The #1 website for NICET Practice Tests, NICET study guides, Fire Alarm Code Knowledge, and General Fire Alarm Topics. We have up to date information on the newest fire alarm trends such as fire service access elevators, mass notification, voice intelligibility, occupant evacuation elevators and two-way communication for Areas of Refuge. Topics also include fire alarm system programming and technical tips. Learn how to build the best ground fault meter with step by step instructions.

- NICET Exam Practice Test

- Bluebeam for Fire Alarm Design

- Occupancy FA Requirements

- 520 HZ Low Frequency Audible Tone

- Industry Links

- Conduit Bending

Tuesday, March 24, 2015

Elevator Shunt Trip Requirements and Codes

Elevator shunt trip explained, what specific codes or standards address elevator shunt trip.

- Elevator may react erratically due to water shorting out controls

- Water on the elevator braking system

- Risk of Shock or Electrocution

Can the Elevator Shunt Trip Activation be Delayed?

Shunt trip control circuits to be monitored for operating voltage , what is the requirement for shunt trip breaker location, resetting a shunt trip breaker.

When is the shut trip breaker tested

- Fire Engineering Training

Elevators: Power Shunt Trip

Greg Havel discusses how an elevator’s power shunt trip, which is activated before automatic fire sprinklers discharge, could affect firefighting operations and how firefighters can deal with them.

Article and photos by Gregory Havel

The ASME and NFPA standards and codes consider the occupants of an elevator car that is stopped between floors or that is evacuated at the nearest floor level to be at less risk than they would be if the elevator continued to operate during fire sprinkler discharge.

3. Arriving firefighters may initiate Phase II Emergency In-car Operation by using a key and pressing buttons inside the elevator car to close and open doors and to move the car between floors. Photo 1 shows a typical lobby elevator control panel with the key switch to select firefighter operation. Photo 2 shows a typical elevator car control panel, with the firefighter key switch and indicator lights in the red panel in the center and operating instructions in red directly above. In this way, firefighters can quickly move equipment to upper floors nearer the location of the fire and evacuate persons who are unable to self-evacuate using stairways.

4. If smoke is present at the top of the elevator hoistway or in the machine room, the smoke detector will activate a circuit in the elevator controller. This will cause the red firefighter helmet indicator light on the control panel (see photos) to begin to flash, indicating that smoke and fire are near the elevator machine or in the hoistway and that a power shunt trip is possible. The instructions on the panel in Photo 2 state, “WHEN [fire helmet] FLASHES, EXIT ELEVATOR.” Firefighters at this time have the choice of manually opening the elevator doors at the nearest floor and exiting the elevator or attempting to return the elevator car to the primary recall floor with the risk of becoming trapped in the elevator between floors when the power shunt trip breaker operates.

5. When significant heat is present at the top of the elevator hoistway or in the machine room, the heat detector near a sprinkler head will sense that sprinkler discharge is imminent and will cause the main elevator power to shunt trip without delay, without any action by the elevator controller. This power shunt trip breaker can only be reset manually in the elevator machine room. Disconnection of the elevator main power does not affect lights or communications with the elevator car, which are on separate circuits.

However, there are two (rare) scenarios in which firefighters or other building occupants could become trapped by a power shunt trip:

- A very slow elevator, or one with a great distance to travel, with a fast-moving fire in or near the elevator machine room. In this instance, the elevator does not have time to complete Phase I recall before the power shunt trip.

- A large-scale incident in a multistory residential building occupied by many persons who are not capable of self-evacuating by way of stairs, which could result in firefighters using the elevator on Phase II operation to the last possible moment to remove as many occupants as possible.

The author acknowledges the valued assistance with the research for this article by Brian Rausch PE, at the Wisconsin Elevator Safety Program of the Wisconsin Department of Commerce.

- Download this article as a PDF!

- More Construction Concerns

- More Building Construction

- More Fire Prevention and Protection

Subjects: Building construction for firefighters

Related Posts

Latest Fire Engineering News

Please check your spam folder and any email filters, in the event that the email gets blocked.

Stay informed about daily FireEngineering news, podcasts, training videos, webcasts, commentary, and exclusive articles about FireEngineering by signing up.

Elevator Switches

Mersen’s Type ES Elevator switches are designed for commercial applications where safety, high performance and continuity of service are essential.

Mersen’s Elevator Switches are available in 30-400 amps and 208VAC, 240VAC, 480VAC, 600VAC. They have 5 enclosure types, NEMA Type 1 (indoor), Type 3R (outdoor), Type 4 and 4X (water and dust-tight, corrosion resistant), and Type 12 (drip and dust-tight). They are UL 98 and cUL 508A listed.

Features & Benefits

Best suited for commercial applications.

Fire safety relay for control interface (3 PDT relay with choice of coil voltage).

Oil-tight key switch to test 2 position selector switch.

Oil-tight power enabled indicator light (green, red or white).

Isolated lug neutral (100% or 200%)

Auxiliary and alarm contacts (Form C). Auxiliary contacts change state when switch is in ON position. Alarm contacts change state when switch is in tripped position

Rotary ON/OFF handle.

Accepts padlock in OFF position.

Suitable for Class J fuses.

Related Industries

Publications

- Application and Technical

Compliance with the 2017 NEC for Elevator Controllers

Traditionally, the electrical system design engineer has given little attention to the elevator controller. In fact, an entire elevator system for a project is most often designed and specified by the architect who has little understanding of the electrical distribution system. Because of this, there is often a communications gap between the electrical system designer, whose design typically stops at the required elevator disconnecting means, and the architect who designs the elevator system. To address this issue, Code Making Panel (CMP) 12 of the National Electrical Code ® acted on several proposed changes to Article 620 during the revision cycle for the 2017 NEC that deal with the proper installation of elevator controllers.

The proposals resulted in adding new requirements in the 2017 NEC for:

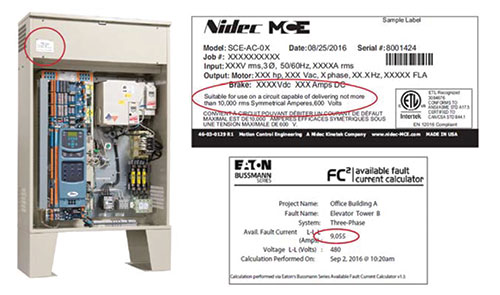

- Marking the elevator controller short-circuit current rating (SCCR) by the elevator controller manufacturer.

- Reinforcing NEC 3 (B) and NEC 110.10 to require the elevator controller marked SCCR to be equal to or greater than the calculated and marked available short-circuit (fault) current at the elevator controller.

- Marking the available short-circuit (fault) current on the controller by the equipment installer.

This article will also discuss other Code requirements that include selective coordination for elevators that are supplied by emergency, legally required standby or critical operation power systems or multiple elevators supplied from a single feeder, and shunt tripping of elevators where the elevator equipment room and/or shaft has a fire suppression sprinkler system. Finally, typical installations and compliance with all these requirements will be discussed.

Equipment SCCR and short-circuit current marking requirements

The reason the NEC CMP 12 added these requirements, as shown in the panel statements, directly relates to the concern that elevator controllers can be installed in locations where the available fault current can be high and the inspector may not be able to clearly determine the SCCR of the elevator controller unless it is marked on the equipment. The panel further clarified that the marked SCCR value must be adequate for the available fault current to ensure a safe installation. In order to aid enforcement, the panel additionally required marking the available fault current at the elevator controller. Below is a summary of these new 2017 NEC sections:

- 620.16(A) Manufacturers must mark their elevator control panels with an equipment short-circuit current rating (SCCR). The SCCR can be based on an assembly product standard listing and labeling, or an approved analysis method, such as UL 508A, Supplement SB.

- 620.16(B) If the elevator control panel SCCR is not equal to or greater than the available fault current, the elevator control panel must not be installed.

- 620.51(D)(2) An elevator control panel must now be field marked with the maximum available fault current along with the date the calculation was made. Further, if there is a change to the available fault current, then this field marking must be revised.

Complying with these new requirements

In order to comply with these requirements a chain of events must occur.

- The electrical system designer calculates the maximum available fault current at the elevator controller.

- The electrical system designer needs to communicate this information to the person responsible for specifying the elevator controller, which is most often the architect.

- The party responsible for procuring the elevator control panel must state the minimum acceptable SCCR or the maximum available fault current where the controller will be installed.

- The elevator controller manufacturer must determine the required elevator controller SCCR as stated in the elevator controller specification and provide an elevator controller SCCR that is equal to or greater than the available fault current that’s indicated in the design documents where there are multiple elevator controllers at different locations.

With these new NEC requirements, there is now the potential that an elevator controller SCCR may be required that’s higher than what elevator manufacturers have historically furnished. As such, elevator controller manufacturers should make the effort to rethink their designs to avoid costly system design changes. For instance, a typical elevator controller may traditionally have SCCR ratings from 5 to 10 kA. However, it is likely that for many elevator controllers, this may not be high enough for the available fault current where they will eventually be installed.

Some elevator controller manufacturers believe this is an issue for the electrical system designer and installer to address and remedy by adding impedance to the system for lowering the available fault current. This, however, can result in a dramatic increase in cost, space availability (lack thereof), and reduced efficiency. For instance, one method to reduce the available fault current is to add an isolation transformer ahead of the elevator controller.

Many new buildings are incorporating an elevator design that does not include an equipment room (sometimes called machine room-less elevators). All equipment in a machine room-less design is installed within the elevator shaft or exterior compartment near the elevator shaft, including the elevator controller and the elevator disconnecting means. In these installations, it is best to design the elevator controller so the elevator controller SCCR is adequate for the available fault current. This is something that can be easily accomplished if the elevator controller manufacturer uses components in combination with overcurrent protective devices that are tested and listed with high combination SCCRs. In many cases, the overcurrent protective devices that are suitable for this level of protection are current-limiting fuses rather than a traditional circuit breaker. In this case, it may be best if the elevator controller manufacturer does not include the elevator disconnecting means (often offered as a circuit breaker) but instead have the installer provide a separate fused disconnect to comply with NEC 620.51(A) and also achieve a high SCCR for the elevator controller when fuses are provided as specified by the elevator controller and marked on the elevator controller nameplate.

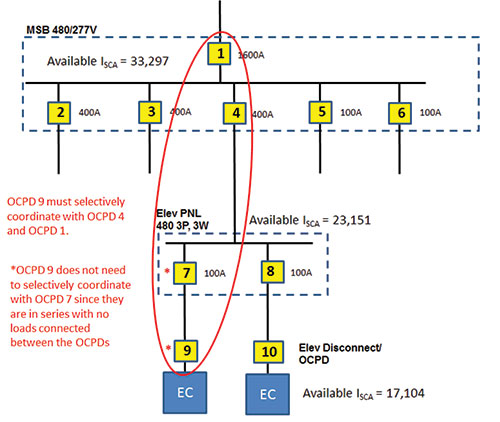

Selective Coordination

If elevators are supplied by the emergency, legally required standby or critical operation power systems, then selective coordination is required per the 2017 NEC in 700.32, 701.27 or 708.54. Selective coordination is also required for multiple elevators per NEC 620.62. Another important electrical system design consideration for supplying power to multiple elevators is NEC 620.62. NEC 620.62 requires the elevator disconnecting means (fused switch or circuit breaker) to selectively coordinate with all supply-side overcurrent devices. Selective coordination is defined by the NEC as: “Localization of an overcurrent condition to restrict outages to the circuit or equipment affected, accomplished by the selection and installation of overcurrent protective devices and their ratings or settings for the full range of available overcurrents, from overload to the maximum available fault current, and for the full range of overcurrent protective device opening times associated with those overcurrents.”

In order to comply, the electrical system designer must determine the maximum available fault current at the elevator disconnecting means and assure the elevator disconnecting means overcurrent protective device will clear any overcurrent condition, up to the maximum available fault current, before any upstream overcurrent devices will operate. Notice the definition mentions the full range of operating times. This is important as the tradition of using only time-current curves for the analysis of overcurrent device operation is usually not sufficient since the time-current curves traditionally stop at 0.01 second (not time “zero”).

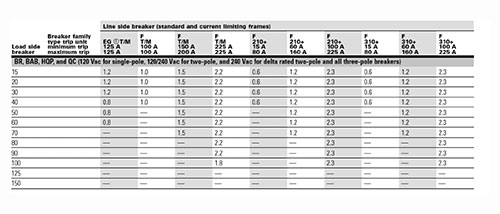

For current-limiting fuses, the information to achieve selective coordination has been available for many years in fuse amp ratio tabular form. These selective coordination tables for current-limiting fuses show the minimum amp ratio required between a pair of fuses of a given type(s) to achieve selective coordination.

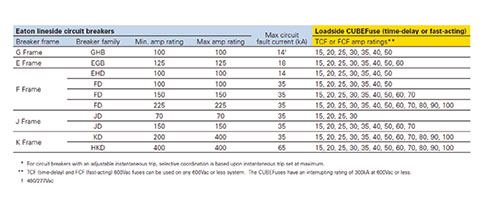

For circuit breakers, time-current curves must be consulted as well as the circuit breaker manufacturer’s selective coordination tables. These circuit breaker selective coordination tables can be used to identify the maximum fault current that a pair of circuit breakers can selectively coordinate. It is important to note, that these selective coordination tables can indicate a lack of selective coordination at a given fault current for circuit breakers that do not show overlap on the time-current curves of the circuit breakers. For some manufacturers, such as Eaton, testing has been completed to determine the selective coordination ability of current-limiting Bussmann TM series fuses with upstream Eaton circuit breakers.

Shunt Tripping

Where the elevator shaft and/or equipment room has a sprinkler fire suppression system installed, the elevator Code requires main line power to the elevator be removed prior to the application of water. This is typically accomplished via a shunt trip device.

There are options available to achieve this depending upon the customer’s needs. The simplest option is to use a shunt trip circuit breaker in either the feeder supplying the elevator or the elevator disconnect. For elevators with battery lowering systems, an additional contact must be supplied and wired to disable the battery lowering system when the elevator disconnect is manually operated for maintenance. NFPA 72 requires the control circuit between the Fire Alarm System and the shunt trip be monitored for integrity. In addition, the shunt-trip voltage must also be monitored by the Fire Alarm System. Loss of voltage to the control circuit for the disconnecting means shall cause a supervisory signal to be indicated at the control unit and required remote annunciation. In some cases, it may require a means to test the shunt trip operation or have one contact operate the shunt trip of more than one elevator. Per the 2017 NEC , if the elevator is designated as an emergency system load, the disconnect must be protected by a surge protective device (SPD). All of these options and special wiring can be challenging depending upon the location of the shunt trip circuit breaker as well as who has responsibility for providing these additional options. Because of this, several manufacturers offer an all-in-one shunt trip elevator disconnect switch that includes all the prewired accessories needed to comply with the various Code sections.

Typical Elevator Installations

The architect has a choice of either traction or hydraulic elevators. Traction elevators are typically faster and more energy efficient than hydraulic elevators, and are often used for high-rise buildings. Hydraulic elevators are typically more cost effective and used for buildings up to 5-6 stories. Traction elevators are typically installed in a “bank of elevators” where fused switches, or circuit breakers in a panelboard are located in the machine room serving the bank of elevators. Each fused switch or circuit breaker in the panelboard is used as an elevator disconnect. Hydraulic elevator installations are typically supplied from the main switchboard and have an elevator fused switch or circuit breaker in the machine room that serves as the elevator disconnect.

As mentioned, traditional installations of a traction or hydraulic elevator include a separate machine room. The vast majority of equipment serving the elevator is located within this room (i.e., elevator controller). Also located in this room might be, but not limited to: exhaust fan, cooling unit (depending on local requirements and/or requirements set forth by the individual elevator supplier), lighting, voice and/or data drop serving the elevator cab emergency phone, elevator controller primary fused disconnect, elevator feeder shunt-trip circuit (i.e., shunt-trip circuit breaker), elevator cab lighting fused switch, and convenience receptacle(s).

Machine room-less elevator installations incorporate the elevator controller and often the primary disconnecting means in a convenient package that is located within the elevator shaft. However, space is frequently limited within the shaft and as such many ancillary components (shunt trip circuit breakers, fused disconnects) may need to be located outside of the elevator shaft. It is important for design engineers to communicate this with the architect and owner during the design phase, as it will impact space needs elsewhere in the facility to accommodate electrical equipment.

A traditional elevator installation (which includes a machine room) requires access inside the elevator shaft. Convenience receptacles and lighting for maintenance purposes are required at the base of the pit and, in some instances (elevator manufacturer dependent), at the top of the elevator shaft. It is important for the design engineer to coordinate with the architect to determine the elevator manufacturer basis of design to determine if and when additional power and lighting is required.

It is of great importance for the design engineer to communicate with their local authority having jurisdiction (AHJ) to determine fire alarm requirements for the respective elevator installation. While machine room-less designs have been commercially available for many years, their use may still be unknown to some AHJs. Design practices that are acceptable in some jurisdictions may not be in others. As always, the best advice in all instances…do your homework, communicate often, and document decisions made. Years may lapse between the design and installation stages of a project. Good documentation is of key importance to recalling what decisions were made and why.

With the new elevator controller requirements, more attention will be focused on the elevator system. First, it is now clear that elevator controllers must be marked by the manufacturer with their SCCR. The design engineer must identify the available fault current at the elevator controller to the installer so an elevator controller with adequate SCCR can be provided. If this is not done and the available fault current exceeds the elevator controller SCCR, other solutions to reduce fault current must be reviewed or equipment changes and field evaluations may be needed. In addition, requirements for selective coordination and shunt tripping should be complied with as needed for the installation.

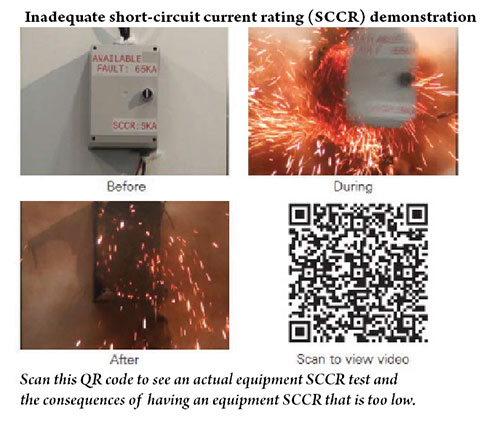

What are the Safety Hazards of Inadequate SCC

The hazards are external to the equipment enclosure since equipment SCCR testing and evaluation criteria for product standards are most often performed with the enclosure doors closed and latched, and the fault occurring external to the enclosure. Installing electrical equipment where its SCCR is less than the available short-circuit current creates serious safety hazards. These may include:

- Shock: The enclosure becomes energized from conductors pulling out of their terminations or device destruction occurring within the enclosure.

- Fire: The explosive power of the internal devices failing causes the closed and latched door to become ajar and spew flame and molten metal to the exterior. This is a fire hazard to both the facility and personnel.

- Projectile (shrapnel): The enclosure door may blow open or off with fire and failing device debris (shrapnel) shooting out. In laboratory tests, equipment SCCR failures have resulted in enclosure doors explosively blowing off and flying up to 100 feet away. Additionally, the shrapnel, from the rapid failure of internal devices, can be ejected at speeds up to 700 miles per hour.

The author would like to recognize Jonathan Kennedy for his assistance in creating this article.

Air-Conditioning Equipment Installations

Basic three-phase power measurements explained

Safety in Marinas

Find Us on Socials

Raceway connections.

As an installer and an inspector, one common issue I've seeen is incompatible connections associated with raceways connections and fittings.

Safety After the Storm — Operating Portable Generators

Electricity is often one of the initial services to fail during a storm. Many people use portable generators until power is restored.

22 Ways to Make Members Feel Valued

Here are 23 ways that both chapters and the national office can meet today’s major challenge of making members feel valued

- Find Authorized Distributors

- About Littelfuse

- Littelfuse Business Center

- Littelfuse University

- Commercial Vehicle Products Portal

- Electronics Technical Resources

- C & K Partner Community

- Search All Automotive Sensor Products Battery Management Battery Mini-Breakers Custom Sensors DC Power Distribution Modules DC Solenoids and Relays Discrete Diodes Discrete IGBTs Discrete Thyristors Fusible Switches and Panels Fuse Blocks Fuseholders and Fuse Accessories Fuses Gas Discharge Tubes Ignition IGBTs LED Protectors Magnetic Sensors and Reed Switches New Products Other Products and Accessories Polymer ESD Suppressors PolyZen Devices Power Semiconductors Protection Relays and Controls PolySwitch Resettable PPTCs Shock Block GFCI SIDACtor Protection Thyristors Silicon Carbide Surge Protection Modules and Devices Switches Temperature Sensors TVS Diode Arrays TVS Diodes Varistors

Automotive Sensors

- Comfort and Convenience

- Passenger Safety

- xEV Sensors

Battery Management

- Battery Combiners

- Battery Isolators

- Electrical Battery Disconnect Switches

- FlexMod Electronic Modules

- Low Voltage Disconnects

Battery mini-Breakers (Thermal Cutoff Devices)

- Metal Hybrid Protection

Capacitors boosts the current and increases the power factor to an electrical motor.

- Motor Hard Start Capacitors

- Motor Run Capacitors

- Auxiliary Switches for Contactors

- Definite Purpose Contactors

- Current Sensing Resistors

DC Power Distribution Modules

- Auto & Commercial Vehicle Fuse Holders

- Configurable PDM

- Fuse Only PDM

- Hard Wired PDM

- Power Distribution Accessories

- POWR-BLOK Modular Power Distribution

- Unsealed PDM

DC Solenoids and Relays

- Bi-Stable Latching Relays

- CAN Controllers and Plug In Relays

- Mechanical Relays

- Plug In Relays

Solid State Relays

- Specialty Relays

- Standard High Current Relays

- Time Delay and High Power Relays

- High Voltage DC Contactors Relays

DC Vehicle Connectors

- 13-Pole Sockets and Plugs

- 15-Pole Sockets and Plugs

- 15-Pole Spiral Coils

- 2-Pole - 3-Pole Sockets and Plugs

- 7-Pole Sockets and Plugs

- 7-Pole Spiral Coils

- ABS - EBS Sockets and Plugs

- ABS - EBS Spiral Coils

- Connector Accessories

- Greycon Connectors

EMC Components

- Common Mode Noise Filters

- Common Mode Filters with ESD Protection

- Electronic Switches, Connectors, and Harnesses

Fuse Block Fuse Holder and Fuse Accessories

- Bodies, Caps, Covers and Terminals

- Box Cover Units

- Dead Front Fuse Holders

- Electrical Power Distribution Blocks

- Fuse Blocks

- Fuse Modules

- Fuse Pullers

- Fuse Reducers

- Fuse Holder

- Inline Watertight Fuse Holders

- POWR-GARD Fuse Blocks

- Specialty Items

- Telcom Disconnect Switches

- POWR BLOK Modular Power Distribution

- AEC-Q200 Qualified Fuses

- Automotive Aftermarket Products

- Automotive Passenger Car

- Axial Radial Thru Hole Fuses

- Hazardous Area Type Fuses

- Industrial Power and UL Fuses

- Medium Voltage Fuses

- Cartridge Fuses

- Military High Reliability Fuses

- Specialty Power Fuses

- Surface Mount Fuses

Fusible Switches and Panels

- XPress-Ship™ Program

Gas Discharge Tubes

- High Voltage GDT

- Low to Medium Surge GDT

- Medium to High Surge GDT

- Squared GDT

- Very High Surge GDT

- Integrated Circuits

- Magnetic Sensors and Reed Switches

- Custom Sensors

- Hall Effect Sensors

- Magnetic Actuators

- Reed Relays

- Reed Sensors

- Reed Switches

- Transformers

- New Products

Other Products and Accessories

- Accessories

- BusBars and Terminal Blocks

- Circuit Breakers

- Knobs and Nuts

- Pilots, Lamps and Alarms

- Power Distribution

- Speciality Items

- Terminals and Contacts

- Tracto-Trailer and Auto-RV Connectors

- Wiring Accessories

Polymer ESD Suppressors

- PESD Protection Devices

- PULSE-GUARD® ESD Suppressors

- XTREME-GUARD™ ESD Suppressors

Power Semiconductors

- AC Bridge Rectifiers

- Breakover Diodes

- Ignition IGBTs

- IXYS Power Semiconductors and ICs

- Diode Modules

- Discrete IGBTs

- Discrete MOSFETs

- Discrete Thyristors

- Thyristor Modules

- IGBT Modules

- MOSFET Modules

- Thyristor-Diode Modules

- Discrete Diodes

- Fast Diodes and Schottky Products

- Silicon Carbide

- Stacks, Subsystems, and Assemblies

Protection IC

- Load Switch

Protection Relays and Controls

- Alternating Relays

- Arc Flash Detection

- Covers and Mounting Adapters

- Feeder Protection

- Ground Fault Relays

- Flashers and Tower Lighting Controls

- Industrial Products

- Intrinsically Safe Relays

- Motor and Pump Protection

- Pump Controls and Liquid Level Controls

- Relay Current Transformers

- Relay Software

- Resistance Grounding

- Retrofit Kits

- Single Function Relays

- Time Delay Relays

- Trailing Cable Protection

- Voltage Monitoring Relays

PolySwitch Resettable PPTC Fuses

- Battery Strap

- Bladed Devices

- Line Voltage Rated Devices

- Low Resistance

- Radial Leaded

- Surface Mount

- TD and Chip

- Semiconductors

LED Protectors

- PLED 5HT SOT 89

SIDACtor® Protection Thyristors

- Baseband Voice DS1 Protection

- Broadband Optimized Protection

- High Exposure Surge Protection

- Line Circuit Access Switch LCAS Protection

TVS Diode Arrays

- Automotive Qualified

- General Purpose ESD Protection

- Lightning Surge Protection

- Low Capacitance ESD Protection

- Ultra Low Capacitance

Shock-Block® GFCI

- Industrial Shock-Block GFCI

- Shock-Block GFCI Rental Products

Surge Protection Modules and Devices

- LED Lighting Surge Protection Modules

- Type 2 Surge Protection Devices - SPD2 Series

- AC Power Relays

- OptoMOS Power Relays

- OptoMOS Relays

- Ignition Switches

- Manual Battery Disconnect Switches

- Momentary Switches

- Push-Pull Switches

- Rocker Switches

- Rotary Switches and Headlamp Switches

- Plunger Switches

- Special Purpose Switches

- Toggle Switches

- Windshield Wiper Switches

- Temperature Sensors

- Digital Temperature Indicators

- Leaded RTDs

- Leaded Thermistors

- Power Thermistors

- RTD Probes and Assemblies

- Surface Mount Thermistors

- Thermistor Probes and Assemblies

- 2Pro Devices

- Industrial High Energy

- Multi-layer

- Thermally Protected

- Automotive Aftermarket

- Automotive and Commercial Vehicle Aftermarket

- Battery Energy Storage Systems

- Building Automation

- Commercial Vehicle

- Communications Infrastructure

- Consumer Electronics

- Data Center Solutions

- Electrical Contractor

- Electrical Maintenance and Repair

- EV Charging

- Food and Beverage

- LED Lighting

- Military Electronic Parts

- Oil, Gas and Petroleum

- Power Generation

- Renewable Energy

- Water Wastewater

- Custom Circuit Protection Solutions

- DC High-Voltage Solutions

- Electronic Testing Services

- MROplus Industrial Fuse Consolidation

- Application Designs

- Building and Home Automation

- Consumer and Personal Computing

- EV Infrastructure

- General Port Protection

- Li-ion Battery

- Medical Devices

- Power Supply

- Datasheets & Downloads

- Application Guides

- CAD Drawings

- Certification

- Engineering Drawings

- Product Catalogs

- Product Manuals

Datasheets & Downloads

- Application Notes

- Obsoletion Notices

- Peak Let Thru Curves

- Plant Certifications

- Product Literature

- Product Presentations

- Product Specifications

- RoHS Declaration

- Simplified Circuit Diagrams

- SPICE Models

- Supplier Quality

- Technical Articles

- Technical Papers

- Time Current Curve

- Tutorials and Demos

- White Papers

- Online Tools

- Arc-Flash Calculator

- Competitor Cross Reference

- Demos and Tutorials

- ECAD Models

- IBU Relay Selection Guide

- Littelfuse Mobile Apps

- SPD Selection Guide

- Temperature Sensor Selection Guide

- Technical Centers

- Arc-Flash Knowledge Center

- Ceramic, Polymer, and Fuse

- Ground-Fault Knowledge Center

- Relays and Controls

Need the Littelfuse equivalent to a competitor part? Enter the competitor part number here.

Search for the part(s) number you wish to receive samples. Or, visit the sample center page.

Check distributor stock levels by entering in full or partial part numbers

- > Fusible Switches and Panels

LPS Shunt Trip Elevator Disconnect Switch

Connect with Littelfuse

- Mobile Site

- Capabilities Brochures

- Investor Relations

- Media Coverage

- Privacy Statement

- Sustainability

- Terms & Conditions of Sale

- Website Feedback

- Website Terms of Use

Explore Littelfuse Products

- Check Distributor Stock

- Disclaimers

- Order Samples

Technical Resources & Quality

- Conflict Free Statement

- Supplier Resources

- Supply Chain Transparency

- Technical Documents

Littelfuse, Inc. 8755 West Higgins Road Suite 500, Chicago, IL, 60631 USA, 773-628-1000 Copyright © 2022 Littelfuse, Inc.

We use cookies to collect information about how you interact with our website and to remember you. We use this information to improve and customize your browsing experience and for analytics about our visitors on this website and other media. To find out more about the cookies we use, see our Privacy Policy .

You can change this setting by clicking on OPTIONS. By continuing, you agree to the use of our cookies.

We use cookies to collect information about how you interact with our website and to remember you. We use this information to improve and customize your browsing experience and for analytics about our visitors on this website and other media. By selecting among and accepting to our use of the cookie categories below, you direct Littelfuse to store cookies on your device and disclose information as described in our Privacy Policy .

If you do not direct us to collect any categories of cookies, a single essential cookie will be used in your browser to remember your preference not to be tracked.

Your Privacy

- Performance and Analytical Technologies

Functionality

Targeting or advertising.

When you use our website, we collect personal data about you and your use of the Website, through cookies and analytics tools. We may also collect personal data such as your name, job title, company name, address, email address and telephone number either directly from you or by combining information we collect through other sources.

Because Littelfuse respects your right to privacy, you can choose to modify the cookies option and disallow some of them. Click on the different category headings to learn more and change default settings. However, blocking some types of cookies may impact your experience of the site and the services we are able to offer.

There are cookies which are needed for our website, applications or services to function properly. For example, these cookies remember your preference not to be tracked and identify trusted web traffic.

Performance and analytical technologies

These cookies collect information about how visitors and users use our website, applications, and services. These cookies enable us to improve our website, for instance, by ensuring that users are finding the required information.

These cookies don't collect information that identifies a visitor or user. All information collected by these cookies is aggregated and anonymous.

These cookies allow our website, applications and services to remember choices you make (such as your preferred language) and provide enhanced, more personal features. They may also be used to provide services you have asked for.

The information these cookies collect may be anonymized and they cannot track your browsing activity on other websites.

These cookies are used to deliver advertising that may be relevant to you and your interests. They are also used to limit the number of times you see an advertisement as well as help measure the effectiveness of an advertising campaign.

They remember that you have visited a website and this information is shared with other organizations such as advertisers.

IMAGES

VIDEO

COMMENTS

The purpose behind this allowance is to increase the potential for elevators to complete their travel to the recall level. Make note that the requirements of A17.1/B44 Safety Code for Elevators and Escalators would still apply. If your fire alarm system utilizes waterflow or pressure switches to activate the elevator shunt trip, any time delay ...

Eaton's elevator control switch, an all-in-one power disconnect solution, enables one to meet NFPA, NEC and local building codes related to hydraulic elevator applications. Shunt trip disconnect, relays to receive FACP signal and monitor shunt trip control voltage, and aux contact for battery...

The Littelfuse® LPS Series provides a simple and economical solution for applications that require selective coordination and shunt trip capabilities. Utilizes Class J time-delay fuses that are easily coordinated with other system overcurrent devices. The shunt trip capability allows the LPS Series to meet the ANSI/ASME standard that requires ...

Features and benefits. The Bussmann series Power Module Switch is a ready-to-install elevator disconnect with popular configurations that can ship in three business days. any single elevator shutdown and disconnect requirement. Easily selectively coordinated, this switch is the best choice for design engineers and electrical contractors that ...

Product description: Eaton's Bussmann® series Quik-SpecTM Power Module Switch is an all-in-one elevator disconnect switch available in configurations to meet virtually any single elevator shutdown and disconnect requirement. Easily selectively coordinated, this switch is the best choice for design engineers and electrical contractors that ...

Shunt-Trip Operation The disconnect means is a shunt-trip operated switch. The control power source for the shunt-trip operator is a 120 Vac supply originating in the Siemens Elevator Control switch. Current to the shunt-trip device is switched by an isolation relay, which is in turn controlled by the FACP.

operation of the shunt trip. A pilot light signaling that the switch is ON and a neutral lug are the only other available options. The available enclosures include NEMA T 1, 3R, 12 and 4 (painted), allowing the Eaton Elevator Disconnect to be mounted in virtually any standard operating environment. In summary, the Eaton Elevator Disconnect is an

Mersen's Fusible Shunt Trip Switch is an all-in-one solution that meets many different code requirements with the protection and safety in elevator shafts. According to NFPA 13, 8.14.5, sprinkler protection is required at the top and bottom of elevator shafts.

A power shunt trip in an elevator operates simply and reliably. Heat detectors are located in the machine room and at the top of the hoistway, within 24 inches of each sprinkler head.

Mersen's Type ES Elevator switches are designed for commercial applications where safety, high performance and continuity of service are essential. They are available in various amps, voltages and enclosure types, and have features such as fire safety relay, oil-tight key switch and indicator light.

The simplest option is to use a shunt trip circuit breaker in either the feeder supplying the elevator or the elevator disconnect. For elevators with battery lowering systems, an additional contact must be supplied and wired to disable the battery lowering system when the elevator disconnect is manually operated for maintenance.

SHUNT TRIP DISCONNECT SWITCH Item #: 0218582 CAT #: LPS1T20R2KGN1BF UPC: 079458793376 $ 4031.60 EA ... Elevator Disconnect, Fused, 200 AMP, 3-Pole, 208V Includes: 120V Fire Safety Interface Relay, Mechanical Interlock with 2NO & 2NC Contacts, Bypass Fire Alarm, NEMA 1, Enclosure Dims: H: 30", W: 20", D: 9" ...

disable the battery lowering system when the elevator disconnect is manually operated for maintenance. NFPA 72 requires the control circuit between the Fire Alarm System and the shunt trip be monitored for integrity. In addition, the shunt-trip voltage must also be monitored by the Fire Alarm System. Loss of

Mersen's fusible shunt trip switch is a UL Listed industrial control panel offering remote load-break disconnection capability to emergency circuits. An array of available options allows for maximum functionality to be built into a single compact panel. Panels built for elevator applications feature control transformers (fusing both

and shunt trip capabilities. Utilizes Class J time-delay fuses that are easily coordinated with other system overcurrent devices. The shunt trip capability allows the LPS Series to meet the ANSI/ ASME standard that requires power to be automatically disconnected before water is turned on by the fire safety system. Applications Elevator circuits

LPS Shunt Trip Elevator Disconnect Switch - Littelfuse. Home. > Products. > Fusible Switches and Panels.

Elevator Disconnect, Fused, 100 AMP, 3-Pole, 208V Includes: 120V Fire Safety Interface Relay, Mechanical Interlock with 2NO & 2NC Contacts, ... The shunt trip capability allows the POWR-Switch to meet the ANSI/ASME standard that requires power to be automatically disconnected before water is turned on by the fire safety system .

shunt trip. A pilot light signaling that the switch is ON and a neutral lug are the only other available options. The available enclosures include NEMAT 1, 3R, 12, and 4 (painted), allowing the Eaton elevator disconnect to be mounted in virtually any standard operating environment. In summary, the Eaton elevator disconnect is an all-in-one solution

Elevator Disconnect, Fused, 200 AMP, 3-Pole, 208V Includes: 120V Fire Safety Interface Relay, Mechanical Interlock with 2NO & 2NC Contacts, ... The shunt trip capability allows the POWR-Switch to meet the ANSI/ASME standard that requires power to be automatically disconnected before water is turned on by the fire safety system.

Eaton's shunt trip safety switches, a market exclusive, provide remote switching and visible means of disconnect for commercial and industrial applications. In addition, the shunt trip technology enhances safety by providing a means to open a safety switch electronically. This product line provides additional code compliant solutions with optional protection schemes including arc energy ...

Add a 120v dedicated ckt for shunt trip control wiring. The shunt doesn't draw much so a 15 amp will do. The fire alarm contractor should supply a set of normally open contacts controlled by the fire alarm panel. Send 2 conductors from here to the shunt trip device. You have now put a single pole switch in line with the load ie the shut trip ...

Standard features. Heavy-duty safety switch design with integrated shunt trip module. Visible means of disconnect—visible blade. 30-1200 A (240-600 Vac) NEMA® Type 1, 3R, 12, 4, 4X. Horsepower ratings same as standard safety switches. Maximum response time of 50 ms.