GM News Release: General Motors Oshawa Assembly Plant Reopens Creating Thousands of Jobs and Boosting Economic Growth

- 1,800 new jobs at Oshawa Assembly supporting thousands of additional jobs with Canadian automotive suppliers

- One of the fastest plant launches in GM history will help meet growing demand for GM pickup trucks

Today, GM Canada announced the first Chevrolet Silverado pickup has rolled off the line at the reopened Oshawa Assembly plant. The return of truck production to Oshawa provides a significant economic boost for Canada’s automotive sector, creating 1,800 new jobs to support two shifts of production in Oshawa, and supporting thousands of additional jobs in the supplier base in Canada.

Pickups are GM’s largest and most important market segment across the continent, and the Oshawa plant will help GM meet strong demand for its leading family of pickup trucks. Oshawa Assembly has been retooled in record time to be one of the most flexible and advanced of its kind in the industry. Oshawa will begin shipping trucks to dealers in December 2021.

“The reopening of Oshawa Assembly is an historic accomplishment for GM Canada and our many community partners who worked together to bring us to this very happy day,” said Scott Bell, GM Canada president and managing director. “The rapid retooling, hiring, and training needed to reach today’s start of production was an extraordinary accomplishment. We continue our work with the federal and Ontario governments toward even larger transformative investments in Canada and we are especially pleased that the first truck off the line will help GM and our Canadian dealers raise money for Sharon’s Kids, one of our favourite charities in Durham Region.”

To continue the plant’s legacy of giving back to the community, GM Canada will raffle one of its first vehicles to our dealers to benefit the Durham Children’s Aid Foundation (DCAF). This continues the legacy of Sharon Clark, a former employee of Oshawa who lost her battle with cancer in 2020. For more than 50 years, Oshawa Assembly employees have donated holiday gifts for children in need, through “Sharon’s Kids.” Since 2018, GM Canada and our employees have donated more than $500,000 to Sharon’s Kids, which is now part of DCAF.

Premier Doug Ford, said:

“Today marks an incredible milestone as the first trucks roll off the assembly line here at GM’s reopened assembly plant in Oshawa. With this plant re-opening, over 1,800 new skilled workers will find steady and important work helping to produce world class, Ontario made GM trucks. As we move forward with our plan to build Ontario, we will continue to create the conditions needed for more investment while restoring good manufacturing jobs just like these.”

The Honourable François-Philippe Champagne, Minister of Innovation, Science and Industry, said:

“The reopening of GM’s Oshawa assembly plant is great news for the city, Ontario and all of Canada. GM’s investments demonstrate clearly that our government’s policies, working alongside our partners in industry and labour, are driving historic private sector investment in Canada’s auto sector. These investments are essential to our economy and are providing good, well-paying jobs for more than 550,000 Canadians. Congratulations to the team at GM Canada for this important announcement and I look forward to continue working together to keep Canada at the forefront of automotive innovation.”

The Honourable Vic Fedeli, Ontario’s Minister of Economic Development, Job Creation and Trade, said:

“Today’s celebration is an important milestone in Ontario’s automotive history with the revitalization of a plant that has been a part of the fabric of Oshawa and Durham Region for decades. This announcement marks the resurgence of Ontario’s auto sector, which we will continue to support though Phase 2 of our Driving Prosperity Auto Plan.”

John Henry, Regional Chair, Durham Region, said:

“On behalf of Durham Region, I am thrilled to see the Oshawa Assembly reopened in record time, as one of the most flexible and advanced of its kind in the automotive sector. This is not only great news for GM Canada and involved partners, but for all of Durham Region, as the creation of thousands of jobs and boosted economic growth comes at such a crucial time. The automotive industry has been at the heart of Durham Region’s economy for more than a century. The industry’s continued support here in Durham reflects the dedication and strong foundations we all share in making this possible. I look forward to the high-quality products that come off the line at this plant, and can’t wait to see the positive effects that cascade throughout the region as a result.”

Dan Carter, Mayor of Oshawa, said:

“We’re excited to celebrate the re-start of the Oshawa truck plant that is bringing quality jobs to our great city and building upon Oshawa’s rich automotive history. Today, we celebrate a bright future for our community and for the automotive sector in Ontario and Canada. We thank GM Canada for believing and investing in Oshawa’s productive, innovative and high-quality workforce.”

Jerry Dias, Unifor National President, said:

“The return of vehicle assembly to the Oshawa plant is unprecedented in our history. It is an achievement owed to the resiliency and dedication of Unifor members. Seeing the first of many trucks roll off the newly re-opened Oshawa assembly line was a proud moment for everyone who fought shoulder to shoulder for these jobs. The auto industry has and will continue to be the bedrock of Oshawa and Durham region’s economy.”

Browser Compatibility Notification

It appears you are trying to access this site using an outdated browser. As a result, parts of the site may not function properly for you. We recommend updating your browser to its most recent version at your earliest convenience.

GM plant slated for death is now a lifeline in a scramble to build pickups

Oshawa Assembly in Canada was once slated for death, but now it is the life-support General Motors needs to build enough hot-selling and profitable Chevrolet Silverado and GMC Sierra pickups to meet high consumer demand.

Located about 40 miles east of Toronto near the Lake Ontario shoreline, Oshawa Assembly has undergone a $1.1 billion overhaul and is on track to start building the full-size light-duty and heavy-duty pickups far ahead of schedule.

In fact, Oshawa is about to execute one of the fastest plant launches in GM history, said Monte Doran, GM spokesman.

"The launch is 6 to 12 months faster than we could normally plan for, despite the challenges of working during the pandemic," Doran said.

The job of retooling the facility is massive. It includes constructing a new body shop that covers 13 acres, installing 1,200 new robots, 10,300 feet of new conveyors and 310 miles of electric wiring. It contains 5,000 parts from 370 different suppliers, Doran said.

GM has moved so fast to get it all in place because it is desperate to get more pickups to dealers after production was derailed due to the COVID-19 pandemic and then a shortage of semiconductor chip parts. Even now, as GM runs its pickup plants at full-capacity, the automaker can't keep up with demand.

More: Everything you need to know about the chip shortage that's plaguing automakers

"We can sell more trucks than our current footprint can produce. That's why we are increasing capacity," Doran said. "While we have not released production volumes for Oshawa, we are confident it will make an impact in 2022 and help meet the strong customer demand for our pickups."

Since GM’s other plants build pickups, Oshawa’s assembly of the vehicles is considered overflow. Therefore, it’s unlikely Oshawa will produce more than 125,000 pickups in its first year, even though the plant can produce about 200,000 vehicles, said Joe McCabe, CEO of AutoForecast Solutions.

'Outhouse to penthouse'

All of it is surreal for Unifor National President Jerry Dias, who just three years ago faced the news that GM had decided to shut down Oshawa Assembly for good as part of the automaker's plan to permanently idle five factories in North America to cut its costs. The plants targeted for closure, of which Oshawa was one, all built cars, and consumer tastes had shifted to pickups and SUVs.

More: General Motors to close Detroit, Ohio, Canada plants

Unifor, the union that represents Canada's autoworkers, went to war with GM over it. There were wild pickets calling GM "Greedy Motors," a call for customers to boycott GM vehicles and a media campaign against the automaker so negative that in 2019, GM threatened to sue Unifor over a union spot critical of GM that aired in Canada during the Super Bowl.

Unifor defied GM's threat and continued the ad campaign during the Academy Awards, the Grammy Awards and other high-profile shows.

But in last year's contract talks, Dias and GM leaders put the animosity behind them and not only did GM allocate new product to the plant , but GM gave Oshawa its top-selling product to build: full-size pickups. GM has spent about $1.1 billion to retool the plant for pickup production.

“There is no question we went from the outhouse to the penthouse," Dias told the Free Press. "I'll never forget the moment after we negotiated reopening the plant and people on the street, strangers I never met, would high-five me. So there’s no question the city of Oshawa has a collective sigh of relief."

Dias has said one of the factors that helped get Oshawa's lines rolling again was the COVID-19 pandemic, which created a vehicle shortage when GM idled all of its plants in North America for eight weeks. It needed Oshawa's capacity to help restock much-in-demand pickups.

In November, about 1,600 Unifor members who worked at GM Canada voted to ratify a three-year contract that also included a GM investment of $109 million in St. Catharines Propulsion Plant near Niagara Falls for new transmission work for the Chevrolet Equinox and a new program to build transmissions for the Chevrolet Corvette.

GM CEO Mary Barra told analysts at that time: "We simply can't build enough (pickups). And because we expect demand to remain strong, we must increase our capacity."

GM currently assembles its light-duty pickups at its Fort Wayne Assembly plant in Indiana and Silao Assembly plant in Mexico. Flint Assembly builds GM's heavy-duty models.

Once Unifor members ratified their contract, Barra said GM will "move very quickly" to retool and prepare Oshawa. She wasn't kidding.

To meet the accelerated timeline, Doran said, GM examined every step in the process, looking for faster and more efficient ways to retool.

"When COVID-19 prohibited the team from training and meeting in person, they transitioned to online training and conducted virtual interviews," Doran said. "When critical equipment was delayed by interruptions in the shipping industry and semiconductor shortages, the team found creative new ways to source equipment to accelerate the schedule."

GM was supposed to start hiring in October for a January launch, instead it's hiring now for an October launch, Dias said. Doran declined to confirm a launch date other than to say it will be in the fourth quarter.

GM's hiring in Oshawa

Dias said the plan is to start building heavy-duty pickups first on one shift, then segue to light-duty and add a second shift. He is confident that eventually the plant will run on three shifts.

GM's Doran declined to confirm the number of shifts Oshawa will run or the product mix. But he said GM has started hiring for the 1,700 jobs there,1,500 of which are assembly line jobs paying $18.90 an hour to start.

"Between wages, benefits, insurances, pension, shift and overtime premiums, the total compensation package for skilled trades has the potential to exceed $82,000 (U.S.) per year," Doran said. "As such, we are confident we will be able to fill our positions in time for launch."

GM will rehire an estimated 450 people who had worked in Oshawa Assembly and opted to be placed on a recall list. The majority of the rest will be new hires, Doran said.

According to Unifor, about 2,650 people worked in the plant in 2018 when GM announced the closure.

About 300 of those workers continue to work in the plant’s stamping facility, an additional 60 workers also temporarily returned to work in the plant’s COVID-19 mask manufacturing facility from May 2020 through this past April. But about 1,650 received retirement or other packages when the plant closed in December 2019.

During negotiations, Dias said language was put in the contract that those on the recall list would get hired back to the plant, which remains unionized. For people who took a severance package, there is no protective language to rehire them, but he said Unifor leaders are talking to GM about rehiring those folks and he suspects most will be hired because they already have the skills to build cars.

GM's production problem

Besides the 1,700 direct jobs, Dias said, there are ancillary jobs from area businesses and the various suppliers that feed into the plant. He said studies showed for every one job at the plant, there are 10 jobs connected to it. Dias wants to be sure that those connector jobs are union represented.

“We’re talking to suppliers right now," Dias said. "There are many suppliers that we already have a bargaining relationship with so they understand as the plant reopens, we have bargaining rights. But some of the nonunion suppliers that are getting jobs, we’re talking to them."

Earlier this month, GM said it will increase vehicle deliveries to its dealers and customers in the United States and Canada despite a massive shortage of semiconductor chips. That includes speeding up the assembly line at Flint Assembly to build an additional 1,000 full-size heavy-duty pickups per month beginning in mid-July.

GM has been in a race to stock enough inventory to meet demand since about this time last year. When GM restarted its North America plants following an eight-week shutdown, there was pent-up customer demand especially for full-size pickups and SUVs. GM has been running its plants at full-capacity ever since, but then a massive worldwide shortage of semiconductor chips hit the auto industry earlier this year.

The chips, most of which are made in Taiwan, are used in a variety of electrical auto parts. Demand for personal electronics, which also use the chips, was so high during the pandemic, it contributed to a global shortage.

GM has had to either idle some assembly lines, shorten shifts or build vehicles shy of the chip parts and await arrival of the parts before finishing production and shipping the completed vehicles to dealers.

But Barra has said the industry should be through the worst of the shortage by the third-quarter and recovered by the fourth quarter, just in time for the assembly lines at Oshawa to start up and help GM refill its pipeline.

Dias has not been inside the plant yet because of COVID-19 restrictions, but he has had regular contact with the union and company leaders on the progress.

He views the Oshawa odyssey as an unexpected, but educational journey: "You can never burn the house down behind you; you have to keep the lines of communication open and, frankly, never give up.”

More: Here's how Canada's autoworker union won big with GM, Ford and FCA

More: Canada union boss talks about his fight with GM in documentary that airs Saturday

More: GM in talks to sell Lordstown plant as company reveals new investment for Canada plant

Contact Jamie L. LaReau at 313-222-2149 or [email protected] . Follow her on Twitter @ jlareauan . Read more on General Motors and sign up for our autos newsletter . Become a subscriber .

- Magazine + Enews

- Multi-Media

- Virtual Events

- 2022 Salary Calculator

- Business Operations

- Digital Transformation

- Health & Safety

- Facilities Maintenance

- Preventative Maintenance

- People and Skills

- Sustainability

- Innovation & Technology

- Construction

- Electronics

- Food & Beverage

- Manufacturing

- Resource Sector

- Transportation

- Digital Edition

General Motors Reopens Oshawa Assembly

Mario Cywinski November 10, 2021

Photo credit: GM Canada

General Motors Canada has begun production at its Oshawa Assembly plant, with the first Chevrolet Silverado rolling off the line.

“The reopening of Oshawa Assembly is an historic accomplishment for GM Canada and our many community partners who worked together to bring us to this very happy day,” said Scott Bell, President and Managing Director, GM Canada. “The rapid retooling, hiring, and training needed to reach today’s start of production was an extraordinary accomplishment. We continue our work with the federal and Ontario governments toward even larger transformative investments in Canada and we are especially pleased that the first truck off the line will help GM and our Canadian dealers raise money for Sharon’s Kids, one of our favourite charities in Durham Region.”

The re-opening has created 1,800 new jobs (two shifts of production at the plant), as well as creating many more cascading jobs, in the Canadian supplier base.

“Today marks an incredible milestone as the first trucks roll off the assembly line here at GM’s reopened assembly plant in Oshawa,” said Doug Ford, Premier of Ontario. “With this plant re-opening, over 1,800 new skilled workers will find steady and important work helping to produce world class, Ontario made GM trucks. As we move forward with our plan to build Ontario, we will continue to create the conditions needed for more investment while restoring good manufacturing jobs just like these.”

The plant, which most recently built the Chevrolet Camaro, Impala, Cadillac XTS, and others, before it was shut down a few years ago, will now be building pick-ups, including the Silverado.

“We’re excited to celebrate the re-start of the Oshawa truck plant that is bringing quality jobs to our great city and building upon Oshawa’s rich automotive history,” said Dan Carter, Mayor of Oshawa. “Today, we celebrate a bright future for our community and for the automotive sector in Ontario and Canada. We thank GM Canada for believing and investing in Oshawa’s productive, innovative and high-quality workforce.”

Oshawa Assembly was retooled quickly and is designed to be flexible. Shipments of trucks to dealers will begin in December 2021.

“The return of vehicle assembly to the Oshawa plant is unprecedented in our history,” said Jerry Dias, National President, Unifor. “It is an achievement owed to the resiliency and dedication of Unifor members. Seeing the first of many trucks roll off the newly re-opened Oshawa assembly line was a proud moment for everyone who fought shoulder to shoulder for these jobs. The auto industry has and will continue to be the bedrock of Oshawa and Durham region’s economy.”

As part of the reopening, GM Canada will raffle one of its first vehicles to dealers to benefit the Durham Children’s Aid Foundation.

Advertisement

- Globe Electric acquires HeathCo

- Schneider Electric to build three manufacturing plants across North America

Sign up for our newsletter and receive the latest automotive news in your inbox!

- Automobiles

- EVs & Environment

- Lawsuits/Legal

- Ride-Sharing

- Safety & Recalls

- The Rearview Mirror: A Sports Car from a Company You've Never Heard Of

Analysts Predict Declining Tesla Sales in Q3

Overlanding is the new hotness.

- New Vehicle Sales Increase in September

- Are EVs Affordable? Only if You’re a Luxury Buyer

- Honda Takes Wraps Off New All-Electric Prologue

- Mercedes to Offer True Self-Driving in Late 2023

- Biden Meets UAW Picketers, Offers Support

- Ford Halts $3.5B MI Battery Plant; Fain Slams Company

- An Electric Acura NSX Could Be Coming

- Classic Cars

- Concept Cars

- Convertibles

- Crossovers/CUVs

- Hot hatches

- Luxury Vehicles

- Muscle Cars

- Sports Cars

- A Week With: 2024 Buick Encore GX Sport Touring AWD

- A Week With: 2023 Mercedes-Benz EQB 250+

- A Week With: 2024 Mazda CX-90 Turbo S Premium Plus

- A Week With: 2024 Mercedes-AMG EQE SUV

- A Week With: The 2024 BMW i7 xDrive60

- A Week With: 2024 Alfa Romeo Tonale Veloce AWD

- A Week With: 2023 Toyota Camry XSE Hybrid

- A Week With: 2024 Subaru Impreza RS

- A Week With: 2023 Chevrolet Colorado ZR2 Desert Boss

- First Drive: 2024 Polestar 2

- Endurance Warranty Reviews

- BMW Extended Warranty

- Extended Warranty For Cars Over 100k Miles

- Extended Car Warranty Cost

- Subaru Extended Warranty

- CarShield Reviews

- CarShield Cost

- Aftermarket Car Warranty

- CARCHEX Warranty Reviews

- Reputable Extended Car Warranty Companies

- Used Car Warranty Companies

- Best Car Warranty

- Is CarShield A Scam?

- Mercedes Extended Warranty

- CarShield Plans

- How To Identify A Car Insurance Company

- Geico Mechanical Breakdown Insurance

- How Far Back Does A Car Insurance Company Look

- Mechanical Breakdown Insurance For Used Cars

- State Farm Mechanical Breakdown Insurance

- Mechanical Breakdown Insurance From Progressive

- Dollar A Day Insurance

- Auto Insurance For SSI Recipients

- Car Insurance Rates After A Suspended License

- Auto Insurance For Salvage Vehicles

- Average Cost of Dodge Ram 1500 Car Insurance

- Car Insurance Florida

- Full Coverage Auto Insurance

- GrubHub Insurance

- Amazon Delivery Auto Insurance

- Car Shipping Companies

- uShip Reviews

- Auto Shipping From California To Hawaii

- Montway Auto Transport Reviews

- Cheap Car Shipping

- Easy Auto Ship Reviews

- Auto Shipping Miami

- Auto Shipping To Alaska

- Car Shipping Cost

- Auto Shipping Hawaii

- Auto Shipping Puerto Rico

- Sherpa Auto Transport Reviews

- Auto Shipping Atlanta

- Auto Shipping Boston

- Auto Shipping. Chicago

- Terms of Use

- Privacy Policy

- Affiliate Disclosure

More than just “another” place to find news, reviews, spy shots, commentary, features, and guides about the auto industry. TheDetroitBureau doesn’t stop with the press releases or confuse a few lines of opinion with insightful, in-depth reporting.

Like what you see? Have some ideas for making The Detroit Bureau.com even better? Let us know, we’d love to hear your voice.

Please leave this field empty.

- Headlight News: All Episodes

- Latest News

- Auto Reviews

TheDetroitBureau.com’s Headlight News offers a look at the past week’s top automotive news stories, as well as what’s coming up in the week ahead. Check out the week’s top story and our latest review…along with a dive into the past with this week in automotive history.

GM Reopens Canadian Plant to Build Full-Size Pickups

Once slated for closure, oshawa site looking to help company slake demand for trucks..

Against the odds, General Motors is once again building pick-up trucks at its Oshawa, Ontario plant, just outside Toronto, where GM has built vehicles for more than 100 years.

In November 2018, the company announced plans to permanently close the Oshawa plant , which has been the home of GM of Canada since the early part of the 20th Century. The closing was part of a sweeping corporate re-organization, which also led to the shutdown — and later sales — of a big GM assembly plant in Lordstown, Ohio.

“The reopening of Oshawa Assembly is an historic accomplishment for GM Canada and our many community partners who worked together to bring us to this very happy day,” said Scott Bell, GM Canada president and managing director, in a statement. “The rapid retooling, hiring, and training needed to reach today’s start of production was an extraordinary accomplishment.”

Pressure and protests by Unifor, the union representing Canadian autoworkers, pushed GM into promising to re-open Oshawa plant during interim negotiations in 2019 and then contract negotiations 2020 .

“Today is an incredibly important day for all of you, your families, and the community of Oshawa,” said Jerry Dias, Unifor president, as the plant reopened. “It is so incredible to see so many of you who maintained your recall rights.”

GM reverses course

The reopening of the Oshawa assembly line comes after the union’s largest and most aggressive campaign aimed at saving the plant, Dias said.

The Oshawa plant will operate on two shifts, employing about 800 workers.

The production from Oshawa comes as GM is engaged in battle for market share in the pickup segment with Ford, Stellantis and now Toyota, which is bringing a completely updated Tundra full-sized pickup truck to market this fall.

Dias said the return of truck assembly work to the Oshawa plant is a significant moment in Canadian manufacturing history, marking the first time that an assembly line has been successfully reopened.

“I was full of joy, pride, and so proud of our members getting this done less than a year from bargaining where we negotiated to get this truck back. Here we are today, with one rolling right off the line,” Jason Gale, Unifor Local 222 Plant chairperson said.

“We never stopped fighting for this. What kept us going was keeping a small operation of 300 people. It kept our foot in the door and kept the lights on. Now, we see a truck rolling off the line. I’m so happy. Happy for Durham. Happy for Oshawa. Happy for all the families that will benefit from this,” he added.

Cheap Car Warranty

Best Extended Car Warranty

The Rearview Mirror: A Sports Car from a Company You’ve Never Heard Of

2 responses to “ GM Reopens Canadian Plant to Build Full-Size Pickups ”

The Japanese have never been a sales threat to the Big 3…ever. since Tundra is still light duty sharing a platform with Tacoma, their biggest threat will be thr onslaught of light duty EV trucks and SUvs coming in the next few years

“While Americans can’t seem to get enough of the mid-size pickups from Japanese automakers, they absolutely shun their full-size trucks. According to data from WardsIntelligence, the highest market share Toyota has seen with Tundra was 9.1% and that was in 2007. It currently hovers in the 5% range. It’s even worse for Nissan. The best the Titan was able to muster was 3.5% of the market in 2005. Today it’s at 1.5%. With the Detroit Three commanding 94% of full-size pickup sales this year, it might almost make more sense for Toyota and Nissan to share a large truck platform.” Autoline

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

The end of GM’s Oshawa plant: What we know so far

This article was published more than 5 years ago. Some information may no longer be current.

Nov. 26, 2018: Laurie Nickle, left, and her daughter Stephanie hold a sign at a meeting at the Unifor union office to discuss the impending General Motors assembly plant closing in Oshawa. Laurie has worked at GM for 21 years, and Stephanie for five. Fred Lum/The Globe and Mail

TABLE OF CONTENTS

What GM is doing and why • Union’s response • Politicians’ response • Oshawa and GM: A history • What will GM do next? • What will Oshawans do next? • Commentary

- Automotive company Martinrea International Inc. says it plans to close a factory that makes parts for the cars rolling off the assembly line in Oshawa, Ont., a ripple effect from GM’s announcement on Monday that it will shut the plant next year.

- The Oshawa plant will be one of five North American facilities scuttled in 2019, the U.S. auto giant confirmed Monday. GM’s changes are part of a worldwide shift to electric and self-driving cars, and an acknowledgement that U.S. consumers are buying fewer cars than they used to. Here’s a primer from The Globe and Mail’s Ian McGugan on the economic challenges GM and the auto industry face.

- Workers at the General Motors plant in Oshawa, Ont., returned to work Tuesday after news of the facility’s closing prompted walkouts the day before. Their union, Unifor, has denounced the plant’s demise and called on GM to stand by a 2016 bargaining agreement to keep jobs there.

- U.S. President Donald Trump threated to cut all GM subsidies including for its electric-cars program on Tuesday in a tweet, shortly after speaking with Prime Minister Justin Trudeau by telephone. The two vowed to work together to help auto workers. GM has not recently taken advantage of Canadian subsidies. Ottawa took a more measured tone, with Mr. Trudeau and Ontario Premier Doug Ford saying they were disappointed but focused on supporting workers who were losing their jobs.

Vehicles are parked in a lot behind the General Motors truck assembly plant in Oshawa. Fred Lum/The Globe and Mail

What GM is doing and why

- When the Oshawa plant is closing: GM’s Monday statement didn’t use the word “close,” instead saying that, as of 2019, the Oshawa plant and several others would be “unallocated,” meaning no products are assigned to be made there. Sources have confirmed to The Globe that the Oshawa plant will indeed be shut down.

- What U.S. plants are closing: In addition to the Oshawa closing, GM says it has no plans to make automobiles at two other factories – one in Warren, Ohio, and the Detroit-Hamtramck plant in Michigan – as well as parts plants in White Marsh, Md., and Warren, Mich. Two unnamed plants outside North America would also be affected, as well as previously planned cuts in South Korea, the company said.

- How many jobs are affected: GM’s layoffs and buyouts could endanger up to 14,700 factory and white-collar workers' jobs in North America. The GM plant in Oshawa employs 2,522 unionized workers and is also GM’s Canadian headquarters.

- What models are being phased out: Several vehicle models that were made at the scuttled plants will be discontinued, including the Chevrolet Cruze, Cadillac CT6 and Buick LaCrosse.

- Why this is happening: The changes are part of a shift in the company’s global production toward autonomous and zero-emission vehicles, Mary Barra, GM’s chief executive officer, said at a Monday news conference. "The actions we are taking today continue our transformation to be highly agile, resilient and profitable, while giving us the flexibility to invest in the future,” she said. The company expects to save US$6-billion from the cutbacks.

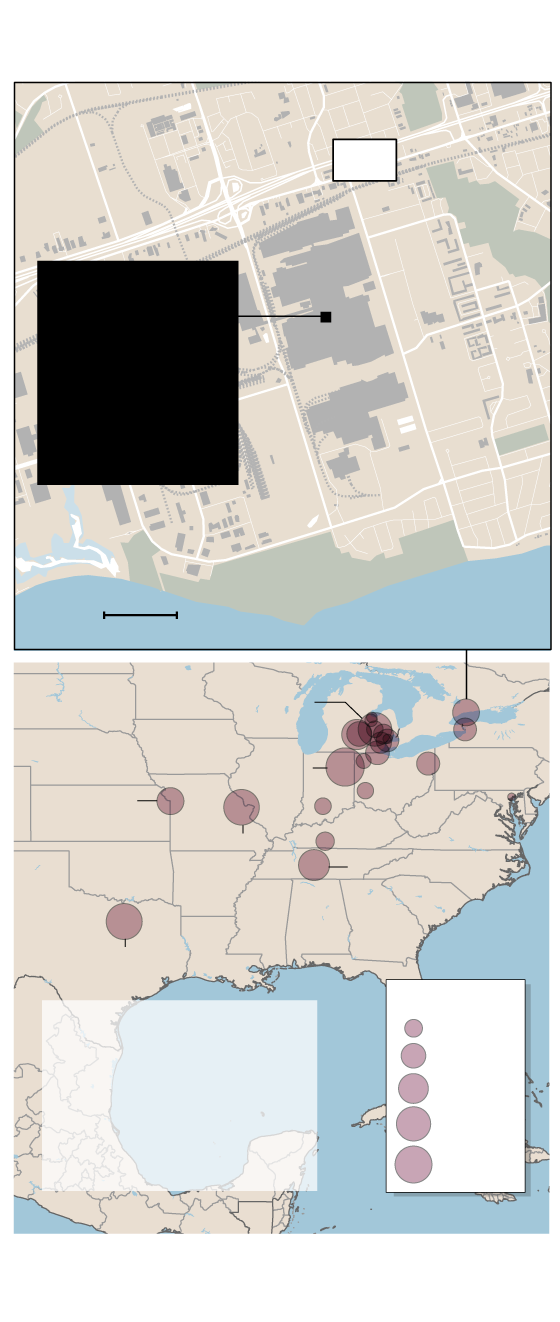

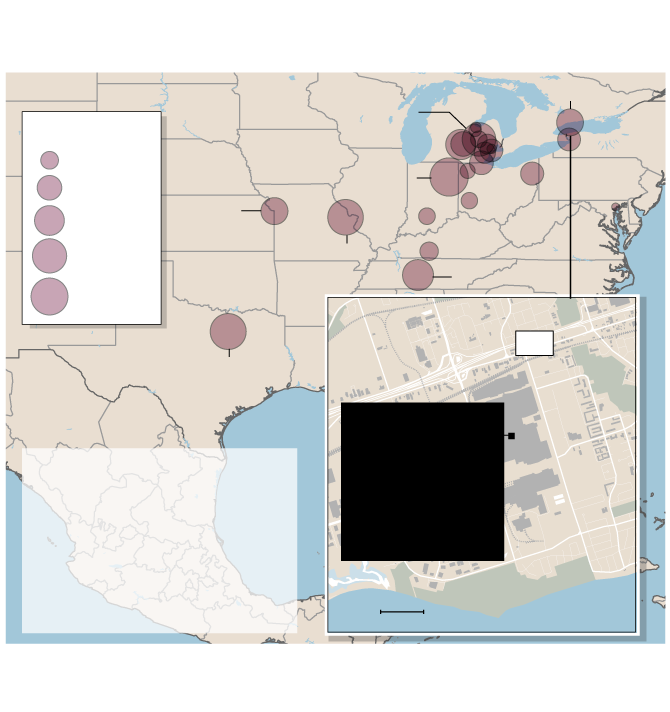

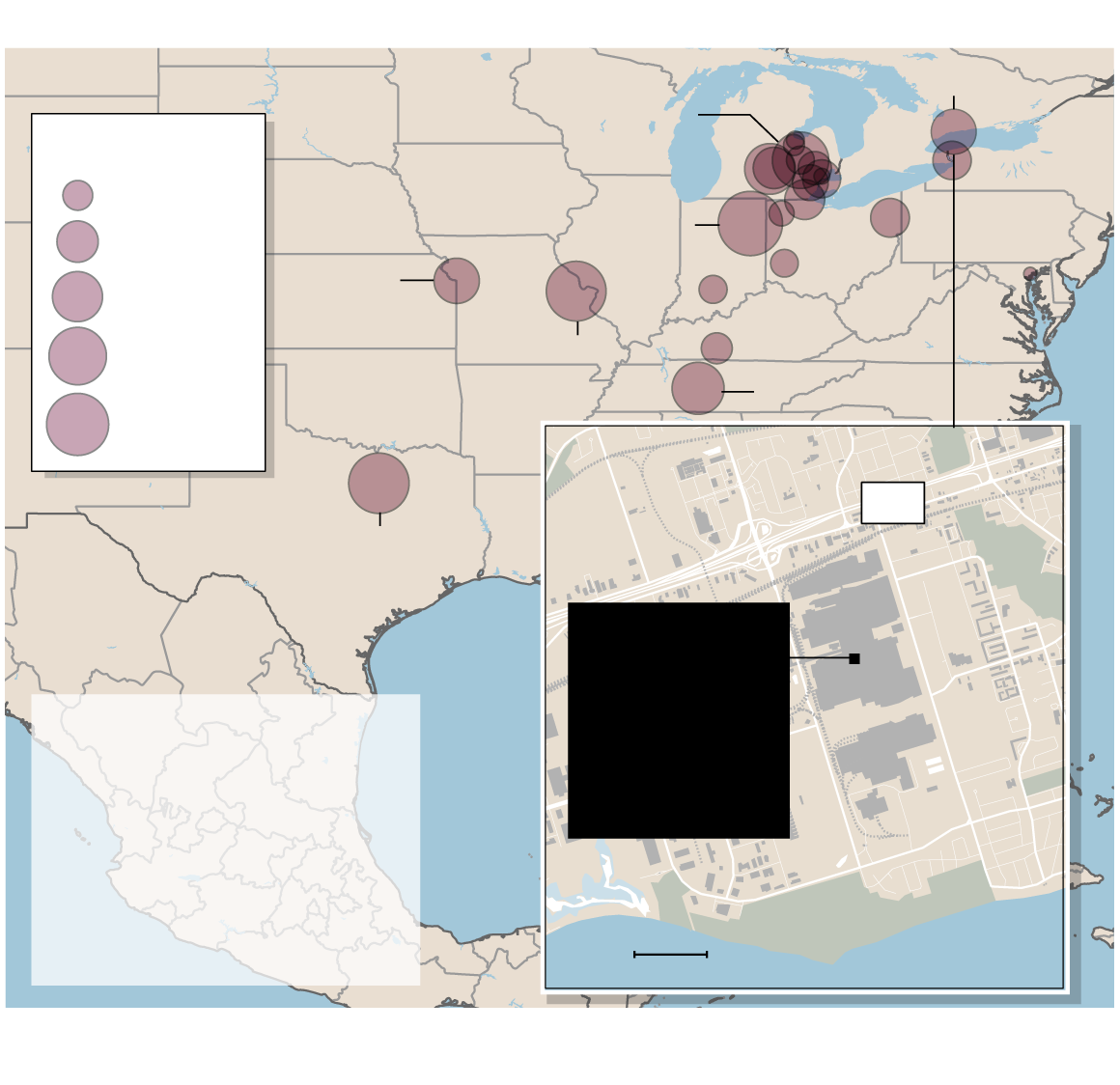

GM assembly or propulsion

plants in North America

PARK RD. S.

Plant opened

in 1953 and

employs 2,522

P. MURRAY AVE.

Lake Ontario

Flint, Mich.

UNITED STATES

Fort Wayne, Ind.

Spring Hill,

Wentzville,

Arlington, Tex.

Note: General Motors also

has plants in Mexico at

Ramos Arizpe, Silao, San

Luis Potosi and Toluca for

which employee information

was not available.

*Assembly and propulsion

JOHN SOPINSKI and murat yükselir/THE GLOBE

AND MAIL SOURCE: gm authority; gm corporate

GM assembly or propulsion plants

in North America

Oshawa, Ont.

JOHN SOPINSKI and murat yükselir/THE GLOBE AND MAIL

SOURCE: gm authority; gm corporate newsroom

GM assembly or propulsion plants in North America

Ramos Arizpe, Silao, San Luis

Potosi and Toluca for which

employee information was

not available.

(Return to top)

The unions' response

General Motors workers picket an entrance to General Motors's truck assembly plant in Oshawa. Fred Lum/The Globe and Mail

In a heated press conference Monday afternoon, president of Unifor Jerry Dias called the announcement a “betrayal," adding that “they are not closing our damn plant without one hell of a fight.” Canada’s largest private-sector union also urged GM to live up to the spirit of a 2016 agreement to save jobs in Oshawa by upgrading an assembly line. That deal, which averted a strike by GM workers, was hailed at the time by Mr. Dias as a commitment to prevent the plant’s closing in 2019.

Mr. Dias met with Mr. Trudeau on Tuesday to discuss the implications of the GM plant closing in Oshawa, saying the company has moved production of five models of vehicles to Mexico and the United States in the past few years, and if the Oshawa plant closes, the company will have only one left here. He says labour standards in Mexico are low and Trudeau has to work with Mr. Trump to keep manufacturing jobs from shifting south.

The biggest U.S. autoworker union also vowed to fight GM’s plans on Monday. “General Motors’ decision today ... will not go unchallenged by the UAW,” said Terry Dittes, the United Auto Workers' vice-president in charge of negotiations with GM.

Politicians' response

Federal: Prime Minister Justin Trudeau vowed Monday that Ottawa would offer help to affected workers and their families, adding that he told GM’s CEO he was disappointed in their move. Later Monday, Innovation Minister Navdeep Bains told a news conference in Ottawa that the Trudeau government is “more than willing to work with the province and work with the municipal leadership to see what we can do for the workers.” Mr. Trudeau later tweeted that he spoke to Ontario Premier Doug Ford and that they are “united in support” for workers in Oshawa, Ont.

GM workers have been part of the heart and soul of Oshawa for generations - and we’ll do everything we can to help the families affected by this news get back on their feet. Yesterday, I spoke with @GM ’s Mary Barra to express my deep disappointment in the closure. — Justin Trudeau (@JustinTrudeau) November 26, 2018

I had a good call with Premier Ford today – we’re united in support for workers in Oshawa, and we’ll work together to do everything we can to help the people and communities affected. — Justin Trudeau (@JustinTrudeau) November 26, 2018

Provincial: The Ontario government will bolster unemployment insurance coverage, from 45 weeks to 50, in all regions affected by the plant closing, Mr. Ford said Monday. He also said he asked GM in a phone call if there was anything Ontario could do to keep the Oshawa plant open, and was told it could not.

Today is a difficult day for GM workers in Oshawa, their families and those impacted through the wider supply chain. We will always stand with you. We have actioned immediate supports, and will work with our federal and municipal partners to support you. https://t.co/54deWGBQYE — Doug Ford (@fordnation) November 26, 2018

The local MPP for Oshawa, New Democrat Jennifer French, also called the news “gravely concerning.”

GM didn't build #Oshawa . Oshawa built GM. If it is true that @GMcanada is abandoning us, then they are in for a fight. Autoworkers & families deserve better than rumours. The Govt better be figuring out a plan... #MadeInOshawaMatters #community pic.twitter.com/wVELqWO7oe — Jennifer French (@jennkfrench) November 26, 2018

Municipal: Oshawa Mayor John Henry said he had not spoken to anyone from GM. He said he heard about the reported closing from CTV News, which first reported the story, when a reporter called him for comment earlier in the day. In a phone interview with The Canadian Press, he said that the plant closing would have ripple effects well beyond the city:

It’s going to affect the province, it’s going to affect the region ... The auto industry’s been a big part of the province of Ontario for over 100 years. This country has also invested a lot in General Motors.

Presidential: U.S. President Donald Trump said on Monday he was not happy with GM’s decision to idle the plant in Ohio, a state where, at a rally a year earlier, he famously promised that factory jobs were “all coming back. Don’t move. Don’t sell your house.” On Monday, Mr. Trump said GM had “better put something else” in the state. He also told the Wall Street Journal GM should stop making cars in China and make them in the United States instead. He said he told Ms. Barra to “get a car that is selling well and put it back in” Ohio. Tuesday, more than 24 hours after the official announcement, Mr. Trump tweeted his disappointment, saying the government is looking at cutting all GM subsidies.

....for electric cars. General Motors made a big China bet years ago when they built plants there (and in Mexico) - don’t think that bet is going to pay off. I am here to protect America’s Workers! — Donald J. Trump (@realDonaldTrump) November 27, 2018

Congressional: In Ohio, both Senate and House politicians denounced the move as corporate greed, and some took direct aim at Mr. Trump. Democratic Representative Tim Ryan, whose district includes Lordstown, said in a statement the community deserves accountability from the President:

The [Mahoning] Valley has been yearning for the Trump Administration to come here, roll up their sleeves and help us fight for this recovery. What we’ve gotten instead are broken promises and petty tweets. Corporations like General Motors and the President himself are the only ones benefiting from this economy – an economy rigged against workers who are playing by the rules but still not getting ahead.

Oshawa and GM: A history

Video: Get caught up on General Motors's 100-year history in Oshawa, and how it became one of the world's largest assembly plants.

Oshawa’s rise

The news of GM scuttling the Oshawa plant comes 100 years after the U.S. auto-making giant first landed in the community, acquiring the McLaughlin family’s car-manufacturing business in 1918.

The McLaughlins had started making horse-drawn sleighs and carriages in the 19th century and switched to Buick and Chevrolet production in the 1900s. Sam McLaughlin was made the first president of General Motors of Canada Ltd., and under his tenure the company grew quickly, with Oshawa as the export manufacturing base supplying the British Commonwealth. When the car boom of the mid-20th century came, Oshawa was poised to take advantage of the growing demand. By the 1980s, the GM Autoplex was one of the planet’s largest car assembly plants and employed 23,000 people.

The General Motors plant in Oshawa, Ont., shown in a recent satellite image. Google Earth

Even before the 2007-08 financial crisis, GM had been whittling down its operations in Oshawa, scuttling one of its plants in 2005 and cutting 3,750 jobs. Then disaster struck: The recession sent car purchases plummeting, oil prices rose and GM’s Canadian production shrank.

General Motors Corp. filed for bankruptcy protection in 2009. A multibillion-dollar bailout made the U.S., Canadian and Ontario governments part-owners of the company. More cuts came under the so-called Government Motors era, and thousands more jobs were lost when Oshawa’s consolidated plant was closed. In all, Ottawa gave $7.23-billion to GM, and the province $3.6-billion, and when both governments unloaded their GM shares in 2015, they lost about $3.5-billion on their taxpayer-funded investment.

More reading: A history of General Motors in Canada

What will GM do next?

GM’s market share has been in decline, and its share of Canadian light-vehicle production has never recovered to its levels from before the 2009 bankruptcy. With demand waning for traditional sedans, all auto makers are under pressure to change the kinds of vehicles they make. GM is now beginning what is expected to be a long and expensive transition to an entirely new business model, one that embraces electrified and automated vehicles, many of which will be shared rather than owned.

Moving into the electric market will be a costly and painstaking process, The Globe’s Ian McGugan explains: Analysts predict auto makers will need to invest heavily to develop the technologies they need. The industry is still profitable for now, but U.S. economic growth is slowing and consumers are expected to buy fewer cars in the future. GM’s cost-cutting may help them to clear those hurdles and enter an electric future, but as Mr. McGugan writes, it “also underlines doubts about whether the industry can return to robust health.”

What will Oshawans do next?

Losing thousands of jobs will shake the economic balance of Oshawa, a town of 166,000 that’s been trying to grow out of its postindustrial malaise. Public infrastructure projects and a real-estate boom for Ontarians priced out of the Toronto market have improved the city’s fortunes in recent years, but GM remained the city’s No. 1 private-sector employer.

The town is also grappling with pervasive problems of economic inequality that the loss of GM jobs can only make worse. Oshawa’s downtown unemployment rate is nearly twice its region’s average, and there are pockets of deep poverty and homelessness in its inner suburbs. Earlier this year, The Globe’s Marcus Gee took a deeper look at Oshawa’s two realities in a tour of “Tarp Mansion,” an encampment for homeless people by a local creek, where anti-poverty activists spoke with him about the growing disparity between the haves and have-nots.

Watch: The Globe visited Oshawa’s ‘Tarp Mansion’ with two anti-poverty activists, Christeen Thornton and Austin Bates.

Commentary and analysis

Sunil Johal: GM’s closing is a warning shot: Canada’s not ready for the age of disruption

Barrie McKenna: Media frenzy overstates significance of GM’s Oshawa plant closing

Konrad Yakabuski: The GM paradox: Sell more pick-ups, prepare for an electric car world

Campbell Clark: After GM's Oshawa plant closure, the Liberals' industrial strategy is losing its credibility

Editorial: No bailout can save Oshawa from GM's hard reality

Barrie McKenna: On the GM bailout, we got what we paid for

Eric Reguly: What just happened with the Oshawa plant closing? Trump happened, it appears

Compiled by Globe staff

With reports from Josh O’Kane, Eric Atkins, Robert Fife, Reuters, Associated Press and The Canadian Press, and reporting from The Globe and Mail archives by Greg Keenan, Thandiwe Vela and Marcus Gee

Editor’s note: A previous version of this story incorrectly said Unifor was Canada's largest public-sector union. In fact, it is Canada's largest private-sector union. This version has been corrected.

Report an editorial error

Report a technical issue

Editorial code of conduct

Follow related authors and topics

- Manufacturing Follow You must be logged in to follow. Log In Create free account

Authors and topics you follow will be added to your personal news feed in Following .

Interact with The Globe

electric scooter

Yadea factory tour: the surprises i found at the world’s largest electric vehicle maker.

I recently took a trip to China, where I had the opportunity to visit one of Yadea’s several global factories used to produce a wide range of light electric vehicle models and styles. As the world’s largest electric vehicle manufacturer, it was a chance to see how the most popular forms of EVs – namely e-bikes, e-scooters, and electric three-wheelers, are built in sophisticated factories featuring high-level quality control processes. The experience was thoroughly eye-opening, and blew my expectations away!

In fact, one of the biggest surprises of my time at the factory was just how much effort is put into quality control along the way. It was a magnitude that, frankly, I was surprised to see.

I don’t mean that as a slight. It’s just that, like most people, I was probably a bit misinformed before this trip. The term “Chinese manufacturing” makes most of us in the West think of cost reductions and competitive pricing – not heavily automated manufacturing and multi-tier quality assurances. But with Yadea’s massive size has come the opportunity to deeply invest in the hallmarks we previously associated with a bygone era of Western manufacturing.

And I’m not exaggerating when I refer to Yadea as “massive.” This was just one of eight global factories, and this one spanned over 1,000 acres (that’s around 750 American football fields). And this is just Phase I of the factory, which was only built a few years ago. Phases II and III are going to be even bigger, adding much more manufacturing capacity.

Yadea is already a household name all over Asia, where it dominates the markets for scooters, bikes, and other micromobility devices. Last year, over 16 million two-wheeled EVs rolled off the company’s production lines. Yadea refers to itself as the world’s largest electric motorbike manufacturer, but it is also the second-largest motorbike maker, period. With 16M annual production volume, that puts the company within striking distance of overtaking Honda’s 18M annual units. And that’s even more impressive considering Yadea exclusively produces electric vehicles, unlike Honda which nearly exclusively produces combustion engine motorbikes.

Yadea now has a growing presence in Europe and has recently set its sights on a major expansion into North America. That means that Americans are set soon to get access to some of Yadea’s impressively designed and built light electric vehicles (though mostly starting with lighter electric bicycles and scooters).

Check out my video below to see inside Yadea’s factory yourself and to join me for my test drives on several of Yadea’s e-bikes, e-scooters, e-mopeds, and e-trikes. You’re not going to want to miss it!

My tour started in just one corner of the sprawling Jinzhai factory, where I watched as rows of plastic injection molding machines worked in rhythm to pump out various scooter-shaped bits and pieces. This is where many of the body panels, shrouds, and other molded components of Yadea’s electric scooters and e-mopeds are produced. Many smaller companies outsource the production of these types of components, but Yadea does it all in-house to maintain better control over the processes and thus the quality of the parts.

The machines run largely autonomously, though a few workers monitor the machines and can respond to any area, if necessary. I poked my head into a few of the lines and saw some machines churning out recognizable parts like shrouds around the handlebar displays and cargo areas under moped seats, with each completed component moseying down a conveyor belt towards a finished parts pile.

The building was massive and already housed 24 injection molding machines, each the size of my college dorm room. However the area of the building that was currently storing stacks of just-produced parts was already taped off with sections where more injection molding machines would soon be installed. They told me that there are plans to operate 60 of these massive machines here. Yadea continues to roll out new EV models and increase its sales around the world, and that means it is always ramping up its own internal component production capacity to match.

From there we hopped aboard a cute little electric shuttle bus and moved to another building in the complex where welding takes place.

This particular welding building was set up for Yadea’s three-wheelers, which are basically the lightweight farm trucks of China. In the same way you see a bunch of clapped-out F-150 pickup trucks all over rural America, you see these electric three-wheelers all over rural China. That’s why, despite Yadea’s scooters and mopeds being built largely for both the domestic and international markets, their three-wheelers are pretty much only sold in China.

I think they could be incredibly powerful utility vehicles in the US, but that’s another issue for another article. For now, I got the chance to see how these local versions of a pickup truck are made. And I was surprised by just how automated the production is.

Robotic welding seems to take care of most of the fabrication, with the vehicles going from steel tubes and sheet metal to mostly formed trikes without ever touching the ground. Laser cutting ensures each raw sub-component is cut to the exact right size and has smooth finished edges. The pieces are passed from machine to machine, sometimes by robots and sometimes by human hands, until full frames come out the other side.

When the frames are finished being welded, multiple steps of electrophoresis for corrosion resistance and then robotic painting await the finished pieces.

I wasn’t able to go through the actual painting area because it’s closed off to ensure a clean environment for the robotic painting machines, but I did get to see the massive environmental protection equipment that filters the air leaving the painting section of the factory, ensuring that any harmful emissions from the aerosolized paint and treatment chemicals are scrubbed and don’t just get pumped out into the atmosphere.

Again, I definitely went into this tour with some preconceptions that turned out to be false. That doesn’t mean there isn’t polluting heavy industry in some areas, but modern factories like Yadea’s take great pains to reduce emissions. The air around the factory was perfectly clean, the grass was greener than my grass back home, and the courtyards around the building were so nice I would have sat and had a picnic in them if there was time. The effort made to create a clean and comfortable work environment pays dividends now and into the future.

Next, we moved on to yet another massive building in the factory complex, this time where assembly of several different electric scooter and e-moped models takes place. It’s a bit hard to gauge scale inside these huge buildings, but I’m told the building was around 450,000 square feet, or roughly 10 acres. It had a legit football field inside of it, but more on that in a moment.

There were 18 assembly lines in the building, each producing a different model of e-bike, e-scooter, or e-moped. Racks of frames that have been welded in another part of the factory roll in at one end of each production line, where they are scanned and loaded onto the line. The bare frames move along the line as workers install all of the components.

In a matter of minutes, the empty frames receive their motors, controllers, batteries, wiring, lights, body panels, seats, and more. A ballet of suspended racks of components automatically lower themselves from the ceiling at precisely the right location for workers to pluck the parts from the air and install them on the scooters. Everything is designed to be as efficient and comfortable as possible, with very little need to bend over or strain.

From what I could tell, a new electric bike rolled off the line around once every 25-30 seconds or so, while an electric moped rolled off the line every 40 seconds.

It looked like it took around 20 minutes for a bare moped frame to work its way down the assembly line and roll off the ramp at the end as a fully functional electric scooter.

The three-wheelers seem to take longer, with one e-trike rolling off the line around every five minutes.

From there, still, more workers receive the scooters and begin going through a several dozen-point inspection to ensure that everything has been assembled correctly and all of the scooter’s functions are working properly. Things like wheel alignment, torque spec, electrical connections, lighting/sound levels, and many other important areas are all examined as part of the end-of-line quality inspections.

Once the vehicles get the seal of approval, they’re walked over to yet another aerial lift that slowly plucks them from the ground and soars them through the air to another part of the factory.

Each of the buildings is connected by a series of catwalk-style sky bridges. There, the tracks suspending the finished vehicles can pass from building to building without actually going outside. In this way, parts and vehicles can move between different areas of the sprawling complex even while it is raining or snowing.

I mentioned a football field in the middle of this factory building, and I wasn’t kidding. There’s an entire turf field in there. In fact, it used to be real grass, but that required opening the skylights for good sun exposure, which the workers said made the building quite hot in the summer. So instead, they turned it into a turf field.

It gets used for a number of different events, from playing sports on breaks to hosting company events and unveiling. When I passed through, there were several models of electric scooters still set up on the field from a recent event. You can see the field in my video at the top of this article.

There’s also a library at the end of the field, featuring around a dozen shelves of books set up in a rectangle to create a little reading room complete with tables and chairs. Workers can read the books there or they can take any books they like (there’s no charge and the books are regularly replaced by the company).

The last area I had the chance to see in the factory was a staging zone for finished three-wheelers that were ready to be trucked away to local stores (Yadea counts over 40,000 brand stores around the world). There was also a display set up showing raw materials from various stages of production, from bare steel tubes to coated frame members and painted panels. They highlighted the quality of each step, such as how the bare frame tubes are laser cut so precisely that the edges are smooth and feel like a factory edge.

Despite wearing my journalist/YouTuber hat most of the time these days, I do in fact have a mechanical engineering degree on my desk that I occasionally get a chance to dust off. As a younger man, I also spent years working as a machinist in a machine shop and I previously ran my own manufacturing operations, so I have at least a cursory knowledge of what I was looking at for each production step around the factory.

I can tell you that of all the light electric vehicle factories I’ve visited in several countries around the world, I’ve never seen an operation run more professionally than what I saw at Yadea. The attention to detail, the level of automation, and even the consideration of workers’ needs, it was all simply above and beyond anything I’ve seen before.

And that was all before lunch!

With the first part of the tour finished, we headed to the employee cafeteria where I got to choose whatever I wanted from a wide a la carte menu. This also surprised me.

While I didn’t expect the workers to be eating gruel, I was caught off-guard at just how good the food was! And this wasn’t some visiting guest cafeteria (many factories have VIP cafeterias off to the side, and I’ve eaten in those before). I was eating where all the factory workers eat, the people’s cafeteria, the great equalizer. And I know that because my entire lunch was spent with hundreds of people staring at me as the only white guy in the room. I definitely caught a few folks taking pictures of me. It’s cool though, I just told them I’m Keanu Reeves.

After lunch, and having already seen how and where Yadea’s vehicles are produced, I had a blast spending the rest of the afternoon test-driving most of them!

The factory tour was impressive, but it’s on the company’s vehicle testing area and proving grounds that I had the most fun! To hear how that went, you’ll have to stay tuned in for Part Two of this story, coming in another couple days (or you can just watch the video at the top of this article, which includes both parts together for a major sneak peak!).

FTC: We use income earning auto affiliate links. More.

Micah Toll is a personal electric vehicle enthusiast, battery nerd, and author of the Amazon #1 bestselling books DIY Lithium Batteries , DIY Solar Power, The Ultimate DIY Ebike Guide and The Electric Bike Manifesto .

The e-bikes that make up Micah’s current daily drivers are the $999 Lectric XP 2.0 , the $1,095 Ride1Up Roadster V2 , the $1,199 Rad Power Bikes RadMission , and the $3,299 Priority Current . But it’s a pretty evolving list these days.

You can send Micah tips at [email protected], or find him on Twitter , Instagram , or TikTok .

Micah Toll's favorite gear

Lectric XP 3.0 e-bike sale

Best $999 electric bike ever!

Rad Power Bikes sales

Great e-bikes at great prices!

IMAGES

COMMENTS

[email protected]. In 2021, Oshawa Assembly was retooled in record time to be one of the most flexible and advanced of its kind in the industry and is now building the Chevrolet Silverado Heavy Duty truck. The return of truck production to Oshawa provides a significant economic boost for Canada's automotive sector, creating ...

Oshawa Assembly was retooled in 2021 to be one of the most flexible and advanced plants of its kind in the industry, building Chevrolet Silverado Heavy and Light Duty pickup trucks. It is the only GM plant producing both heavy-duty and light-duty pickups, which helps GM meet the strong demand for our leading family of pickup trucks, our largest ...

Oshawa Car Assembly. / 43.8676; -78.8664. Oshawa Assembly (also known simply as GM Oshawa) is a manufacturing facility in the city of Oshawa, Ontario, Canada, that built various automobiles for General Motors Canada. Vehicles were primarily produced for the US, Canadian, and Mexican markets, as well as exports for various countries around the ...

The General Motors plant in Oshawa, On has a rich history of building vehicles that goes back over 100 years. Today, this is the only GM plant that builds bo...

OSHAWA, Ont. (November 10, 2021) — Today, GM Canada announced the first Chevrolet Silverado pickup has rolled off the line at the reopened Oshawa Assembly plant.The return of truck production to Oshawa provides a significant economic boost for Canada's automotive sector, creating 1,800 new jobs to support two shifts of production in Oshawa, and supporting thousands of additional jobs in ...

In 2019, GM closed its Oshawa assembly plant as part of a global restructuring plan to cut costs. Then in November 2020, the carmaker invested $1.2-billion to retool and resume full-size truck ...

GM Canada is investing more than $2 billion in Canada to transform manufacturing facilities in Ingersoll and Oshawa. CAMI Assembly in Ingersoll to be Canada's first full-scale EV manufacturing plant when it begins production of BrightDrop fully electric delivery vans in Q4 2022. Oshawa Assembly will add a third shift, bringing the new jobs ...

Today, GM Canada announced the first Chevrolet Silverado pickup has rolled off the line at the reopened Oshawa Assembly plant. The return of truck production to Oshawa provides a significant economic boost for Canada's automotive sector, creating 1,800 new jobs to support two shifts of production in Oshawa, and supporting thousands of ...

The General Motors Oshawa Assembly Plant has been building world class vehicles in Oshawa, Ontario, Canada since November 7 th, 1953. Before 1953, the facility produced McLaughlin Buicks and was ...

Located about 40 miles east of Toronto near the Lake Ontario shoreline, Oshawa Assembly has undergone a $1.1 billion overhaul and is on track to start building the full-size light-duty and heavy ...

Mario Cywinski November 10, 2021. General Motors Canada has begun production at its Oshawa Assembly plant, with the first Chevrolet Silverado rolling off the line. "The reopening of Oshawa Assembly is an historic accomplishment for GM Canada and our many community partners who worked together to bring us to this very happy day," said Scott ...

In Oshawa, that future is V-8-powered pickup trucks. Detroit-based GM is investing more than $1-billion in the plant, hiring 1,400 to 1,700 people to make heavy and light-duty trucks, the only ...

The Ontario and federal governments will each spend $259 million to help General Motors Canada support and transform the company's Oshawa and CAMI manufacturing plants. Ontario Premier Doug Ford ...

Speaking to Automotive News, GM Canada President Scott Bell said the automaker is currently using parts of the GM Oshawa Assembly plant that it hasn't had to use for nearly 60 years. The plant ...

OSHAWA, Ont. - GM Canada today announced it will start production at Canada's first full-scale electric-vehicle manufacturing plant in Ingersoll, Ontario later this year. In addition, at Oshawa Assembly, GM Canada will add light-duty pickup production and a third shift, creating more than 2,600 new jobs since operations resumed at the plant.

1953: Production of Pontiac, Chevrolet and Buick models begins on Nov. 7 at the official Oshawa Assembly for General Motors Canada. 1955: Almost 10,000 workers strike for 148 days in Oshawa ...

Nov. 12, 2021. Against the odds, General Motors is once again building pick-up trucks at its Oshawa, Ontario plant, just outside Toronto, where GM has built vehicles for more than 100 years. GM's Oshawa, Ontario plant will begin shipping trucks to dealers in December. The first truck off the line will be auctioned to raise money for Sharon ...

What GM is doing and why. When the Oshawa plant is closing: GM's Monday statement didn't use the word "close," instead saying that, as of 2019, the Oshawa plant and several others would be ...

OSHAWA, Ont. - General Motors announced today a C$280 million investment in Oshawa Assembly to produce the next-generation internal combustion engine (ICE) full-size trucks. This investment builds on GM's commitment to Canadian manufacturing, which includes more than $1.2 billion invested in the Oshawa plant in 2020.

Your work schedule may also vary on a weekly basis. Our plant is a 3-shift operation. This is a temporary position. As an integral part of the General Motors Oshawa Assembly team, you will be scheduled on a part-time casual basis to perform production assignments in our fast-paced vehicle manufacturing environment.

The factory tour was impressive, but it's on the company's vehicle testing area and proving grounds that I had the most fun! ... GM hopes new EVs like the $35K electric Chevy Equinox will help ...