GFCI Circuit Breakers for Commercial Kitchens

The phone was ringing. Actually, both phones were ringing—desk and cell phones. It must be important. I answered the cell first and let the land line go to voicemail. My field inspector was calling about a couple of items that he had discovered while performing a final electrical inspection for a new restaurant.

Access for inspection was the first problem. None of the final inspections by the Building, Planning, Fire or Health Departments had been completed, but the restaurant staff was already stocking the facility. In my jurisdiction, we are always happy to cooperate with the tight time schedules required in the modern construction world. However, the key word is cooperate . Complete access is necessary so that we can provide a quick and accurate inspection. It is difficult to inspect the (almost) finished space with boxes in the way!

The other item of concern for the inspector was the NEC 210.8(B)(2) requirement for GFCI protection of the commercial kitchen receptacles.

Beginning with the 2002 NEC , all 15- and 20-amp, 125-volt receptacles, located in a nondwelling type kitchen are required to have GFCI protection. The requirement applies to all receptacles whether intended for general use or dedicated for a specific appliance. Application of the rule is intended for all locations within the kitchen, not just those receptacles that serve countertop areas. Accident data was provided to justify the inclusion of kitchens to NEC 210.8(B) Ground-Fault Circuit-Interrupter Protection for Personnel – Other Than Dwelling Units in 2002 . Possible commercial kitchen hazards include wet floors, damaged cords, and poorly maintained equipment. Also, employees may not have the necessary electrical safety training to recognize the resulting electrical hazards. The term kitchen, previously only defined for the purposes of 210.8(B)(2), was added to NEC Article 100 Definitions in 2008 to provide for consistent application of the NEC requirements.

The project electrical engineer had specified the GFCI protection be provided by the circuit breaker for all 15 & 20 ampere branch circuits supplying, 125 volt receptacles as required by 210.8(B)(2) .

The inspector had used a plug-in type GFCI tester to verify the operation of the circuit breakers. Although not recognized by the circuit breaker manufacturer as an accurate operational test, the plug-in type of tester can be useful to at least verify that the receptacle outlets are connected to the correct GFCI branch-circuit breaker. The tester cannot be relied upon to supply a precise ground-fault current to certify the operation of the protective circuitry, but the fault-current, though not precise, may cause the GFCI device to operate. The “test” button on the GFCI device (circuit breaker in this example) must be used to verify proper operation , and that is the procedure we use. There is a distinction between checking the correct operation of the individual GFCI’s protective element and verification that those devices are supplying the intended branch circuits. Do not confuse the two! The better approach would be to use the “test” button on the GFCI device to verify operation, followed up by a voltage test on all receptacles to confirm correct circuiting.

It appeared the receptacles were not protected as none of the GFCI devices operated when tested with the receptacle plug-in device. The inspector then went to the branch-circuit panelboard to verify that the GFCI circuit breakers had been installed correctly. He pushed the ground-fault “test” button on each breaker. To his surprise, all circuit breakers operated properly when tested! At that point, his assumption was that the plug-in testing device was not operational, or at least not accurate enough to verify the circuit breaker operation. Since the circuit breakers operated correctly when the “test” button was pushed, they were obviously working as intended, and the installation met the requirements of NEC 210.8(B)(2) …right?

Not necessarily. I told the inspector to take a closer look at those circuit breakers. Did they provide Class A ground-fault protection?

Circuit Breakers and Ground-Fault Circuit Interrupters (UL Product Category DKUY) will open the circuit when ground-fault current has a value in the range of 4 through 6 mA (Class A). Why that range? Because current through the human body in that range can cause muscle contraction, preventing the victim from self-release of the faulted circuit. Even worse, a current path through the heart may result in ventricular fibrillation, effectively stopping the heart from pumping blood through the body. Where ground-fault protection for personnel is specified by the NEC , Class A ground-fault protective devices must be used.

Circuit Breakers with Equipment Ground-Fault Protection (UL Product Category DIYA) will provide overcurrent protection and ground-fault protection for equipment. The ground-fault trip protection level is more than 6 mA and will be marked on the circuit breaker. Ground-fault protection of equipment is required to prevent fires that could result from low-level leakage current. See NEC 426.28 Ground-Fault Protection of Equipment where equipment ground-fault protection is required for outdoor electric de-icing and snow-melting equipment. The higher current threshold of the devices will not protect people but will protect the equipment from ground-fault current at a far lower threshold than overcurrent protective devices without any ground- fault protection. Equipment that is used in very wet environments can be at a greater risk for developing ground-faults.

The branch circuit panelboard supplying the kitchen receptacle circuits had been supplied with circuit breakers that provided equipment ground-fault protection! Examination of the circuit breaker labels confirmed the rating. The installed circuit breakers were marked to operate when the ground-fault current rises to 30 mA. The plug-in testing device was intended for use with a Class A ground-fault protective element. Therefore, the ground-fault current initiated by the testing device never got close to the 30 mA required for operation of the circuit breakers.

That explains why the circuit breakers never opened the circuit, but how did the equipment GFP devices end up in a panelboard where Class A GFCIprotection would be required?

A correction notice was given to the contractor that required replacement of the equipment GFP circuit breakers with Class A units. I forwarded a copy of that correction notice to the consulting electrical engineer responsible for the project design. His response was quick and raised a new concern.

The new facility was one of many identical restaurants that were being constructed, nationwide, inside of existing “big box” retail establishments. The same design, by the same engineer, had been used for all locations. The electrical engineer was well aware of the need for Class A GFCI protection and the design documents specified such protection. How did the equipment GFP circuit breakers end up in that panelboard? The electrical engineer had the answer. All electrical materials for construction of the restaurants, nationwide, had been purchased and supplied by the host retail chain store. Those who purchased the circuit breakers were not aware of and did not appreciate the difference between Class A GFCI and equipment ground-fault protection. The engineer was quite concerned that the incorrect circuit breakers might have been obtained for all restaurants!

Fortunately, I answered my cell phone instead of the desk phone that day. The field inspector was alerted to the issue, and the correction notice was issued. The electrical engineer, now aware of the problem, would verify that the correct circuit breakers were purchased for the restaurants not yet built, and check all completed projects. Since then, we have seen the same problem occur with other newly constructed restaurant kitchens. I would strongly suggest that all jurisdictions verify that, if GFCI circuit breakers are used for personnel protection, the correct circuit breakers are utilized.

Who had called my desk phone that day? When I finally got around to checking the voicemail messages, I got the answer. It was the restaurant manager, wanting to know if it was ok to stock the freezer.

Air-Conditioning Equipment Installations

Basic three-phase power measurements explained

Safety in Marinas

Find Us on Socials

The use of physical and intangible tools make electrical inspections safer.

Ensuring that you have the right physical tools, NEC knowledge, as well as personal safety and intangible tools, are all critical for being the best inspector you can be.

Practical Fundamentals On Power Quality Studies

This article presents a practical perspective on power quality (PQ) studies in commercial buildings, highlighting their significance, implementation methods, and potential benefits.

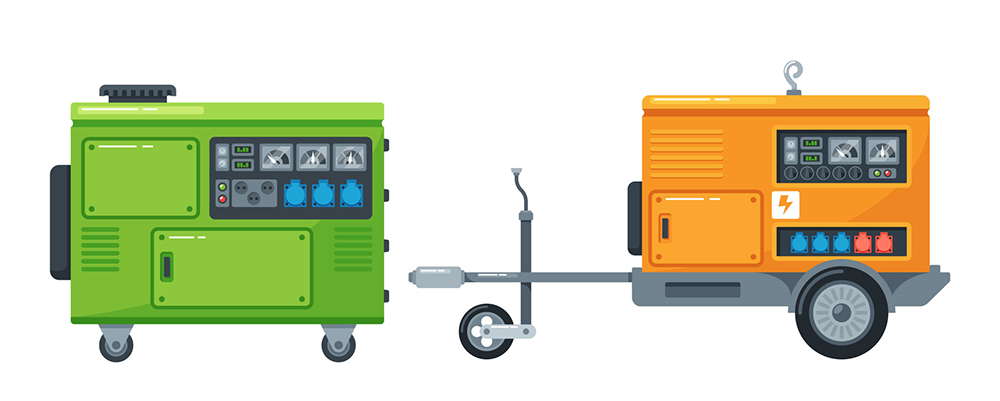

Choosing a Backup Generator for Your Commercial Facility

How can you choose the right backup generator for your commercial facility? Here are some important factors to consider to help you choose the best backup generator.

Familiarizing yourself with commercial kitchen ventilation certifications, codes, and regulations is important when designing your new commercial kitchen space or updating an existing one. As an operator, understanding the requirements can be confusing and challenging especially since specific regulatory and code requirements vary by project location, equipment used and building type, and may even be specific to the type of cooking you’ll need to accommodate for in your kitchen.

The location of a commercial kitchen can have a significant impact on the codes and regulations that apply to it. For instance, a kitchen in Minnesota might require certain exhaust hoods and fans, while a char-broiler in New York could warrant a pollution control unit installed in the exhaust stream. The goals are safety and consistency when comparing ventilation products made by different manufacturers and ensuring that your equipment meets all building codes and regulations.

Many agencies and third-party organizations exist to regulate and test the performance of ventilation equipment within the commercial kitchen industry. For kitchen ventilation systems, commonly referenced codes and standards are the International Mechanical Code (IMC), International Energy Conservation Code (IECC), International Building Code (IBC), ASHRAE Standard 154, and The National Fire Protection Association Standard 96 (NFPA 96).

Acquiring a fundamental understanding of the most prevalent regulatory and code requirements before and during the design phase of your project can establish a strong foundation for success and ensure your kitchen and dining spaces are safe for both your guests and staff.

Learning International Codes

Of the codes developed by the International Code Council (ICC), the mechanical (IMC), energy conservation (IECC), and building code (IBC) requirements are the most relevant in kitchen exhaust systems.

IMC lays the groundwork for kitchen ventilation systems, with various requirements around hoods and controls, grease duct, exhaust, and supply fans. It also covers the various listings and certifications applicable to kitchen equipment, including UL 705 for grease exhaust fans, UL 8782 for pollution control units, and UL 710 for kitchen exhaust hoods.

IECC establishes the baseline for energy-efficient kitchens and supplements both the Mechanical and Building codes. With exhaust fans, tempered supply units, and high BTU cooking appliances, commercial kitchens consume a significant amount of energy. Airflow reductions are critical towards the development of an energy-efficient building. Accurex DCV controls provide up to a 50% reduction in allowed airflow based on cooking volume – reducing energy usage and saving on fan sizes.

IBC provides further guidance on fire suppression systems and additional demands for specific building types. One key component of this code defines the criteria by which buildings and structures are classified into use groups and occupancies, which are then referenced further within the IBC and other international code bodies. The IBC, along with the International Fire Code (IFC), outline requirements for fire suppression systems within kitchen systems, including the need for a manual actuation device and a UL 300 listing.

Recognizing ASHRAE 154 and NFPA 96 Standards

While the International and Unform Code bodies are codes, ASHRAE 154 and NFPA 96 are standards and cover specificities within their respective subjects.

ASHRAE 154 is specifically focused on kitchen ventilation, diving deeper into certain cooking appliances and hood requirements, and is a suitable alternative to IMC specifications. While not as widely utilized as the IMC, certain jurisdictions, including the state of Minnesota, utilize this standard as the basis for kitchen exhaust requirements.

Similar to how ASHRAE 154 expounds further on kitchen ventilation, NFPA 96 greatly expands upon fire protection within commercial cooking and is considered by many to supersede the above-mentioned codes. It defines various clearance requirements, from duct and hood surfaces to combustible surfaces, as well as clearance around exhaust terminations and air intakes. It provides procedures for the inspection, testing and maintenance of ventilation and fire suppression equipment, and specifies how an exhaust system should operate in a fire, including the requirement for all fuel sources and make-up air sources to shut off. With its highly in-depth regulations and focus on fire safety, NFPA 96 is widely enforced and even referenced within the International Codes.

Why Experience with Codes, Regulations, and Certifications Matter

Kitchen ventilation certifications, regulations, and codes affecting the commercial restaurant industry and other foodservice venues continues to evolve. From exhaust hoods and exhaust fans to grease ducts, pollution control, and fire suppression systems, maintaining a safe, efficient, and properly functioning kitchen ventilation system is of utmost importance. Yet, with frequent revisions and numerous regionally specific exceptions, ensuring that your project meets all compliance checks and passes inspection can be overwhelming.

The best way to ensure compliance and learn the specific requirements for your kitchen equipment, is to work with a manufacturer who understands these regulations and can recommend compliant products.

Accurex is a partner you can trust with a dedicated team of experienced kitchen ventilation experts to help you navigate both national and regional requirements. Have more questions about today’s building codes and regulations and their impact on your project? Don’t hesitate to connect with your local Accurex expert .

- Forum Listing

- Marketplace

- Advanced Search

- General Electrical

- General Electrical Discussion

Commercial Kitchen Hood

- Add to quote

Ok so I got thrown into doing this kitchen hood. Not much info given. Basically I have a exhaust fan, make up air, and lights. Doing research on here I have figured basically everything needs to shut off except the exhaust...which could also depend on local requirements. Now my question is how exactly are the make up air and exhaust supposed to be controlled? Basically is it just a on/off PB on the wall that enables both units for normal operation? I can figure out the controlling to be inter connected with the fire suppression without much problems I am just actually unsure of the normal operation side of it.....never done one before. Also I have noticed you guys talk about using shunt trip breakers to kill power to make up air, lights etc, but could I just achieve the same results with contactors....or are the shunt trips needed?

I've seen it done with shunt trips as well as with contactors. Shunt trips are great for it. You would just run your shunt circuit through the contact in the fire suppression control box and if it triggered, it would trip all the breakers. Regarding the exhaust fan, typically (as I understand) the exhaust needs to stay on if it's already running, or it needs to turn on if it's NOT running. To achieve that you could put in a contactor controlled by a contact in the fire suppression box and just run a loop parallel to whatever switch turns the fan on normally.

The MAU should come with a control panel. You will have to install contactors for the exhaust fans. You will have control wiring from the fire suppression, to the control panel. And the control panel will operate the contactors. Don't use shunt trips.

Here you just need to kill the makeup air. Use a microswitch in the suppression box. Can't have positive pressure in a fire. It is also required to interlock the exhaust fan to the makeup air so it won't run without the exhaust fan.

farlsincharge said: It is also required to interlock the exhaust fan to the makeup air so it won't run without the exhaust fan. Click to expand...

Microswitch in the ansul panel operates no and nc contacts in the hood panel. Here we have to kill mau and all underhood electric including lights so I run mau and all underhood electrics on a small subpanel backfed with a two pole shunt trip breaker. Saves a buck that way.

Ok so this job is becoming more and more of a headache. The MAU is not in yet but they need the wiring run now to a JB by the location as the ducting is running through a separate tenant space and they can't have the other tenant shut down too long(don't ask). Is there any control wiring typically needed to go up to the MAU or is it just straight feeds and all the controls are done in the kitchen.

CanadianSparky said: Ok so this job is becoming more and more of a headache. The MAU is not in yet but they need the wiring run now to a JB by the location as the ducting is running through a separate tenant space and they can't have the other tenant shut down too long(don't ask). Is there any control wiring typically needed to go up to the MAU or is it just straight feeds and all the controls are done in the kitchen. Click to expand...

Most the new installs now just need a constant feed to the control panel, the on/off switch and temp sensor are wiref low voltage in parallel. Anything electric under hood and make up air shuts down during ansul op. What u can do is drag a feed from ex fan leg, make/break at ansul and feed contactor( s) feeding said items.

It is looking like All the controls will be done myself. They seem to have an ansul system with just a set of NO and NC contacts...None of the contacts will be able to handle the loads of any of the equipment. This is the equipment that was order....Don't ask me why but not my problem Exhaust fan(120v 20.8fla) :no: Make up air(specs are kinda up in the air because no one has answers but it is a 208 3ph) Hood lights Gas valve (no one has the answer if it is mechanical or electrical) Now I have never wired up a make-up air unit before and not sure what it comes with control wise as I can't get any specs or info on that either. Basically I have the feeds for exhaust and MAU ran up to where the units will be as we had to have this done because the ducting and wiring runs through another tenants space an they have basically been booted out until the ducting is done. Do the MAU typically have control wiring running up to the unit or is it all done in the kitchen. I plan on controlling the MAU, lights, valves, and exhaust all through a series or contractors which will be tied into the Ansul system.

Your in Canada so it may not apply but in the US an updraft hood exhaust has to be mounted with a hinge for NFPA. This means a whip with some slack so the fan can be tilted back for service. NFPA Fire Code #96: 7.8.2.1 “Rooftop terminations shall be arranged with or provided with the following: (8) A hinged upblast fan supplied with flexible weatherproof electrical cable and service hold-open retainer to permit inspection and cleaning that is listed for commercial cooking equipment..” NFPA Fire Code #96: 8.1.1.1 “Approved upblast fans with motors surrounded by the airstream shall be hinged, supplied with flexible weatherproof electrical cable and service hold-open retainers, and listed for this use. Hawkrod

- ?

- 94K members

Top Contributors this Month

Requirements For Commercial Kitchen Fire Suppression Systems That Help Minimize Fire Risks

When it comes to fire, commercial kitchens operate in a very high-risk environment. According to the most recent data from the National Fire Protection Association (NFPA), fires in restaurants result in 110 civilian injuries and $165 million in direct property damage each year. Cooking equipment was responsible for more than 60 percent of the fires studied by the NFPA. Many of the affected businesses never recover. The NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations provides the requirements for commercial kitchen fire suppression systems that help minimize fire risk and keep employees and customers safe if a fire breaks out. The standards cover both automatic fire-extinguishing systems that provide primary protection as well as the portable fire extinguishers that provide secondary backup protection. Wet chemical fire suppression systems are the most common type of automatic fire suppression system used in commercial kitchens today and are recognized by the fire protection industry as the most effective fire suppression system for commercial kitchens available.

Wet Chemical Fire Suppression Systems in Commercial Kitchens

The NFPA 96 requires automated fire suppression equipment for all grease removal devices, hood exhaust plenums, and exhaust duct systems in a commercial kitchen, as well as any cooking equipment that produces grease-laden vapors. Today’s commercial kitchens use high-efficiency cooking appliances capable of extremely high energy input/output rates and vegetable oils that can ignite at high temperatures. When these oils ignite, they are already so hot that a portable extinguisher may not be effective. Wet chemical fire suppression systems are considered to be the most effective fire suppression system for commercial kitchens available.

Wet chemical systems are often referred to as “pre-engineered” systems, which means that they come from the manufacturer with specific specifications that are unique to that system. As such, their installation, repair and maintenance requires a properly trained and qualified technician that has been certified by the system’s manufacturer.

Wet chemical fire suppression systems work by releasing chemical agents that react with oil to create a thick foam that covers the entire cooking surface, smothering the burning oil until the appliance cools below the oil’s flash point. The effectiveness of these systems is not limited to fires that involve oil. The type of chemicals they use are very effective on all types of fires in a commercial kitchen.

The NFPA 96 requires that wet chemical pre-engineered fire suppression systems meet the requirements of ANSI/UL 300 or other equivalent standards that include fire test methods and requirements to protect the various types of cooking appliances and tests to evaluate the ability of pre-engineered equipment to protect plenums and ducts.

Not all grease removal devices, hood exhaust plenums, exhaust ducts, and cooking appliances are addressed in ANSI/UL 300 or other equivalent test standards. If your kitchen uses equipment that isn’t, you must make sure that any non-listed automatic fire suppression system installed is appropriate for the grease removal devices, hoods, ducts and cooking appliances you’re using based on the system manufacturer’s recommendations. The system must also meet all applicable NFPA standard(s), all local building and fire codes, and must be approved by the authority having jurisdiction. If you’re not sure if your system is UL-Listed, you can search the UL website using the manufacturer’s name and model number.

The Jay L Harman Fire Equipment team understands your firefighting needs and is ready to help

Jay L Harman’s DOT Hydrostatic Testing facility and equipment meet all NFPA requirements for the hydrostatic testing of self contained breathing apparatus compressed gas cylinders in addition to testing ABC portable fire extinguisher cylinders.

Jay L Harman is the best and one of the biggest firefighting equipment suppliers and service providers in the region, specializing in fire suppression systems, fire extinguishers, emergency lighting, fire hoses, hydrostatic testing and more. Serving El Paso TX, Las Cruces NM and the surrounding areas, we pride ourselves on buying local and hiring local whenever possible.

Jay L Harman Fire Equipment is your go-to distributor for OVAL low-profile fire extinguishers in West Texas and New Mexico.

Contact Jay L. Harman Fire Equipment in El Paso TX at 915-533-7021 or Las Cruces NM at 575-523-8880 ..

Since 1925, we have protected businesses throughout the area from the harms and hazards of fires. Every Jay L Harman technician is licensed and regulated by the Texas Department of Insurance State Fire Marshal’s Office. Each of these technicians continually receives the most up-to-date factory training and certifications by our manufacturers. Contact Jay L Harman Fire Equipment today. Let our friendly and knowledgeable staff tell you more about our fire suppression systems and help you find the ideal fire suppression system for your needs. Learn more about our full offering of fire extinguisher training , firefighting services , firefighting products , request a quote, ask a question or request additional information .

- Company Profile

- Company Policy

- Mission and Vision

- Certificates

- Aluminium Windows

- Aluminium Doors

- Aluminium Sliding Elements

- Aluminium Curtain Walls

- Aluminium Skylight Elements

- Aluminium Frames for Safety and Security

- Aluminium Conservatories

- Metal Panel Sheet Claddings

- Aluminium Entrance Frames

- Glass Structures

- Complementary Items

- Lightweight Steel Structures

- Human Resources OPEN

Metropolis Office & Shopping Center

Sheremetyevo airport, new georgian parliament building, be ready to view the world from our frame.

Our Projects

New airport, tobolsk, russia.

In progress

Rumyantsevo Home City Residential, Russia

200 East 20th Street, USA

St Pancras Campus, London, United Kingdom

Central Bank of Iraq

Poklonnaya 9, Moscow, Russia

Dar Es Salaam Station, Tanzania

Msk Symphony 34 Residential, Moscow, Russia

Morogoro Station,Tanzania

Multifunctional Medical Center, St. Petersburg, Russia

Setun (JK Hide), Moscow, Russia

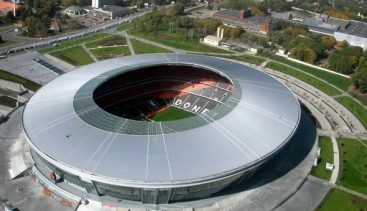

Donbass Arena, Donetsk, Ukraine

ЖК FORIVER, Moscow, Russia

AFI PARK, Moscow, Russia

Paveletskaya Plaza, Moscow, Russia

Upside Berlin, Germany

Nobu Hotel London Portman Square, London, United Kingdom

Perrymount Road, London, United Kingdom

Nusr-ET Restaurant, Knightsbridge, London, United Kingdom

Istanbul Grand Airport, Turkey

New Georgian Parliament Building, Georgia

Anthill Residence, Istanbul, Turkey

Arcus III Office Center, Moscow, Russia

168-176 Shoreditch High Street, London, United Kingdom

Apex House, London, United Kingdom

Addlestone Town Centre, London, United Kingdom

Dream Island, Moscow, Russia

Skolkovo Business Center ‘Gallery’, Moscow, Russia

Cisco IT Skolkovo, Moscow, Russia

Studio Stage ‘Mosfilm’, Moscow, Russia

Sheremetyevo Airport, Moscow, Russia

Varobevskoe Housing, Moscow, Russia

Tushino Housing, Moscow, Russia

Yasniy Housing, Moscow, Russia

One Trinity Place (2nd Phase), St. Petersburg, Russia

Trinity Place, St. Petersburg, Russia

Action 44, Moscow, Russia

White Gardens, Moscow, Russia

I’m Moscow, Russia

Metropolis Office & Shopping Center, Moscow, Russia

Mayak Housing, Moscow, Russia

Dostoyanie Housing

Nasledie Housing 1

Nasledie Housing 2

Nasledie Housing 3

Life Botanic Garden Residential Complex

K2 Business Park, Moscow, Russia

Prisma Business Center

V-House Housing

Kuntsevo Office Complex

House of Justice

Algoritm Business Center, Moscow, Russia

Demidov Business Center

Rublevo Park Housing

Novopetrovskaya Shopping Center

Shopping-entertainement Complex ‘Kaleidoskop’

Barrikadnaya Bank Building

Beyoglu Loft

Radisson Blu, Istanbul

Sutluce Office

Information Center, Istanbul

- Popular Professionals

- Design & Planning

- Construction & Renovation

- Finishes & Fixtures

- Landscaping & Outdoor

- Systems & Appliances

- Interior Designers & Decorators

- Architects & Building Designers

- Design-Build Firms

- Kitchen & Bathroom Designers

- General Contractors

- Kitchen & Bathroom Remodelers

- Home Builders

- Roofing & Gutters

- Cabinets & Cabinetry

- Tile & Stone

- Hardwood Flooring Dealers

- Landscape Contractors

- Landscape Architects & Landscape Designers

- Home Stagers

- Swimming Pool Builders

- Lighting Designers and Suppliers

- 3D Rendering

- Sustainable Design

- Basement Design

- Architectural Design

- Universal Design

- Energy-Efficient Homes

- Multigenerational Homes

- House Plans

- Home Remodeling

- Home Additions

- Green Building

- Garage Building

- New Home Construction

- Basement Remodeling

- Stair & Railing Contractors

- Cabinetry & Cabinet Makers

- Roofing & Gutter Contractors

- Window Contractors

- Exterior & Siding Contractors

- Carpet Contractors

- Carpet Installation

- Flooring Contractors

- Wood Floor Refinishing

- Tile Installation

- Custom Countertops

- Quartz Countertops

- Cabinet Refinishing

- Custom Bathroom Vanities

- Finish Carpentry

- Cabinet Repair

- Custom Windows

- Window Treatment Services

- Window Repair

- Fireplace Contractors

- Paint & Wall Covering Dealers

- Door Contractors

- Glass & Shower Door Contractors

- Landscape Construction

- Land Clearing

- Garden & Landscape Supplies

- Deck & Patio Builders

- Deck Repair

- Patio Design

- Stone, Pavers, & Concrete

- Paver Installation

- Driveway & Paving Contractors

- Driveway Repair

- Asphalt Paving

- Garage Door Repair

- Fence Contractors

- Fence Installation

- Gate Repair

- Pergola Construction

- Spa & Pool Maintenance

- Swimming Pool Contractors

- Hot Tub Installation

- HVAC Contractors

- Electricians

- Appliance Services

- Solar Energy Contractors

- Outdoor Lighting Installation

- Landscape Lighting Installation

- Outdoor Lighting & Audio/Visual Specialists

- Home Theater & Home Automation Services

- Handyman Services

- Closet Designers

- Professional Organizers

- Furniture & Accessories Retailers

- Furniture Repair & Upholstery Services

- Specialty Contractors

- Color Consulting

- Wine Cellar Designers & Builders

- Home Inspection

- Custom Artists

- Columbus, OH Painters

- New York City, NY Landscapers

- San Diego, CA Bathroom Remodelers

- Minneapolis, MN Architects

- Portland, OR Tile Installers

- Kansas City, MO Flooring Contractors

- Denver, CO Countertop Installers

- San Francisco, CA New Home Builders

- Rugs & Decor

- Home Improvement

- Kitchen & Tabletop

- Bathroom Vanities

- Bathroom Vanity Lighting

- Bathroom Mirrors

- Bathroom Fixtures

- Nightstands & Bedside Tables

- Kitchen & Dining

- Bar Stools & Counter Stools

- Dining Chairs

- Dining Tables

- Buffets and Sideboards

- Kitchen Fixtures

- Wall Mirrors

- Living Room

- Armchairs & Accent Chairs

- Coffee & Accent Tables

- Sofas & Sectionals

- Media Storage

- Patio & Outdoor Furniture

- Outdoor Lighting

- Ceiling Lighting

- Chandeliers

- Pendant Lighting

- Wall Sconces

- Desks & Hutches

- Office Chairs

- View All Products

- Designer Picks

- Side & End Tables

- Console Tables

- Living Room Sets

- Chaise Lounges

- Ottomans & Poufs

- Bedroom Furniture

- Nightstands

- Bedroom Sets

- Dining Room Sets

- Sideboards & Buffets

- File Cabinets

- Room Dividers

- Furniture Sale

- Trending in Furniture

- View All Furniture

- Bath Vanities

- Single Vanities

- Double Vanities

- Small Vanities

- Transitional Vanities

- Modern Vanities

- Houzz Curated Vanities

- Best Selling Vanities

- Bathroom Vanity Mirrors

- Medicine Cabinets

- Bathroom Faucets

- Bathroom Sinks

- Shower Doors

- Showerheads & Body Sprays

- Bathroom Accessories

- Bathroom Storage

- Trending in Bath

- View All Bath

- Houzz x Jennifer Kizzee

- Houzz x Motivo Home

- How to Choose a Bathroom Vanity

- Patio Furniture

- Outdoor Dining Furniture

- Outdoor Lounge Furniture

- Outdoor Chairs

- Adirondack Chairs

- Outdoor Bar Furniture

- Outdoor Benches

- Wall Lights & Sconces

- Outdoor Flush-Mounts

- Landscape Lighting

- Outdoor Flood & Spot Lights

- Outdoor Decor

- Outdoor Rugs

- Outdoor Cushions & Pillows

- Patio Umbrellas

- Lawn & Garden

- Garden Statues & Yard Art

- Planters & Pots

- Outdoor Sale

- Trending in Outdoor

- View All Outdoor

- 8 x 10 Rugs

- 9 x 12 Rugs

- Hall & Stair Runners

- Home Decor & Accents

- Pillows & Throws

- Decorative Storage

- Faux Florals

- Wall Panels

- Window Treatments

- Curtain Rods

- Blackout Curtains

- Blinds & Shades

- Rugs & Decor Sale

- Trending in Rugs & Decor

- View All Rugs & Decor

- Pendant Lights

- Flush-Mounts

- Ceiling Fans

- Track Lighting

- Wall Lighting

- Swing Arm Wall Lights

- Display Lighting

- Table Lamps

- Floor Lamps

- Lamp Shades

- Lighting Sale

- Trending in Lighting

- View All Lighting

- Bathroom Remodel

- Kitchen Remodel

- Kitchen Faucets

- Kitchen Sinks

- Major Kitchen Appliances

- Cabinet Hardware

- Backsplash Tile

- Mosaic Tile

- Wall & Floor Tile

- Accent, Trim & Border Tile

- Whole House Remodel

- Heating & Cooling

- Building Materials

- Front Doors

- Interior Doors

- Home Improvement Sale

- Trending in Home Improvement

- View All Home Improvement

- Cups & Glassware

- Kitchen & Table Linens

- Kitchen Storage and Org

- Kitchen Islands & Carts

- Food Containers & Canisters

- Pantry & Cabinet Organizers

- Kitchen Appliances

- Gas & Electric Ranges

- Range Hoods & Vents

- Beer & Wine Refrigerators

- Small Kitchen Appliances

- Cookware & Bakeware

- Tools & Gadgets

- Kitchen & Tabletop Sale

- Trending in Kitchen & Tabletop

- View All Kitchen & Tabletop

- Storage & Organization

- Baby & Kids

- Housekeeping & Laundry

- View all photos

- Dining Room

- Breakfast Nook

- Family Room

- Bed & Bath

- Powder Room

- Storage & Closet

- Outdoor Kitchen

- Bar & Wine

- Wine Cellar

- Home Office

- Popular Design Ideas

- Kitchen Backsplash

- Deck Railing

- Privacy Fence

- Small Closet

- Stories and Guides

- Popular Stories

- Renovation Cost Guides

- Fence Installation Cost Guide

- Window Installation Cost Guide

- Discussions

- Design Dilemmas

- Before & After

- Houzz Research

- View all pros

- View all services

- View all products

- View all sales

- Living Room Chairs

- Dining Room Furniture

- Coffee Tables

- Home Office Furniture

- Join as a Pro

- Interior Design Software

- Project Management

- Custom Website

- Lead Generation

- Invoicing & Billing

- Landscape Contractor Software

- General Contractor Software

- Remodeler Software

- Builder Software

- Roofer Software

- Architect Software

- Takeoff Software

- Lumber & Framing Takeoffs

- Steel Takeoffs

- Concrete Takeoffs

- Drywall Takeoffs

- Insulation Takeoffs

- Stories & Guides

- LATEST FROM HOUZZ

- HOUZZ DISCUSSIONS

- SHOP KITCHEN & DINING

- Kitchen & Dining Furniture

- Sinks & Faucets

- Kitchen Cabinets & Storage

- Knobs & Pulls

- Kitchen Knives

- KITCHEN PHOTOS

- FIND KITCHEN PROS

- Bath Accessories

- Bath Linens

- BATH PHOTOS

- FIND BATH PROS

- SHOP BEDROOM

- Beds & Headboards

- Bedroom Decor

- Closet Storage

- Bedroom Vanities

- BEDROOM PHOTOS

- Kids' Room

- FIND DESIGN PROS

- SHOP LIVING

- Fireplaces & Accessories

- LIVING PHOTOS

- SHOP OUTDOOR

- Pool & Spa

- Backyard Play

- OUTDOOR PHOTOS

- FIND LANDSCAPING PROS

- SHOP LIGHTING

- Bathroom & Vanity

- Flush Mounts

- Kitchen & Cabinet

- Outdoor Wall Lights

- Outdoor Hanging Lights

- Kids' Lighting

- Decorative Accents

- Artificial Flowers & Plants

- Decorative Objects

- Screens & Room Dividers

- Wall Shelves

- About Houzz

- Houzz Credit Cards

- Privacy & Notice

- Cookie Policy

- Your Privacy Choices

- Mobile Apps

- Copyright & Trademark

- For Professionals

- Houzz vs. Houzz Pro

- Houzz Pro vs. Ivy

- Houzz Pro Advertising Reviews

- Houzz Pro 3D Floor Planner Reviews

- Trade Program

- Buttons & Badges

- Your Orders

- Shipping & Delivery

- Return Policy

- Houzz Canada

- Review Professionals

- Suggested Professionals

- Accessibility

- Houzz Support

- COUNTRY COUNTRY

Kitchen & Bathroom Designers in Elektrostal'

Design your dream kitchen and bathroom in Elektrostal' with the expertise of professional designers.

Location (1)

- Use My Current Location

Popular Locations

- Albuquerque

- Cedar Rapids

- Grand Rapids

- Indianapolis

- Jacksonville

- Kansas City

- Little Rock

- Los Angeles

- Minneapolis

- New Orleans

- Oklahoma City

- Orange County

- Philadelphia

- Portland Maine

- Salt Lake City

- San Francisco

- San Luis Obispo

- Santa Barbara

- Washington D.C.

- Elektrostal', Moscow Oblast, Russia

What does an Elektrostal' kitchen designer or bathroom designer do?

Questions to ask an elektrostal', moscow oblast, russia kitchen and bath design professional:.

If you search for Kitchen And Bath near me you'll be sure to find a business that knows all about the latest trends and styles for your bathroom and kitchen, ensuring that the designs are both practical and aesthetically pleasing. These Designers specialize in creating functional and visually appealing bathroom and kitchen layouts, incorporating elements that enhance usability and beauty.

BUSINESS SERVICES

Connect with us.

COMMENTS

So 210.8(B) is a new addition to the NEC with a bit more stringent requirements on GFCI uses in Commercial Kitchens. I am curious how to meet this requirement and provide the requirement to disconnect power to equipment under a kitchen hood upon activation of the fire or ANSIL system.

Within a commercial kitchen, GFCI protection for personnel is going to be required on most receptacle outlets. This requirement applies to both single- and three-phase receptacles on branch circuits rated 150V to ground or less. On single-phase branch circuits, this applies to all receptacles up to 50A, and on three-phase circuits, the cut-off ...

The NFPA NEC 2017 Sec. 210.8 edition has requirements for ground fault protection of electrically operated commercial kitchen equipment. ... If the circuit breaker feeding the equipment can be fitted with a shunt trip operating mechanism, the AG or AGL series sensors with auto reset contacts will detect the fault, and, in turn, will close the ...

Its height above the cooking surface determines how well it operates and depends on the type of appliance below it. These height requirements are as follows: 1.5 feet above: Cooking surfaces without an exposed flame. 2 feet above: Cooking surfaces with an exposed flame and burners. 3.5 feet above: Appliances with exposed charcoal or a charbroiler.

Circuit breaker with equipment ground-fault protection. The other item of concern for the inspector was the NEC 210.8 (B) (2) requirement for GFCI protection of the commercial kitchen receptacles. Beginning with the 2002 NEC, all 15- and 20-amp, 125-volt receptacles, located in a nondwelling type kitchen are required to have GFCI protection.

Learn how to provide personnel protection and safety in your commercial kitchen with the SB5000 Shock Block® that meets the NEC GFCI requirements and offers ...

Commercial Kitchen Hood Installation, Operation and Maintenance Manual ... make sure the method of installation is suitable and satisfactory with their requirements. Contact Should more information be needed please call us at 1-866-439-7984 or send us an email at

Of the codes developed by the International Code Council (ICC), the mechanical (IMC), energy conservation (IECC), and building code (IBC) requirements are the most relevant in kitchen exhaust systems. IMC lays the groundwork for kitchen ventilation systems, with various requirements around hoods and controls, grease duct, exhaust, and supply fans.

This information is found in Sec. 210.8 (B) (3). The requirement that all 125V, single-phase, 15A and 20A receptacles be GFCI protected, combined with a newer requirement that GFCI devices are readily accessible, has resulted in the most common correction notice for new restaurants (commercial kitchens) — the reason being that these GFCI ...

Commercial kitchens in healthcare facilities are exempt from these requirements. When the Energy Code applies, the energy requirements for commercial kitchens can be found in §140.9(b) of Title 24, Part 6. The requirements for commercial kitchens are prescriptive and may be traded off when using the performance method of compliance.

1.) The breaker supplying the power to the trips themselves might get turned off (even with a lockon) and go unnoticed. 2.) Breaker space is usually at a premium in kitchens, never seems to be enough. The shunt trip needs an extra pole space. 3.) Contactor = less $$, and easier to get.

NFPA Fire Code #96: 7.8.2.1. "Rooftop terminations shall be arranged with or provided with the following: (8) A hinged upblast fan supplied with flexible weatherproof electrical cable and service hold-open retainer to permit inspection and cleaning that is listed for commercial cooking equipment..".

The NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations provides the requirements for commercial kitchen fire suppression systems that help minimize fire risk and keep employees and customers safe if a fire breaks out. The standards cover both automatic fire-extinguishing systems that provide primary ...

Welcome to the 628DirtRooster website where you can find video links to Randy McCaffrey's (AKA DirtRooster) YouTube videos, community support and other resources for the Hobby Beekeepers and the official 628DirtRooster online store where you can find 628DirtRooster hats and shirts, local Mississippi honey and whole lot more!

HOME; ABOUT US; TRAVEL AGENTS; FAQ/HELP; CONTACT US; CALL US @ +7-981-863-3502; Copyright © 2000-2024 Moscow Hotels, JSC. All rights reserved.

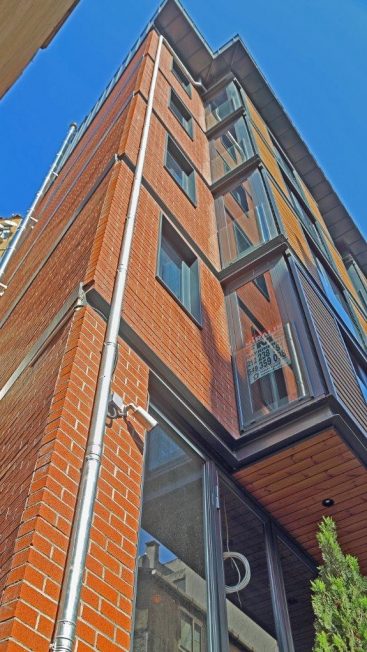

Be ready to view the world from our frame. Established in 1978, Mimsa Aluminium is one of the prominent companies in the industry with over 40 years of industrial experience and aluminum applications which are suitable for any project ranging from large-scaled commercial structures to small-scaled private residences. Company Profile ->.

Search 6 Elektrostal' kitchen & bathroom designers to find the best kitchen and bathroom designer for your project. See the top reviewed local kitchen & bathroom designers in Elektrostal', Moscow Oblast, Russia on Houzz.

My question is, when replacing a 3 phase 30 amp shunt trip breaker for a receptacle located under a commercial kitchen (ansul equipped) exhaust hood, do i need to put the ansul system in a "deactivated state" for the purpose of not setting it off accidentally due to the shunt trip interaction?