Serving your CDL Learner Permit requirement needs

- Oklahoma CDL Permit Training Program

- | 2024 OK CDL Skills Tests

- OK CDL Pre-Trip Inspection

Oklahoma CDL Pre-Trip Checklist Vehicle Inspection (Walk-Around) Skills Test

First of three oklahoma cdl skills tests - the oklahoma cdl vehicle checklist inspection skills test must be passed prior to being allowed to continue., there are three parts to the oklahoma cdl skills test.

- First Part: Oklahoma CDL PreTrip Inspection on THIS page . . .

- Second Part: Oklahoma CDL Basic Vehicle Control

- Third Part: Oklahoma CDL Road Test

Oklahoma CDL Pre Trip Inspection Diagram

Vehicle Pre-Trip Checklist Inspection - Oklahoma CDL Skills Tests:

Quick study guide to oklahoma cdl pre-trip inspection.

- Engine Compartment

- Cab Check and Engine Start

- Brake Check

- External Cab

1. Oklahoma CDL Engine Compartment Pre-Trip Inspection

- Look for puddles on the ground that would indicate a leak.

- Look for dripping fluids on the underside of the engine and transmission.

- Inspect hoses for "good" condition and leaks.

- Indicate the location of dipstick.

- Make sure the oil level is within safe operating range and above the refill mark.

- a) Checking the reservoir sight glass, or

- b) Removing the radiator cap if the engine is not hot and visually checking the coolant level.

- Indicate the location of the power steering fluid dipstick.

- Confirm that there is an adequate power steering fluid level that is above the refill mark.

- power steering belt

- water pump belt

- alternator belt

- air compressor belt

2. Oklahoma CDL Cab Check and Engine Start - Pre-Trip Inspection

- Manual Transmissions:

- Depress the clutch.

- Place the gearshift lever in neutral.

- Start the engine and then slowly release the clutch.

- Automatic Transmissions:

- Confirm the vehicle is in �park� and start the engine.

- Confirm that the oil pressure gauge is functioning.

- Make sure that the pressure gauge shows increasing or normal oil pressure, otherwise that the warning light goes off.

- If equipped with an oil temperature gauge, it should begin to gradually rise to a normal operating range.

- Confirm that the temperature gauge is working.

- The temperature gauge should begin to climb to the normal operating range.

- The gauges should show the alternator and/or generator charging; otherwise the warning light should be set off.

- Check for proper operation and acceptable readings on the air and vacuum gauges.

- The speedometer should not be obscured or obviously broken.

- Mirrors should be clean and adjusted properly from the inside.

- Windshield should be clean with no illegal stickers, obstructions, or damage to the glass.

- Three red reflective triangles.

- One properly charged and rated fire extinguisher.

- Spare electrical fuses.

- Power steering equipped vehicles: With the engine running, play should not exceed 10 degrees (or about two inches on a 20-inch wheel) before the front left wheel barely moves when you turn the steering wheel back and forth.

- Non-power steering vehicles: Play should not exceed 10 degrees (or about two inches on a 20-inch wheel) when you turn the steering wheel back and forth.

- Check that the wiper arms and blades are not damaged and operate smoothly.

- Windshield washers must operate correctly if the vehicle is equipped.

- Left turn signal

- Right turn signal

- 4-way emergency flashers

- High beam headlight

- Check that air horn and/or electric horn are operational.

- Test that the heater and defroster works.

- Check that the safety belt is securely mounted, adjusts, and latches properly.

- Clearance lights (red on rear, amber elsewhere)

- Headlights (high and low beams)

- Turn signals

- 4-way flashers

- Brake lights

- Red reflectors (on rear) and amber reflectors (elsewhere)

3. Oklahoma CDL Brake Check Pre-Trip Inspection

- Apply parking brake only and shift into a lower gear. Gently pull against the brake by releasing the clutch, and it should hold the vehicle.

- With the engine running, apply the foot brake and hold for five seconds. The pedal should not move (lose pressure) during those five seconds.

- If equipped with a hydraulic brake reserve system, with the key in the off position, depress the brake pedal and listen for the sound of the reserve system electric motor turning on.

- Check that the warning buzzer and light is off.

- Check the proper operation of the foot brake by moving the vehicle forward slowly at about 5 mph and applying the brake firmly.

- With a fully-charged air system, typically at 120 psi, turn the engine off, chock the wheels, release (push in) the parking brake button and trailer air supply button (for combination vehicles) and time the air pressure drop. After the initial drop, the rate of pressure loss should not be more than 2 psi per minute for single vehicles and no more than 3 psi per minute for combination vehicles

- Release (push in) the parking brake and trailer air supply button (for combination vehicles), and apply pressure to the foot brake. After the initial drop in pressure, the rate of pressure loss should be no more than 3 psi per minute for single vehicles and no more than 4 psi per minute for combination vehicles.

- Turn the key to the on position. Rapidly depress and release the foot brake to reduce air tank pressure. The low air pressure warning signal must come on before the pressure drops below 60 psi.

- Continue to rapidly apply and release the service brake pedal further reducing air pressure. The trailer air supply button (for combination vehicles) and parking brake button should pop out when the pressure falls to usually between 20 to 40 psi. This should activate the spring brakes.

- While the engine is operating at 1800 RPM, the pressure should rise from 85 to 100 psi within 45 seconds in dual air systems.

- With normal air pressure, release the parking brake and trailer air supply button (for combination vehicles), move the vehicle forward slowly at about 5 mph and apply the brakes firmly using the brake pedal. Test for any pulling to any one side or delayed stopping action.

4. Oklahoma CDL External Cab | Truck | Bus Pre-Trip Inspection

- Check that the steering box is mounted securely and is not leaking.

- Check for damage to power steering hoses and power steering fluid leaks.

- Check that connecting links, arms, and rods from the steering box to the wheels are not worn and cracked.

- Check that the joints and sockets are not loose or worn and that there are no missing nuts, bolts, or cotter keys.

- Check for shifted, cracked, broken, or even missing leaf springs.

- Check for broken and distorted coil springs.

- If equipped, check the air ride suspension for damage and leaks.

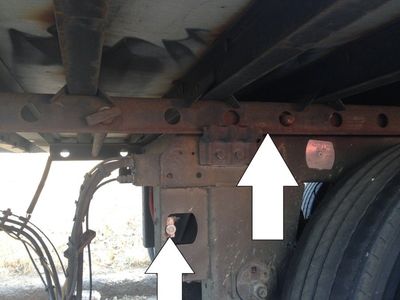

- Look for cracked or broken spring hangers, missing or damaged bushings, and broken, loose, or missing bolts, U-bolts or other axle mounting parts.

- Confirm that the shock absorbers are secure and that there are no leaks.

- Look for missing, loose or broken parts.

- The angle between the adjuster arm and push rod should be not less than 90 degrees when the brakes are applied and when the brakes are released a little over 90 degrees.

- When pulled by hand, the brake rod should not move more than one inch with the brakes released.

- Check that brake chambers are not dented, cracked, or leaking and that they are mounted securely.

- Check for worn, cracked or leaking hoses, lines, and couplings.

- Check for dents, cracks or holes, and loose or missing bolts.

- Brake linings and pads should not be worn thin.

- Where visible, check that a reasonable amount of brake lining is showing.

- Check for damaged or bent rims. Rims cannot have welding repairs.

- Tread depth: need a minimum tread depth of 4/32 on steering axle tires, 2/32 on all other tires.

- Tire condition: Check that tread is evenly worn and without cuts or damage to tread or sidewalls. Valve caps and stems should not be missing, broken, or damaged.

- Tire inflation: Check for proper inflation with a tire gauge or by striking tires with a mallet.

- Check that hub oil/grease seals and axle seals are not leaking.

- Check for any missing lug nuts, cracks, distortions, and for signs of looseness such as rust trails or shiny threads.

- Check for cracked or distorted bolt holes.

- Spacers should not be bent, damaged, or rusted through.

- Spacers should be centered evenly.

- Check doors for any damage and that they open and close properly.

- Hinges should be secure with seals intact.

- Mirrors and mirror brackets should be mounted securely.

- Check for secure tanks, tight caps, and that the tanks or lines don�t leak.

- Check to see that batteries are secure, for tight cable connections, and that cell caps are present.

- Check for signs of excessive corrosion.

- Battery box and cover/door must be secure.

- The drive shaft should not be bent or cracked.

- Couplings should be secure.

- Check system for rust or carbon soot as they are signs of damage or leaks.

- System should be secure and connected tightly.

- Check the longitudinal frame members, cross members, box, and floor for cracks, broken welds, holes or other damage.

- If equipped with mud flaps or splash guards, check that they are mounted securely and not damaged.

- Doors and hinges must open, close, and latch properly from the outside, and should not be damaged.

- Check that any ties, straps, chains, and binders are secure.

- If equipped with a cargo lift, it must be fully retracted and latched securely, and should not be leaking, damaged or missing any parts.

- Check that electrical lines and air hoses are not cut, chafed, spliced, or worn, the steel braid should not show through its outer lining.

- Make sure the lines and hoses are not tangled or dragging against tractor parts.

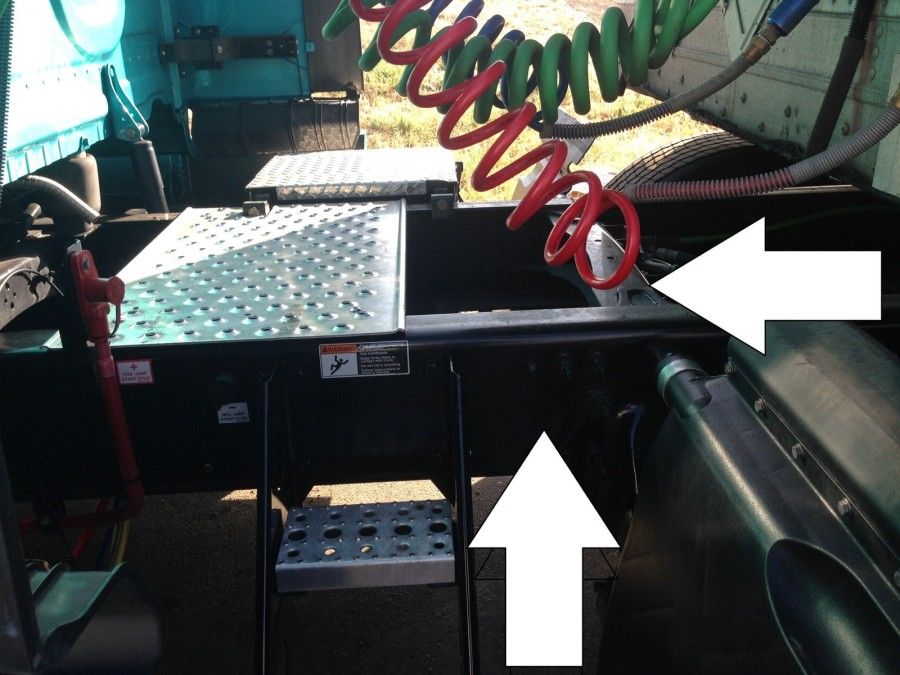

- Make sure the catwalk is securely bolted to tractor frame.

- Check for loose or missing mounting brackets, clamps, bolts, or nuts. The fifth wheel and the slide mounting must be solidly attached.

- Other types of coupling systems should be inspected for missing or broken components.

- Check that the locking jaws fully close around the kingpin

- On other types of coupling systems the locking mechanism should not have missing or broken parts and should lock securely.

- The platform structure supporting the fifth wheel skid plate should be free of cracks or breaks.

- If equipped with a release arm, check that it engaged and that the safety latch is in place.

- The kingpin should not be bent.

- The visible part of the apron should not be bent, cracked, or broken.

- The trailer should be laying flat on the fifth wheel skid plate without any gap.

- Locking pins should be fully engaged.

- The fifth wheel should be positioned so the tractor frame will not strike the landing gear or the tractor.

5. Oklahoma CDL Trailer Pre-Trip Inspection

- The trailer air connectors should be sealed and in good condition.

- Glad hands should be locked in place and free of damage or air leaks.

- The trailer electrical plug should be firmly seated and locked in place.

- If equipped with a header board, check to see that it is secure, damage-free and strong enough to contain cargo.

- If equipped with a canvas or tarp carrier, it should be mounted and fastened securely.

- Check the front area of enclosed trailers for cracks, bulges or holes.

- The landing gear must be fully raised. Check that it has no missing parts with a non-damaged support frame and that the crank handle is secure.

- Check for air or hydraulic leaks if power operated.

- Check that doors are not damaged and that they open, close, and latch properly from the outside.

- Ties, straps, chains, and binders should be secure.

- Any cargo lifts should be checked for leaking, damaged or missing parts, and should be fully retracted and latched securely.

- The frame, cross members, box, and floor should be checked for holes, cracks, broken welds or other damage.

- If equipped, make sure that the release arm is secured and that the locking pins are locked in place.

- Suspension System

- Doors, Ties and Lift

- Splash Guards

Are YOU ready to get YOUR Oklahoma CDL? Prepare for YOUR Oklahoma CDL Tests NOW . . .

- In separate study modules - you won't need all of them - don't waste time on what you don't require.

- 670 practice Oklahoma CDL test questions with actual answers.

- Access to CDL videos covering written and skills tests.

- CDL study guide in both text and audio - listen as you read along .

- CDL study Quick Reviews.

- Interactive online CDL Quizzes.

- and much more!

- Help center

- Send email

- Premium Login

- Car

- CDL (Commercial Vehicles)

- Motorcycle

- Last-Minute DMV Tips

- Driving Tips

- Help Center

Your Progress

- 0 Incorrect ( 4 allowed to pass )

- 0 Correct

- Answer popularity

- Font size Default A A

- Keyboard shortcuts Shift + ?

How to Pass The First Time

- Practice with the Free tests

- Unlock 67 Premium tests

- Review our Premium Cheat Sheets

or we return 100% of your money

- Back to all tests

- View Handbook

Free OK CDL Pre-Trip Inspection Practice Exam

- Perfect for first-time and renewal CDL/CLP applicants, and those adding endorsements

- Based on 2024 OK commercial driver's license manual

- Triple-checked for accuracy

- Updated for April 2024

About this test

This CDL practice test is a great place to start if you’re after the OK Pre-Trip Inspection endorsement. Each of the 20 questions is based on the official 2024 CDL manual . The test is designed to prepare you for the Pre-Trip Inspection portion of your 2024 Commercial Driver’s License exam. There are several answer options, but only one of them is correct. Every time you answer a question, you’ll get immediate feedback with a detailed explanation, so you won’t need to wait until the end of the test to know the correct answers.

Thoroughly prepare for your CDL Pre-Trip Inspection with our detailed guide, offering step-by-step procedures and essential tips at our Pre-Trip Inspection section .

What to expect on the actual OK CDL exam

correct answers to pass

passing score

Helpful links

OK DMV website

Official Oklahoma CDL manual (2024)

More OK CDL Pre-Trip Inspection Resources

- OK CDL Pre-Trip Inspection Test

- OK CDL Pre-Trip Inspection Test 2

- OK CDL Pre-Trip Inspection Test 3

- OK CDL Pre-Trip Inspection Test 4

- OK CDL Pre-Trip Inspection Marathon

- OK CDL Pre-Trip Inspection Exam Simulator

Your trusted source for driver education

Our commitment to accuracy and quality in our practice tests.

Explore our rigorous, multi-tiered verification process that ensures each question mirrors the official manual for unparalleled accuracy.

At Driving-Tests.org, we understand the importance of reliable and accurate practice tests to help you prepare for your DMV exam. That's why we've developed a meticulous process to create and continually update our practice questions, ensuring they reflect the most current driving laws and regulations.

Here's an inside look at how we maintain the highest quality in our practice tests.

Content Creation and Verification Process

- Alignment with Official Manuals: Every question we develop is based on the most recent version of each state's official driving manual. Our team regularly monitors each state DMV's website for the latest updates to ensure our practice tests are always aligned with the most current information.

- Community Feedback Integration: We leverage feedback from our vast community of users to understand which topics are most frequently tested. This helps us focus on the areas that are most relevant and beneficial for your preparation.

- Expert Content Creation: Our in-house editor, Steven , who has extensive experience in driver education, crafts each question with precision. He conducts a thorough review of each question against the official manuals to ensure accuracy.

- Rigorous Review Process: Once Steven has finalized a set of questions, our team conducts a joint review session. This second level of scrutiny involves content accuracy, proofreading, and fact-checking to eliminate any errors.

- User Feedback Mechanism: After a question goes live on our site, we keep the lines of communication open. Each question features a feedback button, inviting users to report any issues or errors. This continuous feedback loop allows us to address and rectify any concerns promptly.

- Responsive Updates: In line with our commitment to accuracy, we quickly update our practice questions to reflect any changes in the DMV manuals. Additionally, we update the free electronic copy of the state's driver's license manuals on our site, typically within a few days after the DMV publishes them.

Our thorough quality control process ensures that you have access to practice tests that are as accurate and up-to-date as possible. We believe in the power of well-prepared drivers and are dedicated to providing you with the best study tools to help you succeed on your DMV exam.

Keyboard shortcuts

Try Driving-Tests Premium

Pass the knowledge test the first time, guaranteed.

Pass Guarantee

How does it work.

Our Premium Membership comes with a Pass Guarantee (30-day access and longer). If you successfully complete all the practice tests for your province/territory, we promise you a passing grade on your official written knowledge test or we'll refund your money. Your most recent completion of all the tests should be not earlier than 30 days before your exam date.

Just send us an email with your full name (must match the name and email address used for your purchase at Tests.ca) within 30 days from the purchase of your Premium membership.

What happens next

We'll check your account to make sure you've successfully completed all practice tests for your state. Once that is confirmed, we'll issue a full refund (you'll receive a separate email confirmation).

If you know the date of your official knowledge exam, select it here:

- CDL Practice Test

- OK Pretrip CDL Practice Test - 1

FREE 2024 Oklahoma (OK) Pretrip Practice Test 1

2024 ok pretrip information.

The pretrip exam is an oral exam that you will need to pass after you have taken all of your CDL written tests, and are at the exam station for your pretrip, skills, and road test exams. During the pretip exam you will need to verbally check components to make sure that the vehicle is safe for operation. In some states there can be over 100 items to check on a tractor trailer.

The exam doesn’t stop at just listing the components, you will have to name the item by its proper name and say at least 3-5 things you would check that item for. Don’t’ forget to mention what you are going to check the 3-5 things for as well. This is a very detailed exam on the vehicle and its parts be ready.

As an example, the air compressor would need checked, we are going to check belts (if not gear driven), air lines, and securement of the air compressor. Because we mentioned belts (if not gear driven) we have to check for play in the belt, check it for wear, and crack. Moving on the air lines, need to be secure, no breaks or cracks, and no leaks. Finally check all bolts, nuts, and securement pieces to make sure none are loose or missing.

Based on the 2024 OK CDL Driver's Manual

Questions appearing on this cdl practice test:, when doing the pre-trip, you should tell the examiner each item you are checking and 2-3 things you check each item for., should you do an overview of your vehicle as you approach it (including looking for leaks, leaning, or excessive damage), when checking the lights at the front of the vehicle what should you check for, when checking the windshield, what should you be looking for, when opening the hood, you should check, checking the mirrors on the outside of the vehicle you should check for, in the engine compartment there are four fluids you must check, they are, in the engine compartment there are four major belt or gear driven components. what are they, what should you check each of the fluids in the engine compartment for, what are the main components of the steering controls found in the engine compartment, what should you check the steering linkage for, which of the following does not get checked in the engine compartment, which of the following is not an engine compartment belt, the leaf springs, shocks, u-bolts, shackles, and air bags are part of what system, hoses in the engine compartment should be checked for, the engine belts should be checked for, brake lines should be checked for, air chambers are, air chambers should be checked for, the slack adjuster is part of the braking system, what is the maximum play allowed with the brakes off, brake pads should be checked for, brake drums, brake drums (or discs) must not have cracks longer than:, tire tread depth depends on the axel. the depth should be no less than ______ for the steer axel, and _____ for any other axel., retreaded tires can be on any axel., tires should be checked for, you should check rims for dents, cracks, illegal welds, valve stem, and that they are tight and secure., all rims have a spacer., lug nuts (that hold the rim to the axle) should be checked for, the hub oil seal should be, differences between the steer axel and the rest of the axles are: tread depth, spacers or budding rims, space between the tires, torsion bars, and air bags., you can leave the hood open when moving on with the pre-trip., more oklahoma cdl practice test: ( indicates current test), general knowledge practice test 1, general knowledge practice test 2, general knowledge practice test 3, general knowledge practice test 4, general knowledge practice test 5, general knowledge practice test 6, general knowledge practice test 7, general knowledge practice test 8, haz mat practice test 1, haz mat practice test 2, haz mat practice test 3, haz mat practice test 4, school bus practice test 1, school bus practice test 2, school bus practice test 3, school bus practice test 4, passenger vehicles practice test 1, passenger vehicles practice test 2, passenger vehicles practice test 3, passenger vehicles practice test 4, air brakes practice test 1, air brakes practice test 2, air brakes practice test 3, air brakes practice test 4, combination vehicles practice test 1, combination vehicles practice test 2, combination vehicles practice test 3, combination vehicles practice test 4, combination vehicles practice test 5, double/triple trailers practice test 1, double/triple trailers practice test 2, double/triple trailers practice test 3, tanker vehicles practice test 1, tanker vehicles practice test 2, tanker vehicles practice test 3, pre-trip inspection practice test 1, pre-trip inspection practice test 2, pre-trip inspection practice test 3, oklahoma free pretrip videos, engine compartment pretrip inspection, inside cab pretrip inspection, rear of tractor pretrip inspection, exterior light pretrip inspection, complete trailer pretrip inspection.

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

Catwalk and Steps

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

Select Your Free 2024 OK CDL Practice Test to Get Started

General Knowledge (150 questions)

General Knowledge Test 1

General knowledge test 2, general knowledge test 3, general knowledge test simulator.

HazMat (30 questions)

OK CDL HazMat Test 1

Passenger Vehicles (20 questions)

OK Passenger Vehicles Test 1

School Bus (20 questions)

OK CDL School Bus Test 1

Air Brakes (25 questions)

OK CDL Air Brakes Test 1

Combination Vehicles (24 questions)

OK Combination Vehicles Test 1

Double/Triple Trailers (20 questions)

OK Double/Triple Trailers Test 1

Tanker Vehicles (30 questions)

OK CDL Tanker Vehicles Test 1

Pre-Trip Inspection (9 questions)

OK CDL Pre Trip Inspection Test 1

Oklahoma cdl handbook 2024.

Get the latest (2024) official OK CDL Handbook.

405-620-4210

- Price and Truck Info

Class A CDL Test Truck

Oklahoma test truck, pre trip videos.

Pre-Trip inspection videos: There are videos for A, B, and C as well as videos showing the In Cab & Applied Brake Test sequence, trailer connections, and 5th wheel setup. These videos are not intended for use as training material, only provided to give you an idea of what to expect for your exam.

Pre Trip - A

This video shows inspection of the truck: forward lighting, external items on the front half of the truck, components in the engine bay, battery box, frame, steering/suspension components, front wheels/brakes.

Pre Trip - B

This video shows inspection of the truck: external items on the side/rear half of the truck, frame, air tanks, wire/hose connections, 5th wheel setup, suspension components, rear wheels/brakes, rear truck lighting.

Pre Trip - C

This video shows inspection of the trailer.

Pre Trip - In Cab Inspection & Applied Brake Test

Pre Trip - Trailer Connections

Pre Trip - 5th Wheel Setup

Copyright © 2017 Oklahoma test truck - All Rights Reserved.

- Real Estate

- Preview Document

- Download PDF Download PDF

School Bus Pre-trip Inspection Sheet - Oklahoma

- United States Legal Forms

- Oklahoma Legal Forms

- Oklahoma State Department of Education

School Bus Pre-trip Inspection Sheet is a legal document that was released by the Oklahoma State Department of Education - a government authority operating within Oklahoma.

Q: What is a pre-trip inspection sheet? A: A pre-trip inspection sheet is a checklist used by school bus drivers to ensure that the bus is in proper working condition before each trip.

Q: Why is a pre-trip inspection important for school buses? A: A pre-trip inspection is important for school buses because it helps identify any mechanical issues or safety hazards that could affect the safety of students and other passengers.

Q: What does an Oklahoma school bus pre-trip inspection sheet include? A: An Oklahoma school bus pre-trip inspection sheet typically includes checks for lights, brakes, tires, mirrors, emergency exits , and other important components of the bus.

Q: Who is responsible for conducting the pre-trip inspection? A: The school bus driver is typically responsible for conducting the pre-trip inspection.

Q: How often should a pre-trip inspection be done? A: A pre-trip inspection should be done before each trip, whether it is a daily route or a special event .

Q: What should the driver do if any issues are found during the inspection? A: If any issues are found during the inspection, the driver should report them to the appropriate maintenance personnel or supervisor for further action.

Q: Are there any specific guidelines or regulations for school bus pre-trip inspections in Oklahoma? A: Yes, Oklahoma has specific guidelines and regulations for school bus pre-trip inspections. It is important for drivers to be familiar with these regulations and follow them accordingly.

Form Details:

- Released on June 1, 2016;

- The latest edition currently provided by the Oklahoma State Department of Education;

- Ready to use and print;

- Easy to customize;

- Compatible with most PDF-viewing applications;

- Fill out the form in our online filing application .

Download a printable version of the form by clicking the link below or browse more documents and templates provided by the Oklahoma State Department of Education.

Download School Bus Pre-trip Inspection Sheet - Oklahoma

Linked topics.

Related Documents

- DD Form 626 Motor Vehicle Inspection (Transporting Hazardous Materials)

- Oklahoma Sde Pre-trip and Post Trip School Bus Inspection Report - Oklahoma

- USAFE Form 69 Vehicle Inspection Checklist - Pre-requisite for the Adr Inspection

- 374 AW Form 7 Motor Vehicle Inspection Report

- Form NIH1382-2 Motor Vehicle Trip Ticket

- Optional Form 296 Vehicle/Heavy Equipment Pre-use Inspection Checklist

- Form CNICCYP1700/26 Pre-trip Vehicle Inspection Daily Form

- 374 AW Form 48 Safety Inspection of Two-Wheeled Motor Vehicles

- Form 200-FS-C3 Annual Vehicle Inspection Report

- AE Form 190-1X Answer Sheet - Driver Examination for Germany for Privately Owned Motor Vehicle Operations

- AFTO Form 91 Limited Technical Inspection - Motor Vehicles

- Convert Word to PDF

- Convert Excel to PDF

- Convert PNG to PDF

- Convert GIF to PDF

- Convert TIFF to PDF

- Convert PowerPoint to PDF

- Convert JPG to PDF

- Convert PDF to JPG

- Convert PDF to PNG

- Convert PDF to GIF

- Convert PDF to TIFF

- Compress PDF

- Rearrange PDF Pages

- Make PDF Searchable

- Privacy Policy

- Terms Of Service

Legal Disclaimer: The information provided on TemplateRoller.com is for general and educational purposes only and is not a substitute for professional advice. All information is provided in good faith, however, we make no representation or warranty of any kind regarding its accuracy, validity, reliability, or completeness. Consult with the appropriate professionals before taking any legal action. TemplateRoller.com will not be liable for loss or damage of any kind incurred as a result of using the information provided on the site.

All driver license services, including issuance, renewals, reinstatements, and disability placards, are now operated by Service Oklahoma. Visit service.ok.gov for more information or call 405-522-7000.

Commercial Driver License Restrictions

- No Manual Transmission (E)

- Intrastate Only (K)

- No Air Brake Equipped CMV (L)

- No Class A Passenger Vehicle (M)

- No Class A or B Passenger Vehicle (N)

- An applicant who passes a skills test using a combination vehicle that is NOT a truck tractor semi-trailer combination (the conventional semi), but is otherwise equipped with a fifth wheel, will be issued a CDL with an “O” restriction.

- No Passengers in CMV Bus (P)

- Medical Variance (V)

- No Cargo in CMV Tank Vehicle (X)

- No Full Air Brake Equipped CMV (Z)

- If a drive test is required then you must get a permit, hold it for the full 14 days, and then do all three parts of the CDL Skills Test. The only exception to this is for removing the restriction E-automatic transmission. If you are just removing the restriction E and not making any other changes to the current CDL license, then you will not have to do the pre-trip inspection. You will do the basic control skills and the road test only.

- If the restriction you are removing requires a drive test, yes, you will be required to obtain a CLP (Commercial Learner Permit) first and hold it for a minimum of 14 days before you are eligible for the skills test to remove said restriction.

*A Commercial License Permit (CLP) holder with a S endorsement is prohibited from operating a school bus with passengers, other than Federal/Federal/State auditors and inspectors, test examiners, other trainees, and the CDL holder accompanying the CLP holder as prescribed by CFR 383.25(a)(1) of this part.

Oklahoma Department of Public Safety

3600 North Martin Luther King Avenue

Oklahoma City, OK 73111

- Oklahoma Highway Patrol

Copyright © 2021 Department Of Public Safety

IMAGES

VIDEO

COMMENTS

The Oklahoma vehicle inspection test (walk-around) requires the driver to point out vehicle components and explain what you are checking and why to the examiner. This includes an under the hood engine compartment inspection. A driver is not required to crawl under the vehicle during the test. The Oklahoma Vehicle Checklist Inspection (walk ...

Last updated on December 8, 2017. School Bus Pre-Trip Inspection Sheet.

DPS employees cannot discuss anything regarding the test that is not in the CDL Manual that is available to the public free of charge. No part of the CDL Skills Test shall be filmed or recorded, unless by the Department of Public Safety (OAC 595:11-3-7).Per AAMVA, "Under no circumstances is a jurisdiction permitted to release copies of any skills test score sheets, scoring criteria, exercise ...

Take the CDL Drive Test. To make a CDL drive test appointment after holding your permit for 14 days, click the "Save Your Spot" button below. This will take you to Service Oklahoma's online check-in page. Select "Get started" and then the "Drive test - Commercial Driver License" service to select a location near you.

01.2020

16 correct answers to pass. 80% passing score. This CDL practice test is a great place to start if you're after the OK Pre-Trip Inspection endorsement. Each of the 20 questions is based on the official 2024 CDL manual. The test is designed to prepare you for the Pre-Trip Inspection portion of your 2024 Commercial Driver's License exam.

Oklahoma CDL Pre-Trip Inspection Overview: 20 Total number of questions. 16 Number of questions required to pass. 80 Percentage required to pass. Show Comments. Prepare for your pre-trip inspection test with our Oklahoma pre-trip inspection practice test. 100% Free. Questions based on the 2024 CDL manual.

Oklahoma SDE Pre-Trip and Post Trip School Bus Inspection Report This report is required each time students are transported in a school bus for any reason. Keep on file for at least ninety (90) days. ... These 14-steps are taken from the SDE Oklahoma School Bus Driver Manual. If any bus defect is found: (1) Document details on the back of this ...

These 14-steps are taken from the State Department of Education Oklahoma School Bus Driver Manual. If any bus defect is found: "Initial" in each box below to indicate the step has been completed. To the right indicate with an "X if a repair is needed. PRE-TRIP 1. Raise the bus hood and check all fluid levels, each belt, and each hose. REPAIR ...

Inside Cab Pretrip Inspection. Rear of Tractor Pretrip Inspection. Exterior Light Pretrip Inspection. Complete Trailer Pretrip Inspection. Preparing for your OK Pretrip exam just got easier. Based off of the 2024 OK CDL manual our free Pretrip CDL Practice Test 1 will help you pass the first time.

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam. Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will ...

3190 W 21 Street #306. Tulsa, Ok 74107. (next to the Tulsa , Ok. CDL Testing site) (918) 585-1323. fax (918) 585-5429. email: [email protected]. Oklahoma Pre-Trip Inspection Test. You must do a complete external inspection and internal inspection, you must show that the vehicle and is safe to drive.

Printable Pre Trip Inspection Checklist (PDF) CDL Manual. CDL General Knowledge Practice Test. Pre Trip Inspection Practice Test. CDL HAZMAT Endorsement Practice Test. Edited for 2024 on 12/5/23. Complete CDL pre-trip inspection checklist with online reference and study guide plus a free PDF pre trip inspection checklist to print.

OK CDL Pre Trip Inspection Test 1 Covers overall vehicle safety, documentation checks, vehicle components, the brake system, and operational elements such as lights, signals, and controls. Oklahoma CDL Handbook 2024

Pre-Trip inspection videos: There are videos for A, B, and C as well as videos showing the In Cab & Applied Brake Test sequence, trailer connections, and 5th wheel setup. These videos are not intended for use as training material, only provided to give you an idea of what to expect for your exam. Pre Trip - A. This video shows inspection of the ...

A: An Oklahoma school bus pre-trip inspection sheet typically includes checks for lights, brakes, tires, mirrors, emergency exits, and other important components of the bus. Q: Who is responsible for conducting the pre-trip inspection? A: The school bus driver is typically responsible for conducting the pre-trip inspection. Q: How often should ...

Pre-trip Inspection (396.13) Before operating the vehicle, the driver must inspect the vehicle and be satisfied that it is in safe operating condition. If the last vehicle inspection report notes any deficiencies, the driver must review and sign to acknowledge and certify that the required repairs were made. Periodic Inspection (396.17, 396.21)

This video will explain the full pre-trip inspection on your Class A truck for the new CDL road test. Watch the whole thing to learn the new pre-trip.Our Web...

Pre-trip Inspection Form 2015. A document for school bus drivers to use to document their pre-trip inspections. Pre-trip Inspection Form 2015. Back to Top. Last updated on December 8, 2017.

CDL Pre-Trip Inspection Tutorial from American Truck Driving School.

Oklahoma State Department of Education (SDE) - 2500 North Lincoln Boulevard - Oklahoma City, Oklahoma 73105-4599 Pre-Trip and Post Trip School Bus Inspection Report This report is required each time students are transported in a school bus for any reason. Keep on file for at least ninety (90) days. OAC 210:30-5-1

Do I have to do a pre-trip to remove a restriction? ... then you will not have to do the pre-trip inspection. You will do the basic control skills and the road test only. ... Oklahoma Department of Public Safety. 3600 North Martin Luther King Avenue. Oklahoma City, OK 73111. About;

Oklahoma Administrative Code 210:30-5-6(b)(c) School Buses (b) School Bus Inspections A driver shall perform a daily pre-trip safety inspection of the vehicle, the report shall cover at least the following parts and accessories: service brakes, parking brake, steering mechanism, lighting devices and reflectors, tires,