- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

Prevent Workplace Slips, Trips, and Falls—8 Safety Tips

Mopping up a spill or double-checking a guardrail might seem like simple common sense, but slips, trips, and falls are the second most common cause of death at work. These are life-saving procedures. Keep reading for practical tips to prevent workplace accidents.

- Slip, Trip, and Fall Hazards Listed

- Clarifying OSHA Standards

- Prevent Workplace Slips, Trips, and Falls

These are familiar scenarios at home: slipping on a wet floor in the kitchen and tripping over a toy left out by the kids. While annoying, these accidents are typically minor hazards in the home. You might stub your toe, but rarely are there severe consequences.

In the workplace, it’s a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They’re also the second-leading cause of workplace fatalities.

As a safety leader, you’re responsible for your company’s duty of care and for providing a safe workplace . This blog post will examine common hazards leading to slips, trips, and falls and the steps you can take to minimize injury risks for your team.

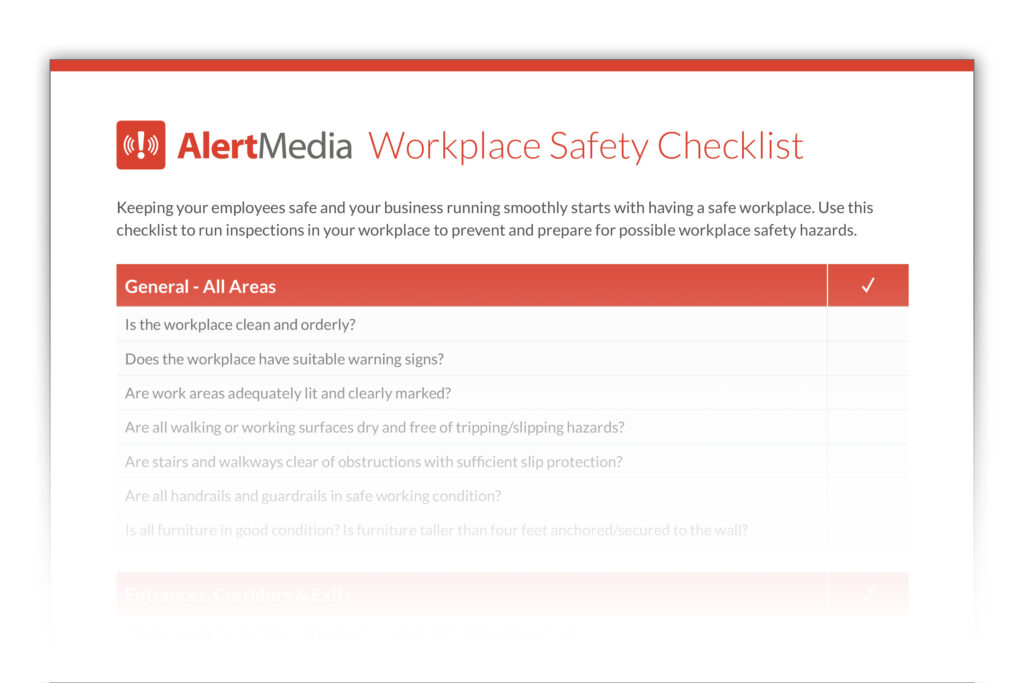

Download Our Workplace Safety Checklist

What are slip, trip, and fall hazards in the workplace.

Accidents involving slips, trips, and falls are often grouped together. While they’re similar, it’s important to understand the distinction since they each have different causes and consequences.

Slips occur when someone’s footwear loses traction with the surface they’re on, causing a loss of balance. Under some circumstances, slipping can lead to a fall.

Trips happen when someone hits their foot or lower leg on an object. As their upper body continues moving forward while their lower body remains stationary, the person may lose their balance in the process.

Falls often result from slips or trips, but they can also happen on their own. For example, a worker on a ladder or scaffolding can lose their balance and fall without slipping or tripping. Falls are also possible on flat surfaces and can still cause serious injuries.

Once you understand the hazards that lead to each type of accident, you can identify and mitigate risks in your workplace. Here are some of the most common causes of slips, trips, and falls in the workplace:

Slip Hazards

- Spills of wet or dry substances

- The cleaning process during spill removal

- Employees rushing or not paying attention to workplace conditions, especially while carrying objects

- Slippery floor surfaces such as marble or laminate

- Wet surfaces

- Poor lighting that obscures hazards

- Inappropriate footwear for the environment

- Transitioning between different types of surfaces

Trip Hazards

- Objects or obstructions in walkways

- Uneven surfaces on flooring or concrete

- Cables, cords, and hoses that aren’t properly secured or organized

- Unmarked steps or ramps

- Irregular stairs or stairs without railings

- Carpet, rugs, or mats with wrinkles or lifted edges

Fall Hazards

- Improperly used or poorly maintained ladders

- Elevated surfaces without guardrails

- Floor and wall openings

- Working in elevated environments without a safety harness

- Ill-fitting or improperly used PPE, such as helmets and safety lines

Preview the Workplace Safety Checklist

Are There OSHA Standards Related to Slips, Trips, and Falls?

Despite how common these injuries are, there is no specific OSHA standard on slips, trips, and falls. However, several OSHA rules indirectly address the same hazards.

The most important regulation to be aware of is 29 CFR 1910 Subpart D, which covers walking and working surfaces. OSHA updated the standard in 2017, introducing many upgrades to fall protection system requirements, improved employer-provided inspection guidelines, and a greater emphasis on safety training for employees.

For the construction industry, 29 CFR 1916 contains numerous fall-related regulations. Subpart M specifically addresses fall prevention, but other sections, such as Subpart L (scaffolds) and Subpart E (personal protective and lifesaving equipment), are also relevant. OSHA used 29 CFR 1916 as guidance when revising 29 CFR 1910, so the two guidelines now reflect many of the same OSHA violations .

As with any other workplace hazard or accident, OSHA recordkeeping requirements still apply in the event of a slip, trip, or fall incident. Internally, the reporting process is also an opportunity to review the details of the incident and determine how you can update your workplace safety policy to prevent similar accidents in the future.

How to Prevent Slips, Trips, and Falls in the Workplace

Many hazards that cause slips, trips, and falls are inevitable. However, injuries and accidents are not. To prevent slips, trips, and falls, train your employees to follow a three-step process:

- Recognize the hazard: Identify conditions that could lead to a slip, trip, or fall.

- Evaluate the hazard: Examine the situation and determine what level of risk it presents and who it affects.

- Control the hazard: Avoid the risk by removing the hazard (such as mopping up a spill) or implementing safety equipment and procedures (such as installing handrails on an elevated platform).

Here are eight workplace safety tips to prevent falls, trips, and slips.

1. Teach situational awareness

Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

- Look at walking surfaces for spills, obstacles, or other potential hazards

- Watch for signage that warns of increased hazards

- Be aware of conditions such as weather or time of day that might increase the risk of an accident

- Take shorter and more cautious steps on slippery surfaces

2. Encourage proper footwear

Like any other form of PPE, proper footwear can significantly reduce the risk of accidents. Research has found that slip-resistant shoes can reduce injury claims by 67% in environments with slippery work surfaces.

Employees should regularly inspect their shoes and make sure the soles aren’t worn out, as the lack of tread increases the danger of slipping. Additionally, anyone who works in conditions exposed to winter weather hazards should wear insulated boots. Cold temperatures can decrease muscle function, increasing the risk of slipping, tripping, or falling.

3. Utilize signage

Signage is an effective warning system for many workplace risks, but it can be especially effective in preventing slips, trips, and falls. There are two types of signs you can use to increase occupational safety:

- Temporary: Use warning signs while addressing a new hazard, such as cleaning up a spill, repairing a handrail, or replacing a ripped carpet. While temporary signage can help prevent injuries, you still need to address the actual hazard as quickly as possible.

- Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it’s easy for people to ignore signs they see every day.

4. Keep floors clear and clean

Good housekeeping can help prevent most slips, trips, and falls. The details of keeping walking areas clean will vary widely by work environment, but there are a few common themes to encourage workplace safety:

- Report spills immediately, and warn nearby employees until someone can clean the contaminated surface

- Keep walkways clear of obstacles, loose objects, and anything that someone could trip over

- Place mats at entrances and exits so people can dry their shoes and avoid tracking water or other substances around the workplace

- Install handrails on stairways and elevated walkways

5. Apply non-slip mats and coatings

In some situations, keeping floors from becoming slippery is nearly impossible. Whether it’s liquid splashing or steam condensing, you must focus on mitigating the risk rather than avoiding it altogether.

For smaller or less demanding settings, non-slip mats can help employees maintain traction while walking around. In other cases, treating the floor with a permanent coating can help reduce slipping risks, even in the constant presence of liquids.

Who is at risk for slips, trips, and falls?

While all industries have some level of risk for a slip, trip, or fall, there are some industries where the risk is much higher, and the potential result could be much more dangerous. Here are some of the highest-risk industries:

- Construction

- Manufacturing

- Transportation/shipping/logistics

- Outdoor maintenance/groundskeeping

- Foodservice/hospitality

6. Ensure proper lighting

To identify slip, trip, and fall hazards, your employees need to be able to see their surroundings. Make sure that all of your work areas have proper lighting, especially in areas that are more prone to unsafe conditions.

While this can be a challenge in outdoor work environments, especially at night, it’s even more critical in those situations. Environmental conditions can lead to increased risks, and employees need to be able to see and avoid them. Adequate lighting should also extend to parking lots and walking areas around your facilities.

7. Develop safety programs

Your company’s safety plans and programs should include specific guidelines for preventing slips, trips, and falls. There are a few key topics to consider when developing these policies:

- The types of surfaces employees work and walk on and whether they present extra risks

- Seasonal or regional conditions that could heighten hazards, such as winter weather threats

- Specific OSHA regulations that apply to your workplace

- Potentially hazardous equipment training such as ladder safety

- Regular inspection plans to ensure your team is maintaining a safe work environment

- Policies to report hazards using your company’s two-way communication platform

- First aid training , so employees are prepared to respond safely should injuries occur

8. Provide Slips, Trips, and Falls Training

Lastly, training your employees to avoid slips, trips, and falls will help keep them safe. Provide specific guidance on the environments they’ll work in and the hazards they’ll face. For example, a slips, trips, and falls safety talk for food service workers should focus on wet floors and walking safely in crowded, fast-paced environments. Conversely, office workers could use extra reminders to watch for stray power cords and keep walkways clear of boxes, files, and other tripping hazards.

Working slips, trips, and falls into your safety topics for meetings is also helpful. Regular safety talks or safety moments are an excellent opportunity to remind your team about seasonal risks or update them on newly installed safety measures.

Don’t Let Your Safety Standards Slip

Slips, trips, and falls are some of the most common workplace injuries. Fortunately, you can usually prevent them with proper planning and safety measures.

By making slip, trip, and fall prevention a part of your company’s safety culture, you can ensure your employees are aware of their surroundings and ready to look out for each other’s safety. Enable them to report hazards easily, address risks quickly, and train them to avoid situations that are likely to cause injury.

With the right planning and prevention, even the most intense work environments can be as safe as a walk in the park.

More Articles You May Be Interested In

Workplace Safety Checklist

Please complete the form below to receive this resource.

Check Your Inbox!

The document you requested has been sent to your provided email address.

Cookies are required to play this video.

Click the blue shield icon on the bottom left of your screen to edit your cookie preferences.

- SafetySign.com

- Help Center

Prevent Slips, Trips, and Falls

JavaScript is not enabled.

This site requires the use of JavaScript. Please enable JavaScript .

10 Simple Ways to Prevent Slips, Trips, and Falls

Slips, trips, and falls are the leading causes of time lost in the workplace. The Occupational Safety and Health Administration (OSHA) has cited fall protection standard violations more frequently than any other standard.

These types of hazards are serious issues for workers and employers, but their risk can be minimized with 10 simple ways to prevent slips, trips, and falls. With the risk of injury ranging from a simple sprained ankle to serious injury or death, fall protection and prevention should be everyone’s top priority.

These 10 ways to prevent injury should be considered best practices in every industry.

Like any other safety hazard, slips, trips, and falls can be highlighted during safety training. Make sure that everyone can recognize and avoid slip, trip, and fall hazards and that they use PPE correctly when necessary.

With these types of hazards being common to every type of work environment, it is important to notify supervisors or maintenance crews of slip, trip, and fall hazards when they are present. With so many ways to avoid or lessen the severity of slip, trip, and fall hazards, hopefully businesses will take steps to abate this hazards and less time will be lost by workers.

Your cart is empty.

Sorry, we're unable to complete your request

We cannot complete your request due to a technical difficulty. You may return to the previous page or go to the homepage and explore other options. For immediate assistance please call us.

Error Ref: %26%2332%3b%26%2335%3b18%26%2346%3b85645e68%26%2346%3b1713051037%26%2346%3b340dc886

- Leave your feedback

- Testimonials

- Buy Kett Products

- Buy Kett Accessories

- Ask a Kett Question

- Kett Answers

Slips, Trips, and Falls: Best Practices + Preventative Procedures from the Ground Up

Here’s a shocking fact: At over 8 million visits per year , fall accidents account for 21.3% of emergency room visits. Slip and fall cases make up 1 million of those visits to the hospital every year.

These visits not only cause broken bones and sometimes even more serious injuries, but they also are the primary cause of lost days from work, as well as the leading cause of worker’s compensation claims .

And the majority of these slips and trips in the workplace come from unsafe, hazardous flooring. In fact, 55% of all slips, trips, and falls happen as a result of hazardous flooring, an easily preventable issue with the proper procedures in place.

Slip and fall cases cost businesses around $11 billion each year. Sure, it costs businesses money to defend these cases, but it also causes the injured person to miss work and potentially deal with the resulting lifelong injuries. What else should you know about slips, trips, and falls ?

- The average slip-and-fall injury costs $20,000, but the cost for a business to defend a slip-and-fall case is around $50,000

- An employee who has been injured in a slip-and-fall incident misses, on average, 38 days of work

- Slips, trips, and falls account for 15% of all accidental deaths, second only to automobile accidents

In today’s world where every cent counts and every worker matters, businesses can’t afford not to take slips, trips, and falls seriously. Businesses then need to implement slip-resistant flooring, and also invest in portable, accurate, and easy-to-use handheld friction measurement tools, so they can be sure their floors are truly slip-resistant, and their employees are always safe.

Flooring Safety Standards

When a building is being constructed, materials are carefully chosen to provide a safe environment. Any flooring that is being used in the construction of a new building has been put through rigorous testing to make sure it is safe.

When this flooring is being tested for safety, evaluators are looking at the flooring’s coefficient of friction (COF) value. What does this mean?

- Coefficient of Friction The coefficient of friction (COF) is a mathematical term used to calculate the effect of one substance or item (a show, for example) over another item (in this case, the floor). It is a way to measure the ability of a surface to resist slipping or sliding. The coefficient value varies based on how "moveable" something is. For example, a tile floor covered in liquid from a spill will have a low coefficient of friction while tires on a tarred road will have a very high coefficient of friction.

OSHA has recommended that flooring has a COF value of at least 0.5. This number was not arbitrarily set in place, but is based upon a great deal of research. And this is not a standard for every floor across the board.

Some flooring needs to have a greater COF, in places where certain responsibilities put individuals at a higher risk of falling. This means that flooring needs to have a higher COF in places where individuals are carrying heavy items, pushing or pulling heavy objects, or walking up and down ramps.

Especially at entryways, in commercial kitchens, or anywhere a surface may become wet, there is a need for an even higher COF to prevent slipping as well.

Of course, when flooring is installed, building supervisors, architects, and safety consultants should always ensure that flooring meets these OSHA standards. However, after regular, daily wear and tear, maintenance, and cleaning, there’s a high likelihood that the slip resistance will wear away and become less safe.

So how can you be sure that your flooring continues to comply with OSHA’s standards, and will help keep your employees and visitors safe from slipping?

On-Site Friction Testing

Perhaps the best way to evaluate your flooring and know that it is up to OSHA’s standards? You should be using a handheld, portable friction analyzer on-site, to regularly test the COF values of your flooring, monitor the wear and tear, and avoid costly accidents.

Our friction test equipment , such as the portable friction meter, can be used by anyone to provide accurate COF data when testing the floor. The operator places the meter on the surface, ensuring the contact point of the meter is touching the floor, and presses a button. That’s it. Multiple measurements are stored within the meter and an average COF is calculated.

Because operation of the meter is so simple, there’s no variance in results between users. You can trust your results to be accurate, which means your test will always correctly indicate where you may need to improve your flooring’s slip resistance, either by replacing or resurfacing the flooring.

Preventing Falls

According to the Consumer Product Safety Commission (CPSC), floors and flooring materials are the cause of more than 2 million fall injuries every year. So how can you mitigate your risk for slip, trip, and fall accidents in your workplace? Here are three practices your company should follow:

- When choosing flooring for a space, consider how the day-to-day activities may affect slip resistance and the COF. Tile flooring is incredibly slippery when it is wet, and should be avoided anywhere that spills may frequently occur, or near entryways where moisture may be carried in. Also, smooth concrete, found in many garages, becomes dangerously slippery after the inclusion of the slightest bit of moisture. However, adding a slip-resistant coating to your floor can help increase the COF and prevent falls.

- Don’t ignore your flooring’s flaws. Over time, cracks and holes in your flooring materials can develop. These can quickly become safety hazards that put you and your employees at risk. Having a regular maintenance and repair schedule to address issues before they become a liability issue is vital to your building’s safety.

Additionally, it’s crucial to regularly test the changing COF of your flooring with a friction analysis meter to ensure your floor is still compliant with OSHA regulations - and still safe for your employees.

- Use floor coatings as a safety factor, not just for aesthetics. A glossy finish on a floor may have a beautiful effect, but is it really safe? Glossy flooring tends to become slippery and unsafe-especially if it gets wet. You don’t have to sacrifice form for function, though. Coatings can be strategically selected to provide the glossy aesthetic you want, while still having slip-resistant qualities to protect your employees.

Coating additives, such as aluminum oxide, increase the slip-resistance of a floor’s finish, and UV-cured coatings provide additional slip resistance on polished concrete and similar surfaces. You should always choose your employees’ safety above anything else, but fortunately, advances in flooring materials mean you can choose a stunning design still, too.

Slips, trips, and falls are the most common accidents in the workplace. Regular testing of your flooring with a friction analysis meter and careful maintenance can help you prevent these easily avoidable, unfortunate accidents. Using a friction analysis meter will provide you with a safer work environment and hopefully, many fewer employee slip, trip, and fall incidents. Your team encounters less risk of falls, and your workplace is a safe space. Not only does this keep you in compliance with OSHA standards, but it can help you avoid costly injury-related expenses too.

Related Posts

Subscribe by email, search kett, product lines.

- NIR Composition Analyzers

- Moisture Balances

- NIR Moisture Meters

- Wood Moisture Meters

- Paper Moisture Meters

- Concrete Moisture Meters

More Products

- Grain Moisture Meters

- Seed Moisture Meters

- Rice Quality Gauges

- Universal Moisture Meters

Other Instruments

- Coating Thickness Gauges

- Friction and Wear Testers

- Portable Friction Meters

- Whiteness Meters

- Laboratory Mixers

1 st Reporting

Slips, Trips, and Falls: A Comprehensive Guide For The Proactive Manager (Part One – Regulatory Requirements)

Posted 11.05.23 by: Jeremy Shantz

Slips, trips, and falls in the workplace are common and the number one cause of workplace injuries. We’re not just talking about minor injuries, either. Believe it or not, something as simple as a carpet in your entranceway can cause severe trauma and, in rare cases, death.

Table of Contents

Understanding Impact

Slips, trips, and falls happen often. In fact, 27.4% of nonfatal workplace injuries in private industry were caused by slips, trips, and falls. If we look at the big data, in 2019 in the United States, there were 888,220 workplace injuries (reported), and 244,000 were slips, trips, and falls caused. ( source )

Statistically, these numbers are quite revealing. The median number of injuries one can expect is 2.8%. So, three of every 100 workers will have an injury at work this year, according to the injury statistics.

This guide will review all the ins and outs of slips, trips, and fall incident management. I’ll provide a roadmap for making management and prevention much easier for you. Stick with me to the end, and I’ll give you my favorite not-so-secret incident management tool advice so you can make your job easier too. Let’s get started.

Understanding Slips, Trips, And Falls

To create a safe and manageable work environment, we must understand exactly what slips, trips, and falls are. You know the common definition, but let’s examine how the authorities view such terms.

Definitions

Most countries in the G20 or UN follow a basic understanding of the incident definition. However, for the purpose of clarity, we’ll use OSHA (Occupational Safety and Health Administration in the United States) for our definitions.

According to OSHA, a slip is when a person loses balance due to a lack of friction between the floor and their footwear. Examples might include wet smooth tile or marble flooring, or if you live in the north, a typical slip scenario is ice on the ground.

Common Causes

- Oil or similar lubricating chemicals

- Wet surfaces

A trip is a scenario where a person loses balance due to a collision between a foot and an object. Practical scenarios might include a fold in a moveable floor rug, uneven flooring or steps, or even objects left on the floor. Trips are potentially dangerous not just due to the collision between foot and object but because they have a tendency to throw a person to the ground. Well, I don’t need to tell you how dangerous that can be when:

- Working at heights

- Working around sharp objects

- Working around moving equipment or vehicles

For obvious reasons, a trip can quickly escalate into a life-or-death severe scenario.

- Uneven flooring

- Objects in walkways

OSHA views a fall as the movement towards a lower level, typically at rapid speed or acceleration (gravity). You might go so far as to assume that the fall is the tail-end of the trip, and in many cases, you would be correct in making that assumption. However, the wording that OSHA uses to define a fall makes the assumption more evident that it intends to regard falling from a higher level to a lower level as the pre-emptive definition of a fall.

Examples of falls include falling off a loading dock edge, falling down some stairs, or falling off your chair (it happens more than you know).

- Unguarded work platforms

- Lack of fall prevention equipment

- Trips and slip events

I’ve provided a few causes of slips, trips, and falls in the workplace, but let’s define the more broad reasons to get the proper perspective.

Environmental Factors

As mentioned earlier, if you’re in North America, Europe, or another place that sees ice and snow in winter, you know that environmental factors can easily cause slips, trips, and falls. Ice, snow, and hail can easily make a person slip and fall.

Rain is also a factor in slipping on smooth surfaces. Naturally, we don’t have many smooth outdoor places where people might slip, but even a wood walkway outside can turn into a slippery surface in the right wet conditions.

Human Factors

Humans are notorious for making problems for each other, and often, it isn’t even intentional. Take a worker who is carrying some boxes and set them down for a moment to answer the phone. Maybe they get distracted and merely forget the box was placed in an aisle. Sure enough, if Murphy is afoot, then someone is going to trip over the box.

Human factors may not be limited to the common practice of leaving a parcel in a walkway. Some jobs require workers to instigate slippery conditions; just think of anyone who has to wash down a truck with soapy water, work with oily equipment, or any number of other common work scenarios that involve processes that could cause slippery conditions. A janitor mopping up a spill is the simplest human factor that comes to mind, especially if there are no slippery when wet floor signs are posted.

Equipment Factors

Although equipment can play a significant role in workplace slips, trips, and falls (in several ways), truth be told, each of the ways that equipment factors into slip, trip, and fall events all go back to a person in some way or another. Here are some of the ways people let

equipment causes dangerous situations that can cause slips, trips, falls, and injury to people.

- Poor Maintenance: Equipment that people improperly maintain can create hazards. For instance, a machine can leak oil or other fluids, creating a slippery surface. Machines or other equipment might also have loose parts that could cause someone to trip.

- Improper Use: Misusing equipment can lead to accidents. For instance, if you use a ladder that’s too short, you might overreach and fall. Don’t stand on chairs or tables in the office instead of using a step stool or ladder. I have found in every job that one person thinks they can stand on a wheeled desk chair to reach something, but I warn you: Don’t do it. You aren’t Spiderman.

- Equipment Placement: The location of equipment can also cause accidents. Electrical cords and cabling are notoriously making people faceplant. If you have ever worked in maintenance (or entertainment), then you’ll know what I’m talking about.

- Inadequate Safety Features: Some equipment may lack necessary safety features that could prevent slips, trips, and falls. For example, a ladder without non-slip feet can easily slide on a smooth surface, leading to a fall.

Similarly, machinery without proper guardrails or other safety devices could put workers at risk of falling. Check your equipment for necessary safety features. Machinery should have proper guardrails or other safety devices to prevent falls. Furthermore, it would be best to insist on daily walk-around safety inspections for all your vehicles or equipment . Enacting smart safety protocols reduces the risk.

- Inappropriate Equipment: Sometimes, the equipment itself is not suited for the job or the environment, increasing the risk of slips, trips, and falls. For instance, forklifts used in an area with a slippery floor can lead to accidents.

- Personal Protective Equipment (PPE): The absence or misuse of PPE can also contribute to slips, trips, and falls. For instance, workers not wearing appropriate footwear for their environment (like non-slip shoes in a wet or oily environment) can easily slip and fall. Similarly, workers who don’t use precautions like a fall protection safety harness are asking for accidents to happen.

To mitigate these risks, ensure that regular maintenance and safety checks of all equipment are standard practice at your workplace. Workers should also have training in correctly using and placing all equipment, and appropriate PPE should be provided and used consistently.

Common injuries

Knowing something and doing nothing about it is pointless. If we look at the data, then we know that each year it is expected that 2.8% of workers will have an at-work accident. That’s 1.4 workers out of 50 (0.7 out of 25). With these numbers, a team of 12 can expect one worker every two years to have an at-work injury. Let’s see what injuries are most common.

Sprains And Strains

Workplace sprain and strain injuries happen most to the torso. In many cases, this means someone’s back. Nearly 40% of injuries in 2021 (In the US) involved the torso.

Not to put too fine a point on it, but the US Bureau of Labor Statistics said back in 2005 that sprains and strains accounted for 43%, and mostly back injuries, of private industry, lost time accidents. That is, 43% of the 1.3 million injuries and illnesses reported in 2003. Twenty years ago, and things haven’t changed much.

According to the injury attorney Adam Skutner (no affiliation), you have a five percent chance of breaking a bone when you slip and fall. I’ve known three people who slipped, fell, and tried to put their hands out to stop the fall. Two of them broke their wrist; the third person sprained it. And that’s just off the top of my memory. So when I hear that five percent break bones, I’m not surprised it’s five percent; I’m surprised it isn’t more.

Dislocations

If you’ve ever dislocated something, then you know it’s as painful as a break. I think of the classic Mel Gibson in Lethal Weapon. He was known for dislocating his shoulder and painfully re-locating it with violent force against a wall or similar structure. However, nothing is entertaining about real-life dislocations, so it’s best to avoid them for obvious reasons.

Contusions And Abrasions

Contusions and abrasions are quite common in workplaces. Even office staff get paper cuts – no one is safe! However, in your business, it’s no laughing matter. A simple paper cut can lead to an infection that can lead to any number of complications. That’s why it’s critical to document everything, even a cut.

At a former job I managed, we had a simple first-aid use form to complete any time a first-aid kit was opened. It was a simple way to document simple injuries like cuts and scrapes that did not require medical attention beyond the first aid kit.

Concussions And Head Injuries

Concussions and head injuries are the most serious concern for anyone in a slip-and-fall event. The healthiest of people can fall the wrong way, hit their head, and end their day (or life).

According to the Washington Post , a study showed that the human skull can withstand 6.5 GPa of pressure. That’s compared to oak (wood) at 11, concrete at 30, aluminum at 69, and steel at 200. Therefore, I wouldn’t put my head in a fight against anything harder than my pillow.

Regulatory Requirements

It’s time to get into regulations. You are responsible for those under your charge as a manager or employer. Let’s see what OSHA has to say about the matter.

Occupational Safety and Health Administration (OSHA) standards

Navigating the landscape of safety protocols and OSHA standards can be overwhelming, but we’re here to break it down for you. The core standards you need to be aware of when it comes to preventing slips, trips, and falls in the workplace are these:

General Requirements (29 CFR 1910 Subpart D): It’s all about ensuring safe walking-working surfaces for your team. Make it a priority to keep these surfaces free from hazards like sharp objects, loose boards, leaks, or spills. Let’s not forget about seasonal hazards like snow and ice too!

Stairways and Ladders (29 CFR 1926.1052 and 1926.1053): These rules are a must-know if you’re in the construction industry. The focus here is on providing safe stairways and ladders to help prevent falls.

Fall Protection (29 CFR 1926.501): Another one for the construction folks out there. This standard mandates that employers provide fall protection systems when workers operate at heights of 6 feet or above a lower level.

Walking-Working Surfaces (29 CFR 1910.22): This one circles back to the general requirements but emphasizes cleanliness and orderliness. You must ensure that all walking and working surfaces are sanitary and well-maintained.

Personal Protective Equipment (29 CFR 1910 Subpart I): Here’s where the right gear comes in. OSHA requires employers to provide employees with appropriate personal protective equipment (PPE) and ensure its proper use. This could include non-slip footwear to help prevent slips and falls.

Remember, it’s not just about ticking boxes and meeting legal requirements. It’s about creating a safe working environment where your team members can perform their duties without fear of slips, trips, and falls.

International Organization for Standardization (ISO) Guidelines

ISO has a specific standard that addresses occupational health and safety: ISO 45001. These standard guides organizations in creating robust health and safety management systems, which inherently involve the prevention of slips, trips, and falls. However, the standard doesn’t go into specific details about these incidents. Instead, it focuses on risk management and hazard identification that would help anticipate and prevent such accidents.

Industry-Specific Regulations

All industries must follow a basic duty standard to provide safe working conditions. However, some industries have specific regulations, which I will review a sample cross-section of below.

Construction Industry

OSHA’s construction safety standards (29 CFR 1926) include detailed requirements for fall protection (29 CFR 1926.501), stairways and ladders (29 CFR 1926.1052 and 1926.1053), and scaffolding (29 CFR 1926.451). These standards mandate using guardrails, safety nets, or personal fall arrest systems when workers are working at heights of 6 feet or above a lower level.

General Industry

OSHA’s walking-working surfaces standards (29 CFR 1910 Subpart D) apply to all general industry workplaces. They require employers to provide safe walking-working surfaces and keep them free from hazards such as sharp or protruding objects, loose boards, corrosion, leaks, spills, snow, and ice.

Healthcare Industry

While there’s no specific OSHA standard for slip, trip, and fall hazards in the healthcare industry, these workplaces must comply with the general industry standards, including the walking-working surfaces standards. OSHA’s guidelines for nursing homes recommend implementing a comprehensive safety and health program that includes an analysis of fall hazards and a plan to control these hazards.

Maritime Industry

For shipyards (29 CFR Part 1915), long shoring (29 CFR Part 1918), and marine terminals (29 CFR Part 1917), OSHA has specific regulations that include requirements for working surfaces, guarding floor and wall openings, and maintaining ladders, stairways, and scaffolds.

Company Policies And Procedures

We have covered what the regulations say, and now it’s time to put that information into action. Creating a health and safety manual is a requirement for most businesses. Although the regulations may vary from state to state or province to province, the concept remains the same: If you operate a business with employees, you should have a health and safety manual.

Along with your health and safety manual, it’s advisable to have job hazard analysis a part of every role within your company or organization. Furthermore, it’s easy to include standards to maintain by providing your team with instructions and procedures to follow within each role. For example, you could include in your housekeeping role manual to utilize wet floor signs and keep pace with any spills to ensure fast clean-up and reduced chances of incidents.

That’s it for part one of our Slips, Trips, and Falls guide for the proactive manager. Check out Part Two for even more about the processes you can implement to take control of slips, trips, and fall incidents at your place of business.

Start reporting today

Join the globally-recognized brands that trust 1st Reporting to safeguard their organizations.

Customize Your Template

Work with our team of experts to customize our templates to your exact business needs.

- First Name *

- Last Name *

- Phone Number * ✓ Valid number ✕ Invalid number

- Changes Requested

- By submitting your information you agree to receive email marketing and promotional communications from 1st Incident Reporting

- Phone This field is for validation purposes and should be left unchanged.

Free Template Download

- I would like to learn more about a digital solution to manage my reports

Best Practices Guide for Slips, Trips, and Falls Prevention

Project Team:

- Newport News Shipbuilding

- General Dynamics Bath Iron Works

- General Dynamics NASSCO

- Alabama Shipyard

- Jeffboat, LLC

- Todd Pacific

- Bollinger Shipyards

- General Dynamics Electric Boat

NSRP ASE Investment: $21K

Industry Investment: $16K

In an effort to reduce slip, trip and fall injuries, associated workers’ compensation costs, and other lost time and production impacts, industry leaders from four shipyards teamed to develop a Best Practices Guide for Slips, Trips and Falls Prevention. This guide provides information on the:

- Frequency and severity of slip, trip, and fall related injuries, including which injuries are most prevalent and which employees are at an increased risk

- Impact of these types of injuries on the shipbuilding and repair industry, the individual and their family

- References and resources on slip, trip, and fall injuries and their prevention

Organized by falls from various locations and conditions (i.e. stairs, ladders, slippery surface), specific accident types and examples of best practices either currently being used or being studied at various shipyards are provided.

Key Deliverables:

Request Final Report from NSRP – Limited Distribution authorized to U.S. shipyards and NSRP ASE Program representatives

EHS Daily Advisor

Practical EHS Tips, News & Advice. Updated Daily.

Back to Basics, Injuries and Illness

Back to basics: slips, trips, and falls.

Updated: Oct 23, 2023

Back to Basics is a weekly feature that highlights important but possibly overlooked information that any EHS professional should know. This week, we examine slips, trips, and falls.

How much are workplace slips, trips, and falls costing you?

“Falls on the same level” often get lumped together with falls from height in slips, trips, and falls. While falls from height can sometimes be fatal, falls on the same level can lead to costly nonfatal injuries, resulting in several days away from work for injured workers and workers’ compensation claims for employers.

According to insurer Liberty Mutual, falls on the same level cost employers $8.98 billion a year. Falls on the same level are the second-leading cause of seriously disabling workplace injuries in the insurer’s 2023 Liberty Mutual Workplace Safety Index .

“Overexertion involving outside sources,” or lifting heavy objects, is the index’s leading cause of disabling injuries.

“Slip or trip without fall” is the ninth leading cause of disabling injury, according to Liberty Mutual’s index. Liberty Mutual reported that injuries on slippery or uneven walkways cost employers $1.98 billion a year.

First, some definitions: Slips are a loss of balance directly caused by too little friction between workers’ feet and walking surfaces. Wet surfaces, spills, and weather hazards like ice and snow can lead to a lack of friction.

Trips occur when workers’ feet hit an object and workers are moving with enough momentum to be thrown off balance.

Falls on the same level occur when workers get too far off their center of balance.

Safety professionals aware of slip, trip, fall hazards

Travelers, another insurer, reported that slips, trips, and falls on the same level are the second-leading cause of injury, accounting for 15% of all accidents, with approximately 25,000 slip, trip, and fall accidents occurring daily in the United States.

According to the National Safety Council (NSC), falls on the same level are the third-leading type of preventable injury at work after exposure to harmful substances and overexertion injuries. Falls on the same level affect every industry and workplace but are prevalent in the service, healthcare, and retail industries, according to the NSC.

Data shows that the median number of days away from work following a fall on the same level is 12 days.

The NSC suggests that effective signage can help prevent injuries, regulatory violations, and higher insurance premiums.

Slip, trip, and fall hazards show up in many industries, but wholesale and retail trade (WRT) establishments suffer high rates of slip, trip, and fall injuries. The National Institute for Occupational Safety and Health (NIOSH) offered several recommendations for protecting workers in the wholesale and retail industries.

Hazardous workplace factors include boxes or containers that obstruct workers’ field of vision; ice, rain, and snow; loose mats or rugs; poor lighting; spills that can create slippery surfaces; and walking surfaces that are in disrepair, have protruding nails and boards, or have changes in floor height.

NIOSH’s recommendations for employers include the following:

- Develop a written slip, trip, and fall prevention policy that spells out both employer and worker responsibilities.

- Ensure that aisles and passageways are free of clutter and other tripping hazards.

- Provide proper lighting in all areas indoors and outdoors to reduce shadows, dark areas, and glare so that trip hazards or surface irregularities are clearly visible, and promptly replace burnt-out light bulbs.

- If electrical cords are regularly used in a workspace, install outlets so that cords don’t cross walkways.

- Select flooring material according to the work performed in an area.

- Provide cleanup supplies—paper towels, absorbent material, “wet floor” signs, etc.—at convenient locations in the facility.

- Provide umbrella bags to prevent rainwater from dripping onto the floor.

- Use mats to provide slip-resistant walking surfaces by absorbing liquid and removing dirt, debris, and liquid from shoes. Mats should be large enough so that several footsteps fall on the mat and clean contaminants off the shoes.

- Provide water-absorbent mats near entrances and other areas where water, ice, or snow may drip or be tracked onto the floor.

- In grocery stores, ensure water from produce spray misters is directed onto produce and not spraying onto the floor.

- In grocery stores, provide customers with paper towels and plastic bags and for wet produce to prevent it from dripping water onto the floor.

You should supplement engineering controls with worker training. You need to train employees to identify slip, trip, and fall hazards and how to prevent slips, trips, and falls by using safe cleaning procedures and placing caution signs and/or cones around the site to warn other employees and visitors to avoid wet walking surfaces.

NIOSH also has employer guidance for preventing slips, trips, and falls in health care. According to NIOSH, the top slip, trip, and fall hazards in health care are:

- Contaminants (fluids, food, grease, oil, and water) on the floor;

- Poor drainage of drains and pipes;

- Walking surface irregularities indoors and outdoors like uneven flooring or ground and holes, protrusions, and rocks;

- Weather conditions like ice and snow;

- Inadequate lighting;

- Stairs and handrails;

- Stepstools and ladders;

- Tripping hazards like clutter, loose cords, hoses, wires, and medical tubing; and

- Improper use of floor mats and runners.

NIOSH’s guide includes an extensive checklist of slip, trip, and fall hazards that should be addressed in a healthcare facility.

OSHA has its own checklist for recognizing slip, trip, and fall hazards in the workplace. The list covers the general work environment, as well as aisles and walkways; escalators; elevated surfaces; floor and wall openings; ladders and scaffolding; parking lots and sidewalks; and ramps, stairs, and stairways.

NIOSH also warns young retail workers that slips, trips, and falls can result in bruises, bumps, cuts, fractures, scratches, sprains, and strains. The institute cautions young workers to clear stairs and walkways of tripping hazards like cords and wires, clutter, and empty cartons; to use handrails when walking up and downstairs; and to clean up spills and anything slippery on floors and the rungs, steps, and feet of ladders.

Control measures and training can be further supplemented with personal protective equipment. Employees who work on wet or contaminated walking surfaces should wear slip-resistant shoes. Workers should choose footwear that’s also resistant to chemicals, heat, and oil.

NIOSH has looked into the value of wearing slip-resistant shoes.

Laboratory studies of slip-resistant footwear to reduce slips, trips, and falls had shown promise in reducing slips, but until a few years ago, there was little research showing the effectiveness of slip-resistant shoes.

In 2019, NIOSH researched the effectiveness of slip-resistant shoes in a study of 17,000 food service workers in 226 school districts serving kindergarten through 12th-grade students. Workers were randomly assigned either to a group that received no-cost, “5-star-rated” slip-resistant shoes or to a group that bought their own slip-resistant shoes.

Researchers looked at workers’ compensation injury claims for accidents caused by slipping on wet or greasy surfaces to evaluate the effectiveness of the shoes.

The group that was provided with highly rated slip-resistant shoes saw a 67% reduction in claims for slip injuries.

There was a baseline of 3.54 slipping injuries per 10,000 months worked among the intervention group, which was reduced to 1.18 slipping injuries per 10,000 months worked after slip-resistant shoes were provided.

Employees who handle materials should ensure the walkways are unobstructed before transporting large materials that might block their view. They should walk with caution and make wide turns at corners. They also should push rather than pull carts to allow a better line of sight.

Housekeeping measures can also help prevent slips, trips, and falls. Your housekeeping policies should include:

- Cleaning floors and work surfaces as soon as they become wet;

- Inspecting refrigerated and freezer cases for water leakage onto the floor surfaces and placing absorbent strips and water-absorbent mats on the floor until the unit is repaired;

- Placing warning signs in wet-floor areas and removing them promptly when floors are clean and dry;

- Using no-skid waxes in slippery areas and using soap that doesn’t leave a slippery residue;

- Maintaining drainage and providing false floors (elevated floors usually 2 to 4 inches above the structural floor designed to provide a surface for safe transit), platforms, or nonslip mats during wet or oily processes;

- Cleaning only one side of a passageway at a time to allow room for passing;

- Keeping passageways clear at all times and marking permanent aisles and passageways; and

- Taping or anchoring electrical cords to floors if they cross walkways.

Workplace housekeeping

In a safety talk handout , the NSC emphasizes the importance of workplace housekeeping in factories and manufacturing plants, offices, and warehouses.

Workplace housekeeping can prevent slip, trip, and fall hazards, as well as control fire hazards and prevent falling objects.

The NSC recommends housekeeping measures suggested by the Canadian Centre for Occupational Safety and Health (CCOSH) that include:

- Cleaning all spills immediately;

- Mopping or sweeping debris from floors;

- Marking spills and wet areas;

- Removing obstacles from walkways and keeping walkways free of clutter;

- Securing carpets, mats, and rugs that don’t lay flat (tacking or taping floor coverings, for example);

- Ensuring file cabinet or storage drawers are closed;

- Covering cables or cords that cross walkways; and

- Keeping working areas and walkways well lit and replacing used light bulbs and faulty light switches.

Some industry groups tout “how to fall” training as a method of mitigating slip, trip, and fall injuries. Others offer “safe walking” tips like “watch where you are going,” “be aware of your environment,” “keep an eye out for changes in elevation,” and “take your time and don’t rush.”

According to the CCOSH, specialty footwear or training on proper walking and “safe falling” will never be fully effective without adequate housekeeping practices.

Federal regulation

Slip, trip, and fall hazards are addressed in the Occupational Safety and Health Administration’s (OSHA) walking-working surfaces standards (29 Code of Federal Regulations (CFR) Part 1910 Subpart D). In 2016, OSHA issued a final rule revising subpart D to incorporate advances in technology, industry best practices, and national consensus standards to ensure cost-efficient and effective worker protection. The revised rule requires employers to inspect walking-working surfaces regularly to correct, repair, or guard against hazardous conditions.

OSHA defines a “walking-working surface” as “any horizontal or vertical surface on or through which an employee walks, works, or gains access to a work area or workplace location.” Ensure aisles and walkways in your facility are kept clear of slipping or tripping hazards that lead to falls on the same level.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

IMAGES

VIDEO

COMMENTS

Given this, it's best to place proper lighting in access and egress points such as halls, ramps, stairs, and exits. 3. Install safety signs. Safety signs and markers are a must in preventing slips, trips, and falls. Installing them warns people about walking in hazardous spaces to keep them safe.

Marking the edges of steps or elevation changes. Other methods for preventing slips, trips, and falls require ongoing participation from workers, including: Proper footwear. Safe work practices. Frequent cleaning. Good housekeeping practices that keep walkways free of clutter. Noticing and marking slip or trip hazards.

Here are eight workplace safety tips to prevent falls, trips, and slips. 1. Teach situational awareness. Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

A fall can end in death or disability in a split second, but with a few simple precautions, you'll be sure stay safe at home and at work. The second leading cause of unintentional injury-related death is falls, resulting in 42,114 deaths at home and at work. Depending on the industry, falls can be the leading cause of death at work.

5. Block off temporary trip hazards. Use barricade tape, cones, and other floor safety products to restrict access to areas that present temporary slip, trip and fall hazards. 6. Mark out clear passageways. Use floor marking tape to show where walkways are and that these areas should be kept clear.

Indoor control measures can help reduce the incidence of slips and falls: Use moisture-absorbent mats with beveled edges in entrance areas. Make sure they have backing material that will not slide on the floor. Display "Wet Floor" signs as needed. Use anti-skid adhesive tape in troublesome areas.

Once you've identified your hazards, you can then institute policies and procedures to help prevent them. Following these best practices can help you create work environments free of the factors that can cause slips, trips and falls. Read more; Along with physical hazards, human factors can play a role in experiencing a slip, trip or fall.

Using the Stop the Fall model, we can identify the three biggest factors of slips, trips, and falls. Understanding these factors helps us all do our part in preventing these injuries. Choosing the right shoes is critical to preventing falls. Wear non-slip soles for environments with wet or slippery floors. Steel toe boots might also be needed ...

Employees are 2.5 times more likely to suffer a disabling fall in an office setting than anywhere else, according to the National Safety Council. The Council offers the following tips on avoiding fall hazards in the office: Walk - don't run Wear footwear that reduces the risk of slips, trips and falls

Best Practices to Mitigate Slip and Fall Accidents Workplace accidents involving slips, trips and falls are preventable with proper safety and risk mitigation protocols in place. According to OSHA ...

The average slip-and-fall injury costs $20,000, but the cost for a business to defend a slip-and-fall case is around $50,000. An employee who has been injured in a slip-and-fall incident misses, on average, 38 days of work. Slips, trips, and falls account for 15% of all accidental deaths, second only to automobile accidents.

SLIP, TRIP AND FALL PREVENTION Slips, trips and falls can result in injuries with lasting effects and even death. It is important to understand how slips, trips and falls happen, how to identify hazards and how to eliminate or minimize the hazards. Slips happen because of a lack of friction or traction between a person's footwear and the walking

Slips, trips, and falls happen often. In fact, 27.4% of nonfatal workplace injuries in private industry were caused by slips, trips, and falls. If we look at the big data, in 2019 in the United States, there were 888,220 workplace injuries (reported), and 244,000 were slips, trips, and falls caused.

The 3 Big Causes of Slips, Trips and Falls A 2014 survey of 1,294 safety professionals* revealed the most frequent factors in slip, trip and fall incidents at their workplaces—and a whopping 95% of respondents cited one of three causes. Most Frequent Factors in Slip, Trip & Fall Incidents

Slip, Trip, and Fall Prevention | 5 Table 1. Slip, trip and fall (STF) workers' compen-sation claims by body part injured, 1996-2005. Body part n % of total STF claims Lower extremities 185 44.9 Upper extremities 69 16.7 Multiple body parts 67 16.7 Back/trunk 73 16.2 Head/neck 18 4.3 Unknown 60 12.7 Total 472 100.0 Source: Bell et al. 2008 ...

Slips, trips and falls can happen in any workplace. They can occur at the entry of a building, in the kitchen, in cold rooms, on loading docks and even as you walk outside the building. More serious slips or trips together with the resulting falls may result in: • sprains or strains • broken bones when trying to break the fall

Slips, trips, and falls Slips are the result of too little friction or a lack of traction between the footwear and the floor surface. A trip is the result of a foot striking or ... With Best Practices (outlined earlier in this section) implemented first, proper footwear can decrease the likelihood of a slip, trip, or fall. When deciding on ...

SLIPS, TRIPS, AND FALLS (STFs)account for about 20% of lost-time injuries for health care personnel. Although the effect that OR layout and equipment choices have on STF risk has not been specifically addressed in the literature, STFs in the perioperative suite are of particular concern because of their potential to cause adverse patient consequences.

falls. In fact, slips, trips, and falls are the second most common causes of lost-workday injuries in hospitals. Patients and visitors are also at risk of slips, trips, and falls in ... Administration, or OSHA, requirements and best practices. It does not address rules or guidance issued by other agencies or organizations such as the Joint ...

Objective: In an effort to reduce slip, trip and fall injuries, associated workers' compensation costs, and other lost time and production impacts, industry leaders from four shipyards teamed to develop a Best Practices Guide for Slips, Trips and Falls Prevention. This guide provides information on the: Organized by falls from various ...

When it comes to worker safety, fall prevention remains a high priority. Despite our best efforts, slips, trips, and falls continue to be one of the leading causes of occupational injuries and deaths. The Song of the Week keeps that in mind with a new wave gem from the early '80s, "Stand or Fall" by the Fixx.

Liberty Mutual reported that injuries on slippery or uneven walkways cost employers $1.98 billion a year. First, some definitions: Slips are a loss of balance directly caused by too little friction between workers' feet and walking surfaces. Wet surfaces, spills, and weather hazards like ice and snow can lead to a lack of friction.