- Skip to main navigation

- Skip to search

- Skip to content

- Leadership Photos of NCC advisors, officers and directors

- Member Benefits Strong industry member participation helps the National Cotton Council represent U.S. cotton on numerous issues and keep it competitive

- Member Web Sites Connect with the cotton community via websites of multiple NCC member firms

- Related Organizations Descriptions of and links to various organizations that serve the U.S. cotton industry

- Report to Members National Cotton Council action on behalf of the U.S. cotton industry is described in annual reports

- Structure The National Cotton Council is a federation that works out common problems and develops programs of mutual benefit for its members.

- Crop Info An abundance of information such as a profile of U.S. cotton’s economic contributions and updated U.S. cotton acreage, production and export numbers

- Government Programs Facts on the federal farm law including details on crop insurance and conservation programs

- Prices Key price data and marketing loan program values.

- Reports & Publications The National Cotton Council’s Weekly Cotton Market Report, its annual Economic Outlook and more

- Textiles Statistics on U.S. cotton textile imports and exports data and a textile trade policy summary

- Weather, Exchanges, & Contacts Links to weather websites and to exchange/market websites

- Available Educational Resources National Cotton Council educational materials available for download offer useful teaching aids/guides to help students learn more about one of the world's major agricultural commodities

- Cotton: From Field to Fabric Describes the major steps involved in producing and processing cotton

- The Story of Cotton Tells the story of cotton -- where and how it's grown, processed and woven into cloth -- in simple terms

- U.S. Production Map This map shows the most recent U.S. cotton production by county

- Frequently Asked Questions Answers about the U.S. cotton industry and the National Cotton Council

- Find Your Congressional Contacts Contact information, including a list of staffers, of House and Senate Members in Cotton Belt states

- Government Web Sites Links to key USDA agencies and services and to other government websites

- Agri-Business Database of agribusiness firms who have a stake in a healthy U.S. cotton industry

- CAC Committee for the Advancement of Cotton

- Bale Packaging Bale packaging, specifications, standards, permanent identification

- Biotechnology Reports, studies, links to other resources

- Contamination-Free Cotton Round Module Wrap Standards, Prevention Video, Guidelines, Resources

- Cottonseed Products, research, general information

- Flow-Shipment Improvement initiatives, warehouse reporting, shipping standards

- Pest Management Boll weevils, nematodes, seedling diseases, cotton pest loss data

- Physiology Best management practices, Cotton Physiology Today newsletters archives, water use

- Pollinator Protection State-managed plans (MP3s)

- Quality Preservation Guidelines, Module Averaging, Bale Moisture

- Safety & Security OSHA, oil spill prevention, fire/building codes, hazardous material rules

- Sustainability U.S. Cotton's Sustainability

- Beltwide Cotton Conferences 2024 Beltwide Cotton Conferences January 3-5, 2024- Fort Worth, Texas

- Audio & Video Broadcasters can download interviews with National Cotton Council leaders/staff, Congressional Members and government officials.

- Cotton's Calendar Dates and places of key meetings of the National Cotton Council, various NCC member firms and cotton interest organizations

- Cotton's Week Archives of the National Cotton Council's premier member newsletter

- Meetings Links to information from National Cotton Council annual meetings and other key NCC forums

- News Releases Current and archived National Cotton Council news releases

- Beltwide Cotton Conferences January 3-5, 2024 Omni Fort Worth, Fort Worth, Texas

- Preferences

- NCC Intranet

- Publications ›

- Cotton Counts ›

- Cotton: From Field to Fabric

Cotton: From Field to Fabric Introduction

Cotton remains the most miraculous fiber under the sun, even after 8,000 years. No other fiber comes close to duplicating all of the desirable characteristics combined in cotton. The fiber of a thousand faces and almost as many uses, cotton is noted for its versatility, appearance, performance and above all, its natural comfort. From all types of apparel, including astronauts’ in-flight space suits, to sheets and towels, tarpaulins and tents, and wipes and other personal care products, cotton in today’s fast-moving world is still nature’s wonder fiber. It provides thousands of useful products and supports millions of jobs as it moves from field to fabric.

From Field To Fabric

- The Journey of Cotton: From Seedlings to Fabric

by Hiller Byrum | Oct 2, 2023 | Blogs | 0 comments

Cotton, the soft, fluffy fiber that has been a staple in our lives for centuries, has a fascinating journey from seedlings to the fabric that graces our homes and wardrobes. This article aims to take you through the intricate process of how a tiny cotton seed transforms into the textiles we can’t seem to live without.

The Planting Process

The journey of cotton begins with the planting of cotton seeds in fertile soil. The planting season usually starts in the spring when the soil temperature is warm enough for the seeds to germinate. Farmers use specialized machinery to plant the seeds at the correct depth and spacing. After planting, the seeds require adequate moisture and warmth to sprout.

Germination and Growth

Once the seeds are in the ground, they undergo germination, breaking open to allow a small cotton plant to emerge. This plant will grow into a bushy cotton plant with broad leaves and a sturdy stem. The growth phase is crucial and requires the right balance of sunlight, water, and nutrients. Farmers often use fertilizers and irrigation systems to ensure optimal growth conditions.

Flowering and Fruiting

After a few weeks of growth, the cotton plant starts to flower. The flowers are usually white or yellow and are pollinated by insects or the wind. Once pollinated, the flowers fall off, leaving behind a small green fruit called a “cotton boll.” Inside these bolls are the cotton fibers, which continue to grow and expand until the boll bursts open, revealing the fluffy white cotton we are familiar with.

When the cotton bolls are mature and have burst open, it’s time for harvesting. This is usually done in the late summer or early fall. There are two primary methods of harvesting cotton: hand-picking and mechanical harvesting. Hand-picking is labor-intensive but results in higher-quality cotton. Mechanical harvesting, on the other hand, is faster and more cost-effective but may result in a mix of mature and immature bolls.

After harvesting, the cotton is taken to a cotton gin, a machine that separates the cotton fibers from the seeds and any remaining plant material. The ginning process is vital for the quality of the final product, as it removes impurities and prepares the cotton for spinning.

Spinning and Weaving

The ginned cotton is then spun into yarn using spinning wheels or industrial spinning machines. The yarn is wound onto spools and is now ready for weaving or knitting. Weaving involves interlacing the yarn to form fabric, while knitting involves looping the yarn to create fabric. The type of weave or knit can significantly affect the texture, appearance, and durability of the fabric.

Dyeing and Finishing

The woven or knitted fabric is often bleached and dyed to achieve the desired color. It may also undergo various finishing processes, such as softening, to enhance its properties. Once the fabric is ready, it is rolled onto large rolls and is ready for the manufacturing of clothing, home textiles, and other products.

The journey of cotton from seedlings to fabric is a complex and fascinating process that involves various stages, each crucial to the quality of the final product. It’s a journey that combines the forces of nature with human ingenuity, resulting in one of the most versatile and widely used materials in the world. The next time you put on a cotton t-shirt or lay down on cotton sheets, you’ll have a newfound appreciation for the incredible journey that brought that cotton from the field to your home.

By understanding this journey, we can also become more conscious consumers, appreciating the labor and resources that go into making the cotton products we use daily. It’s a story of transformation, from a humble seed to the fabric that touches our lives in countless ways.

Submit a Comment Cancel reply

You must be logged in to post a comment.

Recent Posts

- The Journey of Cotton: From Farm to Fabric and Beyond

- The Environmental Impact of Cotton Production: Challenges and Solutions

- Growing from Cotton Seedlings

- Cottonman EZ Ho

Product Categories

- October 2023

- February 2021

- September 2020

- February 2020

Free US Shipping Included! - Visit shop Dismiss

The Journey of Cotton: How Cotton Fabric is Made

As one of the most widely-used and beloved natural fibres, cotton is a staple in the textile industry and an essential element in countless products. But have you ever wondered how this soft, breathable, and versatile material is made? As a versatile and comfortable material, cotton has been a staple in fashion and textiles for centuries. Today, we’ll explore the step-by-step process of how cotton fabric is made, from the fields to the cotton fabric production.

Table of Contents

1.Growing the Cotton Plant

The creation of cotton fabric begins with the cultivation of the cotton plant, scientifically known as Gossypium. These plants are predominantly grown in regions with warm climates, ample sunshine, and moderate rainfall, providing optimal conditions for their Growth and development. Some of the largest cotton-producing countries include the United States, India, China, and Brazil. Cotton seeds are sown in the fields, and the plants grow over several months until they flower and form cotton bolls.

1.1 Preparing the Soil

Before planting, the soil is prepared by ploughing and levelling the field to ensure optimal growth conditions for the cotton seeds. Soil fertility is crucial, as the cotton plant requires essential nutrients such as nitrogen, phosphorus, and potassium to grow strong and healthy.

1.2 Planting the Seeds

Cotton seeds are typically sown in rows during the spring months. The seeds are planted approximately 1 to 2 inches deep in the soil, with 3 to 4 inches spacing between each seed. This allows the plants to have enough room for proper Growth and development.

1.3 Fostering Growth

After planting, the cotton plants require consistent care and attention. Farmers must irrigate the fields, control weeds, and manage pests to ensure the plants grow healthily. Over several months, the plants mature, and their green, lobed leaves transform into stunning, cream-colored flowers. These flowers eventually wither away, giving rise to the cotton bolls – the protective capsules that house the cotton fibres.

1.4 The Cotton Bolls

The cotton bolls develop over approximately six weeks, maturing and expanding until they reach their full size. As they mature, the bolls harden, and their color shifts from green to brown. Inside the bolls, the cotton fibers continue to grow, surrounding and protecting the seeds. Eventually, the bolls reach a point where they can no longer contain the expanding cotton fibres, causing them to burst open and reveal the soft, white, fluffy cotton fibres we all know and love.

2. Harvesting Cotton

After approximately six months, the cotton bolls mature and burst open, revealing the soft, white fibres inside. Harvesting can be done manually or using mechanical cotton pickers. Harvested cotton is cleaned, removing dirt, leaves, and other debris.

As the cotton bolls reach maturity and burst open, it’s time for the harvesting process to begin. This crucial stage in cotton fabric production involves collecting the exposed cotton fibres from the plants.

2.1 Methods of Harvesting

Cotton harvesting can be done in two primary ways: manual picking and mechanical harvesting. Manual picking is labour-intensive and time-consuming, with workers handpicking the cotton fibres from the plants. However, this method ensures minimal damage to the cotton fibres and is still employed in some regions with smaller-scale production.

On the other hand, mechanical harvesting is a more efficient method used in large-scale cotton production. Mechanical cotton pickers and strippers swiftly gather the cotton fibres from the plants, significantly reducing the time and labour required for harvesting.

2.2 Cleaning the Harvested Cotton

Once the cotton fibres are harvested, they must be cleaned to remove dirt, leaves, and other debris. This initial cleaning process, often done in the field, ensures that only the pure cotton fibres move on to the next production stage.

With the cotton fibres harvested and cleaned, the journey toward becoming fabric continues.

3.Ginning: Separating Cotton Fiber from Seeds

Next, the cotton goes through a process called “ginning.” This involves separating the cotton fibres from the seeds using a cotton gin.

The cotton gin, a machine invented by Eli Whitney in 1793, revolutionised the ginning process, making it significantly more efficient. The modern cotton gin has small, closely spaced teeth that pull the cotton fibres through while effectively removing the seeds.

During ginning, the harvested cotton is fed into the cotton gin, where the teeth effectively separate the seeds from the fibres. The seeds, which can be used for oil production or replanting, are collected separately. Meanwhile, the cotton fibres, now free from seeds and other impurities, move on to the next production stage.

4. Carding: Aligning Cotton Fibres

The cleaned and ginned cotton is then carded, aligning the fibres and removing any remaining impurities. Carding machines use rotating cylinders with fine teeth to comb through the cotton fibres, creating a uniform, fluffy mass called “cotton sliver.”

4.1 The Carding Machine

Carding machines use a series of rotating cylinders covered with fine teeth or wire pins to comb through the cotton fibres. The teeth work together as the fibres pass through the machine to disentangle, clean, and align them.

4.2 Creating Cotton Sliver

The carding process results in a continuous, fluffy mass of aligned cotton fibres known as “cotton sliver.” The silver is then coiled into large containers, preparing it for the next production phase. The carding process ensures that the fibres are properly aligned and helps create a more consistent and even yarn during the spinning process.

The next step is spinning with the cotton fibres now aligned and free of impurities. The cotton sliver is transformed into yarn in this stage, bringing us one step closer to the final cotton fabric.

5. Spinning: Turning Cotton Slivers into Yarn

The cotton sliver is transformed into yarn through a process called spinning. The cotton fibres are drawn out and twisted together during spinning, creating strong, thin strands of yarn. This can be done using various methods such as ring, open-end, or air-jet spinning. The resulting yarn is then wound onto spools or bobbins.

With the cotton fibres aligned and prepared, the spinning process begins. This crucial stage transforms the cotton sliver into strong, thin strands of yarn, setting the foundation for the final fabric.

5.1 Spinning Methods

There are various methods of spinning, each with its unique characteristics. The most common methods include ring, open-end, and air-jet spinning. Each method draws out and twists the cotton fibres, creating a continuous yarn strand.

5.2 The Spinning Process

During spinning, the cotton sliver is fed into the spinning machine, where it is drawn out and twisted to create a strong, uniform strand of yarn. The degree of twist and the thickness of the yarn can be adjusted depending on the desired end product, allowing for a wide range of yarn types and textures.

5.3 Winding and Storage

The resulting yarn is then wound onto spools or bobbins, which store and organise the yarn for the next stage in the process. These spools ensure the yarn remains tangle-free and easily accessible for weaving or knitting.

With the cotton fibres now spun into yarn, the journey towards becoming fabric continues to the weaving stage, where the yarn is interlaced to create the final cotton fabric.

6.Weaving: Creating Cotton Fabric

Now that we have our cotton yarn, it’s time to weave it into the fabric. Weaving involves interlacing two sets of yarn (the warp and the weft) at right angles to form the fabric. The warp yarns are held taut on a loom while the weft yarn is threaded through the warp yarns using a shuttle device. The resulting fabric can be lightweight or heavyweight, depending on the yarn’s thickness and the weaving pattern used.

With the cotton yarn now ready, the weaving process can begin. Weaving is a key stage in the journey of cotton fabric production, where the individual yarn strands come together to form the final material.

6.1 The Loom and Its Role

Weaving occurs on a loom machine, which holds the yarn strands in place and facilitates the interlacing process. The loom holds one set of yarn strands vertically, known as the warp, while another set of yarn strands, called the weft, is interlaced horizontally through the warp yarns.

6.2 The Weaving Process

During weaving, a shuttle device carries the weft yarn through the spaces between the warp yarns. The warp and weft yarns interlacing creates a tight, secure structure, resulting in the final fabric. Various weaving patterns, such as plain weave, twill, or satin, can create different textures and appearances.

6.3 Fabric Weight and Characteristics

The thickness of the yarn used, the tightness of the weave, and the specific weaving pattern all contribute to the final fabric’s weight and characteristics. Cotton fabric can range from lightweight and delicate to heavyweight and durable, making it suitable for various applications.

With the cotton yarn now woven into the fabric, the final step is the finishing process, which enhances the material’s appearance, texture, and durability, preparing it for use in various products.

7. Finishing: Preparing Cotton Fabric for Use

Finally, the woven cotton fabric undergoes various finishing processes to enhance its appearance, texture, and durability. This can include bleaching, dyeing, printing, and applying special finishes such as wrinkle resistance, water repellency, or flame retardancy. Once the fabric is finished, it is ready for use in producing a wide range of cotton products, from clothing and bedding to upholstery and industrial applications.

The final stage in the journey of cotton fabric production is the finishing process. This crucial step refines the woven fabric, enhancing its appearance, texture, and overall quality, ensuring it is ready for many applications.

7.1 Cleaning and Scouring

Before any additional finishes are applied, the woven fabric must be cleaned and scoured to remove any remaining impurities or residues from the production process. This step helps create a clean and uniform surface for further finishing treatments.

7.2 Bleaching, Dyeing, and Printing

Depending on the desired end product, the fabric may undergo bleaching, dyeing, or printing treatments. Bleaching removes any remaining color from the fabric, while dyeing and printing add color and patterns, allowing for a vast array of fabric designs and styles.

7.3 Special Finishes

Special finishes can be applied to enhance the fabric’s performance or add specific properties. These can include wrinkle resistance, water repellency, flame retardancy, or stain resistance. Each finish adds unique characteristics to the fabric, tailoring it for specific applications and requirements.

7.4 Inspection and Quality Control

Once the fabric has undergone the necessary finishing treatments, it is inspected and subjected to quality control measures. This ensures that the final fabric meets the highest standards and is suitable for various products, from clothing and bedding to upholstery and industrial applications.

With the finishing process complete, the cotton fabric is now ready to be used, bringing its remarkable journey from plant to fabric to a close. The result is a versatile, comfortable, and sustainable material that is popular in textiles.

You may also like to know “ How much does a 100% cotton shrink in the dryer “.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

How can we help you?

- Story of Cotton

- Homeschoolers

- Educational Organizations

- Miscellaneous Links

- Submit Your Lesson

- Watch Cotton Grow

- Become a Sponsor

- School Curriculum

- Cooking With Cotton

- Planting Cotton

Home | About Us | Contact Us | Watch Cotton Grow

The Story of Cotton

Have you ever thought about where the clothes you and your family wear come from, or the dressing you put on your salad, or the sheets you crawl under at night before you go to sleep? It comes from cotton! Cotton.the most important and widely used fiber ever known to man. Cotton is used for thousands of things, including clothes, space suits for astronauts and ingredients in the food we eat.

How it is grown, cultivated, harvested and finally processed into cloth and other co-products is what you will be learning about in this story of cotton and Cotton’s Journey – A field Trip in a Box.

I History II The Plant III Production IV Processing the Crop V Cotton Lint VI Cottonseed VII The Cotton Industry and You VIII Sample Questions IX Cotton Facts

CottonsJourney.com P.O. Box 811 Hanford, CA 93232

Email: [email protected] Phone Number: 1-800-698-1888 Privacy Policy

From Field to Fashion: Exploring the Journey of Cotton

If you take a look into the world of fashion, you’ll quickly realize that one fabric has stood the test of time and continues to reign supreme — Cotton . As a seamstress and pattern maker, I have come to appreciate the undeniable allure and versatility of this remarkable fabric. In this extensive article, we will delve into the wonders of cotton , exploring its unique characteristics , unraveling its benefits , and uncovering why it has become an enduring favorite among us in the fashion industry.

A Closer Look at Cotton

Cotton, derived from the soft, fluffy fibers of the cotton plant , boasts a rich history dating back thousands of years . This natural fiber is cultivated in cotton fields , where the plants are carefully nurtured , harvested , and processed to create the fabric we know and love. From the moment the cotton plant blooms, to the delicate process of harvesting the fluffy bolls, cotton production involves a blend of art, science, and human ingenuity.

The Benefits of Cotton Garments

1. Breathable Comfort

When it comes to wear-ability, cotton takes center stage. Its breath-ability allows air to circulate freely , keeping the wearer cool and comfortable even in warm climates. The fabric’s ability to absorb and release moisture helps to regulate body temperature, making it perfect for everyday wear or summer fashion statements. Seamstresses and pattern makers cherish this attribute, knowing that garments made from cotton will provide optimal comfort to those who wear them.

2. Skin-Friendly Sensation

Cotton’s gentle touch against the skin is unrivaled. Unlike synthetic fabrics that can cause irritation and discomfort , cotton is hypoallergenic and suitable for even the most sensitive skin . Its natural fibers create a barrier between the skin and external elements, reducing the risk of rashes or allergies . Seamstresses and pattern makers appreciate this quality, knowing that their creations will provide comfort and joy to those who wear them.

3. Durability and Longevity

One of cotton’s most significant advantages lies in its durability . Its fibers are inherently strong , allowing garments made from cotton to withstand the test of time . The fabric can endure frequent washing and daily wear without losing its shape or integrity. Seamstresses rejoice in the knowledge that their creations will continue to bring joy and style to their wearers for years to come.

Cotton in Fashion

Versatility in Design

Cotton’s versatility lends itself well to a myriad of fashion styles. Whether it’s a flowing summer dress , a tailored shirt , or a cozy sweater , cotton can adapt effortlessly to various design aesthetics. As a seamstress or pattern maker, working with cotton means having the freedom to experiment and bring any fashion vision to life .

Easy to Work With

For seamstresses, cotton is a dream to work with . Its natural structure allows for smooth cutting, sewing, and draping (for example Calico fabric ). It responds well to stitching techniques, making it an excellent choice for both beginners and seasoned professionals . Working with cotton fabric provides a satisfying experience, resulting in beautifully crafted garments.

The Process and Production of Cotton

Cultivation and Harvesting

Cotton starts its journey as a humble seed , planted in carefully prepared soil . The cotton plant requires specific climatic conditions and adequate water supply to thrive. As it grows, the plant develops beautiful flowers , which eventually transform into cotton bolls . Skilled farmers carefully monitor the growth process, ensuring the plants receive proper care and protection against pests and diseases.

When the cotton bolls are fully mature, they are handpicked or harvested using specialized machinery. This delicate process ensures that the fibers remain intact and of the highest quality, ready to be transformed into luxurious fabrics .

Ginning and Processing

Once harvested, the cotton undergoes a process known as ginning . This involves separating the cotton fibers from the seeds and any remaining impurities. Ginning machines skillfully extract the fibers, leaving behind clean, fluffy cotton ready for further processing.

The cotton fibers then go through a series of steps, including carding, spinning, and weaving , to transform them into yarn and fabric . During these stages, the fibers are aligned, twisted and interlocked to create strong and uniform threads that form the foundation of cotton fabrics.

Sustainable Practices

The cotton industry is increasingly embracing sustainable practices to minimize its environmental impact . From water conservation techniques to organic farming methods , efforts are being made to reduce the use of chemicals and promote Eco-friendly alternatives. As conscious consumers, we can choose organic cotton , supporting a more sustainable and responsible fashion industry.

Conclusion: Cotton’s Timeless Appeal

As we conclude our exploration of cotton’s charm, it’s evident why this fabric remains an evergreen in the fashion industry . Its unmatched comfort , durability , and versatility have endeared it to both seamstresses and pattern makers. From its cultivation in cotton fields to the intricate processes of ginning and production, cotton embodies a harmonious blend of natural beauty and human craftsmanship.

So, next time you embark on a sewing project or search for the perfect fabric for your fashion creations , remember the enduring allure of cotton . Embrace its timeless charm, relish in its natural beauty, and let cotton weave its magic into your designs. With cotton, the possibilities are endless, and your creations will continue to make a lasting impression in the world of fashion.

Got Questions?

Melissa Villegas Pattern Maker & Seamstress

Mail: [email protected]

Villegas Patterns

- Unique Patterns & Designs

- Detailed, extensive sewing manuals

- Video Tutorials covering the whole process

- Modern, elegant and glamorous patterns

- PDF Sewing Patterns for Instant Downloads and printing at home

Recent Patterns

- PDF Sewing Patterns ·

Cherry Crush Skirt Pattern

4,50 €

- Corsage/Bustier ·

Sugar Plum Corsage Pattern

7,00 €

- Mini Dress ·

Nightlife Nectar Summer Dress

6,00 €

Need A Tutorial?

More interesting articles.

Haute Couture: The Premium League of Fashion

Crepe: Unleashing the Magic of Texture and Elegance

Introducing the Helen Mini Dress: A Must-Have for Unforgettable Nights

My goal is to empower individuals of all levels to create unique and beautiful garments that showcase their personal style

- Sewing & Pattern Glossary

- Privacy Policy

- Terms & Conditions

- Returns & Refunds

Your Cart is Empty

View cart Checkout

- Normal Double Dhotis (8 cubits)

- Permium Double Dhotis (8 Cubits)

- Pure Jari – Gold/Silver/Cream (8 Cubits)

- Wedding Collection Double (8 Cubits)

- Devotional Dhotis (4 Cubits)

- Wedding Collection Single (4 Cubits)

- White Napkins

- Readymade Shirts

- Normal Single Dhotis (4 Cubits)

- Premium Single Dhotis (4 Cubits)

- Color Towels

- White Towels

All Departments

The Journey of Cotton: From Seed to Fabric

Cotton, The scientific name of the cotton plant is Gossypium. It belongs to the mallow family Malvaceae. a soft, fluffy staple fiber, has been a favorite fabric for centuries. It’s used in a myriad of products, from clothing to home furnishings, and even in industrial applications. But have you ever wondered how this versatile material makes its journey from a tiny seed to the fabric we use every day? Let’s explore this fascinating journey.

Raw cotton is also known as cotton lint, is cotton straight off the plant. It is dense and can itch when touched.

The Journey of Cotton

Cotton’s journey begins as a seed planted in warm, fertile soil. The cotton plant, part of the Gossypium genus, thrives in warm conditions with lots of sun and adequate rainfall. After the seeds are planted, they grow into cotton plants, which produce flowers that eventually become cotton bolls.

The Journey of Cotton from Fiber to Fabric

The first step in transforming cotton from fiber to fabric is harvesting. Cotton bolls are carefully plucked from the plants either by hand or using mechanical cotton pickers. Once harvested, the cotton undergoes a process called ginning, where the fibers are separated from the seeds.After ginning, the cotton is thoroughly cleansed to get rid of any leftover contaminants. The cotton fibers are spun into yarn after being cleaned. This process, known as spinning, involves twisting the fibers together to create a long thread. The yarn is then woven or knitted into fabric. The type of fabric produced can range from lightweight voiles and laces to heavy sailcloths and thick-piled velveteens.

The Cycle of Cotton Production

The cycle of cotton production involves several stages. It begins with the planting of cotton seeds and ends with the production of fabric. The stages include harvesting and cleaning, ginning and separating, spinning and yarn production, weaving and fabric formation, and finally, finishing and quality control.

The First Step of Cotton

The first step of cotton is the planting of cotton seeds. These seeds grow into cotton plants, which produce flowers that eventually become cotton balls.

Where is Cotton First Found?

The oldest cotton fabric has been found in Huaca Prieta in Peru, dated to about 6000 BC. It is here that Gossypium barbadense is thought to have been domesticated at its earliest.

When was the First Cotton?

The first cotton was believed to have been domesticated in the Old World about 7,000 years ago. The Neolithic occupancy of Mehrgarh in the Kachi Plain of Balochistan, Pakistan, in the sixth millennium BC, provides the oldest archaeological evidence of cotton use.

Where Does Cotton Grow?

Cotton grows in warm climates.Tropical and subtropical regions of the world like India, Egypt, Southern United States, Uzbekistan, and China are producing most of the cotton.

The Uses of Cotton

- Clothing: Cotton is used in a wide variety of clothing, from jackets to shirts.

- Home Furnishings: It finds its use in bed sheets and curtains.

- Industrial Uses: Cotton is used in industrial applications like tents and book binding.

- Baby Care Products: Cotton is used in top-quality baby care products due to its natural softness and hypoallergenic properties.

- Feminine Care Products: Cotton is used in feminine care products for the same reasons.

- Cottonseed Oil: Cottonseed oil is used in food and cosmetics.

- Coffee Filters: Cotton is used in coffee filters.

- Cottonseed Meal: Cotton seeds are fed to cattle.

- Rubber and Plastics: Cotton is used in the production of rubber and plastics.

Disposable Products: Non woven cotton is useful for making disposable products such as tea bags, tablecloths, bandages, and disposable uniforms and sheets.

How Cotton is Made: A Step-by-Step Journey from Seed to Fabric

Cotton, a soft, fluffy staple fiber, has been a favorite fabric for centuries. It’s used in a myriad of products, from clothing to home furnishings, and even in industrial applications. But have you ever wondered how this versatile material makes its journey from a tiny seed to the fabric we use every day? Let’s explore this fascinating journey.

The 6 Steps of Cotton Production

1.Planting: The journey of cotton begins with the planting of cotton seeds. These seeds grow into cotton plants, which produce flowers that eventually become cotton bolls.

2.Harvesting and Cleaning: Cotton bolls are carefully plucked from the plants either by hand or using mechanical cotton pickers. Once harvested, the cotton undergoes a process called ginning, where the fibers are separated from the seeds.

3.Ginning and Separating: The harvested cotton is taken to a cotton gin, where it undergoes a series of mechanical processes to remove unwanted elements. A procedure known as “ginning” separates the cotton strands from the seeds.

4.Spinning and Yarn Production: After cleaning, the cotton fibers are spun into yarn. This process, known as spinning, involves twisting the fibers together to create a long thread

5.Weaving and Fabric Formation: The yarn is then woven or knitted into fabric. The type of fabric produced can range from lightweight voile and laces to heavy sailcloth and thick-piled velveteen.

6.Finishing and Quality Control: The final stage involves finishing touches and quality control to ensure the fabric meets the desired standards.

The Structure of Cotton

A single living cell with a multi layer structure makes up cotton fiber. The cuticle, primary wall, secondary wall, lumen, and fiber outside are the layers that make up the cell structure. These layers are different structurally and chemically.

Fascinating Facts about Cotton

- Cotton is a completely natural fabric.

- Cotton requires more than 200 days to grow.

- The history of cotton dates back more than 8,000 years.

- Cotton is the most widely used natural fiber cloth in clothing today

- Up to 27 times its own weight in water can be absorbed by cotton.

The Best Type of Cotton

The type of cotton that is considered the best largely depends on what you’re looking for. However, Pima cotton and Egyptian cotton are often considered to be the most luxurious as they produce the longest fibers. Long cotton fibers mean a softer and stronger cotton fabric

The History of Cotton: A Journey from Seed to Fabric

Cotton, a soft, fluffy staple fiber, has been a favorite fabric for centuries. It’s used in a myriad of products, from clothing to home furnishings, and even in industrial applications. But have you ever wondered about the history of this versatile material? Let’s explore this fascinating journey.

What is the History of Cotton?

The history of cotton can be traced back to domestication for an important role in the history of India, the British Empire, and the United States. The precise dates of cotton’s domestication are unknown due to its complicated history. Several isolated civilizations in both the Old and New World independently domesticated and converted the cotton into fabric. All the same tools were invented to work it also, including combs, bows, hand spindles, and primitive looms.

Who Invented Cotton?

The term “invented” may not be the most accurate when discussing a natural resource like cotton. However, it’s worth noting that several isolated civilizations in both the Old and New World independently domesticated and converted the cotton into fabric. The earliest cotton textiles were discovered in dry climate civilizations’ tombs and city ruins, where the textiles did not entirely decompose. The oldest cotton fabric has been found in Huaca Prieta in Peru, dated to about 6000 BC.

What is King Cotton History?

King Cotton” is a catchphrase that encapsulated the tactics employed by southern secessionists (the future Confederate States of America) prior to the American Civil War (1861–1865) in order to assert the viability of their plan and demonstrate that there was no reason to fear conflict with the northern states. According to the hypothesis, a potential sovereign Confederacy would become economically rich if it had control over cotton exports.

Why is Cotton so Popular in India?

Cotton has a significant role in the economy of India since the textile industry of the country is chiefly cotton-based. India is also among the biggest manufacturers and exporters of cotton yarn. Cotton provides jobs to over 51 million people, including unskilled women. India is the world’s leading producer of cotton, and it is the principal crop in the nation. Tens of millions of people work alongside 5.8 million farmers in India, a country that has been producing cotton for textiles for hundreds of years.

Written by sarathidhoties

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Lynn Co. widow shares four-year journey honoring husband’s on-duty sacrifice

LUBBOCK, Texas (KCBD) - Nearly four years after his death, Lynn County Sheriff Abraham Vega will be honored at the Texas State Capitol.

The late sheriff’s widow, Rachel Vega, spoke about her four-year battle with Texas legislature and how he will now be honored. Abraham died in 2020 after contracting COVID. At the time, the virus was not considered a line-of-duty death, but Vega’s wife made it her mission to make sure his sacrifice was remembered and honored.

“COVID broke out and I said to him, ‘this is either one big hoax or the worst thing that ever happened,’” Rachel said. “And it turned out to be the worst thing that ever happened.”

She described Abraham’s long journey in law enforcement. She stated he was a dispatcher, jailer and jail administrator; he also worked as a school resource officer, deputy, chief deputy, and then finally achieved his goal of becoming sheriff.

However, that achievement was short-lived.

Shortly after he was elected in March of 2020, COVID began to spread.

“We were coming home from Florida,” Rachel said. “We had gone on a trip to celebrate his win of being elected sheriff, and he got sick in June and within three weeks he was gone.”

Vega died July 11, 2020 from COVID. His widow wanted her husband’s death to be honored, but Vega’s efforts beyond his call of duty during the pandemic did not qualify as a line-of-duty death.

A month after her husband’s funeral is when her battle began. Rachel petitioned Texas legislators, so her husband and other law enforcement families who lost loved ones to COVID can have their sacrifices honored.

“I just want him to be remembered as an honest, kind law person who was out there to help people,” she said.

In 2021, Senate Bill 22 was passed classifying the virus as a line-of-duty death. Now, four years later, the name, Sheriff Abraham Vega, will join many others on the Texas Peace Officers Memorial in Austin.

The memorial ceremony will be hosted on Sunday in Austin.

Copyright 2024 KCBD. All rights reserved.

62-year-old Lubbock man crushed by cotton bales, Slaton police say

Parents speak of heartache after baby dies at day care

81-year-old Plainview woman found safe by police

Harvey Weinstein’s 2020 rape conviction overturned by NY appeals court

Perryton athletic director arrested on charge of sexual assault of a child

Latest news.

Littlefield students raise money for cancer foundation; organizer recognized for ‘making a difference’

Lubbock citizens meet police chief candidates

Food for Thought: One Lubbock restaurant back open following forced shutdown

Lubbock Police host meet-and-greet with candidates for next chief

Step-by-Step Guide: Cotton Fabric Production Process

Are you curious about how cotton fabric is made? This step-by-step guide will walk you through the entire production process.

From harvesting the cotton to weaving or knitting the fabric, you’ll learn about each essential step along the way.

Discover the fascinating journey of cotton from the fields to the finished product, and gain a deeper appreciation for the craftsmanship behind the clothes you wear.

Let’s dive in and explore the world of cotton fabric production together!

Table of Contents

Cotton Harvesting

To begin the process of cotton fabric production, you’ll need to first understand the steps involved in cotton harvesting.

Cotton can be harvested using either mechanized or manual methods. Mechanized harvesting involves the use of machines, such as cotton pickers or strippers, to remove the cotton bolls from the plants. These machines are highly efficient and can harvest large quantities of cotton in a short period of time.

On the other hand, manual harvesting is a more labor-intensive process. It involves handpicking the cotton bolls from the plants, which requires a lot of manual dexterity and physical effort. Manual harvesting is often used in small-scale operations where machinery isn’t readily available.

Both methods have their advantages and disadvantages. Mechanized harvesting is faster and more efficient, but it can be expensive to purchase and maintain the machinery. Manual harvesting, although slower, allows for more selective picking, resulting in higher quality cotton.

Understanding the differences between mechanized and manual harvesting is crucial in the cotton fabric production process.

Fiber Separation

Now, let’s delve into the next step of the cotton fabric production process: separating the fibers. After the cotton has been harvested, the next step is to separate the fibers from the cotton seeds. This process can be done through mechanical separation or the traditional handpicking technique.

Mechanical separation involves the use of machines to separate the fibers from the seeds. The cotton is fed into a machine called a gin, which uses rotating saws or teeth to pull the cotton fibers away from the seeds. The seeds are then collected separately for further processing, such as oil extraction. This method is efficient and can process a large quantity of cotton in a shorter time.

On the other hand, the handpicking technique involves manually separating the fibers from the seeds. Skilled workers carefully remove the cotton fibers from the seeds using their hands. While this method is slower and more labor-intensive, it’s often preferred for high-quality cotton, as it minimizes damage to the fibers.

Both mechanical separation and the handpicking technique are crucial steps in the cotton fabric production process. Once the fibers are separated, they can be further processed into yarn and eventually woven into fabric.

Cleaning and Sorting

Once the fibers have been separated, you need to clean and sort them to prepare for further processing. Cleaning techniques and sorting methods are essential in ensuring the quality and uniformity of cotton fibers.

Cleaning techniques involve removing impurities, such as dirt, leaves, and seeds, from the cotton fibers. This can be done through various methods, including mechanical cleaning and chemical cleaning. Mechanical cleaning involves the use of machines like gin saws, which remove larger impurities. Chemical cleaning, on the other hand, uses chemicals to dissolve or break down smaller impurities.

After cleaning, the cotton fibers need to be sorted based on their length, strength, and color. Sorting methods include manual sorting and automated sorting. Manual sorting involves skilled workers examining and separating the fibers based on specific criteria. Automated sorting, on the other hand, uses advanced technology to sort the fibers based on predetermined settings.

Spinning and Yarn Formation

After cleaning and sorting the cotton fibers, you’ll proceed to the next step in the cotton fabric production process, which involves spinning the fibers into yarn. This step is crucial in creating the strong and durable yarn needed for fabric production. Here are the key steps involved in spinning and yarn formation:

Spinning Techniques: There are two main spinning techniques used in the cotton fabric production process. The first technique is called ring spinning, where the fibers are twisted and wound onto a bobbin. This method produces high-quality, fine yarn. The second technique is called open-end spinning, which involves twisting the fibers together using a rotor. This method is faster and more cost-effective but produces a coarser yarn.

Yarn Spinning Machines: To carry out the spinning process, yarn spinning machines are used. These machines have various components such as drafting rollers, spindles, bobbins, and rotors. The machines work by pulling the cotton fibers into a continuous strand and then twisting them together to form the yarn.

Drafting: Drafting is an essential part of the spinning process. It involves stretching and thinning the cotton fibers to create an even and uniform yarn. This is achieved by passing the fibers through a series of drafting rollers that gradually reduce the thickness of the strand.

Yarn Formation: Once the fibers have been drafted, they’re twisted together to form the final yarn. The amount of twist applied depends on the desired characteristics of the yarn, such as strength and elasticity. The twisted yarn is then wound onto bobbins or spools for further processing.

Weaving or Knitting

To begin the weaving or knitting process, you’ll need to prepare the yarn that was formed in the previous step. Weaving and knitting are two different techniques used to create fabric from yarn. Weaving involves interlacing the yarns at right angles to form a stable and cohesive fabric. There are various weaving techniques, such as plain weave, twill weave, and satin weave, each producing a different texture and pattern.

In contrast, knitting uses a series of interconnected loops to create fabric. Knitting patterns can be simple or complex, depending on the desired design. The knitting process allows for greater flexibility in creating different shapes and textures in the fabric.

Once the yarn is prepared, you can start the weaving or knitting process. In weaving, the yarn is threaded onto a loom, and the weft yarn is passed over and under the warp yarns to create the fabric. Knitting, on the other hand, requires the use of knitting needles or a knitting machine to create the fabric by interconnecting the loops of yarn.

Both weaving and knitting require skill and precision to ensure the fabric is produced correctly. By mastering the weaving techniques and understanding different knitting patterns, you can create a wide range of beautiful and functional cotton fabrics.

Finishing and Fabric Treatment

To begin the finishing and fabric treatment process, you’ll need to prepare the woven or knitted cotton fabric. Once the fabric is ready, you can proceed with the following steps:

Fabric dyeing : This is the process of adding color to the fabric. Dyeing can be done using various techniques such as immersion dyeing, where the fabric is submerged in a dye bath, or direct dyeing, where the dye is applied directly onto the fabric. The fabric is then rinsed and dried to set the color.

Fabric printing : Printing allows you to add patterns, designs, or images to the fabric. There are different methods of fabric printing, including screen printing, block printing, and digital printing. In screen printing, a stencil is created and ink is forced through it onto the fabric. Block printing involves using carved blocks to apply ink onto the fabric. Digital printing uses specialized printers to directly print the design onto the fabric.

Finishing treatments : After dyeing and printing, the fabric undergoes finishing treatments to enhance its properties. This can include processes like bleaching, where the fabric is treated with chemicals to remove impurities and achieve a brighter white color. Other treatments may include softening, to improve the fabric’s feel, or flame retardant finishes, to make the fabric more resistant to fire.

Quality control : Throughout the finishing and fabric treatment process, quality control measures are essential to ensure that the fabric meets the desired standards. This can involve inspecting the fabric for any defects, checking the colorfastness of the dye or print, and testing the fabric’s durability and performance.

Frequently Asked Questions

What are the environmental impacts of cotton fabric production.

Cotton fabric production has significant environmental impacts. It contributes to a high carbon footprint due to energy-intensive processes. Additionally, it requires large amounts of water, further straining already scarce resources.

How Long Does the Entire Cotton Fabric Production Process Usually Take?

The time it takes to produce cotton fabric depends on several factors, such as the type of machinery used, the size of the production facility, and the level of automation.

What Are the Different Types of Cotton Fabric Available in the Market?

In the market, you can find different types of cotton fabric like poplin and jersey. These fabrics offer various textures and characteristics, making them suitable for different types of clothing and projects.

How Does the Quality of Cotton Affect the Final Fabric Product?

The quality of cotton directly affects the final fabric product. It is important to carefully select the cotton used in production to ensure a high-quality end result.

Are There Any Alternative Methods or Technologies Being Used to Improve Cotton Fabric Production Efficiency?

There are alternative methods and technological advancements being used to improve cotton fabric production efficiency. These innovations aim to streamline processes, reduce waste, and increase productivity in the industry.

- Recent Posts

- Where Does Hemp Come From? - April 22, 2024

- Why Do People Eat Hemp? - April 22, 2024

- Is Hemp Safe for Humans? - April 22, 2024

Related Posts:

Kellogg School of Management at Northwestern University

Entrepreneurship Healthcare Policy Apr 19, 2024

Psychedelic-assisted therapy is going mainstream. how will the industry grow around it, while significant barriers remain—including regulatory uncertainty and the difficulty of scaling a labor-intensive treatment method—industry leaders see a path forward..

David Schonthal

Michael Cotton

David Esselman

In recent years, psychedelics have moved beyond their reputation as the mind-expanding substances that fueled countercultural explorations. Much of this surge of interest has to do with new discoveries about these drugs’ therapeutic potential.

Recent clinical trials suggest that MDMA, ketamine, and psilocybin, when taken under medical supervision, can treat a range disorders, including addiction, major depression, and PTSD. In 2017, MDMA (also known as ecstasy) was designated a “breakthrough” medication by the FDA. Last year, a study found that ketamine might be more effective than electroconvulsive therapy in treating major depression. Meanwhile, psilocybin has been shown to ease the anxiety of terminal cancer patients. Last year, Oregon legalized its use in regulated settings.

For proponents, this research demonstrates that psychedelic-assisted therapy (PAT) might have a role to play in addressing our mental health crisis. And as states move to legalize controlled use of these substances, an industry is taking shape, with some predicting a paradigm shift on par with the rise of SSRIs or medical cannabis.

“The public discourse around behavioral health has elevated in a way where this conversation can happen now,” says David Schonthal , a clinical professor of strategy and Director of Entrepreneurship Programs at the Kellogg School. “There is a recognized need for it. And there’s a growing interest from states and insurers who recognize the power of these medicines, not just in terms of their therapeutic benefit, but also in terms of their business impact.”

But what might this industry look like? There are still significant barriers, including regulatory uncertainty, the hesitance among major insurers to cover novel medicines, and the difficulty of scaling a labor-intensive treatment method. Not to mention the PR challenge of overcoming the cultural stigmas attached to these powerful compounds.

Kellogg Insight assembled a group of entrepreneurs, philanthropists, and investors in the psychedelic-assisted-therapy industry to discuss the way the field is developing, what’s holding it back, and what to expect from the future of psychedelics.

The long journey to acceptance

While attempts to bring PAT into the mainstream are not new—more than a thousand studies on psychedelics were launched in the 1950s and 60s—the drugs’ associations with the 60s counterculture led to regulatory backlash. In 1970, President Nixon had psychedelics classified as Schedule 1 controlled substances, effectively cutting off research on the drugs for decades.

In the late 1990s, however, the DEA opened the door to regulatory approval again. By 2019, Johns Hopkins had launched its Center for Psychedelic and Consciousness Research , a major step in legitimizing the field.

This turn toward psychedelics reflects a broader frustration many have with the mental-healthcare status quo.

“Behavioral-health science in the United States has not been particularly well cared for,” says Michael Cotton, an investor and philanthropist who has owned and operated Medicaid-managed care plans for twenty years. “In fact, we’ve seen a lot of disinvestment in the last few decades. A lot of people don’t have access to mental health services.”

The data on mental health in the U.S. is certainly bleak, with overdose and suicide rates skyrocketing over the past two decades, despite the widespread adoption of antidepressants and other medical treatments.

The hope is that PAT, which aims to address underlying conditions through a temporary shift in the patient’s consciousness, can induce the kind of emotional and cognitive experience that leads to lasting behavioral change. For advocates of PAT, this therapeutic model, in which the medicine and therapy are administered together, has advantages over SSRIs, whose longer-term efficacy is still unclear.

“Neuroplasticity is very real,” says David Esselman , senior advisor to BrainFutures , a nonprofit focused on bringing mental-health innovations, including psychedelic-assisted therapy, into healthcare systems. “These compounds allow you to incorporate insights you have in treatment into your life. This new class of drugs could be monumentally impactful, affecting tens of millions of people.”

The challenges of integrating PAT into the medical system

Despite its clinical promise, there is still the challenge of integrating PAT into existing treatment systems. Not everyone is keen to embrace a class of drugs more commonly seen at raves than in clinics. Even pioneers such as the late Dr. Roland Griffiths have said they worry about provoking another regulatory backlash by moving too quickly.

But Americans’ attitudes might be changing, especially through the adoption of psychedelics by groups not typically associated with the counterculture.

“We’re seeing resonance, particularly in more-conservative areas, around the mental-health needs of first responders and veterans,” Cotton says. In fact, U.S. veterans have been leading the lobbying effort. Women who suffer from PTSD as a result of sexual assault are also strong candidates for psychedelic treatments, as are patients struggling with addiction. Kentucky even considered putting some of its opioid settlement money toward research into psychedelic treatments for this latter group, though the plan eventually fell through.

“When you talk about these options and you show the possibilities, even those who are skeptical of psychedelic drugs see that when you take the drugs plus therapy, it’s monumentally more effective than either the drug or the therapy alone,” Esselman says. “And I think that when the FDA approves MDMA, there’s going to be a huge spike in interest.”

“The public discourse around behavioral health has elevated in a way where this conversation can happen now.” — David Schonthal

Still, it’s going to take more than agency approval for the industry to gain traction.

One major hurdle is the question of training and licensing for therapists. It’s not clear who would qualify to administer these drugs in a therapeutic setting or what the best practices should be. The University of Pennsylvania’s nursing program, together with Columbia’s school of social work, has begun to expand its curriculum to include training in psychedelic-assisted therapy to new nurses and social workers, but this program is still in its pilot stage. Meanwhile, those who know the drugs best tend to come from underground alternative-wellness backgrounds, making for a tricky integration into the traditional medical system.

Major insurers could represent an even larger stumbling block. “The large payers are going to be skeptical, and clinical trials won’t get them there,” Cotton says. “They want to see actual data. They want to know what to expect in terms of reducing hospital admissions or avoiding other services.”

What could push the treatment forward through traditional medical channels, however, is pressure from the business community. “There’s a growing recognition that the current mental-health crisis is now affecting our economics, our business environment, and our workforce,” says Esselman.

Indeed, Cotton says, some of the earliest proponents of psychedelic treatments are currently coming from “self-insured employer groups who emphasize the mental well-being of their employees. Some of them are already purchasing ketamine plans that are not offered by traditional insurance.”

What Oregon’s legalization shows

In Oregon, the first state to legalize psilocybin , an alternative model is taking shape—one that doesn’t rely on fully integrating psychedelic therapy into the medical system.

Instead, trained “facilitators”—licensed by the Oregon Health Authority—offer what the state refers to as “psilocybin services.” Patients don’t need a medical diagnosis to participate, and facilitator certificate programs—which require anywhere from three months to a year of coursework and practicum hours—are open to anyone with a high-school diploma who has passed a background check.

“Everyone expected it to be like cannabis, where there’d be a rush of people wanting to grow mushrooms,” says Ryan Reid , the founder of Bendable Therapy ‚ a nonprofit that educates and prepares potential therapy patients, and Drop Thesis , a for-profit company that includes psilocybin manufacturing and service centers. “But what actually happened was that everyone jumped in to become facilitators. By the end of this year, there might be over a thousand trained facilitators from fifteen or so different schools, but there are only about two dozen services centers licensed in the state right now. There are way more facilitators than there are service centers.”

In part, that’s because conservative county officials who oppose psychedelics have tried to make these centers economically unfeasible, as they did when the cannabis industry cropped up after legalization. “They learned how to throw enough wrenches into the works that you can’t start up,” he says.

But Reid says cannabis isn’t the best analogy for psilocybin services in Oregon, because cannabis is primarily about the sale of a product, where psilocybin is primarily about the sale of a service—facilitation—which is very labor-intensive.

When a typical PAT session—which includes preparation, dosage, and integration—is 12 hours one-on-one with a licensed professional, it’s hard to see how these service centers will be able to design their treatment systems to be sustainable. And once decriminalization expands, that may take a further bite out of the economic viability of PAT.

“I think you’ll probably end up with two-tiered market,” he says. “You’re going to have these little boutiques that offer psilocybin with a mental-health focus. And then you’ll have dispensaries for people who want the consciousness-expansion experience. There will always be demand for the mental-health-access approach, but it’s hard to keep viable.”

Cotton sees group therapy as a possible way forward. “Clinics will need to be embedded in the fabric of local communities,” he says. “Group models will be absolutely crucial, especially for lower-income communities.”

Schonthal points to Alcoholics Anonymous as an example of the power of group therapy. There’s also an interesting pharmacological wrinkle to the birth of AA. The group’s founder, Bill Wilson , credited the supervised use of the psychedelic LSD for his break with addiction.

“AA’s entire model is built upon this concept of having each other’s back. If you’re thinking about how to scale, creating a community is one way to do that.”

What’s next for psychedelics?

Whatever path the industry takes—prescriptions, dispensaries, community-based programs, or some combination of the above—there’s the question of who will benefit and who will be disrupted. The pharmaceutical industry, for example, might not welcome a shift away from Zoloft or Prozac.

“There’s no question the introduction of psychedelics upends their model,” Cotton says of the pharmaceutical industry, which has already been disrupted by patients’ increased access to cannabis.

And while psychedelic enthusiasts say their goal is to fill gaps in care created by years of disinvestment in mental-health services, it may be tough to find business models that will make a significant difference in the mental health of millions.

“Low-income, marginalized communities are where the bulk of trauma is happening. These are the communities that could benefit the most from transformational healing,” Cotton says. But finding profitable business models here is the most difficult to pull off, meaning governments and philanthropists may need to step in. “It’s going to take a lot of work to figure out how to get access to as many people as possible.”

Clinical Professor of Strategy; Director of Entrepreneurship Programs at Kellogg; Faculty Director of the Zell Fellows Program; Director of the Levy Institute for Entrepreneurial Practice

Andrew Warren is a writer based in Southern California.

- International edition

- Australia edition

- Europe edition

Lost Gustav Klimt painting sells for €30m at auction in Vienna

Unfinished Portrait of Fräulein Lieser resurfaced in private collection but questions remain about its journey and its subject

A painting by the Austrian artist Gustav Klimt that was considered lost for 100 years has sold for €30m (£26m) at an auction in Vienna.

Entitled Portrait of Fräulein Lieser, the unfinished picture was painted in the spring of 1917, when Klimt was one of the most celebrated portraitists in Europe , and a year before his death.

Until the Viennese auction house im Kinsky announced at a press conference in January that the portrait had been re-discovered in a private collection, only a black-and-white photograph of the painting was known.

The artwork’s sudden re-emergence, coupled with an intriguing backstory, built up considerable buzz around the painting.

In the run-up to Wednesday afternoon’s sale, about 15,000 visitors had taken the opportunity to see the work displayed at im Kinsky.

The sum the painting fetched was at the bottom of its €30m to €50m valuation, and some way off the £74m that another late-period Klimt portrait, Dame mit Fächer (Lady with a Fan), fetched in London last June – a record for any artwork ever sold at an auction in Europe.

Some key questions about the painting remain unanswered, including the identity of its subject and its provenance during the Nazi era.

A commissioned portrait, it is believed to depict one of the daughters of either Adolf or Justus Lieser, who were brothers from a wealthy family of Jewish industrialists. Some art historians have identified the sitter as Margarethe Constance Lieser, Adolf Lieser’s daughter.

However, im Kinsky has suggested the painting could also depict one of the two daughters of Justus Lieser and his wife, Henriette, a patron of modern art. An AI-based “ageing” of the portrait shows up apparent similarities to Helene Lieser, an economist who died in 1962, the auction house has claimed.

The identity of the sitter is crucial: after Klimt’s death in 1918 the painting ended up with the Lieser family, though which branch of the dynasty could rightfully claim ownership of the picture has been hard to establish. Art historians have struggled to piece together the painting’s journey between 1925 and 1961.

The auction house said the painting’s journey during the Nazi period was “unclear”.

It said: “What is known is that it was acquired by a legal predecessor of the consignor in the 1960s and went to the current owner through three successive inheritances.”

The identity of the last Austrian owners before Wednesday’s sale has not been made public.

- Gustav Klimt

Claudette Johnson’s art for Cotton Capital nominated for Turner prize

‘Not even a pipe dream’: John Akomfrah represents Britain at Venice Biennale

German art museum fires worker for hanging his own painting in gallery

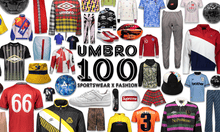

‘Englishness is constantly revised’: Umbro exhibition shows evolution of football shirts

Marlborough Gallery: ‘blue chip’ art institution to close after nearly 80 years

Ron’s Place: Birkenhead flat of outsider art granted Grade II listing

‘Sport is never just sport’: Olympics exhibition in Paris reflects 20th century’s highs and lows

Piero della Francesca’s Augustinian altarpiece reassembled after 450 years

Liverpool museum appeals for information on subject of The Black Boy

Most viewed.

- Cotton Library

- Customer Service

- Request a Quote

- Our Cotton Purification Process

- Sustainability

The Journey of Cotton: Ginning

This post is part of our blog series entitled “The Journey of Cotton.” This series will focus on the seven unique steps that it takes to process cotton, starting with the planting of the crop to the point it becomes a specific consumer product. We previously discussed harvesting cotton, but today’s post will focus on the third step in that journey: ginning the cotton.

First, the Cotton’s Moisture Must Be Measured

Next, It’s Time to Separate the Seed from the Fiber

The cleaned seed cotton is then conveyered over gin feeders, where additional cleaning takes place. At this point the cotton drops into the cotton gin stand. Here the seed is removed from the lint by saw blades that pull the lint away as the seed hits spacers (ribs) that do not let the seed pass through. Next, the seed drops into an auger and will later either be crushed for cotton seed oil or fed to dairy cattle to aid in the production of milk.

Lastly, Cotton Is Pressed into Bales and Tested

Up Next: Cotton Purification

This is part four of our seven-part Journey of Cotton series. (If you missed our Introduction , be sure to visit that blog post.) The next step in the cotton journey is Purification, so keep an eye out on our blog for updates. You can also enter your email address in the “Stay in the Know” field in the right margin to have blog updates sent directly to your inbox.

IMAGES

VIDEO

COMMENTS

The array of products that purified cotton can be used in is almost endless. Look for Our Forthcoming Journey of Cotton Posts. Over the coming months we'll be going into greater detail on each of these seven steps—post by post—so keep an eye out on our blog for updates. Cotton has a long, winding road from the field to the consumer use.

The journey of cotton is a complex and fascinating one, involving multiple stages and processes. As consumers, understanding this journey can help us make more informed choices and appreciate the effort that goes into creating the cotton products we use every day. Moreover, it underscores the importance of adopting sustainable practices at ...

Cotton remains the most miraculous fiber under the sun, even after 8,000 years. No other fiber comes close to duplicating all of the desirable characteristics combined in cotton. The fiber of a thousand faces and almost as many uses, cotton is noted for its versatility, appearance, performance and above all, its natural comfort. From all types ...

Discover the fascinating journey of cotton, one of the world's most important crops. In this video, we'll take you on a tour from the cotton fields where it'...

The Origins of Cotton. Discover the fascinating origins of cotton, a versatile natural fiber that has played a significant role in the development of fabric over generations. The history of cotton dates back thousands of years, with evidence of its early cultivation found in ancient civilizations such as the Indus Valley and the Nile River Valley.

The journey of cotton begins with the planting of cotton seeds in fertile soil. The planting season usually starts in the spring when the soil temperature is warm enough for the seeds to germinate. Farmers use specialized machinery to plant the seeds at the correct depth and spacing. After planting, the seeds require adequate moisture and ...

Apr 26, 2023. Cotton is one of the most widely used and versatile natural fibers in the world, serving as a key ingredient in the textile industry. The journey of cotton, from farm to fashion ...

With the cotton yarn now ready, the weaving process can begin. Weaving is a key stage in the journey of cotton fabric production, where the individual yarn strands come together to form the final material. 6.1 The Loom and Its Role. Weaving occurs on a loom machine, which holds the yarn strands in place and facilitates the interlacing process.

April 13, 2018. Cotton is one of the most important natural fibers on earth, used by everyone every day. We have entered the cotton business over 30 years ago. Today, we are among the world's leading companies managing the journey of cotton, from the field all the way to your clothes. Our new video explains how it's done.

November 12, 2023 by Rohan. Discover the fascinating journey of cotton fabric production and dyeing. You'll explore the process of cultivating cotton plants and harvesting them for processing. Watch as the cotton fibers are spun and woven into beautiful fabrics. Then, delve into the world of fabric dyeing techniques, from traditional natural ...

Cotton is used for thousands of things, including clothes, space suits for astronauts and ingredients in the food we eat. How it is grown, cultivated, harvested and finally processed into cloth and other co-products is what you will be learning about in this story of cotton and Cotton's Journey - A field Trip in a Box. I History.

Moving forward in our journey through the evolution of cotton fabric, we delve into the early innovations that transformed the process from hand-spinning to the use of looms. Hand spinning techniques played a crucial role in the early stages of cotton fabric production. People would manually spin the cotton fibers into yarn using a spindle or a ...

In this cotton video series - you can understand how the cotton plant goes on a journey to make itself as a garment.Ginning is a process in which the cotton ...

Cotton yarns inside a fabric The Process and Production of Cotton. Cultivation and Harvesting. Cotton starts its journey as a humble seed, planted in carefully prepared soil.The cotton plant requires specific climatic conditions and adequate water supply to thrive. As it grows, the plant develops beautiful flowers, which eventually transform into cotton bolls.

Cotton is one of the most popular fabrics available and is used to create a wide range of clothing and accessories. To create cotton fabric, producers must grow cotton plants, extract cotton fibers from cotton seeds, and weave the threads into a textile. Although cotton production is an ancient practice, modern techniques have improved the ...

Cotton is fully mature and ready for harvesting approximately 160 days after being planted. Once the bolls have burst open, the farmers can prepare the cotton plants for harvesting. This occurs in mid-July for the southern parts of Texas, and in early September for the northern parts of the cotton belt. One of the biggest threats to a cotton ...

After 60 Days, the "Squares" Appear. For the first two months after planting the farmer's main priority is keeping the weeds and grass out of the cotton. The weeds and grass compete with the cotton plant for the soil's nutrients and water. Lots of sunlight and heat units are necessary for the plant to make a strong root system.

The 6 Steps of Cotton Production. 1.Planting: The journey of cotton begins with the planting of cotton seeds. These seeds grow into cotton plants, which produce flowers that eventually become cotton bolls. 2.Harvesting and Cleaning: Cotton bolls are carefully plucked from the plants either by hand or using mechanical cotton pickers.

The stages of the cotton processing till the final productplease like,share and followfacebook.com/sonoffarmer1/instagram.com/son.of.farmer/

Discover the fascinating journey of cotton fabric creation as you delve into the hidden secrets of this ancient craft. From the cultivation of cotton plants to the intricate weaving techniques and the vibrant dyeing process, you'll uncover the intricate steps involved in producing the fabrics we wear every day.

She described Abraham's long journey in law enforcement. She stated he was a dispatcher, jailer and jail administrator; he also worked as a school resource officer, deputy, chief deputy, and then finally achieved his goal of becoming sheriff. ... 62-year-old Lubbock man crushed by cotton bales, Slaton police say. Harvey Weinstein's 2020 ...

We previously discussed cotton ginning, but today's post will focus on the fourth step in that journey: cotton purification. The raw cotton arrives in densely packed bales. The bales contain fiber as well as small plant parts and field trash (non-lint or foreign matter). The fiber also has a coating of natural waxes to protect it from rain ...

Discover the fascinating journey of cotton from the fields to the finished product, and gain a deeper appreciation for the craftsmanship behind the clothes you wear. ... Cotton fabric production has significant environmental impacts. It contributes to a high carbon footprint due to energy-intensive processes. Additionally, it requires large ...

The journey to finding sustainable business models for a difficult-to-scale treatment method may take time, however. In this article, entrepreneurs, philanthropists, and other industry leaders discuss how the fledgling industry can overcome significant regulatory and insurance barriers. ... Cotton sees group therapy as a possible way forward ...

Art historians have struggled to piece together the painting's journey between 1925 and 1961. ... Claudette Johnson's art for Cotton Capital nominated for Turner prize . 15h ago

In cotton ginning, the main goal is to separate the seed and lint from the cotton fiber. The freshly picked cotton arrives at the gin with the seeds still in the fiber, as well as sticks, stems, burrs, and other unwanted visible foreign matter. In the first stage of the ginning process, the moisture of the cotton is measured, which determines ...