning on towing a trailer, RV camper van, or any other load, having a weight distribution hitch is a must. A weight distribution hitch with sway control helps distribute the weight of the trailer evenly across the vehicle and trailer axles, which eliminates trailer sway, and makes the drive safer and more comfortable.

However, many people have questions about weight distribution hitches, especially when it comes to backing up with them. This article will answer all of your questions and provide a comprehensive guide on how weight distribution hitches work and how to back up with them.

What is a weight distribution hitch and how does it work?

A weight distribution hitch is a device that attaches to the hitch ball of a vehicle and the frame of a trailer. It helps distribute the weight of the trailer evenly across the vehicle and trailer axles, which eliminates trailer sway and improves handling.

The hitch works by applying tension to the spring bars, which transfer the weight of the trailer to the vehicle’s axles. This helps balance the weight, which in turn eliminates trailer sway and improves handling.

Can you back up with a weight distribution hitch?

One of the biggest concerns people have about weight distribution hitches is whether or not they can back up with them. The good news is, yes, you can back up with a weight distribution hitch. It does not impede your ability to reverse or maneuver your vehicle. In fact, weight distribution hitches are designed to improve handling and stability, so backing up with one will be just as easy as backing up without one.

Can you back up with weight distribution bars?

Weight distribution bars are an essential component of weight distribution hitches, and they do not impede your ability to reverse or maneuver your vehicle. You can back up with weight distribution bars just as easily as you would without them.

Can you back up with sway control?

Sway control is a feature found on some weight distribution hitches that helps prevent trailer sway. Like weight distribution bars, sway control does not impede your ability to reverse or maneuver your vehicle. You can back up with sway control just as easily as you would without it.

Can you back up with a Reese weight distribution hitch?

Reese is a well-known brand in the weight distribution hitch industry, and their hitches are known for their high-quality construction and performance. You can back up with a Reese weight distribution hitch without any issues.

Do you have to remove sway bar when backing up?

One of the common questions people have about sway bars is whether or not they have to remove them when backing up. The answer is no, you do not have to remove the sway bar when backing up. The sway bar is designed to be left in place during all driving conditions, including backing up.

Do you need a sway bar with a weight distribution hitch?

While a weight distribution hitch will help eliminate trailer sway on its own, using a sway bar in conjunction with the hitch will further improve handling and stability. It’s not a requirement, but it is highly recommended to use a sway bar with a weight distribution hitch.

Can you back up with a husky weight distribution hitch?

Husky is another well-known brand in the weight distribution hitch industry, and their hitches are known for their high-quality construction and performance. You can back up with a husky weight distribution hitch without any issues.

Does a weight distribution hitch take weight off the tongue?

Yes, a weight distribution hitch helps distribute the weight of the trailer evenly across the vehicle and trailer axles, which reduces the weight on the tongue. By distributing the weight evenly, the hitch helps balance the load, which in turn reduces the weight on the tongue and improves handling and stability.

What happens if weight distribution hitch is too high?

If the weight distribution hitch is too high, it can affect the handling and stability of the vehicle and trailer. It can cause the trailer to be unbalanced, which can lead to trailer sway and other handling issues. To ensure proper weight distribution, it’s important to set the hitch to the correct height and adjust it as needed.

At what weight should you use a weight distribution hitch?

The weight at which you should use a weight distribution hitch varies depending on the type of hitch and the vehicle being used.

However, it’s generally recommended to use a weight distribution hitch when the total weight of the vehicle and trailer exceeds 50% of the vehicle’s weight capacity. It’s important to consult your vehicle’s owner’s manual or a professional to determine the correct weight capacity and when to use a weight distribution hitch.

Backing up with a Reese Weight Distribution Hitch

Backing up with a Reese weight distribution hitch is similar to backing up with other weight distribution hitches. The Reese hitch helps distribute the weight of the trailer evenly across the vehicle and trailer axles, providing improved handling and stability. This allows you to back up with confidence and ease, ensuring a smooth and safe towing experience.

Pros of backing up with a Reese weight distribution hitch:

- Improves handling and stability

- Reduces trailer sway

- Allows for easy and confident backing up

Cons of backing up with a Reese weight distribution hitch:

- The hitch may need to be removed before backing up, depending on the specific model and design.

Backing up with a Blue Ox Weight Distribution Hitch

Backing up with a Blue Ox weight distribution hitch is effortless and straightforward. The Blue Ox hitch helps balance the load of the trailer, reducing trailer sway and improving handling. As a result, you can back up with confidence and enjoy a smooth and secure towing experience.

Pros of backing up with a Blue Ox weight distribution hitch:

- Improves handling

Cons of backing up with a Blue Ox weight distribution hitch:

Backing up with a Curt Weight Distribution Hitch

Backing up with a Curt weight distribution hitch is simple and stress-free. The Curt hitch evenly distributes the weight of the trailer across the vehicle and trailer axles, reducing trailer sway and improving handling. This allows you to back up with ease, ensuring a smooth and safe towing experience.

Pros of backing up with a Curt weight distribution hitch:

Cons of backing up with a Curt weight distribution hitch:

Backing up with a Husky Weight Distribution Hitch

Backing up with a Husky weight distribution hitch is effortless and straightforward. The Husky hitch helps balance the load of the trailer, reducing trailer sway and improving handling. As a result, you can back up with confidence and enjoy a smooth and secure towing experience.

Pros of backing up with a Husky weight distribution hitch:

Cons of backing up with a Husky weight distribution hitch:

- This brand also has other hitch trailer load levelers that may need to be removed before backing up, depending on the specific model and design.

How sharp can you turn with a weight distribution hitch?

With a weight distribution hitch installed, you can make tight turns such as u-turns on the road [1] . However, it is important to be careful when making sharp turns as this may cause the trailer to jackknife [2] .

The amount of tension in the spring bars of the weight distribution hitch will affect how sharp you can turn. Increasing tension will allow for sharper turns, while decreasing tension will limit your turning ability [3] .

In real-world scenarios, a weight distribution hitch should be able to make wide turns around 90-degree corners or higher [4] . However, it is recommended to avoid making sharp turns with a trailer with a weight distribution hitch as this may cause damage to the trailer and vehicle [5] .

Can a weight distribution hitch damage a trailer?

Aweight distribution hitch can not damage a trailer. A weight distribution hitch can add stress to both the trailer and vehicle frame, but this is usually not enough to cause damage [1] . The danger lies in the extra weight added to the trailer axles, which can be too much for some half-ton trucks [2] .

However, most RV trailers are designed to handle the extra weight from a weight distribution hitch [3] . There have been reports of damage or similar issues from using a hitch weight distribution bar or sway bar with a lightweight camper [4] , but overall, a weight distribution hitch is safe when used correctly [5] .

Backing up with a weight distribution hitch is just as easy as backing up without one. It does not impede your ability to reverse or maneuver your vehicle and provides numerous benefits, including improved handling, stability, and reduced trailer sway.

If you’re planning on towing a trailer, RV camper van, or any other load, a weight distribution hitch is a must-have item. By using this comprehensive guide, you can confidently back up with a weight distribution hitch and enjoy a safer and more comfortable towing experience.

Recent Posts

The Magnalite Roaster 4267 VS The Magnalite Roaster 4269 Pot: Which one is better?

When it comes to choosing the perfect roaster pot for your culinary endeavors, the Magnalite roaster 4267 vs Magnalite roaster 4269 are the go-to choices among these classic cookware pots. Sadly,...

What Are Magnalite Pots Made Of? A Deep Dive into Their Unique Composition

Ever wonder what Magnalite pots are made of? Discover the secrets behind the unique composition of Magnalite pots and why Magnalite cookware is still a beloved choice for many cooks in 2023 and...

Home » Towing, Coupling and Docking » Can You Backup with a Weight Distribution Hitch?

Can You Backup with a Weight Distribution Hitch?

RV Expeditioners may collect a share of sales or other compensation from the links on this page. This comes at no additional cost to you, and all the prices and availability are accurate at the time of publishing.

A weight distribution hitch can be handy regardless of the size and weight of the trailer. What’s more, if the gross trailer weight is over 5,000 lbs., you are required to have a weight distribution hitch.

This type of hitch helps to stabilize the trailer and distribute the weight evenly. In turn, this improves handling as you drive.

What about backing up? Can you back up with a weight distribution hitch? The answer to this question depends on the type of WDH. Keep reading to find out what types of weight distribution hitches allow you to back up and how to find the right one for your vehicle and trailer.

What Is a Weight Distribution Hitch?

A weight distribution hitch is one that spreads the trailer tongue’s weight from your car’s bumper to its axles. It is quite a bit more complex than the standard weight carrying hitch and highly recommended if you’re towing a big and heavy trailer.

Generally, it is recommended to go for a weight distribution hitch if the overall weight of the trailer exceeds 50% of your vehicle’s towing capacity, as it makes it both safer AND increases the total weight you can tow.

For example, a trailer that’s far below its maximum weight is unstable and will sway as you drive. Also, it could swing uncontrollably back and forth, potentially causing an accident.

If there’s too much weight on the tongue, the hitch will dive. Your car’s bumper will also dive, which has the effect of lifting the front wheels. This affects steering and braking, representing a constant danger to the passengers and surrounding vehicles.

Recommended read: Benefits of Using a Weight Distribution Hitch

Enter the weight distribution hitch. While it can’t increase your car’s towing capacity, it can transfer some of the trailer’s weight to its rear and front axles, and thus improving handling. Some of the weight might be transferred to the trailer’s axle as well. This will raise the level of safety for you and other vehicles on the road.

Gross Trailer Weight

The gross trailer weight (GTW) is the overall weight of your trailer, whether it is empty or stacked with firewood or hauling jet skis.

For the purpose of determining which weight distribution system to buy, you should only consider your regular GTW. The easiest way to determine that is to weigh your trailer on a public scale. Make sure to disconnect the trailer when it is on the scale to get an accurate reading.

Tongue Weight

The tongue weight is the force that the trailer tongue exerts on the hitch. Ideally, it should be between 9% and 15% of the trailer’s GTW. If it’s below 9%, the trailer might sway and become hard to control. Conversely, if it is above 15% the hitch might sink and compromise your car’s handling.

If you have a small trailer, you can measure the tongue weight with your bathroom scale. For example, your trailer weighs 500 lbs. so you’d want the tongue to weigh around 12% or 60 lbs. Place the trailer’s tongue on the scale and read the weight. If it’s above your target weight, move some cargo back and behind the trailer’s axle. If it’s below the target weight, move some cargo forward and ahead of the axle.

If you have a big trailer, the tongue weight is going to exceed the weight limit of your bathroom scale, but you can buy a tongue weight scale.

The answer is both yes and no; it depends on the hitch. Some models completely prohibit reversing. Some only allow backing up in a straight line but there are others that allow reversing.

If you have a weight distribution system with sway control, then you should avoid reversing as much as possible. If you decide to back up anyway, disengage the sway control and spring bars beforehand.

If your system doesn’t have a sway control system, you shouldn’t have any problems backing up. However, be careful not to make sharp turns as you may jackknife the trailer.

How to Pick a Weight Distribution Hitch

There are various types of weight distribution hitches and you’ll need to select one that’s right for your car and trailer. Also, they differ in terms of weight capacity, so you should take that into consideration. Finally, weight distribution hitches can be expensive. They start at around $200 and up to a grand or so. I've spent a significant amount of time researching the market and here are the top 5 hitches I recommend you invest your money on.

While that article covers the topic in a lot more depth, here’s a quick rundown of what you need to consider when buying a weight distribution hitch.

Overall Weight Capacity

The overall weight capacity of the weight distribution system is perhaps the most important thing to consider when buying a weight distribution hitch. If you pick a system with an overly low weight capacity, you won’t be able to tow your trailer.

On the other hand, going for the biggest and strongest model may not be recommended, either. Some experts say that going 10-15% above your GTW is the best option, while others recommend going up to 50% above.

The main problem with systems that are rated far above your GTW is that they won’t have good shock absorption and they’ll transfer vibration to the trailer. Over time, this might damage both your trailer and your car.

Ball and Shank

Next, you’ll need to pick the right ball and shank that match your weight distribution system. Hitch balls are rated 2,000 to 30,000lbs and you should never go with one that’s rated below your weight distribution system.

You’ll also need to pick the right size. The most common hitch ball sizes are 1-13/16”, 1-7/8”, 2”, and 2-5/16”.

The shanks come in various sizes as well, most commonly ¾”, 1”, and 1-1/4”. If you intend to install a weight distribution system, you’ll have to go with a 1-1/4” shank.

There are two main types of weight distribution hitches – round bar and trunnion. The main difference between the two is in the way they attach to the head.

Alternatively, you can go with the Andersen Weight Distribution Kit. It is a bit more sophisticated. In terms of supported tongue weight, it sits between round and trunnion. Here’s a bit more on each type.

Round bar hitches are generally a bit harder to install, as they require clips to keep them in place. They typically slide up into the head. Furthermore, experts recommend them for lighter loads and smaller trailers. These systems are easy to adjust to the angle of the ball mount.

Round bar systems tend to be slightly more affordable than the trunnion variety. They are recommended for trailers with 600 to 1,200 lbs. tongue weight. Round bar systems are great for flat and well-maintained concrete roads.

As opposed to round bar systems, trunnion hitches are installed from the back or the sides. They are easier to install as they don’t need clips to hold them in place. Most people agree that trunnion systems should be used with bigger and bulkier trailers. Trunnion systems are less prone to ground clearance problems than the round bar variety, making them a better choice for low-clearance trailers.

Trunnion systems are generally a little more expensive and recommended for tongue weights of up to 1,700 lbs. When cornering, trunnion systems lift one bar up and put some extra pressure on your car’s front wheels. This helps handling, especially on macadam and gravel roads.

Andersen Weight Distribution Kit

An Andersen Weight Distribution Kit comes with shock absorbers and chains instead of spring bars. This almost completely eliminates bounce, making for a far smoother ride. The Andersen system includes the trailer ball and friction sway control. It uses a nut to tighten the shocks and chains. The supported tongue weights are between 200 and 1,400 lbs.

Sway Control

Sway control is an important aspect of a weight distribution hitch. Only the most affordable models (designed for the lightest trailers) don’t have sway control. There are four basic types – friction bars, dual cam stabilizers, two-point sway control, and four-point sway control. The quality of the sway control system is reflected in the price.

Friction bars offer basic sway reduction and are best used with compact trailers. You shouldn’t use them with large and heavy trailers.

Dual-cam stabilizers are the next step up. Usually, you’ll see them on smaller setups with lightweight trailers. You may also see them used with flatbed-style trailers.

Two-point sway control is a good option if you have a large trailer that’s longer than 24 feet and has a long overhang behind the rear axle.

Four-point sway control gives the ultimate stability. You should use it if your trailer is over 30 feet long.

Most people would also take the budget into consideration. You can find basic weight distribution systems that are designed for ultra-light trailers for around $200. These models are usually not equipped with sway control or any other fancy features.

At the other end of the spectrum, weight distribution systems with advanced sway control can cost up to $1,000. These are usually heavy duty systems made for the biggest trailers.

Availability

Another thing to consider when buying a weight distribution hitch is availability. Though they’re good to have with compact trailers and mandatory for big ones, they might be hard to obtain. Car dealerships and RV parts stores may not keep them in stock nowadays, or at least not in any variety. You may have to order one online or through a local dealer.

Is it possible to backup with a sway bar?

Friction sway control bars work better going forward than the reverse (backing up straight is fine). However, they are not designed to work when turning backward. Due to the different force that appears to be applied to them when in reverse, it is possible and likely to cause damage to them.

What’s th e Takeaway?

So, can you backup with a weight distribution hitch? Generally yes, though you should be careful.

Backing up with a weight distribution hitch works pretty much the same as backing up with a regular hitch. However, you should always disengage the sway control before backing up.

Sharing is caring!

1 thought on “Can You Backup with a Weight Distribution Hitch?”

I tried one of the new and wonderful WDH when I bought my 39′ Grand Design bumper trailer. That was a mistake, there is no way to keep the torsion bars from slipping out of the hangers on a tight turn, plus I have had people chase me down to tell me that it sounded like I had broken a spring. Never was happy with it.

I still had my Easy-Lift system that I purchased when I bought my 1977 Prowler. I made a ball change and I am currently using it now, now noise, no binding when backing up and the torsion bars side into the bottom of the hitch and are connected to the hangers with chains so they can be adjusted to the trailer weight.

I do have a Sway Control, also from 1977 that works just fine, I do however remove the sway bar when I am baking into a RV slot. I will never go back to the ‘NEW AND WONDERFUL” torsion bar system they have come out with now. Just look at what the design engineers came up with to retro fit a 5 gal gas can!!!!

Just because they are the latest design does not mean they are the best!!

Leave a Comment Cancel reply

The Savvy Campers

Can You Back Up With a Weight Distribution Hitch Connected?

If you’re new to the world of towing trailers or campers, it’s a surprisingly confusing one. There are many different factors to consider if you’re trying to set your vehicle up for towing purposes. Weight distribution hitches, for example, are quickly becoming the hitch of choice for heavy towing, but there are questions surrounding this type of hitch that make it less than desirable.

Most weight distribution hitches allow backing up in straight lines or making slight turns. Some hitches have no backing restrictions, while most require you to loosen or remove the spring bars and sway control system when making turns while in reverse.

In general, you should always check the specifications of your particular hitch before attempting any backing maneuvers. A big factor determining whether or not you can back up with a weight distribution hitch is the type of hitch you have. In this article, we’ll review some of the different rules for different weight distribution hitches and help you become more prepared for future towing.

What is a Weight Distribution Hitch?

A weight distribution hitch is exactly what it sounds like. It’s a hitch designed to better distribute the weight from the tongue of the trailer or camper you’re towing. It takes a bulk of the weight directly off the bumper of your towing vehicle and distributes it across the front and rear axles. This makes for a smoother towing experience and reduces the amount of stress on your towing vehicle.

A weight distribution hitch makes the connection between the trailer and towing vehicle more level. Rather than having the back of your vehicle buckle and dip under the added weight of the trailer tongue, the weight distribution hitch will keep it level.

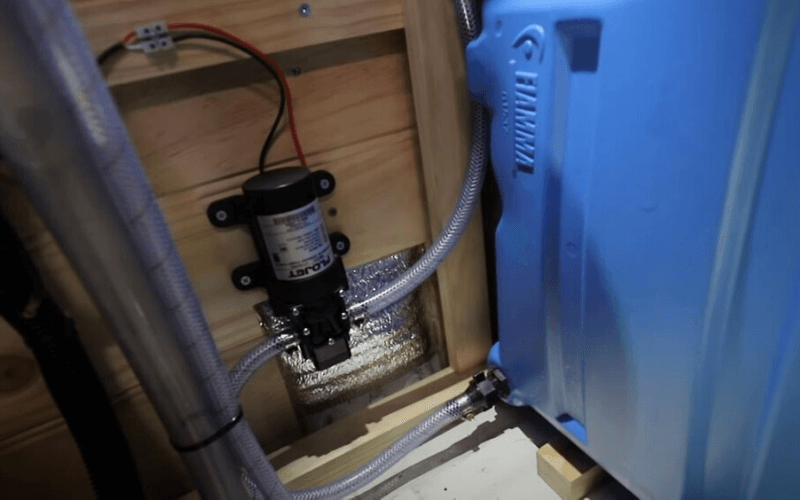

Weight distribution hitches usually have bars or chains and use friction to slow down the sway of trailers using friction. This can work at speeds as usually you are not turning very sharp, but when you are backing up, you most likely are making tight turns which can bind your weight distribution hitch and not allow you to remove it.

Can You Back Up When You Have a Weight Distribution Hitch?

Because of how weight distribution hitches are designed and attached to your towing vehicle, they don’t always allow for driving in reverse. Generally, it all comes down to the type of hitch and what the manufacturer specifies about backing up with their weight distribution hitch connected.

Most newer weight distribution hitches allow for backing up and maneuvering. However, you must know what type of hitch you have before attempting to back up because you could damage your hitch, towing vehicle, or trailer.

The Equal-i-zer weight distribution hitch system , for example, allows for full backing up and maneuverability. The system is designed with sway bars and springs that can handle the pivoting action of tight turns in reverse.

However, many weight distribution hitches, such as the Curt Weight Distribution System , don’t have full backing up capabilities. To do anything outside of backing up in a straight or relatively straight line, you’ll have to disconnect the sway bars and friction control system. Attempting to turn at sharp angles and jackknife your truck and trailer won’t be possible with these systems.

Does My Weight Distribution Hitch Allow for Backing Up?

If you currently have a weight distribution hitch installed on your truck or SUV but aren’t sure what its capabilities are, you should check before attempting to back up.

The best way to do this is to find your particular hitch’s brand and model number and look it up online. The manufacturer of your hitch should know whether your model allows for full, partial, or no backing up.

Now when we say you can’t back up, this doesn’t mean you can’t back up at all, it just means you can’t perform sharp turns when in reverse.

How to Safely Back Up With a Weight Distribution Hitch Connected

If your weight distribution hitch has no limitations to backing up, you’re free to drive and maneuver in any way necessary. If your weight distribution hitch has restrictions and limitations to its backing abilities, you’ll first have to disconnect the spring or sway bars and the friction control system. Here’s what you’ll have to do.

- With the ball of the hitch still connected to the trailer, raise the tongue of the trailer to remove tension from on top of the hitch.

- Use your break bar to loosen the saddle of the sway bar where it attaches to the trailer or camper.

- Use the bar to maintain tension as you loosen the bar from the trailer, as it could spring loose and hit something below it.

- Remove the locking mechanism holding the sway bar in place on the trailer.

- Slowly lower the saddle and remove the chain connecting the bar to the trailer.

- Move the bar sideways away from the trailer until it releases from the towing vehicle.

- Repeat these steps on the opposite side so that both bars are loose from the weight distribution hitch.

As you can see, backing up with a restricted weight distribution hitch is more of a hassle than with unrestricted hitches. However, as long as you follow proper procedures for your specific hitch, you can drive your vehicle and trailer in reverse with little issue.

If you don’t want to have to perform all of these steps to back up, we use the Andersen No Sway Hitch and it allows us to back up and fully drive without removing anything from the hitch.

What are the Benefits of a Weight Distribution Hitch?

With all the work and restrictions associated with weight distribution hitches, are they worth the hassle? Here are some top reasons people opt for weight distribution hitches rather than traditional ones.

- It reduces strain and stress on the rear axles of your towing vehicle by distributing weight evenly on all axles

- It ensures that the front axles of your towing vehicle won’t lift off the ground.

- It ensures you’ll have enough braking power to stop your vehicle when necessary.

- It makes for a smoother, more level towing experience

- You’ll have more peace of mind as you’re hauling something down the road

Do I Need a Weight Distribution Hitch?

There’s no question that using a weight distribution hitch can make for a smoother, more enjoyable towing experience. However, weight distribution hitches are costly, take time to install, and aren’t one size fits all. These obstacles have people looking for ways around installing a weight distribution hitch on their towing vehicle.

In general, it’s recommended that if you’re towing anything heavier than 5,000 pounds, you should have a weight distribution hitch. It’s also recommended that you have one of these hitches if your trailer weight is more than one-half of your vehicle’s weight.

Regardless of what you think or what the internet says, however, the best thing you can do is check your owner’s manual for advice. It should specify when you need to add a weight distribution hitch to your towing vehicle based on its weight and the weight of whatever you’re towing.

When buying, make sure you purchase a model with sway control as that is just as important as weight distribution. Once again, our favorite model is the Andersen.

Safe travels!

Be the first to be notified about FREE tips, hints, coupon codes, and email-exclusive information. All for FREE!

Related Posts:

Similar Posts

Why Does My Weight Distribution Hitch Make Noise and How to Quiet It?

Weight distribution hitches (WDH) are meant to make your towing experience easier and more enjoyable. However, depending on your setup and the condition of your hitch, there’s a chance that it can make it more uncomfortable and noisy. Like all types of hitches, weight distribution hitches are prone to squeaking, popping, and creaking noises. If…

Does a Weight Distribution Hitch Reduce Payload on My Tow Vehicle?

Whether you’re a trucker, RVer, or haul trailers as part of your daily job description, things can get dangerous at times. A nifty tool invented to make towing as safe and easy as possible is the weight distribution hitch. While weight distribution hitches have a lot of capabilities, there are certain things it can’t do. …

Does a Weight Distribution Hitch Reduce Sway While Towing?

Whether you’re a first-time tower or a seasoned veteran who does it professionally, trailer sway is a constant fear and problem. No matter how experienced you are in towing trailers or RVs, you can never predict when a stiff breeze will come from out of nowhere. You also can’t predict when you’ll have to swerve…

Why a Travel Trailer Weight Distribution Hitch is Essential: Choosing the Right One for Your Needs

Are you a regular traveler who loves touring the world using a travel trailer? If yes, you may recall one nerve-wracking moment when the trailer swayed off the road, and you nearly lost control of the vehicle. Although swinging is a common phenomenon when pulling a heavy load, you can prevent it and avert accidents…

Does a Weight Distribution Hitch Increase Towing Capacity?

Towing a trailer or RV with your truck or car can be a daunting task when you’re not properly prepared. There are tons of horror stories out there about vehicles overturning or going off the road because their trailer swayed or tipped and took them with it. However, with the proper equipment, such as a…

Can You Use a Sway Bar Without Weight Distribution Hitch on your Travel Trailer?

Thanks to tools like sway bars and weight distribution hitches, towing trailers and RVs is safer than ever. However, not everyone wants to invest in both towing tools and would prefer to spend their money on just a sway bar. This begs the question, though, about whether or not it’s ok to use a sway…

Join our Newsletter to stay up to date on the latest RV topics and receive our FREE RV Inspection Cheat Sheet Today. Use this tool to inspect new or used campers you are looking at purchasing.

No thanks, I’m not interested!

- Find a Location

How To Hook Up a Weight Distribution Hitch

A weight distribution hitch is a hitch that connects your tow vehicle to your trailer and more evenly distributes the load across all axles. It disperses the weight across the entire tow vehicle and towable RV setup, making your trailer more easily towable, reducing trailer sway , and other issues that may arise from an imbalance load.

When you hook up your travel trailer or motorhome without a weight distribution hitch, there can be too much weight on the hitch itself which will lead to instability. The same can be said for too much weight on the trailer itself. With too much weight too far back, you’re much more likely to experience trailer sway or fishtailing.

The weight distribution hitch still uses a standard ball hitch, so it’s used with travel trailers and other small towable RVs. It’s an altogether different setup from a fifth-wheel and helps bring stability to the standard towable options.

How Do You Hook Up a Weight Distribution Hitch?

When you purchased your RV, you most likely had the dealership install it on your vehicle. If you didn’t, go back to your local Camping World and have it installed. The initial setup of the hitch is best performed by a specialist.

With the hitch installed, it’s time to discuss the process of actually hitching up your RV with a weight distribution hitch. Let’s dive in.

Read the Instructions

I can’t stress this enough. Read the instructions. Even if you’re reasonably mechanically inclined, the instructions for your hitch will be helpful. Don’t skip this step. You’ll need to read the instructions to know how to adjust your hitch so that it will work with both your RV and your tow vehicle.

Steps in the Process

- Park your RV in a level position with the wheels chocked.

- Distribute the weight evenly inside your RV.

- Set your parking brake on your tow vehicle.

- Measure the height of your RV from the ground to the bottom of the body of the RV. Do this at the front and rear of the RV.

- Measure the height of your tow vehicle from the ground up through the axle to the top of the wheel well (see the video for clarification). Do all four wheels.

- Inspect your hitch bar and ball mount assembly.

- Insert the shank into the rear receiver tube on your tow vehicle.

- Insert the hitch pin and secure it with the clip.

- Grease the hitch ball.

- Raise the tongue of the trailer higher than the hitch ball.

- Release the parking brake and back the tow vehicle up so that the hitch ball is directly under the coupler. Set the parking brake again.

- Lower the trailer coupler onto the hitch ball. Latch the coupler and insert the latch pin.

- Raise the trailer tongue and rear of the tow vehicle to remove weight from the hitch.

- Inspect the spring bars, lift chain links, and snap-up brackets.

- Grease the spring bar attachment points.

- Insert the spring bar into the hitch head assembly. Put the bottom knob in and rotate it into place so the top knob moves into place. Then swing the spring bars into a position parallel with the frame.

- Position the snap-up bracket yolk parallel to the ground. Slip the yolk chainlink over the hook and make sure the lift chain is not twisted. (There should be a minimum of five chain links between the hook and the spring bar.) Secure the yolk with a locking container pin.

- Do the last three steps again on the other side.

- Lower the trailer tongue so the weight rests on the hitch.

- Hook up your safety chains by crisscrossing them under the coupler.

- Connect the breakaway electrical cable to your tow vehicle and check the trailer’s lights.

- Do a final check of all hitch pins, brackets, chains, etc.

- Double-check the jacks and stabilizers are up, and then remove the wheel chocks.

You did it! To ensure you completed the process properly, you should remeasure the trailer and tow vehicle at the exact same points you did in steps 4 and 5. These measurements will be different than when you first started. You’ll need to determine the difference between those numbers and then refer to the weight distribution hitches manual to ensure you’re within the recommended specifications.

If you’re not within the recommended specifications, then you should either head to your local Camping World or Good Sam members can reach out to the Elite Service Tech Advisor line for help.

- Comment (2)

My spring bar on the driver’s side comes out of the hitch insertion cup when the chain is hooked up to the RV tongue. We learned the hard way, that when we travel the bar drops down onto the road and drags on the pavement. We stopped that from happening by tying a rope around the spring bar and the RV tongue. What needs to be done to stop this from happening?

Hey Gary, sounds like an issue with the hitch adjustment or possibly the hitch itself. If you have time, it could be worth it to take it into a service center to have it checked out.

Leave Your Comment Cancel Reply

Save my name, email, and website in this browser for the next time I comment.

Shop By RV Type

Your Adventure Awaits

Copyright © 2023 cwi, llc all rights reserved.

- RV Glossary |

- Privacy Policy |

- California Privacy Rights |

- Do Not Sell or Share My Personal Information |

- Targeted Advertising Opt Out |

- Terms of Use

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

- My Purchase Orders

- Compare Products

Weight Distribution Hitch Setup

8 Easy-to-Follow Steps!

Weight distribution hitch installation involves leveling the trailer, measuring vehicle and trailer height, mounting the hitch head, shank, spring bars and hookup brackets, and adjusting the weight distribution hitch as needed.

In this guide, we will cover step by step how to set up a weight distribution hitch. Each hitch is unique, so make sure you follow the instructions included with your particular model.

Weight Distribution Hitch Installation Video

How to Install and Adjust Your Weight Distribution Hitch

Step 1: measure vehicle and trailer height.

Park your vehicle and trailer on a level surface and use the trailer tongue jack and a level to make sure your trailer is parallel with the ground.

Measure and record the height of your vehicle and trailer. You will need to know the distance from the ground to the top of the trailer coupler and the distances from the ground to the bottom of the rear bumper and front bumper on your tow vehicle. You can also use the distance from the ground to wheel well if you prefer.

Step 2: Attach the WD shank and hitch head

Insert the weight distribution shank into the receiver tube. Be sure that the shank is fully inserted in the receiver tube of your trailer hitch and secure it using a hitch pin & clip.

Position the head assembly on the adjustable shank. The head should be raised into position so that the top of the trailer ball is one to three inches above the coupler height. Use one mounting bolt at the bottom of the assembly to hold it in place, but do not tighten with a nut.

Need more drop or rise? Shop replacement shanks

Step 3: Set weight distribution hitch head angle

Pivoting the head downward, place two washers on the adjustment rod and insert the rod into the lower hole on the head. Some weight distribution hitches may not require this step, having a different adjustment mechanism. Remember to consult the instructions specific to your weight distribution hitch.

Rotate the head up into the mounting position on the shank. It should be vertical or tilted slightly back. You may need to add or remove washers to achieve the proper angle.

Finally, insert the second bolt into the top hole in the hitch head and fasten both bolts with the provided nuts and washers. Tighten the bolts but only enough to hold the head in place.

Step 4: Install spring bars and couple the trailer

Mount the spring bars on the hitch head. If the spring bar chains have not yet been attached, attach them to the spring bars before mounting the bars to the head.

Raise the trailer coupler, and back the tow vehicle up to couple the trailer to the trailer ball.

Step 5: Raise the trailer jack

With the coupler latched onto the trailer ball, lift up the coupling point using the trailer jack. The coupler should be raised about three inches above the level position.

Step 6: Engage the hookup brackets

Position the spring bar hookup brackets on the trailer frame using the spring bar chains as a guide. Mount the brackets onto the trailer frame using the provided bolts.

Then, attach the spring bar chains to the brackets. Make sure both sides are spaced the same vertically, with number of chain links between the spring bars and the hookup brackets. Then pry the brackets into the locked position using the provided lift handle.

Note: There must be a minimum of five chain links between the bracket and the spring bar.

Step 7: How to adjust weight distribution hitch

Retract the trailer jack so that the full weight of the trailer is resting on the hitch. Then, re-measure the distances between the ground and the front and rear bumpers. Each distance should be within 1/2" of the original measurement. If the distances have changed too drastically, you can adjust the number of links on the spring bar chains to increase or decrease tension. You can also adjust the tilt of the head unit.

Step 8: Fully tighten the bolts

Uncouple the trailer and torque all hardware to the values specified in the instructions.

Weight distribution setup differs across various models. With your weight distribution hitch, always follow the instructions provided by the manufacturer, and remember to take your time.

Weight distribution and sway control in one product!

The TruTrack™ weight distribution hitch features an innovative design that levels the vehicle-trailer combination, while actively keeping the trailer from swaying.

No need for a separate sway control unit!

How to Choose and Install the Right Weight Distribution System

Travel trailers offer an incredible sense of freedom and adventure, but they also require careful attention to safety and performance. One critical aspect of towing a travel trailer is ensuring proper weight distribution. In this guide, we’ll explore everything you need to know about choosing and installing the right weight distribution system for your travel trailer.

Table of Contents

Understanding the Importance of Weight Distribution Systems for Travel Trailer Safety

Weight distribution systems play a crucial role in travel trailer safety by evenly distributing the trailer’s tongue weight across the tow vehicle and trailer axles. This helps to:

- Improve steering and handling

- Enhance braking performance

- Minimize trailer sway

- Maintain even tire wear

Using a weight distribution hitch can significantly improve your towing experience and help prevent dangerous situations on the road.

Types of Weight Distribution Hitches: Trunnion Bars vs. Round Bars

Weight distribution hitches come in two main types: trunnion bars and round bars. Both types use spring bars to distribute weight, but they differ in design and functionality:

- Trunnion bars have a square profile and attach directly to the hitch head, offering greater ground clearance and increased weight capacity.

- Round bars have a round profile and attach to the hitch head using chains, providing a smoother ride and easier installation.

Consider your specific towing needs and preferences when choosing between trunnion bars and round bars.

How to Calculate the Required Weight Distribution Hitch Capacity for Your Travel Trailer

To determine the right weight distribution hitch capacity for your travel trailer, you’ll need to know the Gross Trailer Weight (GTW) and Tongue Weight (TW) . The GTW is the total weight of your loaded trailer, while the TW is the amount of weight pressing down on the hitch. As a general rule, the hitch capacity should be greater than the GTW and within the range of the TW.

Choosing the Right Weight Distribution Hitch Based on Your Travel Trailer’s Tongue Weight

Selecting a weight distribution hitch based on your trailer’s tongue weight is essential for optimal performance and safety. To find the right hitch, follow these steps:

- Determine your travel trailer’s tongue weight.

- Consult the hitch manufacturer’s guidelines for weight capacity.

- Choose a hitch that falls within the range of your trailer’s tongue weight.

Tips for Selecting a Weight Distribution System Compatible with Your Tow Vehicle

To ensure compatibility between your tow vehicle and weight distribution system, consider:

- Your tow vehicle’s towing capacity

- The receiver hitch size on your tow vehicle

- The hitch ball size required by your travel trailer

- The drop or rise needed to keep the travel trailer level

Always consult your tow vehicle’s owner’s manual and the hitch manufacturer’s recommendations to ensure compatibility.

The Benefits of Integrated Sway Control in Weight Distribution Systems

Integrated sway control can help to further minimize trailer sway and improve towing stability. There are two main types of sway control:

- Friction sway control uses friction to resist trailer sway, which can be adjusted to suit your towing needs.

- Dual-cam sway control uses cams to keep the trailer centered and reduce sway.

Consider a weight distribution system with integrated sway control for enhanced safety and performance.

How to Properly Measure Your Travel Trailer and Tow Vehicle for Weight Distribution Hitch Installation

Before installing a weight distribution hitch, measure your travel trailer and tow vehicle to ensure proper fit and adjustment. Key measurements include:

- Hitch ball height : Measure the distance from the ground to the top of the hitch ball on both the tow vehicle and travel trailer.

- Coupler height : Measure the distance from the ground to the bottom of the trailer coupler.

- **Drop or rise**: Determine the difference between the hitch ball height and the coupler height. This value will help you select the appropriate shank for your hitch.

Follow these steps to install a weight distribution hitch on your travel trailer:

- Park your tow vehicle and travel trailer on a level surface, and engage the parking brakes.

- Assemble the hitch head, shank, and hitch ball according to the manufacturer’s instructions.

- Attach the assembled hitch to your tow vehicle’s receiver and secure it with the appropriate hitch pin.

- Measure and adjust the hitch ball height to match the trailer coupler height.

- Connect the trailer coupler to the hitch ball and secure the coupler latch.

- Install the spring bars and brackets according to the hitch type (trunnion bars or round bars).

- Adjust the spring bar tension as per the manufacturer’s recommendations.

- Connect any additional sway control devices, if applicable.

Adjusting the Weight Distribution Hitch for Optimal Performance and Safety

Once your weight distribution hitch is installed, it’s essential to fine-tune the adjustments for optimal performance and safety. Key adjustments include:

- Spring bar tension : Adjust the tension to distribute the trailer’s tongue weight evenly across the tow vehicle and trailer axles.

- Sway control : If using a friction sway control device, adjust the friction to match your towing conditions.

- Hitch ball height : Recheck and adjust the hitch ball height as needed to ensure the travel trailer remains level.

The Role of Shank Length and Rise in Weight Distribution Hitch Selection

The shank length and rise play an essential role in ensuring proper hitch ball height and trailer leveling. The shank length determines the distance between the hitch head and the tow vehicle’s receiver, while the rise is the vertical distance required to match the hitch ball height to the trailer coupler height. Select a shank with the appropriate length and rise for your specific towing setup.

How to Choose and Install the Right Hitch Ball for Your Weight Distribution System

Choosing the right hitch ball is crucial for a secure connection between your travel trailer and tow vehicle. Consider the following when selecting a hitch ball:

- Ball size : Ensure the hitch ball size matches your trailer coupler.

- Shank diameter : Choose a hitch ball with a shank diameter compatible with your weight distribution hitch.

- Weight capacity : Select a hitch ball with a weight capacity greater than your trailer’s Gross Trailer Weight.

To install the hitch ball:

- Insert the hitch ball shank into the hitch head.

- Secure the hitch ball with a washer and nut, tightening it to the manufacturer’s torque specifications.

- Use a torque wrench to ensure proper tightening.

Troubleshooting Common Weight Distribution Hitch Issues and Solutions

Common weight distribution hitch issues include:

- Trailer sway : Check and adjust spring bar tension and sway control settings as needed.

- Uneven weight distribution : Reevaluate your travel trailer’s loading and adjust the spring bar tension.

- Hitch noise : Lubricate the hitch ball, spring bars, and other moving parts to minimize noise.

The Impact of Weight Distribution Systems on Tow Vehicle Handling and Stability

Properly installed weight distribution systems can significantly improve tow vehicle handling and stability by:

- Distributing weight evenly across the tow vehicle and trailer axles

- Reducing trailer sway

- Improving steering and braking performance

Always adjust your driving habits to account for the added weight and size of your travel trailer.

Proper Maintenance and Care for Your Weight Distribution Hitch System

Regular maintenance and care for your weight distribution hitch system will prolong its lifespan and ensure optimal performance. This includes:

- Inspecting the hitch components for wear

- Lubricating moving parts, such as the hitch ball, spring bars, and sway control devices

- Checking and tightening bolts and connections as needed

- Cleaning and protecting the hitch from corrosion and rust

- Storing the hitch in a dry and protected area when not in use

How to Safely Disconnect Your Weight Distribution Hitch When Not in Use

To safely disconnect your weight distribution hitch:

- Park your tow vehicle and travel trailer on a level surface and engage the parking brakes.

- Lower the trailer’s tongue jack to take the weight off the hitch ball.

- Release any tension on the spring bars, and remove them from the hitch head and brackets.

- Disconnect any sway control devices.

- Release the trailer coupler latch and raise the tongue jack to separate the trailer from the hitch ball.

- Remove the hitch from your tow vehicle’s receiver and store it properly.

Choosing Between Fixed and Adjustable Weight Distribution Systems

Fixed weight distribution systems have a set hitch head angle and shank drop/rise, while adjustable systems allow for customization to suit various towing setups. Adjustable systems offer greater flexibility, especially if you tow different trailers or change your tow vehicle, but they may be more expensive than fixed systems.

Upgrading Your Travel Trailer Suspension to Complement Your Weight Distribution Hitch

Upgrading your travel trailer suspension can enhance the performance of your weight distribution hitch and improve overall towing stability. Suspension upgrades include:

- Shock absorbers : Improve ride quality and reduce bouncing.

- Air springs : Enhance load leveling and support.

- Equalizer systems : Further distribute weight across the trailer axles.

Consult with a professional or your travel trailer manufacturer for recommendations on suspension upgrades.

The Role of Air Bags and Helper Springs in Improving Weight Distribution

Air bags and helper springs can be added to your tow vehicle’s suspension to enhance weight distribution, stability, and ride comfort. These components work by providing additional support to the tow vehicle’s suspension, helping to level the vehicle and maintain proper alignment when towing a heavy trailer.

Understanding the Limitations of Weight Distribution Systems and When Not to Use Them

Weight distribution systems have limitations and may not be suitable for all towing situations:

- Towing capacity : A weight distribution hitch does not increase your tow vehicle’s towing capacity.

- Surge brakes : Some travel trailers with surge brakes may not be compatible with certain weight distribution systems due to potential interference with the braking mechanism.

- Tow vehicle compatibility : Some vehicles, such as those with unibody construction or specific suspension types, may not be compatible with weight distribution hitches.

Always consult your tow vehicle’s owner’s manual and the hitch manufacturer’s guidelines to ensure the proper use of a weight distribution system.

Comparing Popular Weight Distribution Hitch Brands and Models

There are several popular weight distribution hitch brands and models on the market. When comparing options, consider factors such as:

- Weight capacity

- Hitch type (trunnion bars vs. round bars)

- Integrated sway control

- Ease of installation and adjustment

- Price and warranty

Some well-known weight distribution hitch brands include:

- Equal-i-zer

Take the time to research and compare different models to find the best weight distribution system for your travel trailer and towing needs.

Good luck, and happy camping!

Check out our article on: Best Weight Distribution Hitch For (Safe Proper Towing)

Please keep in mind that we may receive commissions when you click our links and make purchases. However, this does not impact our reviews and comparisons. We try our best to keep things fair and balanced, in order to help you make the best choice for you.

As an Amazon Associate, I earn from qualifying purchases.

How To Back Up a Trailer

Jackknives are cool in the pool, not when pulling trailers.

We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

The Drive and its partners may earn a commission if you purchase a product through one of our links. Read more.

So you want to back up a trailer? Whether that be taking the jet ski to the lake or snaking a trailer full of paver bricks to the backyard for landscaping, you’re gearing up for an adventure that’ll put your driving skills to the test.

The know-how needed to back up a trailer uses the same simple techniques despite vehicle size, steering ratios, and the size of the trailer. Ultimately, the goal is to prevent hitting anything with the trailer or the vehicle and to avoid jackknifing , when the trailer and vehicle end up in a v-shaped position that could result in damage. That said, the task at hand will also present different challenges based on the space and surroundings.

Regardless of the mission, having the dexterity to place a trailer while in reverse is useful knowledge that can be tackled with a little guidance and a pocket full of patience. To aid in getting you backing up a trailer like a pro, The Drive ’s crack How-To team is here to help. Ready?

Backup a Trailer Basics

Estimated Time Needed: Less than a half-hour

Skill Level: Beginner-Intermediate

Vehicle System: Dynamics

What Is Backing Up a Trailer?

Although a trailer will be pulled forward for 90 percent of its life, it’s the 10 percent when it’s pushed back that causes issues and frustration for inexperienced towers. This skill becomes valuable when launching a watercraft, stowing something away in a barn or garage, delivering supplies for a house remodel, or placing a pop-up camper at a state park. Even when you pull forward into a driveway, somebody’s gotta back it out!

Trailers operate somewhat counterintuitively as turning the steering wheel left will push the trailer right. Turning the wheel right will kick the truck’s rear end right and push the trailer left. Essentially, the direction the wheel is turned will be the opposite of the direction the trailer will go.

One major factor in backing up a trailer is speed. Take it slow. The quicker you drive, the quicker something can go wrong, and you’ll have to correct it by starting over.

What Are Some Common Trailer Hitch Variants?

A trailer’s hitch is where it and the vehicle towing it couple together and commonly features a ball-in-socket design, along with chains and an adapter for brake and indicator lights. However, there is a variety of hitches available. Here’s a rundown of the most common trailer hitches.

- Weight-carrying : The most common hitch that does not feature add-on accessories for a weight-distribution system. Thus, the weight is loaded on the hitch.

- Weight-distributing : Using add-ons such as a spring bar, a weight-distributing hitch system distributes trailer tongue loads to the vehicle’s front axle and the trailer axle(s).

- Fixed Tongue : Features with a permanent ball that cannot be removed.

- Receiver : Features a hollow square tube where a variety of tongues or inserts, such as a bike rack, can be attached.

- Gooseneck : A ball at the center of a truck bed is paired with a coupling on the trailer.

- Fifth-Wheel : These hitches are typically used for heavier recreational vehicles. Similar to a gooseneck, it uses an attachment in a truck bed, but instead of a ball, there is a C- or U-shaped coupling that is mounted to the bed on a large plate. The trailer connects with a large pin and a plate of its own.

- Pintle : This type of hitch pairs what is known as a pintle hook to a lunette eye. Basically, a hook connects to a circle. Typically used for heavy-duty commercial, military or farming settings.

What Are the Trailer Hitch Classes?

Overstressing any component involved in towing, whether that’s the vehicle, the trailer or the hitch, could be disastrous, so it’s important to know the differences between hitch classes.

- Class 1 : Also known as Light Duty, Class 1 hitches can handle Up to 2,000 pounds gross trailer weight and up to 200 pounds tongue weight. These are typically found on cars and crossovers and feature 1.25-inch receivers.

- Class 2 : Also known as Regular Duty, Class 2 hitches can handle up to 3,500 pounds gross trailer weight and up to 350 pounds tongue weight. These are typically found on cars, crossovers, and minivans and feature 1.25-inch receivers.

- Class 3 : Also known as Heavy Duty, Class 3 hitches can handle up to 8,000 pounds gross trailer weight and up to 800 pounds tongue weight. These are typically found on crossovers, minivans, SUVs, and light trucks and feature 2-inch receivers.

- Class 4 : Also known as Super Duty, Class 4 hitches can handle up to 10,000 pounds gross trailer weight and up to 1,000 pounds tongue weight. These are typically found on trucks and SUVs and feature 2-inch receivers.

- Class 5 : Also known as Extra Duty, Class 5 hitches can handle between 16,000-17,000 pounds gross trailer weight and up to 2,550 pounds tongue weight. These are typically found on trucks and SUVs and feature 2-inch receivers.

- Class 5 : Also known as Commercial Duty, Class 5 hitches can handle between 18,000-20,000 pounds gross trailer weight and up to 2,700 pounds tongue weight. These are typically found on dually and chassis cab trucks and feature 2.5-inch receivers.

Trailer Backup Safety

Backing up a trailer could quickly go south, so preparation is paramount. Here’s what you’ll need to do to ensure you don’t destroy property, injure yourself and others or crumple your trailer and vehicle.

- Check your tires for adequate air pressure for proper towing capability, stability and traction.

- Check the security of the pin connector that links the truck to the trailer's brake and indicator lights and double-check that they function properly.

- Balance between a vehicle and its trailer is crucial. If the vehicle is squatting, meaning the rear is lower than the front, there’s a chance the trailer is too heavy near the trailer’s tongue. If the rear of the vehicle is lifting, the trailer is likely too heavy near the rear.

- The primary connection between the vehicle and the trailer is the hitch ball and coupling. Check to make sure the hitch ball is the proper size for the coupling and double-check that the coupling is locked in place.

- Make sure the pin or a padlock on the coupling latch adds the final layer of protection from disconnection.

- Large-link, cross-linked safety chains act as the last wall of defense and resemble an “X” when set correctly.

- Angle the vehicle’s side-view mirrors so that the vehicle, the trailer, the destination and the surroundings are all in view.

- Keep the windows down. You never know when somebody shouting to stop will save you thousands of dollars.

Organizing your tools and gear so everything is easily reachable will save precious minutes waiting for your handy-dandy child or four-legged helper to bring you the sandpaper or blowtorch. ( You still won't need a blowtorch for this job. Please don’t have your kid hand you a blowtorch—Ed. )

You’ll also need a wide, flat piece of pavement, such as a parking lot or nice quiet street. A parking lot is a great place to start, as there is more open area and the parking spaces can be used as guidelines. Once comfortable in a lot, try backing up into your driveway. This will allow you to practice backing into a spot at a 90-degree angle.

Everything You’ll Need To Backup a Trailer

If you have a stylish speckled-floor garage that has wrenches, hammers, saws, nuts, and bolts neatly organized in black and red Craftsmen chests, nice work. That’s beautiful, but you won’t need any of it, save for a couple things. The items below will prove useful in preparing for towing, forward or reverse.

- Trailer Hitch

- A truck or SUV

- Tire pressure gauge

- Mirror extensions (optional)

- Sunglasses (optional)

Here’s How To Backup a Trailer

Let’s do this!

- Check the trailer’s hitch, chains, and brake and indicator lights.

- Get into your vehicle, put your foot on the brake, start the car, and move the shifter into reverse.

- Check your surroundings.

- Try to line up as straight as possible, with the desired destination aligned with the outside edges of the vehicle and trailer.

- Be aware of obstacles and try not to fixate on them as you’re sure to do exactly what you didn’t want to do; hit them.

- With a foot on the brake, slowly release to allow the idle to begin reversing the vehicle.

- Use the side mirrors to maintain your view of the intended destination. (In some cases, the driver will need to look over his or her shoulder.)

- Countersteer when necessary and continue to reverse until the trailer is in the desired position.

- Hit the brakes and shift the vehicle into park.

- If this is the final position, turn the car off and you’re set. If this is a drop-off, release the cargo and pull away.

You did it, congratulations!

It’s important to understand that there is a point where the backup is a failed mission and will need to be reset. If you notice your steering is a Mortal Kombat combo of left-right-left-right-left-right, it might be worth driving forward, returning to the starting point and trying again (there’s no shame in that!). The goal is to steer the trailer with a few smooth, continuous inputs.

Pro Tips to Backup a Trailer

Here are The Drive’s pro tips for how to backup a trailer.

- Shift your hand position to the bottom of the steering wheel. With your grip on the lower part of the wheel, moving your hands left will result in the trailer angling left because the wheel is turning right. Move your hands right, and the trailer will angle right because the wheel is turning left. This might be more difficult for some, but many might find the direct correlation of movement to be helpful.

- Use a spotter! No matter the experience level, safety nets are tremendously helpful. There are often blind spots when backing up a trailer, and extra eyes will make the process smoother and quicker.

How Often Do You Need To Backup a Trailer?

- Every time a boat needs to be launched, a camper needs to be parked in a site, or a flatbed needs to be backed up a driveway.

How Much Does It Cost To Set Up a Trailer?

- Depending on the hitch type, needed accessories and labor, setting up your truck or SUV to towa trailer can cost anywhere between $10 and a couple thousand dollars.

Life Hacks To Backup a Trailer

Even with the right tools, the proper equipment and a high-tech truck, backing up a trailer can be a frustrating process. Take some of the guesswork out of the process with this simple and cheap hack.

- Pick up four wooden dowel rods, or any type of long straight stick, and put one at each corner. This will ease and aid trailer visibility and help the driver keep track of its size at all times. This is particularly helpful when a small trailer is obscured from view behind the large vehicle it’s attached to.

Featured Trailer Products

Tow Tuff Adjustable Trailer Dolly with Caster

Reese 7031400 Tri-Ball Mount with Hook

CURT 56070 7-Foot Vehicle-Side Truck Bed 7-Pin Trailer Wiring Harness Extension

Got a question? Got a pro tip? Send us a note: [email protected]

- Types Of RVs

- Tow Vehicles

- Maintenance & Repairs

- RV Power & Electrical Supplies

- RV Appliances

- Living In An RV

- Travel & Destinations

- RV Gear Buyer’s Guides

![8 Best Stabilizer Hitches for Travel Trailers in [currentyear]: Find the Perfect Weight Distribution Hitch 1 Best Weight Distribution Hitch](https://www.rvingknowhow.com/wp-content/uploads/2020/06/Best-Weight-Distribution-Hitch.jpg)

8 Best Stabilizer Hitches for Travel Trailers in 2024: Find the Perfect Weight Distribution Hitch

- Last Updated: March 19, 2024

- 40 minutes read

As someone who has rigorously tested numerous stabilizing solutions for travel trailers, I understand the importance of having a reliable weight distribution hitch to ensure safety and comfort on the road.

The right hitch can significantly alleviate the swaying and instability that often plagues trailers, making your journey smoother and worry-free.

Among the variety of options I’ve evaluated, focusing on anti sway hitch and spring bar technology specifically designed for travel trailers, one product stood out distinctly.

After testing 8 top contenders in the market, the Blue Ox BXW1000 SWAYPRO Weight Distributing Hitch earned its place as my best overall recommendation.

This hitch excels in providing superior sway control and weight distribution, ensuring your trailer remains steady in various driving conditions.

Based on my experience, the top stabilizer hitches for travel trailers are:

- Blue Ox BXW1000 SWAYPRO Weight Distributing Hitch : Best overall for its exceptional sway control and weight distribution.

- EAZ LIFT 48053 Elite Bent Bar Weight Distributing Hitch : Great for its bent bar design that enhances stability.

- Husky 32218 Center Line TS with Spring Bars : Excellent for integrating weight distribution and sway control in a robust design.

- Reese Pro 49903 Weight Distributing Hitch : Ideal for its versatility and ease of use.

- CURT 17063 MV Weight Distribution Hitch with Sway Control : Top choice for those seeking a durable and reliable option with integrated sway control.

- Camco Eaz-Lift ReCurve R6 Weight Distributing Hitch Kit with Sway Control : Perfect for those who prioritize easy setup and effective sway control.

- Andersen Hitches 3350 No Sway Weight Distribution Hitch : Best for its no-sway technology and lightweight design.

- Fastway 10K RB Fastway e2 2-point Sway Control Distribution Hitch : Good for its straightforward installation and efficient sway control mechanism.

8 Best RV Weight Distribution Hitches for Safe and Stable Towing

1. best overall: blue ox bxw1000 swaypro weight distributing hitch.

![8 Best Stabilizer Hitches for Travel Trailers in [currentyear]: Find the Perfect Weight Distribution Hitch 2 Blue Ox BXW1000 SWAYPRO Weight Distributing Hitch 1000lb Tongue Weight for Standard Coupler with Clamp-On Latches](https://www.rvingknowhow.com/wp-content/uploads/2024/02/31Mj36HuqiL._SL500_.webp)

The Blue Ox BXW1000 SWAYPRO is our pick for the best overall weight distribution hitch because it comes with a pre-adjusted hitch head that doesn’t require any further fine-tuning once it’s installed.

That’s not always the case with these hitches and it makes this a great choice if you don’t have a ton of experience using them.

This trunnion-style hitch has excellent sway control which allows you to tow at faster speeds without worrying about your trailer fishtailing behind you.

Trunnions on either side of the hitch head work together with the hitch’s spring bars to create a caster effect. This effect continuously pushes inward to keep everything in line.

You’ll also be able to navigate easier when you arrive at a new campground. Some locations have tight turns and others require you to back up to get into your site.

With this hitch, you won’t have to disconnect in order to back up. But when you do want to disconnect, it’s super easy to do so.

It takes just minutes to connect and disconnect to this hitch, which gives you the freedom to drop your trailer or vehicle without any added headaches.

If the tongue of your trailer already boasts a coupler welded to the top of the frame and it doesn’t have any cross-members on the tongue, you’ll be able to utilize this hitch out-of-the-box.

It is compatible with other trailer tongues, however. You just may need to purchase additional bolt-on latches or an optional hitch head to ensure safe towing.

The Blue Ox BXW1000 has a maximum tongue weight rating of 1,000 pounds and a maximum gross weight rating of 10,000 pounds.

It also boasts spring steel construction that adds durability and strength to the entire unit and you won’t have to disconnect this hitch when you need to back your trailer up.

Things We Like

- Sway Control: Keeps everything in line so you avoid fishtailing.

- Pre-Adjusted Hitch Head: Requires no additional fine-tuning after installation.

- Easy Connection: The spring bars on this hitch are self-locking.

- Clamp-On Latches: Don’t require the use of any additional hardware for installation.

Things We Don’t Like

- Compatibility: Works best with trailer tongues with coupler welded to the top of the frame and without cross-members on the tongue.

- Price: You’ll pay a little extra for the quality of this hitch.

2. Best Budget-Friendly: EAZ LIFT 48053 Elite Bent Bar Weight Distributing Hitch

![8 Best Stabilizer Hitches for Travel Trailers in [currentyear]: Find the Perfect Weight Distribution Hitch 3 EAZ LIFT Camco Eaz-Lift Elite 1,000lb Weight Distribution Hitch with Height Adjustable Forged Shank (48053)](https://www.rvingknowhow.com/wp-content/uploads/2024/02/41nnAFIsw8L._SL500_.webp)

The EAZ LIFT 48053 weight distribution hitch is the most budget-friendly round bar hitch we could find on the market today.

The good news is that you won’t have to severely sacrifice quality to get a hitch that fits your budget.

EAZ LIFT is actually made by Camco, which is one of the more reliable brands in the industry.

It comes with an adjustable ball mount but does not include the hitch ball itself. So you’ll have to grab this accessory separately to make this hitch work for you.

The bars on this hitch, however, are actually interchangeable. This is uncommon amongst this type of hitch but it serves to provide a smoother ride.

The bars use positive latching action to attach to your trailer tongue and the round spring bars on this hitch are machine tapered and forged longer for added strength and durability.

These spring bars can actually be removed if you chose to operate it as a more standard weight distributing hitch. Doing so, however, significantly reduces the hitch’s tongue weight and gross weight ratings.

The hitch is adjustable to fit many different trailer-vehicle combinations and it comes with clips and bolt package for easy installation.

The shank size is 2” x 2” with a 10-inch length, a 2.5-inch drop, and a 5.5-inch rise.

The entire package is also backed by the manufacturer’s 5-year warranty, which is always a good sign when it comes to your safety and the safety of your vehicle/trailer investments.

The EAZ LIFT 48053 also has a maximum tongue weight of 1,000 pounds and a maximum gross weight rating of 10,000 pounds. If you remove the spring bars, however, those ratings drop down to 600 pounds and 6,000 pounds, respectively.

- Price: It’s the most budget-friendly hitch on our list.

- Versatility: Spring bars can be removed to use it as a more standard hitch.

- 5-Year Manufacturer’s Warranty: Camco stands behind the quality of their product.

- Adjustable Hitch: Can adapt to fit a variety of trailer-vehicle combinations.

- Hitch Ball Not Included: You’ll have to purchase a compatible hitch ball separately.

3. Best For Quiet Use: Husky 32218 Center Line TS with Spring Bars

![8 Best Stabilizer Hitches for Travel Trailers in [currentyear]: Find the Perfect Weight Distribution Hitch 4 Center Line TS Weight Distribution Hitch - 2-5/16" Ball - 12,000lbs](https://www.rvingknowhow.com/wp-content/uploads/2024/02/3164m3UjsvL._SL500_.webp)

If you’re looking for a trunnion-style hitch that doesn’t cause a bunch of extra noise while you’re driving down the highway, check out the Husky 32218 Center Line TS.

Annoying noise can be an issue with other sway bars and weight distribution products, but that’s not the case with this hitch.

One of the reasons for this noise reduction is the fact that this hitch doesn’t use chains to attach to the tongue of your trailer.

Those chains jangling around are primarily what causes the noise in other models. But you’ll be able to hear (and feel) the difference when you drive with this hitch.

The unit combines sway control and weight distribution to provide quiet performance without the need for any additional hardware. This makes it super easy to install.

The handles on the bars further aid in securing them to (and removing them from) your trailer and the frame brackets are easily adjustable to mount on a variety of trailer tongues.

The Husky 32218 Center Line TS has a maximum tongue weight rating of 1,200 pounds and a maximum gross weight rating of 12,000 pounds.

The hitch itself weighs a total of 116 pounds, which is lighter than many. This lighter weight makes it easier to install and remove as needed.

- Quiet Operation: No noisy chains like other hitches.

- Built-in Sway Control: Doesn’t require installation of any additional hardware or accessories.

- Lightweight: This is a relatively lightweight hitch compared to similar models.

- Easy Installation: Handles on the frame brackets make it easier to install.

- Compatibility: This hitch is built for a 2 and 5/16” hitch ball.

4. Best With Preinstalled Hitch Ball: Reese Pro 49903 Weight Distributing Hitch

![8 Best Stabilizer Hitches for Travel Trailers in [currentyear]: Find the Perfect Weight Distribution Hitch 5 Reese Pro 49903 Round Bar Weight Distribution Kit with Sway Control](https://www.rvingknowhow.com/wp-content/uploads/2024/02/31u9q1VtAML._SL500_.webp)

The Reese 49913 Wd Rb Pro round bar hitch is a great option if you’re looking for a weight distribution hitch with a preinstalled hitch ball.

This means you won’t have to worry about finding a hitch ball separately and risk picking one that’s not compatible. With a preinstalled hitch ball, compatibility is a non-issue.

The hitch ball is 2 and 5/16ths of an inch in diameter and it arrives already torqued to the hitch head.

The spring bars on this hitch are tapered to provide more even weight distribution over your trailer axles.

This provides an even smoother ride and the include friction sway control prevents fishtailing at high speeds.

For an RV accessory that’s consistently exposed to dirt, debris, rain, and other elements, it’s important to know it’s going to last.

That’s why I like the fact that all the metal components of this hitch are finished with powder coating.

This finish improves the overall corrosion resistance and durability of the hitch over its lifetime.