Car Moto Manuals

- 121 Automakers

- 25 121 Models

User's manuals Add

Repair manuals (1) add.

- English 1. hyosung cruise 125 parts list.pdf English 100 pages

Data sheets and catalogues Add

Hyosung GA 125 F (Cruise II) (2000 - ....)

- Hyosung Forums

- Latest Topics

- Members List (Riders)

- Hyosung Blogs & Bike Specs

Username or email *

Password *

Remember me Login

Lost your password?

Lost password

No products in the basket.

📥 Service Manuals & Owners Books

Forums 🚥 PiT STOP 📥 Service Manuals & Owners Books

- The forum ‘📥 Service Manuals & Owners Books’ is closed to new topics and replies.

- by Brand

- by Year

- by Category

- New 2024 models

- All 2023 models

- Newest additions

- 50cc motorcycles

- 125cc motorcycles

- 150cc motorcycles

- Electric motorcycles

- 1960s motorcycles

- 1950s motorcycles

- 1940s motorcycles

- 1930s motorcycles

- Contribute your specs / pics

- MC of the Year

- Advanced search

- Unit converters

- Words & terms

- Riding safety

- Insurance quotes

- News & reviews

- General topics

- Motorcycle brands

- Motorcycle categories

- Best forum for your bike

- Latest discussion posts

- Free classifieds

Hyosung Cruise II 125 Workshop Manuals

If you have to carry out auto repairs to your Hyosung Cruise II 125 then it will always be a good plan to possess a Workshop Manual to keep just for a guide if you need to know the best way to take off a specific part including Exhaust and install it again efficiently.

Hyosung Cruise II 125 Workshop Manuals can provide exact diagnostic facts for the automobile therefore if something is wrong it helps you ascertain what the situation is and how you can make it better. After that you can decide if you can do this on your own or if the job is just too big you can still make a booking for your Cruise II 125 in to a decent mechanic.

Motorcycle Manufacturers

Popular manuals.

- Kymco Top Boy 50

- Italjet JetSet 50

- Maico 500 Supermoto

- Titan Roadrunner

- Benelli Tre 1130K Amazonas

- Yamaha RD 350

- Kawasaki Prairie 360 4x4

- BMW R1200GS

- Ducati 620 Sport Full Fairing

- Puch 250 SGS

- Kawasaki KH 500

- Yamaha RD 250 LC

- Moto Guzzi V11 Sport

- Daelim History

- Factory Bike Minidesert RC 14

Recent Searches

- 1984 Kawasaki GT 750 Workshop Manual

- mz charly scooter

- Jawa 50 - 20 / Yezdi - Colt

- factory 1986 -1990 xlh service manual

- cfmoto v5 cf250t-5 manuel

- aprilia Sportcity 50cc workshop manual

- UM USA Matrix II-170 manual

- clipic cj80

- SPEEDOMETER FOR KYMCO HIPSTER

- servisni manual Suzuki RM 250 r.v.1994

- jincheng c50q motorcycle

- werkplaatshandboek kx 125 2000

- workshop manual cf moto e charm

- gpz305 cafe racer bobber

- Jawa 50 - 20 Yezdi Colt Manual

Hyosung Motorcycles, Scooter's and ATVs: Service Repair Manuals & Owner's Manual PDF

Hyosung , a South Korean company, began operations in 1952 as a manufacturer of computers and semi-finished products. She opened a motorcycle manufacturing department in 1978. Initially, this area produced products under the Suzuki license, which limited exports and reduced the profits of the Korean company. In this regard, Hyosung management decided to secede from the Japanese corporation, which happened in 1980. After the separation, the company opened its research center in Japan. Own developments, in which Japanese experts took part, increased the productivity and quality of the company's products.

Hyosung's first success came from its own development of V-engines. They were used in all models, from the "street" class, to heavy stylish motobikes with 650 cc engines. see. Then two successful models with two-stroke power units were released - FR80 and GP125. Hyosung motorcycle production has reached 15 thousand copies per year. At the peak of its popularity in 1994-1996, about 150 thousand motorcycles rolled off the assembly lines of the company. In 1999, a Korean company participated in a motorcycle salon in Milan, gaining the trust of foreigners. This led to an increase in the company's exports, which in 1999 reached 75 thousand.

In 2000, Hyosung introduced its new model - the Comet roadster, which was further developed. Currently, the Korean company Hyosung has become one of the largest manufacturers of motorcycle equipment in Asia. Its products are characterized by modern design and build quality. Among the latest models of the company, the Hyosung GV650 sports cruiser, which is an example of the Korean motorcycle industry, can be distinguished. As of June 2014, Hyosung's production facilities allowed it to assemble about 200 thousand motorcycles per year.

J. BORG ( Monday, 14 August 2023 10:04 )

Can you please aquire a service manual for the Hyosung GV 300 s bobber service manual as cannot do any serious work on my one year old EFI machine Thank you

- Scroll to top

Look - Hyosung Motorcycle Fault Codes DTC

HYOSUNG Motorcycle Manuals PDF

History of Hyosung Motorcycle

Some HYOSUNG Motorcycle Owner's Manuals, Spare Parts Catalog & Service Manuals PDF are above the page - GT650, GV650, GT125 Comet, GV250, Prima, Aguila, GF125 .

Hyosung has been a leader among Korean motorcycle manufacturers since its very first founding in 1978.

Thanks to a contract signed with Suzuki Motor Corp of Japan in 1979, it allowed the company to stand on its own and achieve production of 200,000 motorcycle units per year, gaining 40 percent of the national market.

In recent years, Hyosung began importing light and medium motorcycles into the United States.

In addition to motorcycles, Hyosung Motors & Machinery Inc also manufactures automotive parts and components.

- Scroll to top

- HYOSUNG Manuals

- COMET 125 - SERVICE

- Service manual

HYOSUNG COMET 125 Service Manual

- Manual (84 pages)

- Manual (80 pages)

- User manual (82 pages)

- page of 199 Go / 199

Table of Contents

- Troubleshooting

General Information 1

- General Precautions

- Serial Number Location

- Fuel and Oil Recommendations

- Break-In Procedures

- Cylinder Classification

- Exterior Illustration

- Specifications

Periodic Maintenance 2

- 2-1 Periodic Maintenance

- Periodic Maintenance Chart

- Lubrication Points

- Valve Clearance

- Air Cleaner

- Engine Oil Filter

- Drive Chain

- Brake System

- Rear Suspension

- Chassis Bolts and Nuts

- Compression Pressure

- Oil Pressure

- Engine Removal

- Engine Reinstallation

- Starter Moter

- Cylinder Head Cover

- Magneto Cover

- Magneto Rotor

- Clutch Cover

- Primary Drive Gear

- Gearshift Shaft

- Engine Component Inspection and Service

- Engine Reassembly

Electrical System

- Location of Electrical Components

- Ignition System

- Charging System

- Starter System and Side Stand Ignition Interlock System

- Fuel System

- Exterior Parts

- Front Wheel

- Front Brake

- Rear Shock Absorber

Servicing Information

- Special Tools

- Tightening Torque

- Service Data

- Wire and Cable Routing

- Wiring Diagram

Advertisement

Quick Links

- 1 Carburetor

- Download this manual

- General Information 1 6

- Periodic Maintenance 2 16

- Electrical System 102

- Chassis 124

- Servicing Information 164

Related Manuals for HYOSUNG COMET 125

Summary of Contents for HYOSUNG COMET 125

- Page 1 SERVICE MANUAL...

- Page 2 HYOSUNG vehicles. Without such knowledge and skills, you should not attempt servicing by relying on this manual only. Instead, please contact your nearby authorized HYOSUNG motorcycle dealer. HYOSUNG MOTORS & MACHINERY INC. COPYRIGHT HYOSUNG MOTORS & MACHINERY INC. 2002.

- Page 3 HOW TO USE THIS MANUAL TO LOCATE WHAT YOU ARE LOOKING FOR: 1. The text of this manual is divided into sections. 2. As the title of these sections are listed on the previous page as GROUP INDEX, select the section where you are look- ing for.

- Page 4 SYMBOL Listed in the table below are the symbols indicating instructions and other information necessary for servicing and meaning associated with them respectively. SYMBOL DEFINITION SYMBOL DEFINITION Torque control required. Apply THREAD LOCK 1324 . Data beside it indicates specified torque. Apply oil.

- Page 5 NOTE Difference between photographs and actual motorcycles depends on the markets.

Page 6: Table Of Contents

Page 7: general precautions.

- Page 8 GENERAL INFORMATION 1-2 WARNING If parts replacement is necessary, replace the parts with HYOSUNG Genuine Parts or their equivalent. When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orientation.

Page 9: Serial Number Location

Page 10: fuel and oil recommendations, page 11: break-in procedures, page 12: exterior illustration.

- Page 13 1-7 GENERAL INFORMATION EXTERIOR ILLUSTRATION...

Page 14: Specifications

- Page 15 1-9 GENERAL INFORMATION CHASSIS Front suspension Telescopic type Rear suspension Swingarm type Steering angle 33 (right & left) Caster 25.5 Trail 85 mm (3.35 in) 76 mm (2.29 in) Front brake Disk brake Rear brake Disk brake Front tire size 110/70 - 17 54H Rear tire size 150/70 - 17 69H...

- Page 16 PERIODIC MAINTENANCE CONTENTS 2 - 1 PERIODIC MAINTENANCE SCHEDULE 2 - 1 PERIODIC MAINTENANCE CHART 2 - 2 LUBRICATION POINTS MAINTENANCE PROCEDURES 2 - 3 2 - 3 VALVE CLEARANCE 2 - 5 SPARK PLUG 2 - 5 EXHAUST PIPE NUTS AND MUFFLER MOUNTING BOLTS 2 - 6 AIR CLEANER 2 - 7...

Page 17: 2-1 Periodic Maintenance

Page 18: lubrication points, page 19: maintenance procedures.

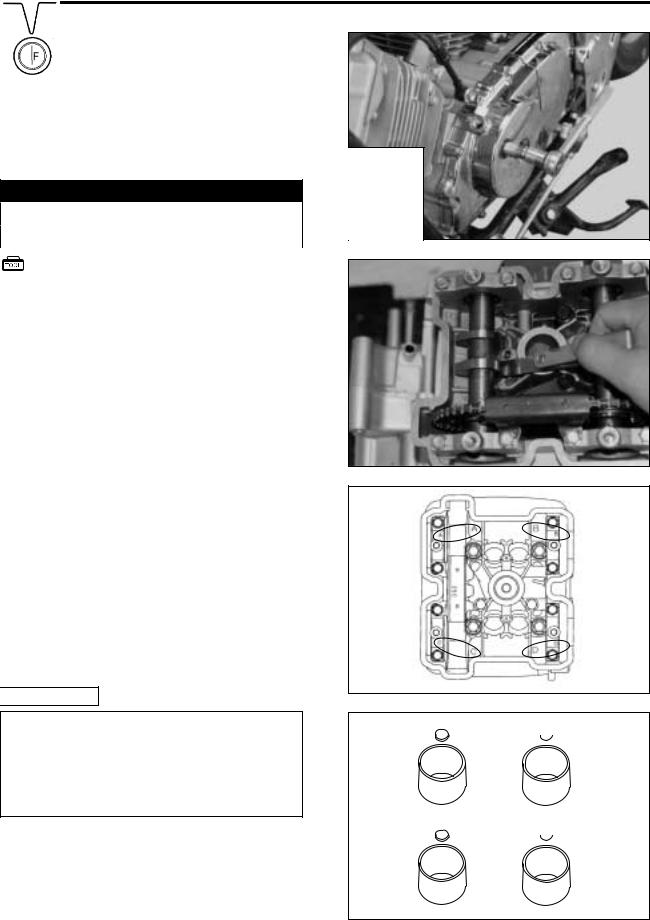

- Page 20 PERIODIC MAINTENANCE 2-4 If the clearance is out of specification, first remove the cam chain tensioner, camshaft housing, camshaft. To install the tappet shim at original position, record the shim NO. and clearance with A , B , C , D mark on the cylinder head as the illustration.

Page 21: Spark Plug

Page 22: air cleaner, page 23: carburetor, page 24: fuel hose, page 25: engine oil, page 26: engine oil filter, page 27: drive chain.

- Page 28 PERIODIC MAINTENANCE 2-12 NOTE When replacing the drive chain, replace the drive chain and sprocket as a set. Loose the axle nut Tense the drive chain fully by turning both chain adjusters Count out 21 pins (20 pitches) on the chain and mea- sure the distance between the two points.

Page 29: Brake System

- Page 30 PERIODIC MAINTENANCE 2-14 BRAKE FLUID LEVEL CHECK Keep the motorcycle upright and place the handle- LOWER LIMIT LINE bars straight. Check the brake fluid level by observing the lower limit line (LOWER) on the front brake fluid reservoir. When the level is below the lower limit line (LOWER), replenish with brake fluid that meets the following specification.

- Page 31 2-15 PERIODIC MAINTENANCE FRONT AND REAR BRAKE FLUID REPLACEMENT Place the motorcycle on a level surface and keep the handlebars straight. Remove the master cylinder reservoir cap and diaphragm. Suck up the old brake fluid as much as possible. Fill the reservoir with new brake fluid. Specification and Classification : DOT 3 or DOT 4 Connect a clear hose...

- Page 32 PERIODIC MAINTENANCE 2-16 AIR BLEEDING OF THE BRAKE FLUID CIRCUIT Air trapped in the brake fluid circuit acts like a cushion to absorb a large proportion of the pressure developed by the master cylinder and thus interferes with the full brak- ing performance of the brake caliper.

Page 33: Steering

Page 34: tire, page 35: compression pressure, page 36: oil pressure.

- Page 37 ENGINE CONTENTS ENGINE REMOVAL AND REINSTALLATION 3 - 1 ENGINE REMOVAL 3 - 1 3 - 5 ENGINE REINSTALLATION 3 - 7 ENGINE DISASSEMBLY 3 - 7 STARTER MOTER 3 - 8 CYLINDER HEAD COVER 3 - 12 PISTON 3 - 13 MAGNETO COVER MAGNETO ROTOR 3 - 13...

Page 38: Engine Removal And Reinstallation

- Page 39 ENGINE 3-2 CLUTCH CABLE Disconnect the clutch cable end out of clutch lever. Disconnect the clutch cable end out of clutch release arm. EXHAUST PIPE AND MUFFLER With the exhaust pipe bolts and muffler mounting bolts removed, remove the exhaust pipes and muf- flers.

- Page 40 3-3 ENGINE ELECTRIC PARTS With take out the spark plug caps, remove the spark plug. [ Front Cylinder ] [ Rear Cylinder ] Remove the starter motor lead wire. Remove the engine ground lead wire Disconnect the magneto coupler...

- Page 41 ENGINE 3-4 ENGINE SPROCKET Remove the engine sprocket cover. Remove the breather hose. Loosen the bolt and remove the link rod. Flatten the lock washer. Remove the engine sprocket nut and washer. NOTE When loosening the engine sprocket nut, depress the brake pedal. Remove the engine sprocket.

Page 42: Engine Reinstallation

- Page 43 ENGINE 3-6 ENGINE SPOCKET Loosen the rear axle nut and chain adjusters, left and right. Install the engine sprocket. Tighten the engine sprocket nut to the specified torque. Engine sprocket nut : 80~100 N m (8.0~10.0 kg m) NOTE When tightening the engine sprocket nut, depress the rear brake pedal.

Page 44: Engine Disassembly

Page 45: cylinder head cover.

- Page 46 3-9 ENGINE With the three bolts removed, remove the cam chain guide NO.2. Remove the camshaft housing. Remove the camshaft (IN. EX.). Remove the C-ring.

- Page 47 ENGINE 3-10 Loosen the two cylinder head base cover nuts. Loosen the three cylinder head base nuts. Loosen the four cylinder head stud bolts. Remove the chain guide NO.1 and cylinder head.

- Page 48 3-11 ENGINE Remove the tappet and the shim. CAUTION Draw out the tappet and shim with the strong magnet not to be scratched. CAUTION The tappet and shim should be lined so that each will be restored to the original position during reassembly.

Page 49: Piston

Page 50: magneto cover, page 51: clutch cover, page 52: clutch, page 53: primary drive gear, page 54: gearshift shaft.

- Page 55 ENGINE 3-18 Remove the crankcase securing bolts. Separate the crankcase into 2 parts, right and left, with a special tool. Crankcase separator : 09920-13120 CAUTION When separating the crankcase , necessarily, remove it after installed the special tool (Crankcase separator) on the side of clutch. In case separate oppositely, the gearshift cam stop- per will be damaged in the side of magneto.

Page 56: Engine Component Inspection And Service

- Page 57 ENGINE 3-20 CAMSHAFT (T.D.C) (B.T.D.C) The camshaft should be checked for runout and also for (A.T.D.C) Intake open wear of cams and journals if the engine has been noted Exhaust close to produce abnormal noise or vibration or a lack of out- 17 45 put power.

- Page 58 3-21 ENGINE VALVE HEAD RADIAL RUNOUT Place a dial gauge as shown and measure valve head radial runout. If the service limit is exceeded, replace the valve. Service limit Valve head radial runout 0.03 mm (0.0012 in) Dial gauge : 09900-20606 Magnetic stand : 09900-20701 V-block : 09900-21304 VALVE GUIDE-VALVE STEM CLEAR-...

- Page 59 ENGINE 3-22 Service limit Valve spring free length(IN. & EX.) 37.64 mm 37.80 mm (1.482 in) (1.488 in) Venier calipers : 09900-20101 Standard Valve spring tension 12.0~13.9 kgf 30.0 kgf (IN. & EX.) (26.7~30.6 lbs) (66.1 lbs) at length 33.7 mm (1.33 in) at length 27.95 mm (1.10 in) CYLINDER DISTORTION Check the gasketed surface of the cylinder for distor-...

- Page 60 3-23 ENGINE CAM CHAIN TENSIONER Check the contacting surface of the cam chain tensioner. If it is worn or damaged, replace it with a new one. CAM CHAIN AND CAM CHAIN GUIDE Check the cam chain for wear, damage and kinked or bind- ing links.

- Page 61 ENGINE 3-24 PISTON PIN HOLE BORE Using a dial calipers, measure the piston pin hole bore both in the vertical and horizontal directions. If the measurement exceeds the service limit, replace the piston. Service limit Piston pin hole bore 15.030 mm (0.5917 in) 13.030 mm (0.513 in) Dial calipers : 09900-20605 PISTON PIN DIAMETER INSPECTION Using a micrometer, measure the piston pin outside...

- Page 62 3-25 ENGINE Piston ring end gap(Assembly condition) Service limit 0.5 mm (0.02 in) 0.5 mm (0.02 in) Thickness gauge : 0990-20806 PISTON RING-TO-GROOVE CLEAR- ANCE INSPECTION Remove carbon deposit both from the piston ring and its groove. Fit the piston ring into the groove. With the ring com- pressed and lifted up, measure the clearance on the bottom side of the ring using a thickness gauge.

- Page 63 ENGINE 3-26 CONROD SMALL END INSIDE DIAM- ETER INSPECTION Using a dial calipers, measure the conrod small end inside diameter both in vertical and horizontal directions. If any of the measurements exceeds the service limit, replace the conrod. Service limit Standard Conrod small 15.006~15.014 mm...

- Page 64 3-27 ENGINE Service limit Crankshaft runout 0.05 mm (0.002 in) Magnetic stand : 09900-20701 Dial gauge : 09900-20606 V-block : 09900-21304 CRANKSHAFT REASSEBLY Measure the width between the webs referring to the fi- gure below when rebuilding the crankshaft. (2.84 0.004 in) Standard Width between webs 72 0.1 mm...

- Page 65 ENGINE 3-28 REASSEMBLY Apply a small quantity of THREAD LOCK 1324 to the starter clutch bolts and tighten them to the spec- ified torque while holding the rotor with the rotor holder. Thread Lock 1324 Rotor holder : 09930-44510 Starter clutch bolt : 15~20 N m(1.5~2.0 kg m) STARTER DRIVEN GEAR STARTER DRIVEN GEAR BUSHING...

- Page 66 3-29 ENGINE REASSEMBLY Drive in the oil seal using the special tool. Bearing installer : 09913-75820 Install the circlip. CLUTCH DRIVE PLATES Measure the thickness and claw width of the clutch drive plates using vernier calipers. If a clutch drive plate is not within the service limit, replace the clutch plates as a set.

- Page 67 ENGINE 3-30 CLUTCH SPRING FREE LENGTH Measure the free length of each clutch spring using vernier calipers. If any spring is not within the service limit, replace all of the spring. Service limit Clutch spring free length 36.2 mm (1.43 in) 29.5 mm (1.16 in) Vernier calipers : 09900-20101 CLUTCH RELEASE BEARING Inspect the clutch release bearing for any abnormality,...

- Page 68 3-31 ENGINE GEARSHIFT SHAFT Disassemble and reassemble the gearshift shaft as shown in right picture. TRANSMISSION INSPECTION GEAR-SHIFTING FORK Using a thickness gauge, check the clearance between in the groove of its gear and shifting fork. The clearance for each of the three shifting forks plays an important role in the smoothness and positiveness of shifting action.

- Page 69 ENGINE 3-32 CAUTION Never reuse a circlip. After a circlip has been removed from a shaft, it should be discarded Thrust and a new circlip must be installed. When installing a new circlip, care must be taken not to expand the end gap larger than required to slip the circlip over the shaft.

- Page 70 3-33 ENGINE Thickness for washers, circlips and spacers 1.2mm 6.0mm 0.5mm 1.0mm 1.0mm CRANKCASE play play BEARING INSPECTION Rotate the bearing inner race by finger to inspect for abnormal play, noise and smooth rotation while the bearings are in the crankcase. Replace the bearing in the following procedure if there is anything unusual.

- Page 71 ENGINE 3-34 DISASSEMBLY RIGHT CRANKCASE BEARING Remove the bearing retainer. Remove the bearings Bearing remover(17 mm) : 09923-73210 Bearing remover(20~35 mm) : 09923-74510 Remove the bearing Bearing installer : 09913-76010 CAUTION The removed bearing should be replace with a new one. LEFT CRANKCASE BEARING Remove the oil seals Oil seal remover : 09913-50121...

- Page 72 3-35 ENGINE Remove the bearing retainer. Remove the bearings Bearing remover(17 mm) : 09923-73210 Bearing remover(20~35 mm) : 09923-74510 REASSEMBLY RIGHT CRANKCASE BEARING Drive in the bearings Bearing installer : 09913-70122 Bearing installer : 09913-76010 LEFT CRANKCASE BEARING Drive in the bearings Bearing installer : 09913-70122 Bearing installer : 09913-76010...

Page 73: Engine Reassembly

- Page 74 3-37 ENGINE GEARSHIFT CAM AND GEARSHIFT FORKS Install the gearshift fork NO.1 , NO.2 , and NO.3 Install the gearshift cam , and gearshift fork shaft Install the oil pump idle gear shaft Install the dowel pins Before assembling the crankcase, apply the engine oil to each gear and bearing.

- Page 75 ENGINE 3-38 NOTE After the crankcase bolts have been tight- ened, make sure that the crankshaft, counter- shaft and driveshaft rotate smoothly. If these shafts do not rotate smoothly, try to free it by tapping with a plastic hammer. Apply the SUPER GREASE A to the driveshaft O- ring and oil seal lip.

- Page 76 3-39 ENGINE GEARSHIFT SHAFT Install the gear shifting shaft. Match the center teeth of the gear on the shifting shaft with the center teeth on the shifting driven gear as shown. CAUTION After the cam driven gear, cam guide, gear shift shaft and neutral cam stopper have been fitted, confirm that gear change is normal while turning, the countshaft and driveshaft.

- Page 77 ENGINE 3-40 CAUTION When installing the oil pump to the crankcase, turn the pump gear and check that rotation is smooth by the hand. CAM CHAIN TENSIONER Install the washer and cam chain tensioner tighten the cam chain tensioner bolt. Cam chain tensioner bolt : 6~8 N m(0.6~0.8 kg m) Install the cam chain...

- Page 78 3-41 ENGINE CAUTION Pay attention to the two washer to lower end of the primary drive gear nut in times of assemblage. With the magneto rotor held immovable using special tool, tighten the primary drive gear nut. Conrod holder : 09910-20115 Primary drive gear nut : 40~60 N m(4.0~6.0 kg m) PRIMARY DIRVEN GEAR...

- Page 79 ENGINE 3-42 Install the clutch sleeve hub nut, and tighten it to the specified torque using the special tool. Clutch sleeve hub holder : 09920-53710 Clutch sleeve hub nut : 30~50 N m(3.0~5.0 kg m) Bend the lock washer securely. Install the clutch drive plates and driven plates.

- Page 80 3-43 ENGINE Install the clutch pressure plate clutch springs and clutch spring mounting bolts. Hold the primary drive gear nut and tighten the clutch spring mounting bolts in a crisscross pattern. NOTE Make sure that the clutch pressure plate is installed correctly.

- Page 81 ENGINE 3-44 NEUTRAL CAM STOPPER Put in the neutral cam stopper, spring and washer, tighten the cam stopper plug to the specified torque. Neutral cam stopper plug : 20~25 N m(2.0~2.5 kg m) OIL DRAIN PLUG Tighten the oil drain plug to the specified torque. Engine oil drain plug : 18~20 N m(1.8~2.0 kg m) STATOR...

- Page 82 3-45 ENGINE Tighten the magneto rotor nut to the specified torque. Conrod holder : 09910-20115 Magneto rotor nut : 50~60 N m(5.0~6.0 kg m) STARTER IDLE GEAR AND MOTOR Install the starter idle gear, shaft and spacer. Install the starter motor. MAGNETO COVER Install the new gasket and dowel pin.

- Page 83 ENGINE 3-46 Install the magneto cover and tighten the magneto cover bolts. Magneto cover bolt : 8~12 N m (0.8~1.2 kg m) PISTON RING Install the piston ring in order of oil ring, 2nd ring and 1st ring at first at the front cylinder. CAUTION Be careful not to cause scratch on the piston when inserting the piston ring to the piston.

- Page 84 3-47 ENGINE CYLINDER Apply BOND 1215 to the parting line of crankcase. BOND 1215 Place the dowel pin and new gasket on the crankcase. CAUTION Make sure to replace the gasket with a new one. Apply the engine oil to the conrod big end, piston and the piston rings.

- Page 85 ENGINE 3-48 Tighten the cylinder head base nuts. Cylinder head base nut : 7~11 N m (0.7~1.1 kg m) Cylinder head base nut : 15~20 N m (1.5~2.0 kg m) Tighten the two cylinder base cover nuts. Tappet Install the tappet and shim. CAUTION Shim With fit the tappet, it should be replaced if turn...

- Page 86 3-49 ENGINE CAMSHAFT ASSEMBLY Distinguish the EX mark for the exhaust camshaft, the IN mark for the intake camshaft. Be distinguished always each camshaft what has notch at the rightside end and leftside end of it. When installing the camshaft and cam sprocket, apply a small quantity THREAD LOCK 1324 to the bolts and tighten with the specified torque.

- Page 87 ENGINE 3-50 The notch mark of exhaust camshaft should be aligned with the plane of cylinder head. At that time, the 2 arrow of exhaust camshaft sprock- et should be in a vertical position to the plane of cylinder head when exhaust camshaft sprocket was geared into camchain.

- Page 88 3-51 ENGINE CAUTION The cam chain is installed to the all of three sprocket. Be sure to lie the crankshaft until the four holder and cam chain tension adjuster are installed completely. 16 Pin Notch mark Exhaust Intake [Front cylinder] 16 Pin Notch mark Exhaust...

- Page 89 ENGINE 3-52 Each camshaft housing is punched with A B C D . Put on the housing A to the A of head surface, the housing B to the B , the housing C to the C and the housing D to the D as that A C D is punched also to the cylinder head upper surface.

- Page 90 3-53 ENGINE Get out the pushrod for the front to turn the lock shaft handle in counter-clockwise ( ). Turn the crankshaft about 10 times counter-clock- wise ( ) on the basis of the magneto rotor. If the valve clearance is within standard after measured the valve clearance, begin the next operation.

- Page 91 ENGINE 3-54 SPARK PLUG Install the spark plug.(Refer to page 2-5) Install the rear cylinder head and cylinder with the same manner which installed the front cylinder head and cylinder. Front Cylinder Rear Cylinder GEAR POSITION SWITCH Install the spring and contact Apply SUPER GREASE A to the O-ring and install the gear postion switch.

- Page 92 FUEL SYSTEM CONTENTS 4 - 1 FUEL TANK / FUEL COCK 4 - 2 FUEL PUMP 4 - 4 CARBURETOR CAUTION Gasoline must be handled carefully in an area well ventilated and away from fire or sparks.

- Page 93 4-1 FUEL SYSTEM FUEL TANK / FUEL COCK REMOVAL WARNING Gasoline is very explosive. Extreme care must be taken. Remove the front seat. (Refer to page 6-1) Remove the fuel tank mounting bolt, and take off the hooks. Disconnect the fuel hose and remove the fuel tank.

- Page 94 FUEL SYSTEM 4-2 FUEL PUMP ( REMOVAL Remove the front seat and fuel tank. Turn the fuel cock to OFF . Disconnect the fuel hoses Remove the fuel pump mounting bolts. Remove the fuel pump lead wire coupler . INSPECTION WARNING Gasolin is very explosive.

- Page 95 4-3 FUEL SYSTEM FUEL PUMP ( REMOVAL Remove the front seat and fuel tank. Turn the fuel cock to OFF . Disconnect the fuel hoses and vacuum hose INSPECTION WARNING Gasolin is very explosive. Extreme care must be taken. Disconnect the fuel hose , connect the suitable hose and insert the free end of the hose into a recep- tacle.

- Page 96 FUEL SYSTEM 4-4 CARBURETOR...

- Page 97 4-5 FUEL SYSTEM LOCATION OF CARBURETOR I.D. The carburetor I.D. is stamped on the location on the carburetor as shown in the right photo. REMOVAL Remove the fuel tank. (Refer to page 4-1) Remove the fuel hose. Remove the throttle cables and choke cable Loosen the clamp screw and remove the carburetor.

- Page 98 FUEL SYSTEM 4-6 Remove the jet needle cap spring retainer and jet needle Remove the float chamber body Remove the float assembly along with the needle valve by removing the pin. Remove the valve seat Remove the main jet jet holder and pilot jet...

- Page 99 4-7 FUEL SYSTEM Remove the throttle cable bracket Remove the pilot screw with count and tighten the number of turn. NOTE Record the number of turn for the pilot screw when install to confer. INSPECTION Check the following parts for damage and clogging. Pilot jet Piston valve Check for...

- Page 100 FUEL SYSTEM 4-8 FLOAT HEIGHT ADJUSTMENT To check the float height, turn the carburetor upside down. Measure the float height while the float arm is just contacting the needle valve using vernier calipers. Float height 17mm (0.67 in) Vernier calipers : 09900 - 20101 Bend the float arm as necessary to bring the height...

- Page 101 4-9 FUEL SYSTEM Install the jet needle with the pin on the spacer securely engaged with the hole on the piston valve. Align the hole of the diaphragm with passage way on the carburetor body. Install the eight screw CAUTION Never adjust CO adjust screw of the carbure- tor.

- Page 102 ELECTRICAL SYSTEM CONTENTS 5 - 1 LOCATION OF ELECTRICAL COMPONENTS 5 - 3 IGNITION SYSTEM 5 - 7 CHARGING SYSTEM STARTER SYSTEM AND 5 - 11 SIDE STAND IGNITION INTERLOCK SYSTEM 5 - 15 SWITCHES 5 - 16 LAMP 5 - 18 BATTERY 5 - 21 FUEL SYSTEM(...

Page 103: Location Of Electrical Components

- Page 104 ELECTRICAL SYSTEM 5-2 Ignition coil (NO.1 & NO.2) Regulator / Rectifier Magneto Gear position switch Fuse Fuel pump relay...

Page 105: Ignition System

- Page 106 ELECTRICAL SYSTEM 5-4 INSPECTION MAGNETO Using the pocket tester, measure the resistance between the lead wires in the following table. Pick-up coil G - L Approx 90 110 Charging coil Y - Y Approx 0.6 0.9 Pocket Tester : 09900 - 25002 CAUTION When mounting the stator on the magneto cover, apply a small quantity of THREAD LOCK 1324...

- Page 107 5-5 ELECTRICAL SYSTEM CAUTION Numberical value may differ a little according to the tester. Please remind that there may be a defect which can not be identified even though the measurement by using the tester indicates a low voltage. The range of measurement adjust a [ unit.

- Page 108 ELECTRICAL SYSTEM 5-6 SPARK PLUG Clean the plug with a wire brush and pin. Use the pin to remove carbon, taking care not to damage the porce- lain. Check the gap with a thickness gauge. Thickness gauge : 09900 - 20806 0.8 mm Spark plug gap (0.028...

Page 109: Charging System

- Page 110 ELECTRICAL SYSTEM 5-8 When the engine rpm become higher, the generated voltage of the AC generator also becomes higher and the voltage between points of the regulator according becomes high, and when it reaches the adjusted voltage of the control unit, consequently the control unit becomes ON condition. On the ON condition of the control unit, signal will be sent to the SCR (Thyristor) gate probe and SCR will become ON condition.

- Page 111 5-9 ELECTRICAL SYSTEM INSPECTION CHARGING OUTPUT CHECK Start the engine and keep it running at 5,000 rpm. Using the pocket tester, measure the DC voltage between the battery terminal If the tester reads under 14.0 V or over 15.0 V, check the magneto no-load performance and regulator / rectifier.

- Page 112 ELECTRICAL SYSTEM 5-10 REGULATOR / RECTIFIER Disconnect the coupler. Using the multi-tester ( range), measure the resistance between the terminals in the following table. If the resistance checked is incorrect, replace the regu lator / rectifier. Unit : Probe of tester 30 55 0.8 2 0.8 2...

Page 113: Starter System And Side Stand Ignition Interlock System

- Page 114 ELECTRICAL SYSTEM 5-12 TRANSMISSION : Neutral - ON Side stand - Down ( OFF ) IGNITION SWITCH IGNITION COIL BATTERY Unit NEUTRAL INDICATOR LIGHT SIDE STAND SWITCH GEAR POSITION DOWN POSITION SWITCH ON TRANSMISSION : Neutral - OFF Side stand - Up ( ON ) IGNITION SWITCH IGNITION COIL BATTERY...

- Page 115 5-13 ELECTRICAL SYSTEM STARTER MOTOR REMOVAL AND DISASSEMBLY Disconnect the starter motor lead wire With loosen the bolt , remove the starter motor. Disassemble the starter motor. STARTER MOTOR INSPECTION CARBON BRUSH Inspect the brushes for abnormal wear, crack or smoothness in the brush holder. If the brush has failed, replace the brush sub assy.

- Page 116 ELECTRICAL SYSTEM 5-14 STARTER MOTOR REASSEMBLY Reassemble the starter motor. Pay attention to the following points : Reassembly the starter motor as shown in the illustration. Align the mark on the housing with the line on the housing end. Apply SUPER GREASE A to the O-ring and remount the starter motor.

Page 117: Switches

Page 118: lamp.

- Page 119 5-17 ELECTRICAL SYSTEM COMBINATION METER Remove the combination meter. Disassemble the combination meter as shown in the illustration. INSPECTION Using the pocket tester, check the continuity between lead wires in the following illustration. If the continuity measured incorrect, replace the respec- tive part.

Page 120: Battery

- Page 121 5-19 ELECTRICAL SYSTEM Seal Pouring of battery electrolyte When insert the nozzles of the electrolyte container into the battery s electrolyte filler holes, holding the container firmly so that it does not fall. Take precaution not to allow any fluid to spill. CAUTION The pouring of electrolyte may not be done if the electrolyte container is pushed slopely.

- Page 122 ELECTRICAL SYSTEM 5-20 Separation of electrolyte container After confirming that you entered the electrolyte into bat- tery completely, remove the electrolyte containers from the battery. CAUTION Draw the empty receptacle out slowly because there may be a chance which remaining elec- trolyte vaporize.

Page 123: Fuel System

- Page 124 CHASSIS CONTENTS EXTERIOR PARTS 6- 1 6 - 2 FRONT WHEEL FRONT BRAKE 6- 6 6 - 12 HANDLEBARS 6 - 14 FRONT FORK ( FRONT FORK ( 6- 20 6 - 27 STEERING REAR WHEEL 6- 30 REAR BRAKE 6- 34 REAR SHOCK ABSORBER 6- 36...

Page 125: Exterior Parts

Page 126: front wheel.

- Page 127 6-3 CHASSIS Remove the brake disc. INSPECTION AND DISASSEMBLY TIRE For inspection of the tire : Refer to page 2-18. FRONT AXLE Measure the front axle runout using the dial gauge. If the runout exceeds the limit, replace the front axle. Service limit Axle shaft runout 0.25 mm (0.01 in)

- Page 128 CHASSIS 6-4 WHEEL BEARING REMOVAL Remove the wheel bearing by using the special tool. Wheel bearing remover : 09941 - 50111 CAUTION The removed bearing should be replaced with new ones. REASSEMBLY Reassemble the front wheel in the reverse order of removal and disassembly.

- Page 129 6-5 CHASSIS Tighten the front axle bolt and axle pinch bolt the specified torque. Front axle bolt : 50~80 N m (5.0 ~8.0 kg m) Front axle pinch bolt : 15~25 N m (1.5 ~2.5 kg m)

Page 130: Front Brake

- Page 131 6-7 CHASSIS CAUTION Do not allow brake fluid to contact the paint surface, plastic or rubber parts, or its chemical reaction can cause discoloration or crack. BRAKE FLUID REPLACEMENT For replacing procedure of brake fluid : Refer to page 2-15 BRAKE PAD REPLACEMENT For replacing procedure of brake pad : Refer to page 2-14 CALIPER DISASSEMBLY...

- Page 132 CHASSIS 6-8 Remove the dust seal and piston seal CAUTION Care not to cause scratch on the cylinder bore. Do not reuse the piston seal and dust seal that have been removed. CALIPER INSPECTION Inspect the caliper cylinder wall and piston surface for scratch, corrosion or other damages.

- Page 133 6-9 CHASSIS Apply SILICONE GREASE to the brake caliper hold- SILICONE GREASE Install the brake pads. (Refer to page 2-14) Tighten the caliper mounting bolts With the hose end seated to the stopper, tighten the union bolt Front brake caliper mounting bolts :18~28 N m (1.8~2.8 kg m) Front brake hose union bolts :20~25 N m (2.0~2.5 kg m)

- Page 134 CHASSIS 6-10 MASTER CYLINDER DISASSEMBLY Drain brake fluid the master cylinder. Disconnect the brake lamp switch lead wire coupler. Remove the union bolt CAUTION Place a rag under the union bolt so that brake fluid can not contact the parts. Remove the two clamp bolts and take off the master cylinder.

- Page 135 6-11 CHASSIS MASTER CYLINDER INSPECTION Inspect the master cylinder bore for any scratches or other damage. Inspect the piston surface for any scratches or other damage. MASTER CYLINDER REASSEMBLY Reassemble the master cylinder in the reverse order of disassembly. Pay attention to the following points : CAUTION Wash the master cylider components with new brake fluid before reassembly.

Page 136: Handlebars

- Page 137 6-13 CHASSIS NOTE The gap between the handlebar clamp and holder should be even. Align the mating face of clutch lever holders with the respective punch marks and tighten the bolt. Install the brake master cylinder. (Refer to page 6- 11).

Page 138: Front Fork

- Page 139 6-15 CHASSIS REMOVAL AND DISASSEMBLY Take off the front wheel. (See page 6-2) Loosen the front fork upper and lower clamp bolts. Remove the front brake hose clamp. Pull down right and left front forks. Remove the front fork cap, O-ring , and seat lever.

- Page 140 CHASSIS 6-16 Remove the damper rod bolt by using the special tool. T Handle : 09940-34520 D Attachment : 09940-34561 T Type hexagon wrench (6mm) : 09914-25811 Separate the inner tube from outer tube. Remove oil lock piece and damper rod with rebound spring.

- Page 141 6-17 CHASSIS INSPECTION DAMPER ROD RING Inspect the damper rod ring for wear and damage. INNER TUBE AND OUTER TUBE Inspect the inner tube and outer tube sliding surfaces for any scuffing or flaws. FORK SPRING Measure the fork spring free length If it is shorter than the service limit, replace it.

- Page 142 CHASSIS 6-18 DAMPER ROD BOLT Apply Bond 1215 and Thread Lock 1324 to the damper rod bolt and tighten the bolt with specified torque by the Special tool Bond 1215 Thread Lock 1324 T Handle : 09940-34520 D Attachment : 09940-34561 T Type hexagon wrench (6mm) : 09914-25811 Front fork damper rod bolt : 30 40 N m (3.0 4.0...

- Page 143 6-19 CHASSIS FORK SPRING The narrow pitch side of spring face to the upper side when installing the front fork spring. Up side STOPPER RING To install a new stopper ring, it will be necessary to push the spring seat inward. CAUTION Always use a new stopper ring.

Page 144: Front Fork

- Page 145 6-21 CHASSIS DISASSEMBLY Remove the front wheel. (Refer to page 6-2) Remove the brake caliper. (Refer to page 6-7) CAUTION Secure the brake caliper to the frame with a string etc., taking care not to bend the brake hose. Remove the front fender. (Refer to page 6-1) Remove the front fork after loosening the front fork upper and lower...

- Page 146 CHASSIS 6-22 With the damper rod held immovable, remove the damper rod bolt. Remove the damper rod and rebound spring from the inner tube. Remove the dust seal and oil seal stopper ring Separate the inner tube from the outer tube. Remove the following parts.

- Page 147 6-23 CHASSIS INSPECTION FRONT FORK SPRING Measure the free length of the front fork spring If the length is found shorter than the service limit, replace the spring. Service limit Fork spring free length 354 mm (13.9 in) INNER TUBE AND OUTER TUBE Check the sliding surface of the inner tube, outer tube and damper rod ring for scratch, wear, bend- ing, or other abnormal condition.

- Page 148 CHASSIS 6-24 With the oil lock piece fitted to the inner tube, assem- ble the inner tube to the outer tube. Apply SUPER GREASE A to the lip of the oil seal and install it into the outer tube using the front fork oil seal installer.

- Page 149 6-25 CHASSIS Apply THREAD LOCK 1324 to the damper rod bolt With the damper rod held immovable, with the gasket fitted, tighten the damper rod bolt Front fork damper rod bolt : 30~40 N m (3.0~4.0 kg m) THREAD LOCK 1324 CAUTION Replace the gasket with a new one.

- Page 150 CHASSIS 6-26 Fit the O-ring to the front fork upper bolt and apply SUPER GREASE A . SUPER GREASE A CAUTION Use a new O-ring to prevent oil lieakage. Install the front fork to the motocycle. Align the upper surface of the inner tube with the upper surface of the steering stem upper bracket.

Page 151: Steering

- Page 152 CHASSIS 6-28 Remove the handlebar clamp bolts. Remove the steering stem head nut and take off the steering stem upper bracket Remove the steering stem nut and draw out the steering stem. Clamp wrench : 09940-10122 Take off the steering stem lower bracket CAUTION Hold the steering stem lower bracket by hand to prevent from falling.

- Page 153 6-29 CHASSIS INSPECTION Inspect and check the removed parts for the following abnormalities. Handlebar distortion. Handlebar clamp wear. Abnormality operation of bearing. Worn or damaged races. Distortion of steering stem. REASSEMBLY Reassemble and remount the steering stem in the reverse order of disassembly and removal, and also carry out the following steps : Apply SUPER GREASE A to the upper bearing and lower bearing...

Page 154: Rear Wheel

- Page 155 6-31 CHASSIS Remove the rear wheel by removing the rear axle Remove the brake disc. Remove the spacer Remove the rear sprocket with mounting drum from the rear wheel. NOTE Before separating the rear sprocket and mounting drum, slightly loosen the rear sprocket bolts. Remove the rear wheel shock absorber Remove the rear sprocket from the rear sprock-...

- Page 156 CHASSIS 6-32 INSPECTION WHEEL AXLE : Refer to page 6-3 WHEEL : Refer to page 6-3 WHEEL BEARING : Refer to page 6-3 TIRE : Refer to page 2-18 REAR WHEEL SHOCK ABSORBER Inspect the rear wheel shock absorber for wear and damage. Replace the rear wheel shock absorber if there is any- thing unusual.

- Page 157 6-33 CHASSIS Install the rear wheel. After installing the drive chain to the rear sprocket, adjust the drive chain. Tighten both chain adjusting nuts securely. Tighten the rear axle nut to the specified torque. Rear axle nut : 90~140 N m (9.0~14.0 kg m)

Page 158: Rear Brake

- Page 159 6-35 CHASSIS Brake fluid replacement : Refer to page 2-15 Brake pad replacement : Refer to page 2-14 Disassembly of caliper : Refer to page 6-7 Inspection of caliper : Refer to page 6-8 Reassembly of caliper : Refer to page 6-8 Inspection of brake disc : Refer to page 6-9...

Page 160: Rear Shock Absorber

Page 161: swingarm.

- Page 162 CHASSIS 6-38 Remove the chain case. Remove the two spacers. Remove the bearing by using the special tools. Bearing remover (17 mm) : 09923-73210 Rotor remover sliding shaft : 09930-30102 INSPECTION SWINGARM Inspect the swingarm for damage. If any defects are found, replace the swingarm with a new one.

- Page 163 6-39 CHASSIS REASSEMBLY Reassemble the swingarm and rear shock absorber in the reverse order of disassembly. Pay attention to the following points : Press the needle bearings into the swingarm pivot using the special tool. Steering race installer : 09941 - 34513 Apply SUPER GREASE A to the needle bearing and spacers.

- Page 164 SERVICING INFORMATION CONTENTS 7 - 1 TROUBLESHOOTING 7 - 8 SPECIAL TOOLS 7 - 11 TIGHTENING TORQUE 7 - 13 SERVICE DATA 7 - 23 WIRE AND CABLE ROUTING WIRE AND CABLE ROUTING 7 - 27 WIRING DIAGRAM 7 - 31 7 - 32 WIRING DIAGRAM...

Page 165: Troubleshooting

- Page 166 SERVICING INFORMATION 7-2 Complaint Symptom and possible causes Remedy Noisy engine. Noise seems to come from transmission 1. Gears worn or rubbing. Replace. 2. Badly worn splines. Replace. 3. Primary gears worn or rubbing. Replace. 3. Badly worn bearings. Replace. Slipping clutch.

- Page 167 7-3 SERVICING INFORMATION Complaint Symptom and possible causes Remedy Engine lacks power. 1. Loosen of valve clearance. Adjust. 2. Weakened valve springs. Replace. 3. Valve timing out of adjustment. Adjust. 4. Worn piston ring or cylinder. Replace. 5. Poor seating of valves. Repair or replace.

- Page 168 SERVICING INFORMATION 7-4 ELECTRICAL Complaint Symptom and possible causes Remedy No sparking or poor 1. Defective ignition coil. Replace. sparking. 2. Defective spark plug. Replace. 3. Defective CDI unit. Replace. Spark plug soon 1. Mixture too rich. Adjust carburetor. become fouled with 2.

- Page 169 7-5 SERVICING INFORMATION BATTERY Complaint Symptom and possible causes Remedy Sulfation acidic 1. Not enough electrolyte. Add distilled water, if the battery white powdery has not been damaged and substance or spots sulfation has not advanced on surfaces of too far, and recharge. cell plates.

- Page 170 SERVICING INFORMATION 7-6 CHASSIS Complaint Symptom and possible causes Remedy Steering feels too 1. Steering stem nut overtightened. Adjust. heavy or stiff. 2. Worn bearing or race in steering stem. Replace. 3. Distorted steering stem. Replace. 4. Not enough pressure in tires. Adjust.

- Page 171 7-7 SERVICING INFORMATION BRAKES Complaint Symptom and possible causes Remedy Poor braking 1. Not enough brake fluid in the reservoir. Refill to level mark. (FRONT and REAR) 2. Air trapped in brake fluid circuit. Bleed air out. 3. Pads worn down. Replace.

Page 172: Special Tools

- Page 173 7-9 SERVICING INFORMATION Special tools Part Number Part Name Description Special tools Part Number Part Name Description 09913-80112 09910-32812 Bearing installer Crankshaft installer Used to install the crankshaft in the crankcase. Used to drive bearing in. 09910-34510 09915-63310 Piston pin puller Compression gauge adapter Use to remove the piston pin.

- Page 174 SERVICING INFORMATION 7-10 Special tools Part Number Part Name Description Special tools Part Number Part Name Description 09921-20200 09930-44510 Bearing remover(10mm) Rotor holder Used to remove oil seal or bearing. Widely used to lock rotary parts such as a flywheel magneto. 09921-20210 09940-10122 Bearing remover(12mm)

Page 175: Tightening Torque

- Page 176 SERVICING INFORMATION 7-12 CHASSIS ITEM kg m Rear shock absorber mounting nut (Upper) 40 ~ 60 4.0 ~ 6.0 Rear shock absorber mounting nut (Lower) 40 ~ 60 4.0 ~ 6.0 Rear sprocket nut 20 ~ 30 2.0 ~ 3.0 Rear axle nut 90 ~ 140 9.0 ~ 14.0...

Page 177: Service Data

- Page 178 SERVICING INFORMATION 7-14 VALVE + GUIDE Unit : mm (in) ITEM STANDARD LIMIT Valve diam. 18.0 (0.71) 14.5 (0.57) Valve clearance (When cold) 0.1 ~ 0.2 (0.004 ~ 0.008) 0.2 ~ 0.3 (0.008 ~ 0.012) Valve guide to valve stem clearance 0.010 ~ 0.037 (0.0004 ~ 0.0015) 0.030 ~ 0.057 (0.0012 ~ 0.0022) Valve stem deflection...

- Page 179 7-15 SERVICING INFORMATION CYLINDER + PISTON + PISTON RING Unit : mm (in) ITEM STANDARD LIMIT Compression pressure 14~16 kg/cm (at 500 rpm) 12 kg/cm Piston to cylinder clearance 0.050 ~ 0.060 (0.0020 ~ 0.0024) 0.120 (0.0047) Cylinder bore 57.000 ~ 57.015 (2.2441 ~ 2.2447) 57.080 (2.2473) Piston diam.

- Page 180 SERVICING INFORMATION 7-16 CYLINDER + PISTON + PISTON RING Unit : mm (in) ITEM STANDARD LIMIT Compression pressure 11~13 kg/cm (at 500 rpm) 10 kg/cm Piston to cylinder clearance 0.03 ~ 0.04 (0.0012 ~ 0.0016) 0.1 (0.0040) Cylinder bore 44.000 ~ 44.015 (1.7323 ~ 1.7329) 44.080 (1.7354) Piston diam.

- Page 181 7-17 SERVICING INFORMATION OIL PUMP ITEM STANDARD NOTE Oil pressure 0.5 kg/cm (at 65 , 3,000 rpm) 58/19 14/20 = 2.137 Oil pump reduction ratio OIL PUMP ITEM STANDARD NOTE Oil pressure 0.9 ~ 1.1 kg/cm (at 65 , 3,000 rpm) Oil pump reduction ratio 70/20 14/20 = 2.45 CLUTCH...

- Page 182 SERVICING INFORMATION 7-18 TRANSMISSION + DRIVE CHAIN Unit : mm (in) ITEM STANDARD LIMIT Primary reduction ratio 3.053 (58/19) Secondary reduction ratio 3.286 (46/14) Gear ratio 2.462 (32/13) 1.556 (28/18) 1.190 (25/21) 0.957 (22/23) 0.840 (21/25) Shift fork to groove clearance 0.10 ~ 0.30 (0.004 ~ 0.012) 0.5 (0.020) Shift fork groove width...

- Page 183 7-19 SERVICING INFORMATION CARBURETOR Unit : mm (in) ITEM SPECIFICATION Carburetor type MIKUNI BDS26 TYPE(DOUBLE) Bore size 1,450~1,550 r.p.m. Idle r.p.m. 17 (0.67) Float height Throttle cable play 0.5~1.0 (0.02 ~ 0.04) FRONT REAR Main jet (M.J.) 92.5 Main air jet (M.A.J.) Jet needle (J.N.)

- Page 184 SERVICING INFORMATION 7-20 ELECTRICAL Unit : mm (in) ITEM STANDARD NOTE Ignition timing 15 /2,000rpm ~ 30 /6,000rpm Type CR8E 0.7~0.8 (0.028 ~ 0.032) Hot type CR7E Spark plug Standard type CR8E Cold type CR9E Spark performance Over 8mm (0.32) Ignition coil resistance 0.19 ~ 0.24 Primary...

- Page 185 7-21 SERVICING INFORMATION SUSPENSION Unit : mm (in) ITEM STANDARD LIMIT Front fork stroke 120 (4.27) Front fork spring free length 433.3 (17.1) Front fork oil type TELLUS #22 Front fork oil level 146 (5.8) Front fork oil capacity (each leg) 2.5cc Rear wheel travel 110 (4.33)

- Page 186 SERVICING INFORMATION 7-22 BRAKE+WHEEL Unit : mm (in) ITEM STANDARD LIMIT Rear brake pedal height 290 (11.4) [when one person riding from the ground] Brake disc thickness Front 4.0 (0.16) 3.0 (0.12) Rear 4.3 (0.17) 3.0 (0.12) Brake disc runout Front Rear 0.3 (0.012) Master cylinder bore...

Page 187: Wire And Cable Routing

- Page 188 SERVICING INFORMATION 7-24...

- Page 189 7-25 SERVICING INFORMATION...

- Page 190 SERVICING INFORMATION 7-26...

Page 191: Wire And Cable Routing

- Page 192 SERVICING INFORMATION 7-28...

- Page 193 7-29 SERVICING INFORMATION...

- Page 194 SERVICING INFORMATION 7-30...

Page 195: Wiring Diagram

Page 196: wiring diagram.

- Page 199 Prepared by HYOSUNG MOTORS & MACHINERY INC. Overseas Technical Department 1st Ed. NOV. 2002. Manual No. 99000-94710 Printed in Korea...

This manual is also suitable for:

Rename the bookmark, delete bookmark, delete from my manuals, upload manual.

- My Downloads 161523

- Account Settings

- How it Works

- Questions and Suggestions

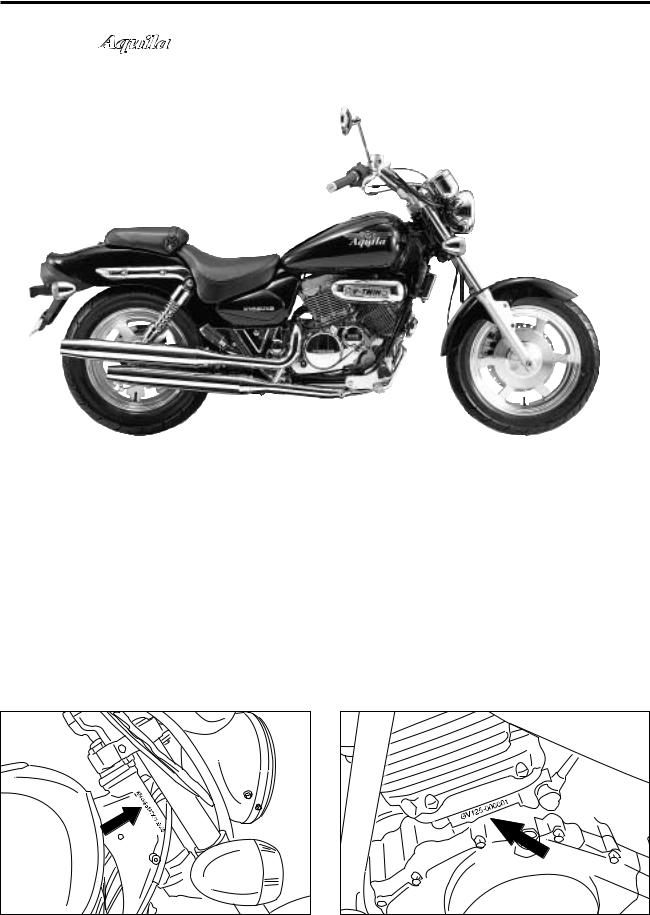

- GV 125 Aquila 2

- GV 650 Aquila 2

- GV650 Pro 2011

- RT 125 Karion

HYOSUNG GV 125 Aquila User Manual

HYOSUNG MOTORS & MACHINERY INC.

SERVICE MANUAL

MANUAL SERVICE

99000-95210

Other information considered as generally known is not included.

Read GENERAL INFORMATION section to familiarize y o u r s e l f w i t h o u t l i n e o f t h e v e h i c l e a n d MAINTE-NANCE and other

stomers of your optimum and quick service.

This manual has been prepared on the basis of the latest specification at the time of publication.

If modification has been made since then, difference may exist between the content of this manual and the actual vehicle.

Illustrations in this manual are used to show the basic principles of opertion and work procedures.

They may not represent the actual vehicle exactly in detail.

T h i s m a n u a l i s i n t e n d e d f o r t h o s e w h o h a v e e n o u g h k n o w l e d g e a n d s k i l l s f o r servicing

HYOSUNG vehicles. Without such knowedge and skills, you should not attempt servicing by relying on this manual only.

Instead, please contact your nearby authorized HYOSUNG motorcycle dealer.

GROUP INDEX

GENERAL INFORMATION

PERIODIC MAINTENANCE

FUEL SYSTEM

ELECTRICAL SYSTEM

SERVICING INFORMATION

Overseas Technical Department

COPYRIGHT HYOSUNG MOTORS & MACHINERY INC. 2000

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE

LOOKING FOR:

1. The text of this manual is divided into sections.

2. As the title of these sections are listed on the previous page as GROUP INDEX, select the section where you are looking for.

3. Holding the manual as shown at the right will allow you to find the first page of the section easily.

4. On the first page of each section, its contents are listed. Find the item and page you need.

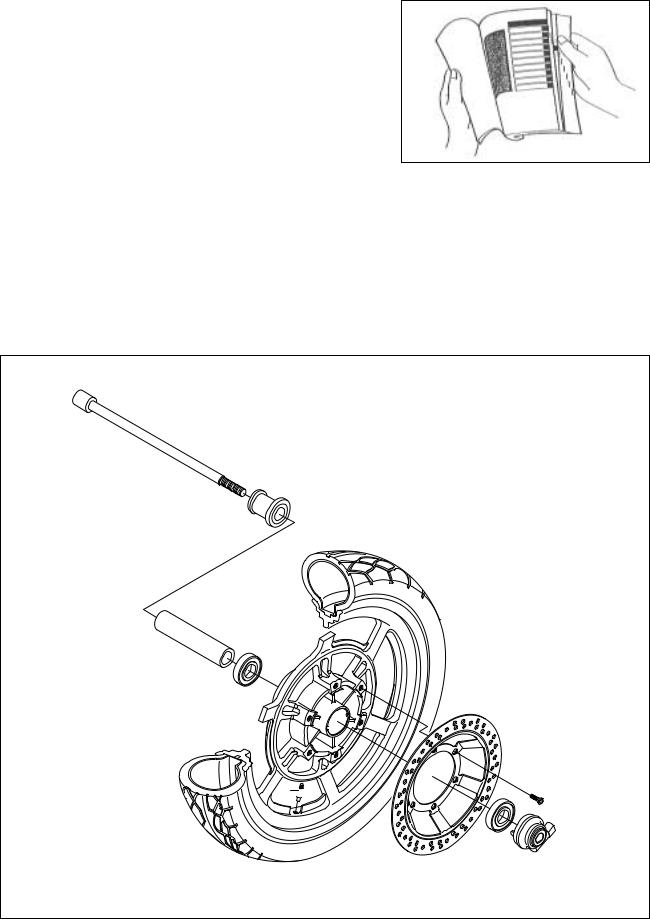

COMPONENT PARTS

Example: Front wheel

Listed in the table below are the symbols indicating instructions and other information necessary for servicing and meaning associated with them respectively.

Torque control required.

Apply oil. Use engine oil unless

Apply or use brake fluid.

otherwise specified.

Apply BOND“1215”.

1-1 GENERAL INFORMATION

WARNING / CAUTION / NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the symbol and the words WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by these signal words.

Indicates a potential hazard that could result in death or injury.

Indicates a potential hazard that could result in vehicle damage.

Indicates special information to make maintenance easier or instructions cleaner.

Please note, however, that the warning and cautions contained in this manual cannot possibly cover all potential hazards relating to the servicing, or lack of servicing, of the motorcycle. In addition to the WARNING and CAUTION stated, you must use good judgement and basic mechanical safety principles. If you are unsure about how to perform a particular service operation, ask a more experienced mechanic for advice.

GENERAL PRECAUTIONS

Proper service and repair procedures are important for the safety of the service machanic and the safety and reliability of the vehicle.

When 2 or more persons work together, pay attention to the safety of each other.

When it is necessary to run the engine indoors, make sure that exhaust gas is forced outdoors.

When working with toxic or flammable materials, make sure that the area you work in is well-ventilated and that you follow all off the material manufacturer ’ s instructions.

Never use gasoline as a cleaning solvent.

To avoid getting burned, do not touch the engine, engine oil or exhaust system during or for a while after engine operation.

After servicing fuel, oil, exhaust or brake systems, check all lines and fittings related to the system for leaks.

GENERAL INFORMATION 1-2

If parts replacement is necessary, replace the parts with HYOSUNG Genuine Parts or their equivalent.

When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orientation.

Be sure to use special tools when instructed.

Make sure that all parts used in reassembly are clean, and also lubricated when specified.

When use of a certain type of lubricant, bond, or sealant is specified, be sure to use the specified type.

When removing the battery, disconnect the negative cable first and then positive cable. When reconnecting the battery, connect the positive cable first and then negative cable, and replace the terminal cover on the positive terminal.

When performing service to electrical parts, if the service procedures do not require use of battery power, diconnect the negative cable at the battery.

Tighten cylinder head and case bolts and nuts, beginning with larger diameter and ending with smaller diameter, from inside to outside diagonally, to the specified tightening torque.

Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, cotter pins, circlips, and certain other parts as specified, be sure to replace them with new ones. Also, before installing these new parts, be sure to remove any left over material from the mating surfaces.

Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than required to slip the circlip over the shaft. After installing a circlip, always ensure that it is completely seated in its groove and securely fitted.

Do not use self-locking nuts a few times over.

Use a torque wrench to tighten fasteners to the torque values when specified. Wipe off grease or oil if a thread is smeared with them.

After reassembly, check parts for tightness and operation.

To protect environment, do not unlawfully dispose of used motor oil and other fluids: batteries, and tires.

To protect Earth ’ s natural resouces, properly dispose of used vehicles and parts.

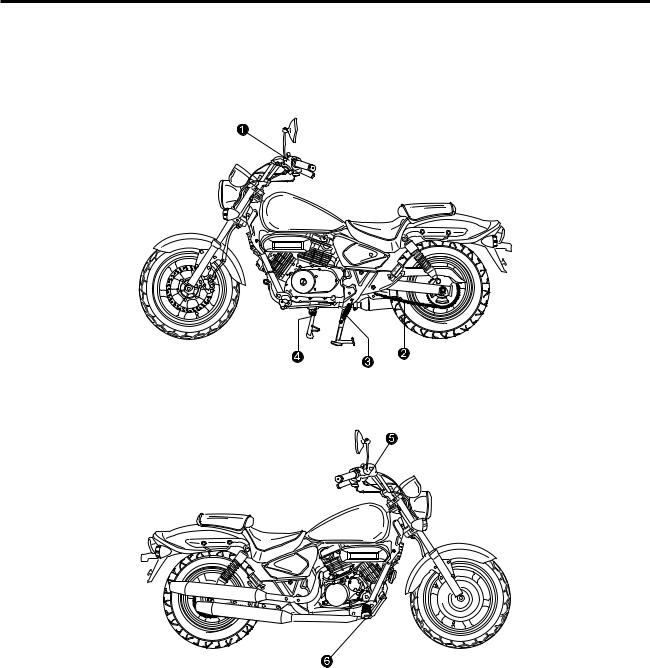

1-3 GENERAL INFORMATION

* Difference between photographs and actual motorcycles depends on the markets.

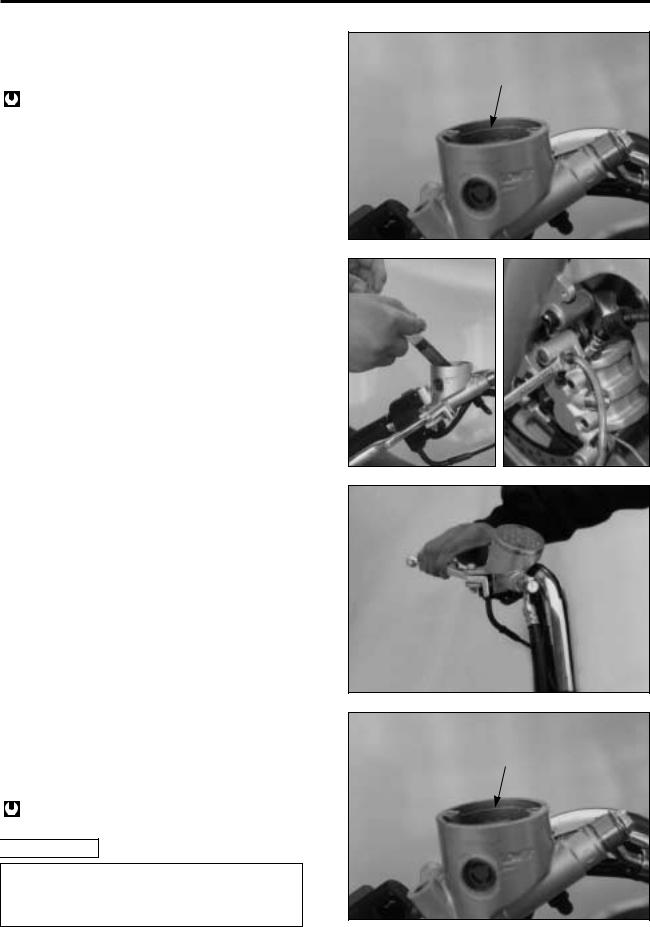

SERIAL NUMBER LOCATION

The frame serial number or V.I.N. (Vehicle Identification Number) is stamped on the steering head tube. The engine serial number is located on the left upside of crankcase assembly.

These numbers are required especially for registering the machine and ordering spare parts.

GENERAL INFORMATION 1-4

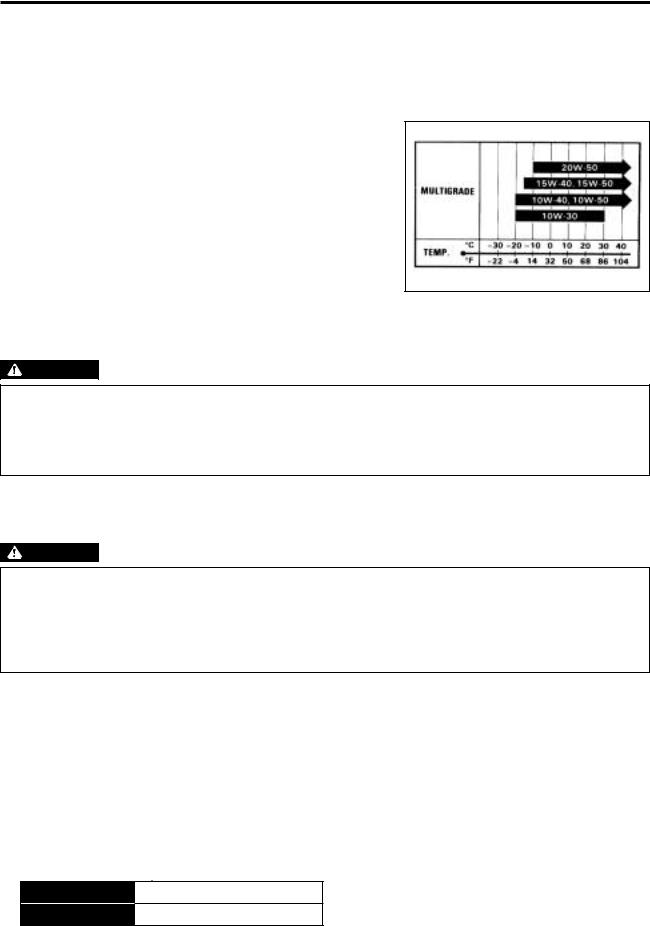

FUEL AND OIL RECOMMENDATION

Gasoline used should be graded 91 octane (Research Method) or higher. An unleaded gasoline type is recommended.

■ ENGINE OIL SPECIFICATION

If an SAE 10W-40 motor oil is not available, select an alternative according to the following chart.

Use a premium quality 4-stroke motor oil to ensure longer service life of your motorcycle.

Don t mix the unrecommended oil. It could damage the engine.

When refilling the oil tank, don t allow the dust to get inside.

Mop the oil spilt.

Don t put the patch on the cap. It could disturb the oil to be provided and damage the engine.

BRAKE FLUID

Specification and classification: DOT3 or DOT4

Since the brake system of this motorcycle is filled with a glycol-based brake fluid by the manufacturer, do not use or mix different types of fluid such as silicone-based and petroleum-based fluid for refilling the system, otherwise serious damage will result.

Do not use any brake fluid taken from old or used or unsealed containers.

Never re-use brake fluid left over from a previous servicing, which has been stored for a long period.

FRONT FORK OIL

Use fork oil : TELLUS #22

BREAK-IN PROCEDURES

During manufacture only the best possible materials are used and all machined parts are finished to a very high standard but it is still necessary to allow the moving parts to“BREAK-IN”before subjecting the engine to maximum stresses. The future performance and reliability of the engine depends on the care and restraint exercised during its early life. The general rules are as follows:

● Keep to these break-in procedures:

Initial 800km Less than 1/2 throttle

Up to 1,600km Less than 3/4 throttle

1-5 GENERAL INFORMATION

● Upon reaching an odometer reading of 1,600 km you can subject the motorcycle to full throttle operation.

● Do not maintain constant engine speed for an extended period during any portion of the break-in. Try to vary the throttle position.

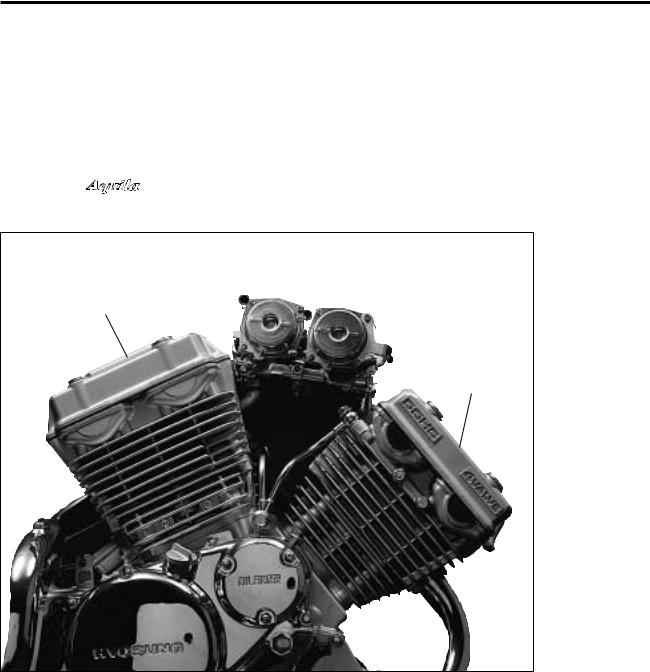

CYLINDER CLASSIFICATION

basis of the motorcycle ahead.

Rear cylinder

Front cylinder

GENERAL INFORMATION 1-6

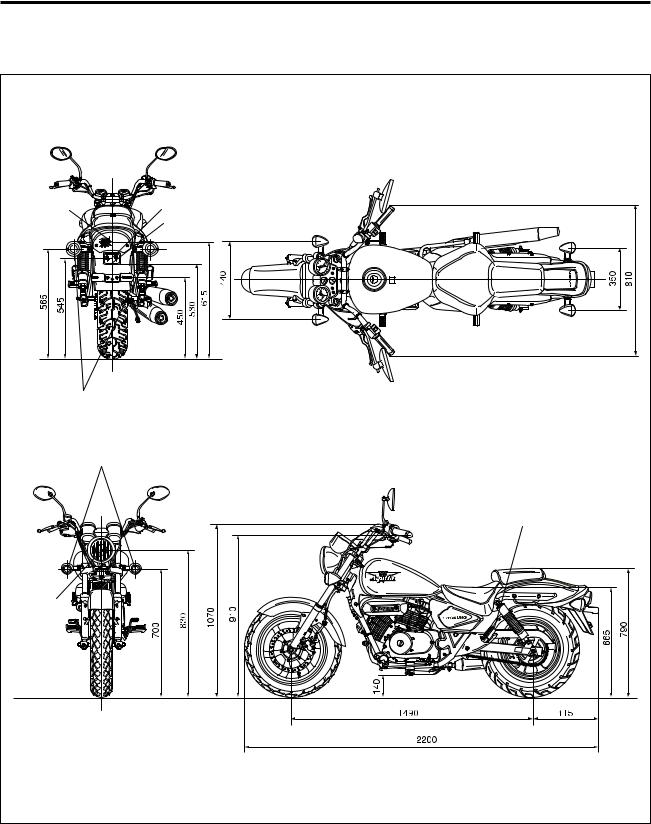

EXTERIOR ILLUSTRATION

1-7 GENERAL INFORMATION

SPECIFICATIONS

DIMENSIONS AND DRY MASS

TRANSMISSION

The specifications are subject to change without notice.

2-1 PERIODIC MAINTENANCE

PERIODIC MAINTENANCE SCHEDULE

The chart below lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy.

More frequent servicing should be performed on motorcycles that are used under severe conditions.

PERIODIC MAINTENANCE CHART

PERIODIC MAINTENANCE 2-2

LUBRICATION POINT

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated below.

∙ Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or grime.

∙ Lubricate exposed parts which are subject to rust, with either motor oil or grease whenever the motorcycle has been operated under wet or rainy condition.

2-3 PERIODIC MAINTENANCE

MAINTENANCE PROCEDURE

This section describes the service procedure for each section of the periodic maintenance.

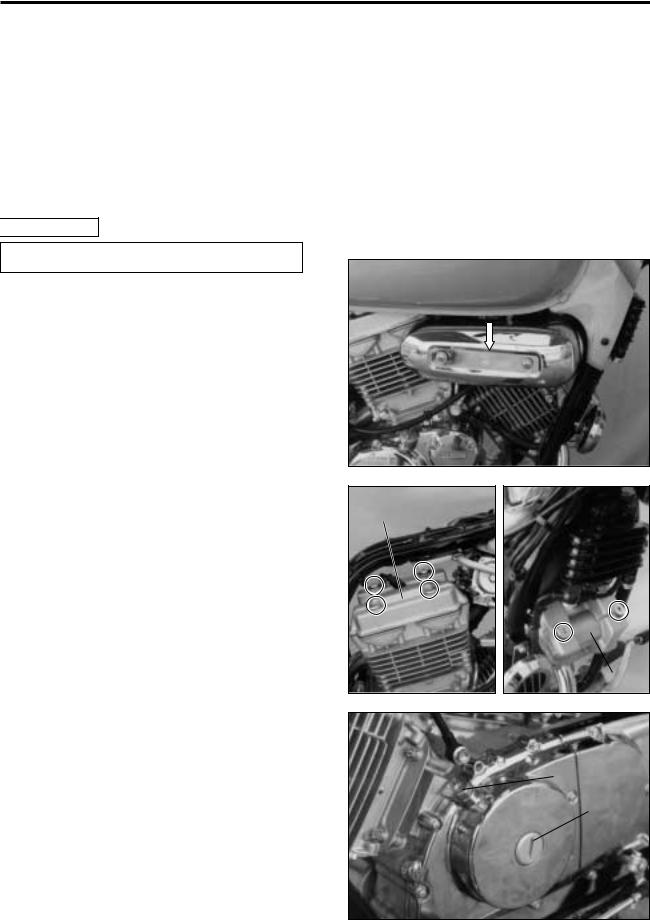

VALVE CLEARANCE

Inspect Initial 1,000 km and Every 4,000 km.

The clearance specification is for COLD state.

The valve clearance specification is different for intake and exhause valves.

Valve clearance adjustment must be checked and adjusted, 1) at the time of periodic inspection, 2) when the valve mechanism is serviced, and 3) when the camshaft is disturbed by removing it for servicing.

● Remove the spark plug. (Refer to page 2-5)

● Remove the right air cleaner box.

● Remove the fuel tank. (Refer to page 4-1)

● Remove the cylinder head cover and .

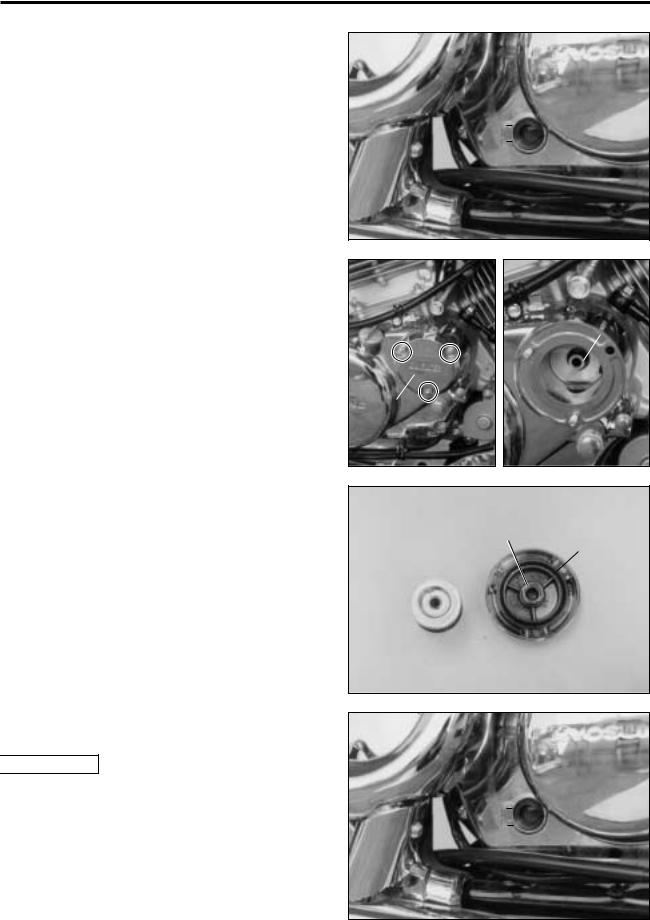

● Remove the magneto cover plug and the timing inspection plug .

PERIODIC MAINTENANCE 2-4

● Rotate the magneto rotor to set the front cylinder’s piston at TDC (Top Dead Center) of the compression

(Rotate the rotor until“ F”line on the rotor is aligned with the center of hole on the crankcase.)

● To inspect the front cylinder’s valve clearance, insert the thickness gauge to the clearance between the camshaft and the tappet.

Valve clearance (when cold)

Thickness gauge : 09900-20806

● If the clearance is out of specification, first remove the cam chain tensioner, camshaft housing, camshaft.

To install the tappet shim at original position, record the shim NO. and clearance with“A”,“B”,“C”,“D” mark on the cylinder head as the illustration.

Select the tappet that agree with tappet clearance (vertical line) and shim NO.(horizontal line) as refer to the tappet shim selection chart. (Refer to page 7-25, 26)

Adjust valve timing, install the camshaft housing and the tensioner.

After the crankshaft rotate about 10 times, measure the valve clearance.

If the clearance be not agree, adjust the standard clearance as the same manner above.

● In case that valve adjustment which there is no the tappet shim selection chart, please follow instructions of example in the below.

For example, the intake clearance is 0.4 and the shim is 170 (1.70 mm), select 195 (1.95 mm) of the shim which 170 (1.70 mm) of the shim add up the excess clearance 0.25 mm when adjust with the standard 0.15 as the intake standard clearance 0.1 0.2 mm.

Valve clearance should be checked when the engine is cold.

If you don t rotate the crankshaft about 10 times before measuring the valve clearance, there is no meaning of valve clearance.

2-5 PERIODIC MAINTENANCE

● Rotate the magneto rotor to set the rear cylinder’s piston at TDC(Top Dead Center) of the compression stroke.

(Rotate the rotor 285 counter-clockwise from the

“ F”line, and until the“ R”line on the rotor is aligned with the center of hole on the crankcase.)

● Inspect the rear cylinder’s valve clearance with the same manner of the front cylinder.

Clean Initial 1,000 km and Every 4,000 km,

Replace Every 8,000 km.

● Disconnect the spark plug caps.

● Remove the spark plugs.

Remove the carbon deposite with wire or pin and adjust the spark plug gap to 0.7 0.8 mm, measuring with a thickness gauge.

Check to see the worn or burnt condition of the electrodes.

If it is extremly worn or burnt, replace the plug.

And also replace the plug if it has a broken insulator, damaged thread, etc.

● Install the spark plug, and then tighten it to specified torque.

Spatk plug : 20~25 N ∙ m (2.0~2.5 kg ∙ m)

PERIODIC MAINTENANCE 2-6

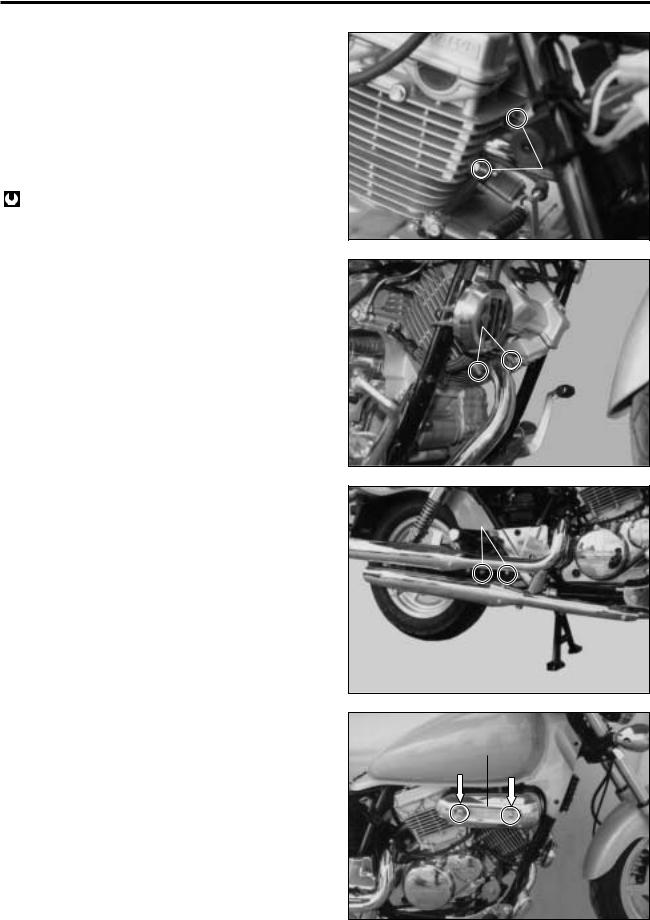

EXHAUSE PIPE NUT AND MUFFLER MOUNTING BOLT

Tighten Initial 1,000 km and Every 4,000 km.

● Tighten the exhaust pipe nuts , and muffler mounting bolts to the specified torque.

Exhaust pipe nut

: 18~28 N ∙ m (1.8~2.8 kg ∙ m)

Muffler mounting bolt

: 20~30 N ∙ m (2.0~3.0 kg ∙ m)

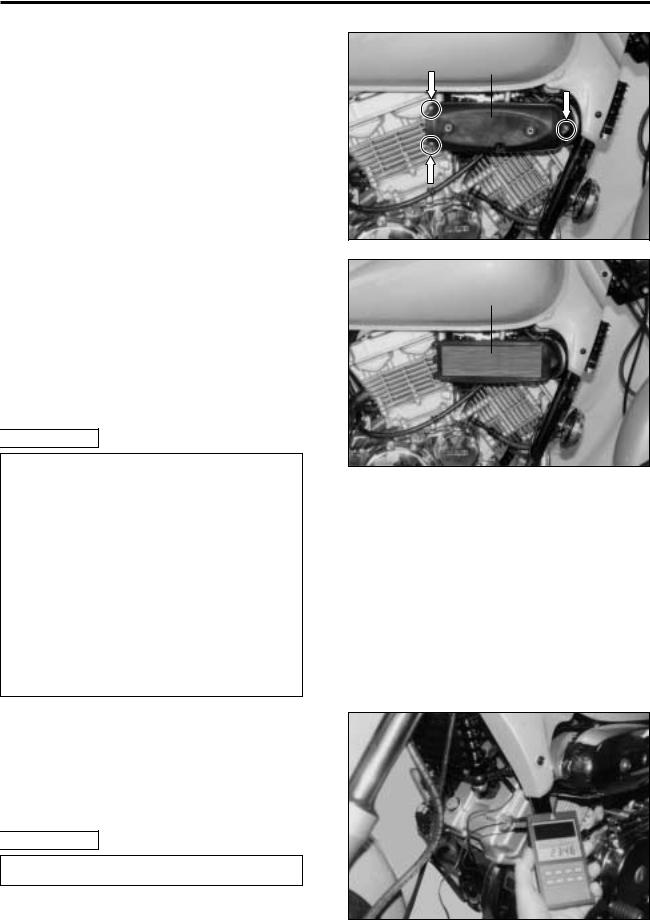

AIR CLEANER

Clean Every 3,000 km.

● Remove the air cleaner box cover .

2-7 PERIODIC MAINTENANCE

● With the three of air cleaner cap mounting bolts removed, remove the air cleaner cap .

● Remove the air cleaner element .

● Clean the air cleaner element with the air gun.

Always apply air pressure to the inside of the air cleaner element only.

A torn air cleaner element will allow dirt to enter the engine and can damage the engine. Carefully examine the air cleaner element for tears during cleaning.

Replace it with a new one if it is torn.

Failure to position the air cleaner element properly can allow dirt to bypass the air cleaner element.

This will cause engine damage.

Be sure to properly install the air cleaner element.

Make this inspection when the engine is hot.

PERIODIC MAINTENANCE 2-8

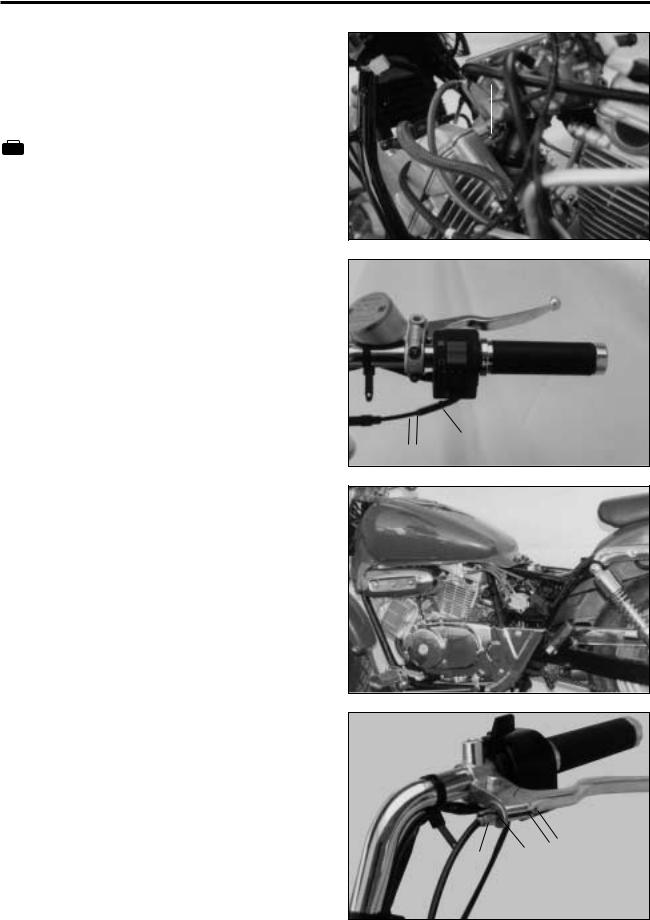

● Connect an engine tachometer to the high tension cord.

THROTTLE CABLE PLAY

There should be 0.5 1.0 mm play on the throttle cable. To adjust the throttle cable play.

● Tug on the throttle cable to check the amount of play.

● Loosen the lock nut and turn the adjuster in or out until the specified play is obtained.

● Secure the lock nuts while holding the adjuster in place.

Inspect Initial 1,000 km and Every 4,000 km, Replace every 4 years.

● Remove the left frame cover. (Refer to page 6-2) Inspect the fuel hoses for damage and fuel leakage. If any defects are found, the fuel hoses must be replaced.

Clutch play should be 4 mm as measured at the clutch lever holder before the clutch begins to disengage. If the play in the clutch is incorrect, adjust it in the following way :

● Loosen the lock nut and screw the adjuster on the clutch lever holder all the way in.

● Loosen clutch cable adjuster lock nut .

● Turn the clutch cable adjuster in or out to acquire the specified play.

● Tighten lock nut while holding the adjuster in position.

● The clutch cable should be lubricated with a light weight oil whenever it is adjusted.

2-9 PERIODIC MAINTENANCE

GEARSHIFT LEVER HEIGHT ADJUSTMENT

● Loosen the lock nut .

● With the link rod turned, adjust the gearshift lever height.

Replace Initial 1,000 km and Every 4,000 km.

Necessary amount of engine oil

Oil should be changed while the engine is warm. Oil filter replacement at the above intervals, should be together with the engine oil change.

● Keep the motorcycle upright.

● Place an oil pan below the engine, and drain the oil by removing the filter cap and drain plug .

● Tighten the drain plug to the specified torque, and pour fresh oil through the oil filter. Use an API classification of SF or SG oil with SAE 10 40 viscosity.

Oil drain plug : 18~20 N ∙ m (1.8~2.0 kg ∙ m)

PERIODIC MAINTENANCE 2-10

● Start up the engine and allow it to run for several minutes at idling speed.

● Turn off the engine and wait about three minutes, then check the oil level through the inspection window. If the level is below mark“F”, add oil to“F”level.

● Install the new O-ring .

● Install the new oil filter.

● Install the new O-ring and spring to the oil filter

Before installing the oil filter cap, apply engine oil lightly to the new O-ring .

● Add new engine oil and check the oil level as described in the engine oil replacement procedure.

2-11 PERIODIC MAINTENANCE

DRIVE CHAIN

Clean and Lubricate Every 1,000 km.

Visually check the drive chain for the possible defects listed below. (Support the motorcycle by the center stand, turn the rear wheel slowly by hand with the transmission shifted to Neutral.)

● Loose pins

● Excessive wear

● Damaged rollers

● Improper chain adjustment

● Dry or rusted links

● Kinked or binding links

If any defects are found, the drive chain must be replaced.

When replacing the drive chain, replace the drive chain and sprocket as a set.

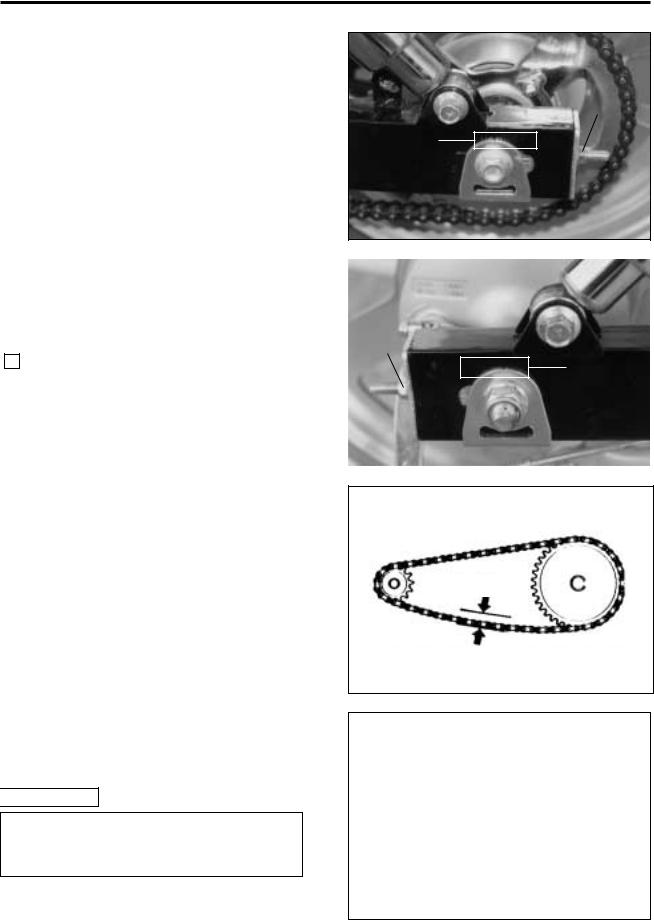

● Loose the axle nut.

● Loose the rear torque link nuts.

● Tense the drive chain fully by turning both chain adjusters , .

● Count out 21 pins (20 pitches) on the chain and measure the distance between the two points. If the distance exceeds the service limit, the chain must be replaced.

Service limit

Drive chain 20-pitch length

PERIODIC MAINTENANCE 2-12

● Loosen or tighten both chain adjusters , until the chain has 20 30 mm of slack in the middle between the engine and rear sprockets. The marks, on both chain adjusters must be at the same

● Recheck the drive chain slack after tightening the axle nut.

● Wash the drive chain with kerosine. If the drive chain tends to rust quickly, the intervals must be shortened.

● After washing and drying the chain, oil it with a engine oil.

The standard drive chain is a 428HO Hyosung recommends that this standard drive chain should be used for the replacement.

2-13 PERIODIC MAINTENANCE

BRAKE SYSTEM

[ BRAKE HOSE & BRAKE FLUID ]

Inspect Initial 1,000 km and Every 4,000 km. Replace the brake hoses Every 4 years, Replace the brake fluid Every 2 years.

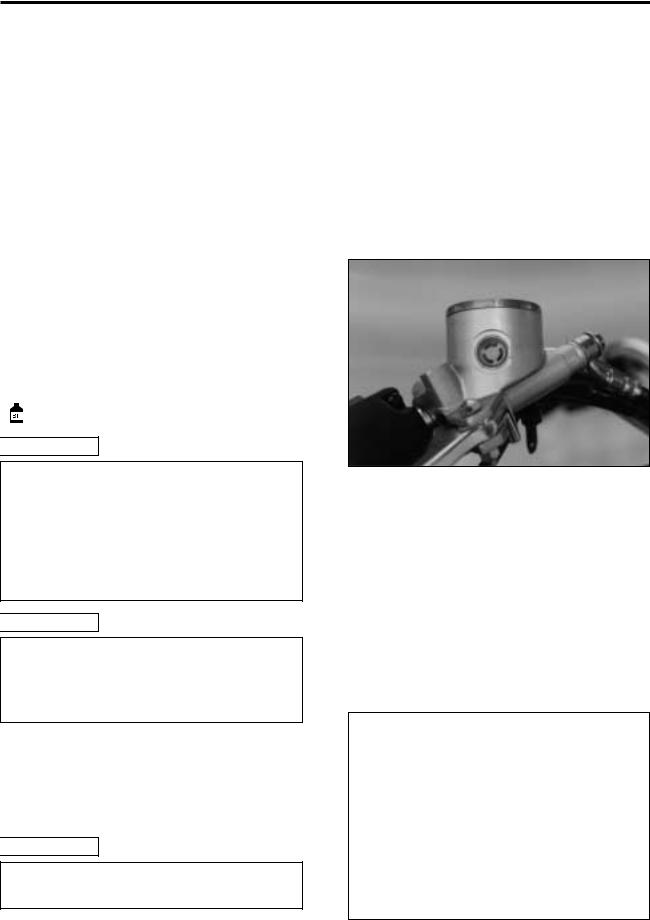

BRAKE FLUID LEVEL CHECK

● Keep the motorcycle upright and place the handlebars straight.

● Check the brake fluid level by observing the lower limit line (LOWER) on the front brake fluid reservoir.

● When the level is below the lower limit line (LOWER), replenish with brake fluid that meets the following specification.

Specification and Classification : DOT 3 or DOT 4

The brake system of this motorcycle is filled with a glycol-based brake fluid. Do not use or mix different types of fluid such as silicone-based or petroleum-based. Do not use any brake fluid taken from old, used or unsealed containers.

Never re-use brake fluid left over from the last servicing or stored for a long period.

Brake fluid, if it leaks, will interfere with safe running and immediately discolor painted surfaces. Check the brake hoses and hose joints for cracks and oil leakage before riding.

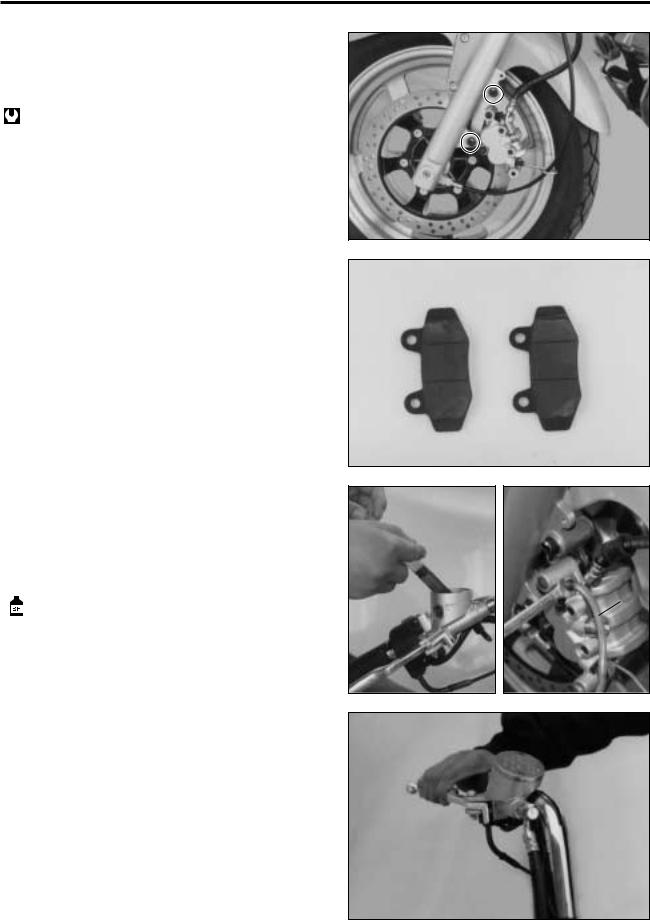

BRAKE PAD WEAR

The extend of brake pad wear can be checked by observing the grooved limit on the pad. When the wear exceeds the grooved limit, replace the pads with new ones.

Replace the brake pad as a set, otherwise braking performance will be adversely affected.

PERIODIC MAINTENANCE 2-14

FRONT BRAKE PAD REPLACEMENT

● Remove the brake caliper.

● Remove tne brake pads.

● To reassmble, reverse the above sequence.

Brake caliper mounting bolt

FRONT BRAKE FLUID REPLACEMENT

● Place the motorcycle on a level surface and keep the handlebars straight.

● Remove the master cylinder reservoir cap and diaphragm.

● Suck up the old brake fluid as much as possible.

● Fill the reservoir with new brake fluid.

Specification and Classification

: DOT 3 or DOT 4

● Connect a clear hose to the air bleeder valve and insert the other end of the hose into a receptacle.

● Loosen the air bleeder valve and pump the brake lever until the old brake fluid is completely out of the brake system.

2-15 PERIODIC MAINTENANCE

● Close the air bleeder valve and disconnect the clear hose. Fill the reservoir with new brake fluid to the upper line.

Front brake caliper air bleeder valve

:6~9 N ∙ m (0.6~0.9 kg ∙ m)

AIR BLEEDING OF THE BRAKE FLUID

Air trapped in the brake fluid circuit acts like a cushion to absorb a large proportion of the pressure developed by the master cylinder and thus interferes with the full braking performance of the brake caliper. The presence of air is indicated by“sponginess”of the brake lever and also by lack of braking force. Considering the danger to which such trapped air exposes the machine and rider, it is essential that, after remounting the brake and restoring the brake system to the normal condition, the brake fluid circuit be purged of air in the following manner :

● Fill the master cylider reservoir to top of the inspection window. Replace the reservoir cap to prevent dirt from entering it.

● Attach a hose to the air bleeder valve, and insert the free end of the hose into a receptacle.

● Bleed air from the brake system.

● Squeeze and release the brake lever several times in rapid succession and sqeeze the lever fully without releasing it. Loosen the bleeder valve by turning it a quarter of a turn so that the brake fluid runs into the receptacle, this will remove the tension of the brake lever causing it to touch the handlebar grip. Then, close the air bleeder valve, pump and squeeze the brake lever, and open the valve. Repeat this process until the fluid flowing into the receptacle no longer contains air bubbles.

While bleeding the brake system, replenish the brake fluid in the reservoir as necessary. Make sure that there is always some fluid visible in the reservoir.

● Close the air bleeder valve, and disconnect the hose. Fill the reservoir with brake fluid to the upper line.

: 6~9 N ∙ m (0.6~0.9 kg ∙ m)

Handle brake fluid with care : the fluid reacts chemically with paint, plastics, rubber materials, etc.

Upper limit line

JavaScript is disabled

Sorry, your browser does not support JavaScript! Bad luck :( This site, like most others, needs JavaScript to function properly.

Financial aid to Ukraine

Czechs helping Ukraine ... Defence material for the Armed Forces and Militia of Ukraine Will you help, too?

Ukraine's Armed Forces ... Fundraising account to support the Armed Forces of Ukraine.

IMAGES

VIDEO

COMMENTS

hyosung-cruise-125-parts-list.pdf. Menu. Register ... Classifieds; Events; Chat; Members; Our moto; Articles; Videos; Partners; Surveys; Search; Board Financial aid to Ukraine. Czechs helping Ukraine... Defence material for the Armed Forces and Militia of ... hyosung cruise 125 parts list.pdf Repair manuals 3 MB: English ...

User and service manuals for vehicles of all automobiles. All in one place in more than 10 languages. From cars, motorbikes, trucks, buses to tractors. Car Moto Manuals. 121 Automakers; 25 019 Models; Hyosung . All brands; Aixam (65) Alfa Romeo (958) Aprilia (493) Aston Martin (743) ATV (407) Audi (2548) Avia (114) ... Hyosung GA 125 F (Cruise ...

User and service manuals for vehicles of all automobiles. All in one place in more than 10 languages. From cars, motorbikes, trucks, buses to tractors. Car Moto Manuals. 121 Automakers; 24 027 Models; Hyosung . All brands; Aixam (57) Alfa Romeo (603) Aprilia (492) Aston Martin (665) ATV (390) Audi (1562) Avia (111) ... Hyosung GA 125 F (Cruise ...

[Download] GF125 GA125F Cruise 1 & 2 - Service Manuals & Hyosung Owners Books. Forums 🚥 PiT STOP 📥 Service Manuals & Owners Books [Download] GF125 GA125F Cruise 1 & 2 - Service Manuals & Hyosung Owners Books. This topic has 0 replies, 1 voice, and was last updated 6 years ago by ♠️ MARCEL. ... GF 125 📦 - SERVICE MANUAL ...

Download / Read Hyosung service manuals Owners Books for GT125R GT250 TE450 GD250 450 GV650 GV125 & DIY Tutorials Diagrams Hyosung Forums 🏍 ... GT GTR 125 250 R Comet Carby & EFi Service Manual & Hyosung Owners Books. Started by: ♠️ MARCEL. 1; 1; ... GF125 GA125F Cruise 1 & 2 - Service Manuals & Hyosung Owners Books. Started by: ♠️ ...

Summary of Contents for HYOSUNG RX125. Page 1 Proper break-in operation during this time will help ensure maximum life and performance WARNING from your new motorcycle. Hyosung parts are manufactured of high quality The personal safety of the rider may be materials, and manufactured parts are finished involved.

Manuals Hyosung GA 125 F (Cruise II) Upload new manual. Repair manuals (1) Add. Model Year Document Language Size Pages; GA 125 F (Cruise II) hyosung cruise 125 parts list.pdf English: 3 MB: 100 Videos Hyosung GA 125. Our vehicles Hyosung GA 125 F (Cruise II) Add a vehicle. 1999 Hyosung ...

Hyosung Comet 250 R User Manual (82 pages) Hyosung bike. Fuel and Oil Recommendation Names of each Parts Starting the Engine Clutch Cable Specifications. Manual is suitable for 2 more products: Comet 125 R Comet 125. Brand: Hyosung | Category: Motorcycle | Size: 3.81 MB.

Our GA125 Cruise Hyosung workshop manuals contain in-depth maintenance, service and repair information. Get your eManual now! Toggle Nav ... HYOSUNG CRUISE 125 GA125F Parts Manual Catalog . $18.99. 1 Item . Show. per page. Cruise. GA125. Catalogue . Rated on average 4.5 out of 5 stars.

View and Download HYOSUNG GF125 service manual online. Hyosung GF125 Motorcycle Service manual. GF125 motorcycle pdf manual download. Sign In Upload. Download ... GENERAL INFORMA TION 1-2 SPECIAL FEATURES HYOSUNG GF 125 is a improved model that has been revised from 2 valve evgine of GF 125 to 4 valve engine and has much more developed features ...

The 1999 Hyosung Cruise II 125 and all other motorcycles made 1894-2024. Specifications. Pictures. Rating. Discussions. ... Find parts, fluids. filters, maintenance tools and service manuals at Amazon.com. Ask questions: Join the 99 Hyosung Cruise II 125 discussion group or the general Hyosung discussion group. Related bikes:

Hyosung Cruise II 125 Workshop Manuals. If you want to accomplish maintenance on your own Hyosung Cruise II 125 then it is usually a good plan to possess a Workshop Manual to use as reference should you need to know simple methods to take off a certain component for example, the Clutch and fit it again accordingly. ... Moto Morini 350 K 2;

View and Download HYOSUNG GT 125 R manual online. GT 125 R motorcycle pdf manual download. Also for: Gt 250 r, Comet 250r, Comet 125r, Comet 250, Comet 125.

Hyosung Motorcycles, Scooter's and ATVs: Service Repair Manuals & Owner's Manual PDF. Hyosung GT650. Full factory workshop & service manual.pdf. Hyosung, a South Korean company, began operations in 1952 as a manufacturer of computers and semi-finished products. She opened a motorcycle manufacturing department in 1978.

HYOSUNG Motorcycle Service Manuals PDF download free - GT650, GV650, GT125 Comet, GV250, Prima, Aguila, GF125; Hyosung Motorcycles History ... Hi I'm looking for a workshop manual for KSR Moto race 125 GT. If any one has an idea.. #851. Eric beck (Wednesday, 15 June 2022 06:02)

2. BATTERY INSTALLATION ① Fill the electrolyte to the battery. ② Leave the battery for 30 minutes. ③ Charge the battery by standard charging. This is necessary for reliability of the battery. Page 3 FOREWORD Thank you for choosing a Hyosung motorcycle.

Comet 125: manual de propietario comet 125 125r 250 250r espanol.pdf User's manuals 4 MB: Spanish 84 Aquila GV 650: comet gt650 efi aquilla gv650efi service manual.pdf Repair manuals 3 MB: English 90 GT 250: gt250rsm.pdf User's manuals 4 MB: English

The Hyosung Cruise II 125 has 14.30 HP (10.4 kW) @ 8600 RPM. How fast is a Hyosung Cruise II 125? The Hyosung Cruise II 125 top speed is 111.0 km/h (69.0 mph). How tall (seat height) is a Hyosung Cruise II 125? The Hyosung Cruise II 125 seat height is 740 mm (29.1 inches) If adjustable, lowest setting. How many gears does a Hyosung Cruise II ...

CAMSHAFT HOLD ② Apply HYOSUNG MOLY PASTE to the rocker arm ④ shafts ⑤, then inserting the camshaft hold. Install the rocker arm spring ③, rocker arm ④... Page 55 3-25 ENGINE Fit the two dowel pins and install the camshaft holder ①. ① Tighten the camshaft holder nuts diagonally to the specified.

View and Download HYOSUNG COMET 125 service manual online. COMET 125 motorcycle pdf manual download. Also for: Comet 250, 2002 comet 125, 2002 comet 250, 2002 gt 250 naked, 2002 gt 125 naked, Comet 125.

1-5 GENERAL INFORMATION. Upon reaching an odometer reading of 1,600 km you can subject the motorcycle to full throttle operation. Do not maintain constant engine speed for an extended period during any portion of the break-in. Try to vary the throttle position.