The Best 3D Printing Speed Settings For Every Filament

Written by: Tom Bardwell

October 26, 2023

Key Takeaways

- Print speed basics : Print speed affects print time and quality, and depends on filament, printer, and model.

- Slicer settings : Adjust print speed and other settings like outer wall speed, infill speed, and retraction speed for optimal results.

- Filament-specific speeds : PLA, ABS, PETG, TPU, and Nylon have different recommended print speeds based on their properties.

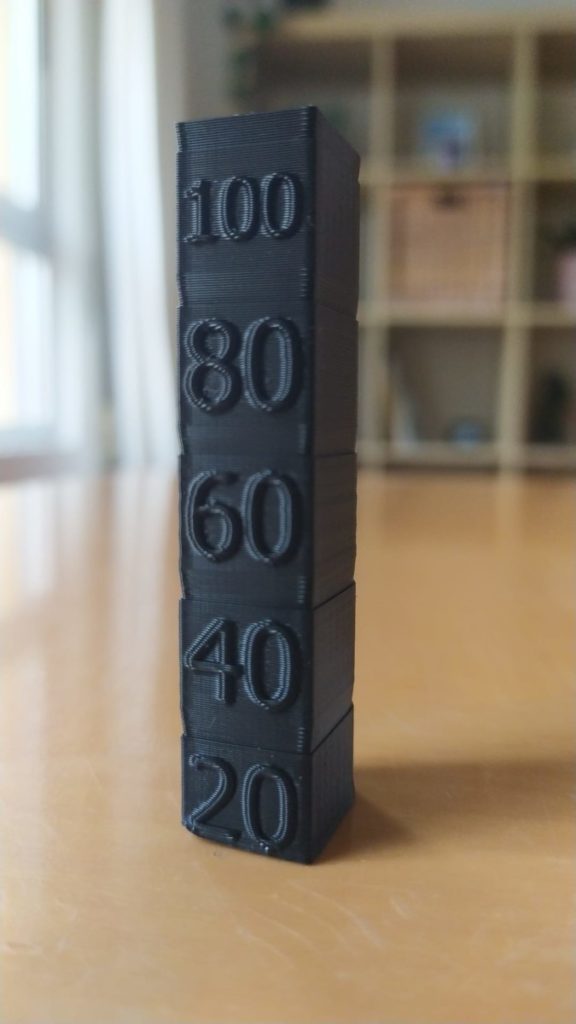

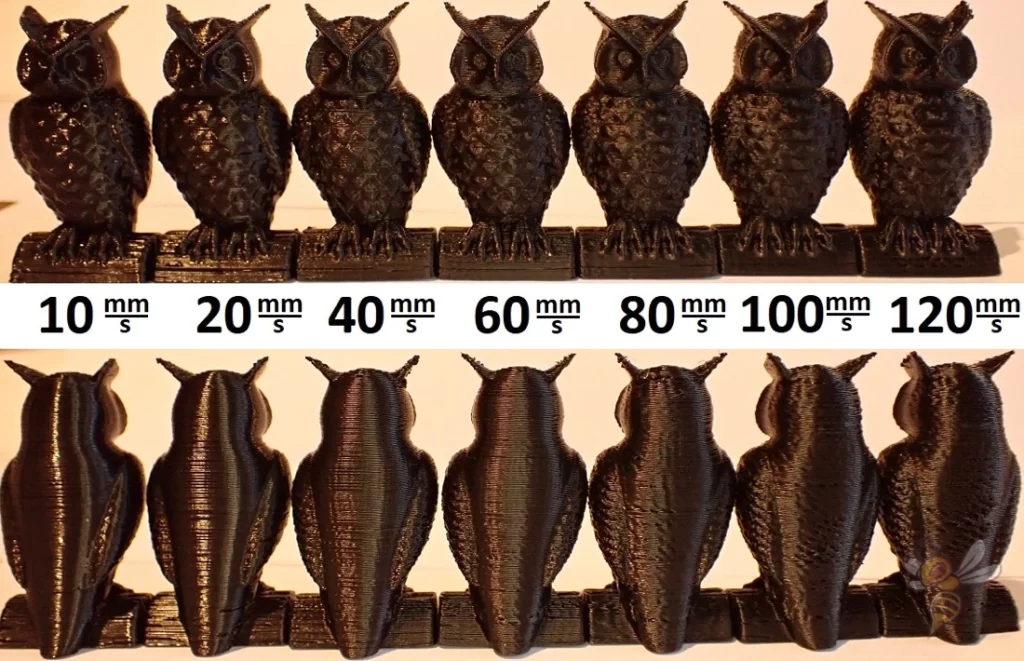

- Test prints : Use test prints to find the best balance between speed and quality for your printer and filament.

Print speed is one of the most important settings when 3D printing. It affects both print speeds and the quality of printed parts, and therefore the likelihood of errors and failures. The best speed settings requires striking a balance between speed and quality.

As with most aspects of 3D printing, print speed differs depending on the material. PLA and, say TPU, require a very different approach, so unfortunately there’s no universal ‘best’ print speed for all filament types.

Here is a table of the optimal print speeds for the most popular FDM filaments:

To further complicate matters, different 3D printers have their own hardware and quirks, and this even extends to different brands of the same type of filament, given that formulations and additives can drastically alter the speed requirements.

The type and size of parts also affect print times and the ideal print speed, as do slicer settings such as:

- Infill density

- Layer height

- Support structures

A lot of factors play into finding the best print speed settings. In this guide, we’ll explain what we consider to be the best settings for the most popular filament types, including PLA, ABS, PETG, TPU, and more.

The idea is to give you a solid starting point, and from there, you can tweak and experiment to zero in on the optimum speed for your printer, filament, and specific project.

What Is Speed in 3D Printing, and Why Is It Important?

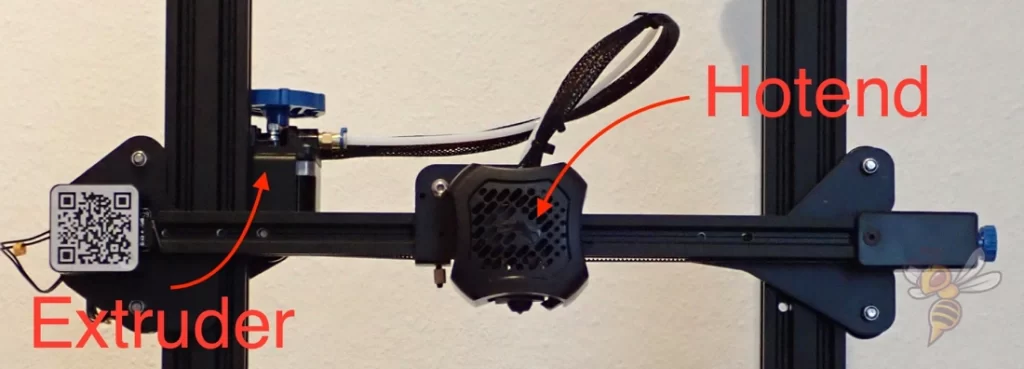

Your 3D print speed determines how fast the printhead assembly motors on a 3D printer move as the extruder deposits material to create a 3D print . This should NOT be confused with travel time, which is the rate at which the printhead moves when it isn’t depositing filament. Print speed is measured in mm/s.

More specifically, the speed affects how fast the printhead travels along the X and Y axes of the print bed, and how fast the extruder motor feeds filament into the printhead.

Print speed is not to be confused with printing time , which is how long the 3D part or model takes overall. The distinction is important because a fast print speed can still lead to a long print time, especially for larger and more complex prints.

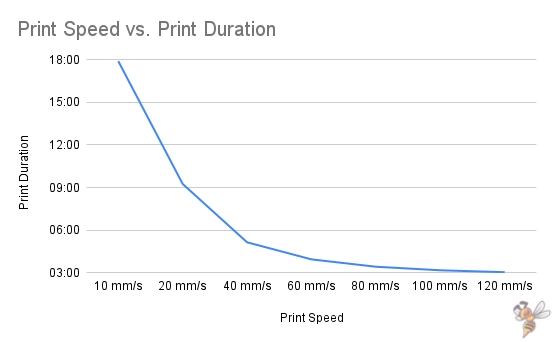

Print speed is important because it not only affects print times – faster speeds can reduce print times by hours in some cases – but also impacts the overall quality of a print (details, features, surface finish) and, therefore, the success of the print. Too fast or too slow, and print errors and failures can arise.

Benefits of Correct 3D Print Speed

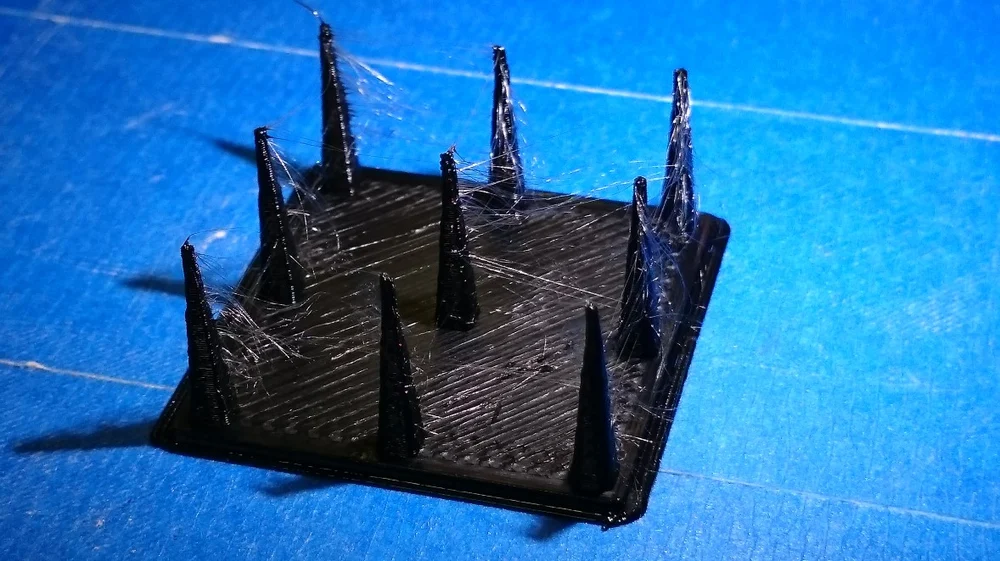

- Reduce instances of ringing, ghosting , and stringing

- Improves first and subsequent layer adhesion

- Reduces under-extrusion and clogging

- Better overall print quality

- Fewer errors and print failures

How Fast Is Too Fast in 3D Printing?

To determine what speed is too fast, you’ll need to identify the speed where issues like under-extrusion, ringing, ghosting, and insufficient inter-layer adhesion start to occur.

Quality is subjective, so what may be acceptable to someone may not be to someone else. So, using test prints is a great way to find your personal balance on quality and print time for your projects and filament.

Best 3D Printing Speed Settings

To hone in on the best print settings, we have to look at individual slicer settings , specifically those that relate to speed.

There’s no universal best print speed, so we recommend taking the following as guidance rather than gospel. Experiment and test print to find settings that work for your printer and filament.

Print Speed Settings

To begin, check your filament spool to see the manufacturer’s recommendations. These offer a solid starting point to work forward from. Otherwise, check out our table above for what is considered the typical best speeds for each filament.

From here, make small adjustments to print speed, either up or down in small increments, until you find a happy medium between print quality and print time that you’re satisfied with.

As with so many aspects of 3D printing, experimentation and fine-tuning is the key to finding the optimal print speed. Don’t hesitate to dedicate a few hours to print test and calibration models to zero in on the ideal print speed for your filament and project.

You can further fine-tune the overall print speed setting by adjusting the following settings:

- Outer Wall Speed – the speed the printer prints outer walls (sometimes called the outer shell). Ideally, you’ll want a slower speed for these as they form the finish of a model, and therefore benefit from extra print times to improve the print’s surface finish.

- Inner Wall Speed – sets how fast the inner walls of the model are deposited (sometimes called inner shell). These are not usually visible, so there’s no need to worry too much about the quality of the finish for inner walls.

- Infill Speed – determines how fast infills are printed. Infills are the inner parts of a model, between the inner and outer walls. Here, it’s all about balance, aesthetics aren’t important, but print too fast and you’ll reduce the print’s structural integrity.

- Top and Bottom Layer Speed – sets out how fast the top and bottom layers of the model are printed, which can help with first-layer adhesion and the overall surface quality of the final layer. Here, slower speeds are recommended to ensure that first layer adheres properly, setting you up for the rest of the print, and you always want the top layer to have a good surface finish.

- Skirt, Support, Brim, Raft speed – determines how fast supports and adhesion aids like skirts and rafts print. These tie into first-layer adhesion, so taking a bit more time to deposit a solid initial set of layers helps with the rest of the print.

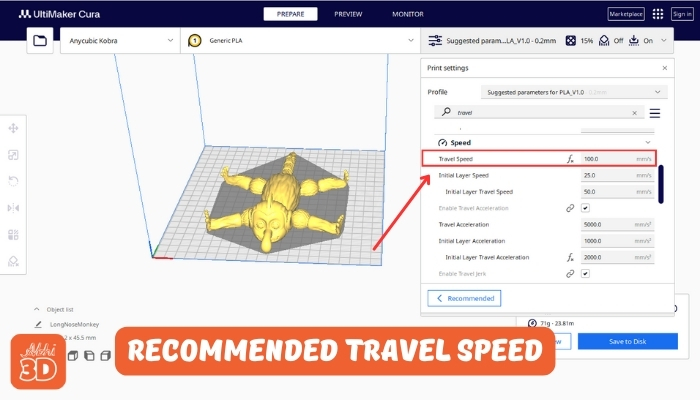

Travel Speed Settings

Travel speed determines how fast the printhead moves across the build surface when it isn’t depositing filament.

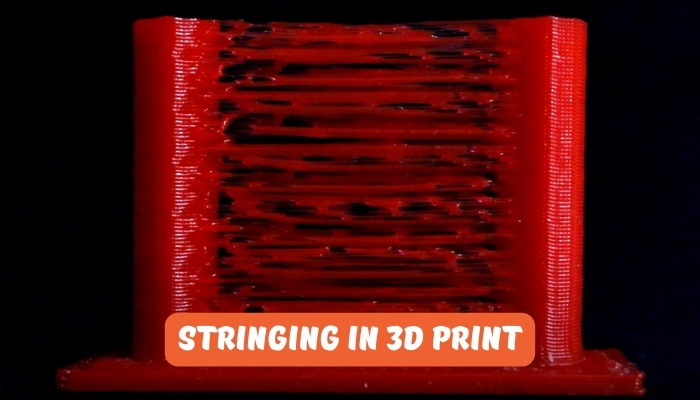

A faster travel speed tends to shorten print time, but runs the risk of introducing print errors such as ringing, layer shifting (where layers don’t line up properly, creating a stair-like effect), and ghosting that can affect the overall quality of a print.

Use test prints and make small adjustments until you find the sweet spot between print time and quality. Start somewhere between 80 and 100 mm/s and work your way up/down progressively.

Retraction Speed Settings

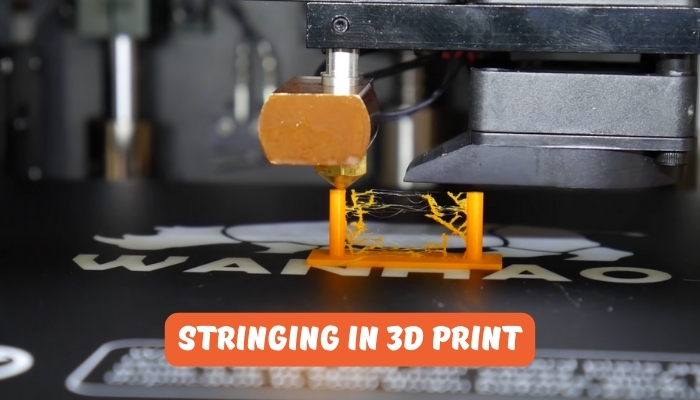

Retraction speed sets how fast the printer retracts filament back into the hot end as it moves or travels across the build surface. The aim is to avoid stray filament landing on the print when it isn’t required, causing stringing and reducing finish quality.

Again, balance is key. If retraction is too slow or two shallow, unsightly blobs and wisps of filament can appear, while upping speeds too far can cause similar effects.

Turn to a test print , and make small adjustments as you go until you eliminate all instances of stringing and blobbing. The perfect starting point really depends on the characteristics of your printer and the filament, but starting around 30 mm/s should set you on the right path.

Factors that Affect 3D Printing Speed

- First-layer adhesion – Printing too fast can cause issues for the printer when laying down the first layer. It can also affect bonds between layers, leading to issues like ghosting, shifting, and ringing. This is often caused by insufficient cooling – the material doesn’t have time to cool properly before the next layer is deposited.

- Nozzle size – Larger nozzle sizes can deposit more material faster. We explain more in our nozzle size 3D printing guide .

- Hot End Temperature – Faster printing requires the hot end to work harder to keep up with the temperature requirements of melting more filament faster. High temperatures can, however, lead to blockages and clogging if too much melted filament is fed through the nozzle at once, forcing it back up into the print head mechanism. It then solidifies, blocking the filament pathway.

- Your printer’s hardware – if your printer is not designed to work at high speeds, it will struggle to keep up, whether that’s the motors, the belt, or the frame simply not being designed to handle the vibrations caused by such rapid movement.

- Type of model – The more detail, the more a model or part benefits from slower speeds, and more pronounced retraction settings. Essentially, your expectations for the overall quality of the print have a big say in the right print speed.

- Material types – less demanding filaments like PLA can handle higher speeds with a small impact on overall quality, while more challenging materials like TPU and PETG only thrive at slower speeds.

Best 3D Printing Speeds For Every Filament

- Best PLA Print Speed : 50 – 80 mm/s

- Retraction Speed – 6 mm at 25 mm/s. Watch out for stringing and adjust downward to avoid it.

For a good balance between speed and print quality, we recommend 50-80 mm/s for most printers for PLA.

For parts where finish and detail aren’t all that important, feel free to crank up the speed to reduce print times. Or, if your printer handles high print speeds, adjust it accordingly.

For detailed prints, stick to the lower end of the recommended print speeds.

For larger prints where aesthetics aren’t all that important, don’t hesitate to push speeds at around 80 mm/s. A good quality FDM printer should be able to handle these speeds and produce a decent-quality model without too many blemishes and errors.

- Best ABS Print Speed: 40 – 60 mm/s

- Retraction Speed – 6 mm at 40 mm/s. Adjust lower to reduce stringing if needed.

Typically, a good print speed for ABS is around 40-60 mm/s, though you can reduce the speed if the print quality isn’t good enough.

For the best results, print ABS inside an enclosure. Without one, ABS is extremely susceptible to warping – the filament needs a controlled thermal environment to truly thrive.

- Best PETG Print Speed : 20 – 40 mm/s

- Retraction Speed – We recommend 4 mm at 25 mm/s. Stringing is generally an issue with PETG, so adjust as needed – shorter retraction distance and higher retraction speed tends to work well for most printers.

We recommend starting at around 40 mm/s, then reducing print speed in small increments until you find a balance between quality and print times.

Note that overall, PETG tends to shine at slower print speeds, so dropping as low as 20 mm/s is recommended for the best results.

- Best Nylon Print Speed : 25-50 mm/s

- Bed Temperature : 55-65°C

For printing Nylon on an FDM printer, aim for somewhere between 25 and 50 mm/s. Any faster and it’s likely the print will struggle to keep up with the high extrusion temperatures required to print Nylon.

As with ABS, Nylon is highly prone to warping, so ensure you are printing in an enclosed chamber and using a heated bed for the best results.

- Best TPU Print Speed : 25-30 mm/s

- Retraction Speed – 3 mm at 20 mm/s. TPU fares best with a shorter retraction distance to avoid introducing too much movement into the filament path potentially causing bending and clogging.

TPU is a fairly tricky filament to print, especially compared to PLA.

It much slower print settings, around 25 to 30 mm/s, though dropping down as low as 10 mm/s for the first layer to promote solid first-layer adhesion is a common step to ensure TPU prints don’t fail.

What Is a Good 3D Printing Speed?

There is no universal good 3D printing speed as it depends on the model, filament, and the printer itself. The key is finding the right speed for all these factors. As a general rule though, most standard FDM filaments (PLA, ABS, PETG, etc) tend to perform well at speeds between 20 mm/s and 60 mm/s, though this is a generalization.

For this reason, we recommend tests to figure out the best print speed for your combo of printer and filament, especially those geared towards calibrating print speeds. They include multiple instances of the same model printed at progressively faster speeds, allowing you to visually inspect the results and select the optimal speed based on the quality produced.

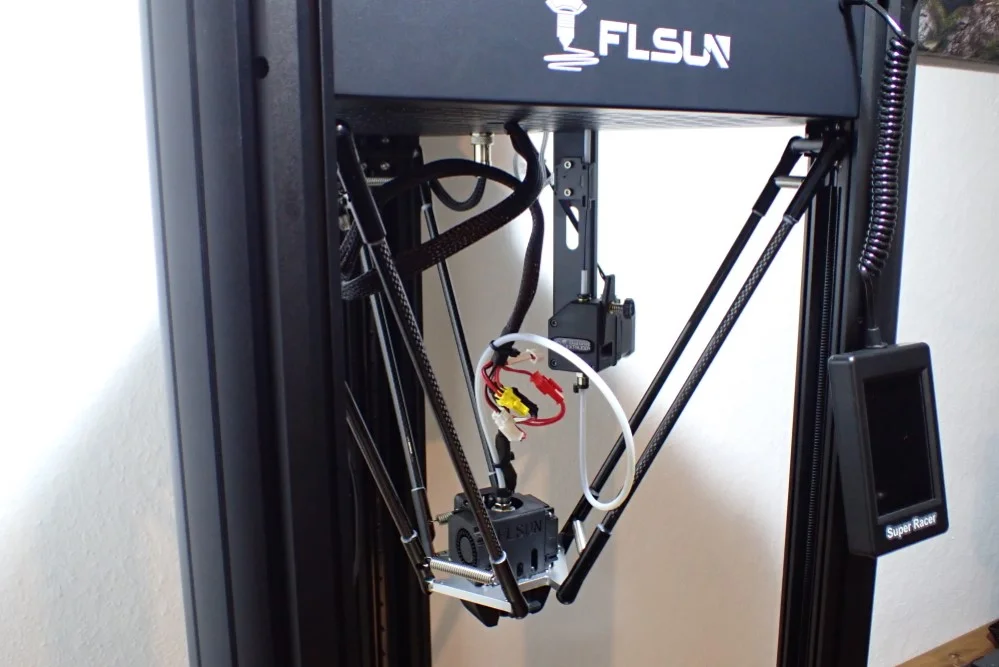

However, if you want a 3D printer capable of printing at higher speeds without losing quality, then some printers are better suited for this than others. The best delta 3D printers print faster than standard Cartesian printers due to their build and bowden extruders – they can often print more than twice as fast. For more information, we have also written an article on the fastest 3D printers .

If you’re one of the 1000s worldwide with an Ender 3, you can read out guide to the best speed settings for Ender 3 here.

Was this content helpful? Give us your feedback here.

Tom Bardwell

Learn More About 3D Sourced

6 Best Large 3D Printers in 2024 (All Budgets)

5 Best 3D Printers for Miniatures & Terrain in 2024

4 Fastest 3D Printers in 2024 (All Budgets)

The 56+ Coolest Things To 3D Print in 2023

44 Common 3D Print Problems – Troubleshooting Issues 2023

13 Best Free 3D Modeling Software (For Beginners) 2024

11 Best 3D Printers in 2024 (All Budgets)

5 Best 3D Printers For Beginners in 2024

Exceptional value with anycubic’s latest 3d printer deals.

40+ 3D Printing Industry Statistics (2024 Update)

22+ Coolest 3D Printed Robotics Projects (2024 Update)

8 Best DIY 3D Printer Kits in 2024 (From $150!)

3D Printing In Space – Top Projects in 2023

Best 3D Printed Shoes in 2023 (Sneakers, Heels & More)

The Best 3D Printer Buyer's Guide Resource & 3D Printer Reviews

[email protected]

3D Printers 3D Scanners 3D Software Guides Rankings Interviews News

Most Popular

Best 3D Printers Best 3D Scanners Best 3D Modeling Software Best 3D Slicers Best Resin 3D Printers Fastest 3D Printers Best Large 3D Printers

Useful Links

About us About the team How we do our reviews Careers Contact Us

Sign up to our newsletter

Privacy policy

Affiliate disclaimer

Editorial policy

- Best 3D Pens

- Top 5 Large 3D Printer – Best Machines To Build Large-Scale Objects

- Top 10 Cheap 3D Printers for Budget Under $500/$1000

- Best 5 Cheap Small 3D Printers – Price Comparison 2017

- 15 Best 3D Printer Reviews – Beginners, Hobbyist, Professionals | Buyers Guide

- PETG Filament Complete Guide | Durability, Flexibility and Reliability

- Wood Filament Review – Easy 3D Printing with Wood Filament

- ABS Filament – 1.75, 3mm Transparent Fiber For Your 3D Printer

- HIPS Filament – An Excellent Support Plastic Material for 3D Printing

- PETT Filament – Strength, Properties, and Tips for Better 3D Printing

- Glow in the Dark Filaments – Producing Perfect 3D Prints with GITD Materials

- TPU Filament 3D Printing Material – The Complete Guide

- Nylon Filament – Features, Properties, and Techniques on Printing Nylon

- TPE Filament – Durable, Elastic, and Versatile 3D Printing Filament

- PVA Filament Review – Best Soluble, Dissolvable Strand For 3D Printing

- 10 Insane Benefits of 3D Printing

- 10 Weird 3D Printed Objects You Do Not Know About

- 13 Mind-Blowing 3D Printed Things You Will Find At The Rio Olympics 2016

- 55 Useful, Cool Things To 3D Print: Best 3D Printing Ideas & Projects

- How to 3D Print with 3D Printing Pen?

- 3D Print – How To Price Your 3D Printing Project

- The History of 3D Printing

- What are 3D Pens or 3D Printing Pens?

- 10 Best 3D Printing Services Online – Cheap and Fast 3D Printing Services US

Creality Ender 3 Pro Review

3D Printing In Constructions: How It Works

3d printing for car parts: a complete guide.

3D Printed Gun: Legality, Models, & STL File Kits

3D Printing Food: 7 Best Food 3D Printers For Customization &…

3D Printing Speeds: 10 Speed Settings Tips To Print Faster

Beginners usually find themselves experimenting with printing speed because they aren’t sure how to choose the correct setting for their project.

However, aside from delaying production, poor printing speeds could also lead to imperfections and flawed outputs.

Thus, it’s something you should be sure of whenever you do your 3D object, especially if it’s for rapid prototyping .

If you need to learn more about setting your printing speeds, you are just on the right page. By the end of this article, you will know how to determine the perfect speed to produce a quality 3D printed object. Also, I will give you several tips if you want to print faster.

So, let’s get started!

What Is 3D Printing Speed?

3D printing speed is the main speed setting when you are 3D printing.

It refers to how fast your 3D printer’s motor moves, including the X- and Y-axis control and the extruder motor. It is usually measured in seconds (unit of time) and kg, mm or cm3 (unit of manufactured material).

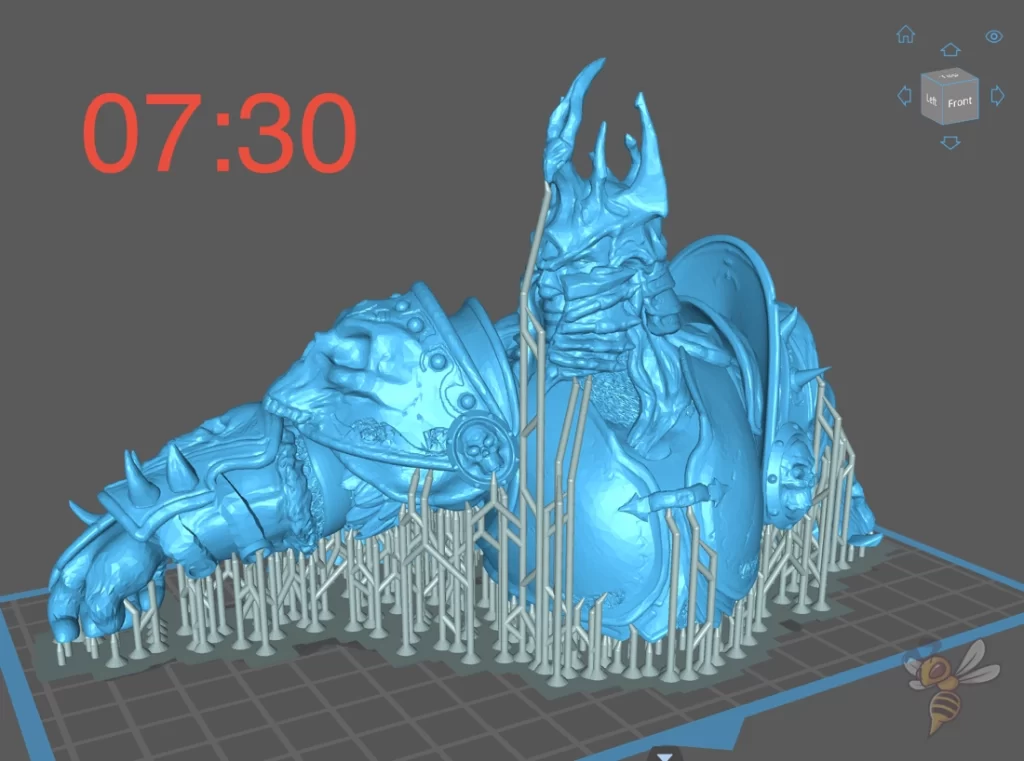

You can download a print speed test model to test your printer’s speed. The test model comes with instructions on adjusting the correct settings because the model linked will essentially print the same shape at gradually increasing speeds, allowing you to see for yourself the optimal setting to achieve a flawless output.

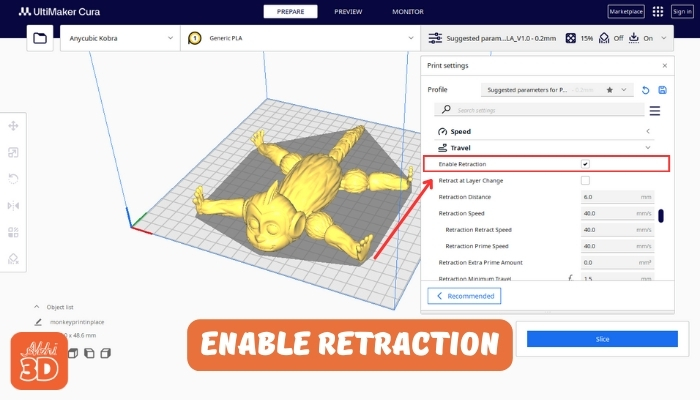

There are many factors when we talk about printing speeds like retraction speed, travel speed and more.

Retraction speed is the speed at which the extruder motor drives back the filament. A good retraction speed is between 1200-6000 mm/min (20-100 mm/s) where retraction performs best. When the retraction speed is too fast, the drive gear may grind away pieces of the filament.

Travel speed is the moving speed of the print head during non-printing status. It refers to the movement of the print head without squeezing the printing material out from the nozzle.

When travel speed is too slow, it could lead to stringing issues on the 3D printed object. A good travel speed for a 3D printer is 100 millimeters per second. But the optimum travel speed might differ for each 3D printer.

Here’s why you should aim for the accurate speed:

When the print speed is too slow, it could cause deformation due to the nozzle sitting on the plastic for too long. And when the speed is too fast, it results in ringing, which is caused by overly excessive vibrations.

Also, when you go too fast, the extruder might not be able to keep up and end extruding less filament than it should.

Hitting the sweet spot will enable the 3D printer to work fast, accurately, and flawlessly without sacrificing the quality of the output.

Print speeds and quality go hand-in-hand; that’s why it’s very important to use the right speed to achieve the desired results.

Overall, you will get a better quality output if you use a lower speed than a higher speed. However, that is only true when your 3D printer is not operating at its optimal conditions.

Also, some would argue that printing speed doesn’t impact print quality. That’s because other factors directly impact the print quality, which is as follows:

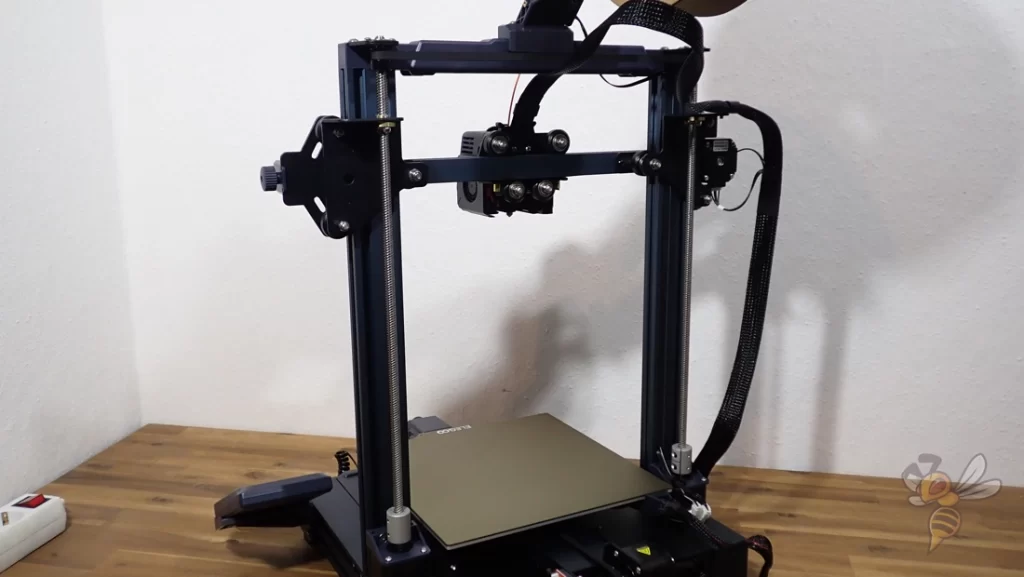

Type of 3D printer

The type of 3D printer will also affect the quality of the 3D prints without being influenced by the print speed.

A high-quality 3D printer can be set in a high-speed setting and achieve first-class quality 3D prints.

However, if you use a 3D printer of lower quality with the same speed, you won’t get the same high-quality results.

Type Of 3D Printing Material

The speed will be faster when using a high-quality support material because you do not need to keep unclogging the nozzle.

Also, you do not need to deal with support material getting stuck.

When you are done printing, you will remove the material without reducing the print quality.

How Fast Is A 3D Printer?

Regardless of whether you are using a slow 3D printer or the fastest 3D printers , several factors directly affect how fast your printer could finish a certain project.

Let’s get into more details below.

Resolution of the 3D printed part

Part of the process before 3D printing is slicing the model into layers on a 3D slicer such as Cura or Repetier-Host.

The more layers, the thinner each layer and the longer it will take to print. For instance, a part printed with 50-micron layers will have twice as many layers as the same part printed with 100-micron layers and take twice as long at the same speed.

Quality of print

Theoretically, you could run a budget 3D printer at its maximum speed — make it work at extremely high speed.

However, do not expect it to yield a result the same as on your slicer. Instead, it will probably result in a mess because the speed was too fast.

Some 3D printers, especially fast 3D printers, can handle high-speed 3D printing, but others don’t, especially budget 3D printers with limited capacity.

3D printing technology

The technology used is another factor that affects the speed. Resin 3D printers are faster than FDM 3D printers.

Yes, that’s true; even expensive FDM printers are slower than low-cost LCD 3D printers.

Aside from resin technologies used in SLA, DLP and LCD 3D printers, the fastest 3D printing technologies include Multi Jet Fusion.

Here’s an overview of the different printing speeds of the different 3D printing technology.

Materials or type of filaments use

However, the filaments mentioned above have different complexity.

Some are easier to print than others because they put less demand on the printer and make it print faster.

Model’s complexity

The 3D object you are about to print could also affect the speed of your machine. Printing a simple box will be easier for a 3D printer to finish than an intricate 3D printed jewelry piece.

Printing a larger object that’s not complex could make the printer work at a faster print speed without significant loss of quality because there are no intricate details needed.

However, the more complex or intricate the model, the more slow the speed is to ensure that it could follow the design as it is.

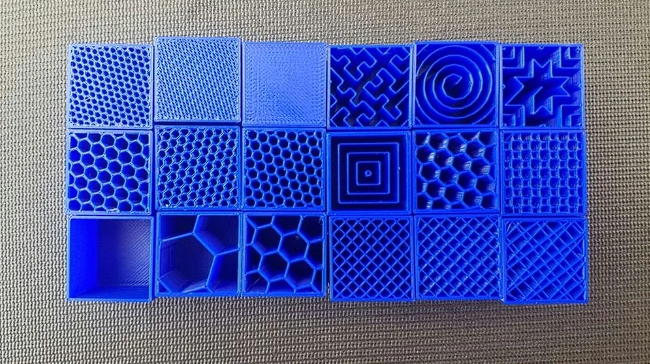

Infill settings

This factor affects the amount of materials extruded — depending on the level of the infill percentage; it could be between 10% to 100%. Infill settings affect the 3D printing space depending on the complexity.

The more complex the pattern, the longer it will take to finish printing. The effect of infills on printing speeds is through density.

A heavy density infill could promote the strength of the model. However, it also means that 3D printing will take more time or the printing speed is slower.

Size of print

Obviously, the larger the object to 3D print, the longer it will take for the 3D printer to finish. A full-size vase printed using an FDM printer could take 12 hours or more. But a small statue could only take under an hour.

It is true, provided that the two models are not very complex and have a significant difference in their sizes.

Nozzle size

For FDM 3D printers, the nozzle size matters in speed and performance. Smaller nozzles are great for working on models with intricate details.

Larger nozzles are not the best when printing objects with intricate details, but they can print faster.

How Fast Can The Fastest 3D Printer Print

There are a lot of fast 3D printers on the market today and the fastest FDM 3D printer — WASP 2040 PRO Turbo — could work as fast as 500mm/s.

Some said it could even print faster than that. Another great thing about it is that it is extremely accurate. However, DLP/SLA printers will always work faster than the fastest FDM 3D printer.

What Is A Good 3D Printing Speed

Here’s the recommended setting:

For slow 3D printers, it’s best to use 40 mm per second to 80mm per second. Mid-speed printers work best with 100mm per second. If you want to print faster, you can go 150mm per second. Fast-speed 3D printers can work beyond 150mm per second.

But you should note that there is no general print speed that works for all. There are many things that you need to consider to get the best print speed for your 3D desktop printer.

Here are some factors to consider:

Model’s outer wall. You should ask yourself, “how fast do you want the exterior of your model to be printed?” If your priority is surface quality, you better reduce the speed or opt for lower print speed settings.

Interior walls. For the interior, it is recommended that you use the same print speed in printing the overall model. The 3D printer speed needs to reduce the print time without lowering the 3D print strength.

Infill printing speed. For this, you also need to reduce printing time without compromising stability.

Bottom and top layers. For the last speed setting, you have to consider the top and bottom layers, and the best option is to go for a slightly lower print speed for better surface quality.

Print Speed Settings for PLA, ABS & More

But after a bit of trial and error, you will surely be able to find what works best for your 3D printer’s software and hardware.

The different 3D printing materials have different recommended print settings.

Here’s the good print speed for PLA, ABS, and more, so you will know how to get started when using them. You can refer to the following section for that.

What is a good 3D printing speed for PLA? When using PLA, you can start in the 40-60 mm/s range. It will give a good balance of print quality and speed.

However, depending on your 3D printer type, stability and set-up, you can increase the speed up to 100 mm/s. Some achieved great results at a higher speed, but the quality of your printer matters too.

A good print speed for ABS is typically similar to PLA between 40-60 mm/s. However, you can increase if you have an enclosure around your printer.

You can print ABS filament at a speed of 60 mm/s and keep the first layer speed to 70% of that and see if it will work for you. It works well for adhesion in some cases, ensuring that enough plastic is extruded out of the nozzle for proper and safe adhesion.

For PETG filament , a good print speed starts in the range of 50-6- mm/s. The filament could rise to string issues, so some will usually opt for 40 mm/s, and according to them, they find good results. PETG is a blend of ABS and PLA; that’s why the recommended print speed is not too far from the two’s recommended settings.

If you are using TPU, you can start with a speed between 15 mm/s to 30 mm/s. The filament is soft and should be printed much slower than the average filament. But if you are using a Direct Drive extrusion system, you can increase the speed to about 40 mm/s.

You can go a bit higher from the recommended speed of 15 – 30 mm/s and experiment. But then again, always remember that this is best printed at a low speed.

A good 3D print speed for nylon is between 30 mm/s to 60 mm/s, but most print with 40 mm/s for great quality and great details. You can also go higher, like 70 mm/s, because it is still sustainable if you increase the nozzle temperature side by side.

10 Tips to Get the Best Print Speed Calculation

In addition, it reduces problems such as warping or curling.

Yes, speed is very important because it has to do with your 3D printed model’s quality, accuracy and strength. With the right print setting, you can strike a perfect balance to achieve the three.

Here are some tips to increase print speed from 3D printerly. However, you should note that some of them might affect the quality of your print.

1. Increase print speed in slicer settings

Find the balance of your print speed in the slicer settings. It will be very helpful, especially if you depend on how big the print is because the size of the object is relatively related to printing time. Again, experiment to find the perfect balance of speed and quality, and in time, you will find it.

2. Adjust acceleration and jerk settings

Jerk settings refer to how fast the print head moves from a still position. When setting this, you want its movement to be smooth and fast at the same time.

You can test jerk settings by printing the vibration test cube and seeing whether the vibrations are visible on each axis by inspecting the corners, edges and letters on the cube.

Acceleration settings are how the print head gets to its top speed. A low acceleration means that the printer won’t get its top speed with smaller prints. Acceleration depends on several factors and is not the same in all of your 3D printing projects.

According to AK Eric, who did the test, comparing low jerk values (10) to high ones (40) on a 60 mm/sec speed made no difference in print speed. However, the lower value had better quality.

Increasing the speed at 120 mm/sec decreased printing time by 25% but at the expense of the quality. So, you can use the print speed settings to get what you want, but you might have to choose between speed and quality.

3. Infill pattern

For this, you can choose an infill pattern that prints faster than the others to save much time on increasing the print speed. The best has to be the “lines” pattern due to its simplicity and lower number of movements compared to other patterns. Depending on your model, the infill pattern can save you up to 25% of printing time.

The infill pattern is the strength of your model. It’s the honeycomb pattern. The more detailed it is, the more time it will take, because it will include more turns and movements to follow the pattern. If you want to print fast, you can adjust the infill pattern not to be that high.

4. Infill density

Density is what’s inside your print. An infill density of 0% means that the inside of the model is hallow. On the other hand, a 100% density infill means the inside will be solid. The density could depend on the purpose of the model.

For example, if you want a functional print, you should not sacrifice infill density to achieve the strength of the model. However, if it’s for aesthetics, it’s up to you to go all out for the density or skip it and focus on speed to reduce the print time.

5. Wall Thickness/shells

There is a relationship between the wall thickness or shells and density, so you should consider the other when adjusting either one. The good thing is getting a good ratio will help you achieve a great structure.

The thicker the wall, the longer the print till will be. To speed up the printing time, you can decrease the number of shells or perimeters of your prints in the settings.

You can play around with the print speed settings to find the perfect number, so you can maintain the strength while keeping it low to speed up the printing time.

6. Dynamic layer height/adaptive layer settings

It can improve the print speed and save you a decent amount of time compared to using the traditional layer method.

For example, 3D printing a chess piece without the adaptive layers setting takes 2 hours and 13 minutes.

However, using this featured in the speed settings could reduce the printing time by up to 30% down to 1 hour and 33 minutes.

7. Print multiple objects

To speed up the process, you can utilize all the space in the printer bed rather than doing one print at a time. To make it possible, use the center and arrange function in the slicer.

It will make a significant difference in the printing speed. However, this method might not apply to big prints.

Printing small objects will allow you to copy and paste the design multiple times on the print bed and print them all together simultaneously to speed up the entire process. Those who have tried this approach agreed that printing multiple objects could increase the speed.

8. Remove support

If your 3D object doesn’t need support, the printing time will be shorter. You can eliminate the need for support in many cases when you split the model in the right place and orient them properly.

So use the best orientation for your model, and you’ll definitely reduce the printing time. It is perfect if you want to increase printing speed.

9. Use a large nozzle when practical

Another great way to speed up the printing time is to use a large nozzle. However, doing so might not apply to all models and could reduce your print quality.

Using a large nozzle might not work when you are printing intricate models. But if your 3D objects are not as complex or intricate, go for a large nozzle to increase the printing speed.

There are many sizes of nozzles to choose from. Choose one that is most appropriate for your model.

• 4x 0.2mm nozzles • 4x 0.3mm nozzles • 36x 0.4mm nozzles • 4x 0.5mm nozzles • 4x 0.6mm nozzles • 4x 0.8mm nozzles • 4x 1mm nozzles • 10 cleaning needles

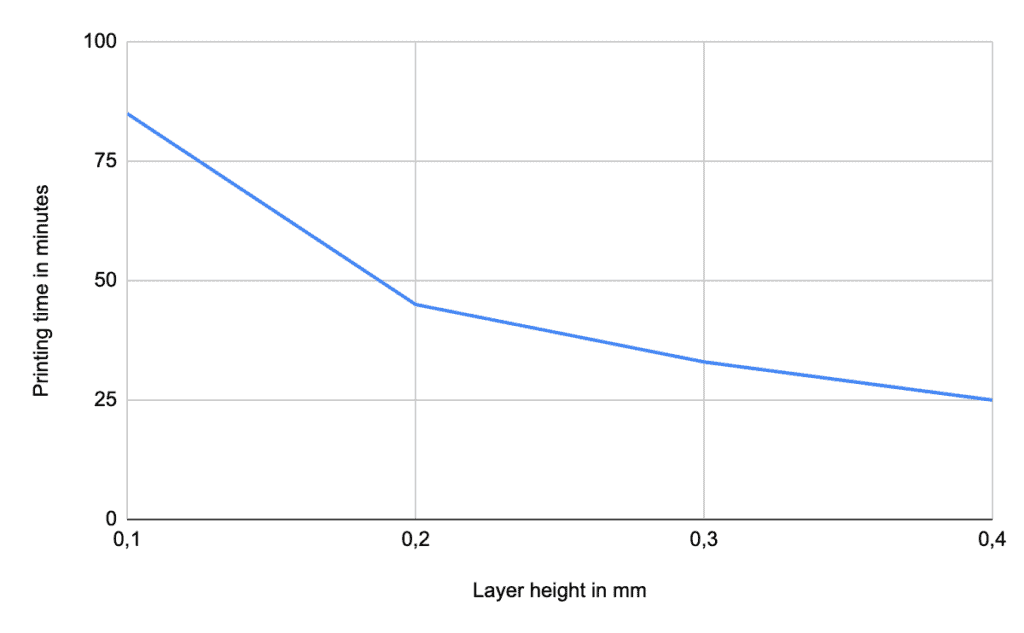

10. Increase layer height

The lower the layer height, the better the quality of your prints, but the longer the 3D printing time takes. If quality is not the top priority, you can increase the layer height and improve the printing speed.

You have to familiarize your printer and explore its print speed settings to get the optimal speed and enjoy quality outputs without the unnecessary long wait.

There are many ways to increase print speeds like using a large nozzle and reducing layer thickness, but always consider the results because when the printer works too fast, it might not achieve the quality you desire.

Also, always remember that the different 3D printing technologies offer different 3D printing speeds. SLA printers will always work faster, even when compared to the fastest FDM 3D printer.

The printing speed will affect the quality of your 3D printed object, so always make sure to strike the right balance, so you will achieve the strength, quality, and look you desire for your 3D project.

If you wish to learn more about 3D printing, better check our 3d printing home page .

- 3dprinterly.com/best-print-speed-settings-for-3d-printing/

- 3dprinterly.com/8-ways-how-to-speed-up-your-3d-printer-without-losing-quality/

- 3dsourced.com/3d-printers/fastest-3d-printer/

- rigid.ink/blogs/news/3d-printing-basics-how-to-get-the-best-results-with-pla-filament

- the3dprinterbee.com/3d-printer-speed/

- 3dsolved.com/3d-printing-speed-vs-quality/

- m3dzone.com/3d-printing-speed/

- all3dp.com/2/3d-printing-speed-optimal-settings/

- all3dp.com/3d-printing-speed/

- dyzedesign.com/2018/07/3d-print-speed-calculation-find-optimal-speed/

- thingiverse.com/thing:277394

RELATED ARTICLES MORE FROM AUTHOR

A Complete Selective Laser Sintering 3D Printing Guide

Advantages & Disadvantages Of 3D Printing Technology

10 Best Site To Find Anime 3D Print STL Files

How to Use a 3D Printer Step by Step (10 Tips...

7 Best Dual Extruder 3D Printers in 2024

Popular category.

- 3D Printing 56

- 3D Print 36

- 3D Printer 24

- 3D Printing Filaments 15

- 3D Printer Kit 9

- 3D Printing Service 8

- 3D Scanner 2

- Amazon Affiliate Disclosure

Best 3D Printing Speed Settings for PLA, PETG, ABS & More: What Is The Fastest Print Speed?

If you’ve ever opened a 3D slicer before, then you’ve probably realized there are tons of different settings you can change. And while they all matter, few settings are as important as those related to print speed.

Settings in this category, including the main “Print Speed” setting, control how fast your model is printed, which affects the print time and print quality.

The best 3D printing speed for PLA and ABS is in the 45-70 mm/s range. And, if you’re printing PETG, 40-50 mm/s should work well, yielding high-quality prints with minimal stringing.

But that’s not all! You can also change the other print speed settings, like wall speed and top layer speed, to further control the print time and quality.

Want to learn more about print speed and the best settings? Just keep reading!

Table of Contents

What is Print Speed?

Why is print speed important, what is the fastest print speed, what happens if you print slow, print quality, print speed, infill speed, top/bottom speed, first layer speed, travel speed, retraction speed.

Print speed is a category of settings found in 3D slicers (e.g. Cura) that controls how fast your 3D printer prints your desired model. The higher the 3D printing speed, the faster the printhead moves, the faster filament is pushed out, and the less time prints take.

In most slicers, there is a single setting called “Print Speed” which controls a handful of other types of speed settings, such as infill speed and wall speed. Changing the “Print Speed” value will automatically change the other speed settings accordingly (usually based on a fraction).

So you’re not confused throughout the rest of the article, when we say “Print Speed”, we are referring to the specific “Print Speed” setting and not the other print speed settings.

Print speed is important because it is one of the main groups of settings that contributes to how long a print job takes. Moreover, if you change the print speed, the print time will also change.

But that’s not all. As we’ll go over later, 3D printing speed also has an effect on the quality of prints . That’s because higher print speeds typically lead to a higher chance of printing issues and defects that hurt the quality of the model.

Because print speed has very significant effects on the outcome of your 3D print, it’s vital that you use the right speed settings in your 3D slicer!

What is the Best 3D Printing Speed?

The best 3D printing speed for your printer depends on a handful of different factors, like the type of extruder and nozzle diameter on your printer. But the most important factor for determining the best 3D printing speed is the filament material.

Different filament materials, like PLA and TPU, can’t always be printed at the same speed. This is due to differences in the chemical and physical properties of each material. And, even with filaments of the same material, there’s no one-size-fits-all print speed value.

However, we can estimate the best print speed for a certain filament material within a range. In the sections below, I’ve provided a range of possible print speed values for some of the most popular filament materials. I suggest trying a 3D printing speed in the range of the filament material you’re using and starting the tuning process from there.

PLA is easily the most popular 3D printing filament material, and it’s also the material you can print the fastest. I suggest using a 3D printing speed value between 45-70 mm/s , as many users have found success in this range.

I suggest starting with 60 mm/s and adjusting in increments of 5 mm/s. Doing so will ensure that you never over-adjust the print speed and accidentally cause other printing issues.

While ABS is significantly more difficult to print than PLA because it requires an enclosure, you can actually use pretty much the same 3D printing speed. Moreover, I also recommend using a 3D printing speed in the 45-70 mm/s range and adjusting in 5 mm/s increments.

PETG is another very popular filament material, but if you want to achieve high-quality prints, you’ll need to use a print speed value a bit lower than you would with PLA or ABS. A print speed of about 40-50 mm/s should work pretty well.

But, if you notice stringing on your prints, consider lowering the print speed by 5 mm/s. Or you can try to preserve the 3D printing speed and fix the problem by lowering the nozzle temperature or increasing the retraction distance.

TPU is a flexible filament, and, as such, it requires a very low print speed. 25 mm/s should work fine, and you might be able to increase it to around 35 or 40 mm/s. However, don’t try to go above 40 mm/s, as TPU filament might start to cause problems in your extruder or hot end at this speed.

Nylon isn’t as flexible as TPU, but it’s still more flexible than PLA or ABS. A 3D printing speed between 30 and 55 mm/s should work perfectly for printing this type of filament. However, feel free to change it in increments of 5 mm/s based on your print results.

Lastly, polycarbonate , or PC for short, needs to be printed much slower than some of these other rigid materials due to the material’s inherent properties. A value in the 25-45 mm/s should work just fine, as long as you take some time to properly tune the setting. Furthermore, I suggest trying out 35 mm/s and then adjusting the value in increments of 5 mm/s based on how your prints come out.

The fastest print speed you can use is probably around 100 mm/s if you’re printing PLA and using a very high nozzle temperature.

Of course, not just any stock 3D printer can handle printing PLA (or any other material) at this high of a speed. But, if you fine-tune your slicer profile and are using a hot end and extruder that is capable of high-flow printing, then you might be able to print successfully with 100 mm/s.

But, if you’re just printing normally and are wondering how fast you can go without any significant changes or a lot of tuning, then 70-80 mm/s is your answer. At this speed, your prints might be a little bit lower quality, but your printer probably won’t break or completely fail.

Check out our related article on the fastest 3D printers here .

Printing slowly is one way you can try to achieve higher-quality prints. That’s because when the printhead has more time to lay down each layer, the layers have more time to solidify and cure, leading to prints that look better.

However, printing too slowly can also cause issues . If not enough filament is being pushed through the nozzle, then heat will creep up the hot end assembly and cause a clog. This phenomenon is known as “heat creep” and can be prevented by increasing your 3D printing speed.

Check out our article on how to speed up 3D printing here to avoid this issue.

What Does Print Speed Affect?

Print speed can have a very big effect on your 3D prints. I’ve gone over the two main areas of impact of the print speed setting below:

The first and most obvious effect of changing the print speed setting is the print time. As you probably figured out, the faster the printhead lays down filament, the faster your 3D model is completed.

However, you might be a bit surprised at the small effect changing the print speed has on the estimated print time. Moreover, a more effective way to cut down the print time is by increasing the layer height or shrinking your 3D model.

PRINT QUALITY

Changing the print speed can also affect the quality of prints. Moreover, the correlation between print speed and print quality is direct, so increasing the 3D printing speed is likely to lead to a drop in print quality.

However, you can manage the effect that print speed has on print quality through other slicer settings. For example, increasing the nozzle temperature with an increase in the 3D printing speed will help prevent under-extrusion and other printing issues to help increase the print quality.

The moral of the story: when you change the print speed, try to optimize the other slicer settings to ensure that you don’t experience a big drop in print quality.

Types of Print Speed

In any 3D slicer, there are a handful of different print speed settings. Each covers a different type of print speed based on what section of the print is being printed. I’ve gone over the main types of print speed in the sections below.

First, we have the print speed, which is the main setting for controlling the speed of the printing process. Moreover, the print speed value determines how fast the printhead moves across the X and Y axes of the print area. The higher the speed, the faster the printhead moves and the less time your print job takes to complete.

The print speed acts as the parent setting for most of the other speed settings, like infill speed and wall speed. This means that the values of these other types of print speed are derived from the value of the print speed setting. So change this setting, and all of the other ones will change accordingly.

Because it’s the parent setting, this is the most important speed setting to get right.

Infill speed controls how fast the printhead moves (the print speed) during the infill section of a print. For reference, infill is the internal filling inside a 3D model, so this speed value is referenced (used) by your printer every time it’s printing an infill structure, which is a large portion of a 3D print job.

In most 3D slicers, the infill speed is automatically set equal to the value of the main print speed setting.

Wall speed is the print speed when the printer is making the walls of a 3D printed model. The walls are what contain the infill structures of a print, so it’s very important that the wall speed is set correctly. Otherwise, the outer sides of your model might look bad.

The wall speed is usually split into two settings: inner wall speed and outer wall speed. Splitting the settings this way allows you to use a faster speed on the inner wall because you won’t see it once the print is done and then use a slower speed for the outer wall.

Most slicers automatically set both wall speed settings to one-half of the main print speed setting. However, personally, I like to drop the outer wall speed so that it’s 5 mm/s less than one-half of the main print speed. I also increase the inner wall speed by 5-10 mm/s from one-half of the main print speed setting, as this helps speed up my prints.

Just like walls contain the infill of a model from the sides, the top and bottom layers of a model cover a model’s infill from above and below. And, as you probably guessed, the top/bottom speed is the speed for the top and bottom layers of a 3D print.

I like to keep the top and bottom speed settings at a little over one-half of the main print speed setting. This is a little higher than Cura’s default value of exactly one-half of the main print speed setting. But, adding 5-15 mm/s to this default value isn’t likely to cause any issues with your print and will speed up the printing process.

Next, the first layer speed, sometimes called the initial layer speed, is another speed setting, and it controls how fast the printhead is moving during the first layer of a print. If you’ve ever worked with a 3D printer before, then you probably know how important getting the first layer of a print right is. Because of this, it’s equally as important to use a good first-layer speed setting.

The first layer speed should always be slower than every other speed setting. I like to use the Cura default value of 20 mm/s, no matter what filament material I’m using.

While you might be thinking, “20 mm/s is super slow”, well, you’re right. However, it’s only for one layer, so it won’t significantly increase your print time.

But, if you rush the first layer, your print will likely fail. Because of this, I suggest staying on the slow side of things to be safe and never going above 20 mm/s.

Next, the travel speed dictates how fast the printhead moves during travel or non-extrusion moves. For example, if you were printing two models at once, when the printhead is moving between the two items (and not extruding filament), that is a travel move.

Believe it or not, travel moves make up a lot of the movement of your machine’s printhead. As such, travel speed is very relevant when it comes to print time.

Cura’s default value of 150 mm/s for the travel speed works pretty well, but you can definitely go higher. If your printer is a Bowden extruder printer, then feel free to go as high as 200 or even 220 mm/s. But, if you’ve got a direct drive 3D printer , like the Ender 3 S1 , due to the heavier printhead, you should try to stay closer to 180 mm/s.

Retractions are when your 3D printer pulls back filament from the hot end to relieve the nozzle of built-up pressure from the constant extrusions. Retractions happen basically every time the printhead makes a travel move, and the retraction speed controls how fast they happen.

While retractions don’t make up a significant amount of the print time, increasing the retraction speed can still help reduce the time prints take. Also, a higher retraction speed can help reduce stringing in prints. I recommend going with a retraction speed of around 40-45 mm/s , as this is pretty fast and also helps with stringing.

Overall, print speed is one of the most important and impactful categories of print settings. The main reason you should change the setting is to cut down the print time of a model, but you can also change the print speed to solve issues with print quality.

While there’s no single best print speed because many factors play into what value works best, there are ranges based on the filament material you’re using.

If you’re printing with PLA, then a print speed of 45-70 mm/s should work pretty well. The same goes for ABS, as the material is very similar. But, if you’re printing PETG, 40 to 50 mm/s should work better and reduce stringing in your prints.

You also should consider changing the other print speed settings besides just the main “Print Speed” setting. Furthermore, increasing the inner wall speed by 5-10 mm/s and the top/bottom speed by 5-15 mm/s from their default values will help speed up prints a bit. And lowering the outer wall speed by 5 mm/s from the default value will make your prints look a bit better.

About The Author

Jackson O'Connell

FacFox Docs

Knowledgebase of manufacturing

- The Best 3D Print Speed Settings for PLA & More

Tuning 3D print speed can be tricky. Learn how to find the perfect print speed settings for PLA and more materials!

One of the ways that 3D printing is often used is for “rapid prototyping”. The slight irony here is that individual prints can take hours or even days to complete! Fortunately, printing speed can be adjusted to reduce production time, but poor adjustment may also lead to print imperfections and failures.

Here, we’ll run you through the common 3D printer speed settings. By the end of this guide, you’ll know how to strike the perfect balance between printing speed and quality. Keep in mind that different printers, slicing software, and filament may behave differently, so repeated testing may be necessary.

Fire up your slicing software and let’s get started!

Print Speed

Print speed is the main speed setting that will influence your 3D prints. As the name suggests, print speed determines how fast the motors of your printer move. This includes the motors controlling the X- and Y-axes, as well as the extruder motor.

To test for print speed, download a print speed test model . These models generally come with instructions on how to set the correct settings. The model linked here will essentially print the same shape at gradually increasing speeds, allowing you to visually identify the optimal setting.

Too slow of a print speed may cause print deformation due to the nozzle sitting on the plastic for too long. Too fast and there may be other overheating artifacts caused by insufficient cooling, as well as ringing , under extrusion , and weak layer adhesion . The sweet spot should be as fast as your printer can get without sacrificing too much print quality (and some use cases might demand a higher level of quality than others).

To better refine print speed, this setting is commonly split into many more secondary settings :

- Outer wall/shell speed: This setting adjusts how fast the outermost perimeter of the model is printed. It’s typically decreased slightly to improve surface quality.

- Inner wall/shell speed: This setting adjusts how fast the inner perimeter(s) of the model is/are printed. It’s typically the same as the overall print speed to decrease print times while maintaining print strength.

- Infill speed: This setting adjusts how fast the infill of the model is printed. It’s typically the same as the overall print speed, to decrease print times while maintaining print strength.

- Top/bottom speed: This setting adjusts how fast the top and bottom surfaces of the model are printed. It’s typically decreased slightly to improve surface quality.

Travel Speed

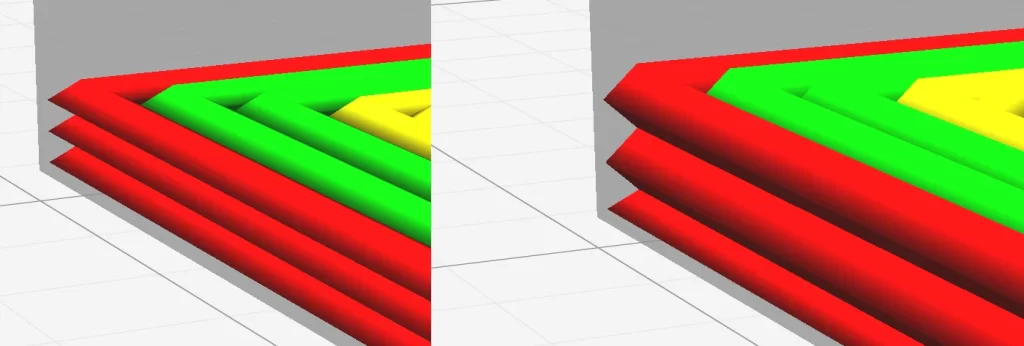

Travel speed adjusts how fast the printer’s printhead moves when it’s not extruding filament. Increasing travel speed can save significant amounts of print time, but increasing it too much may lead to ringing or ghosting artifacts or even layer shifting (and thus print failure).

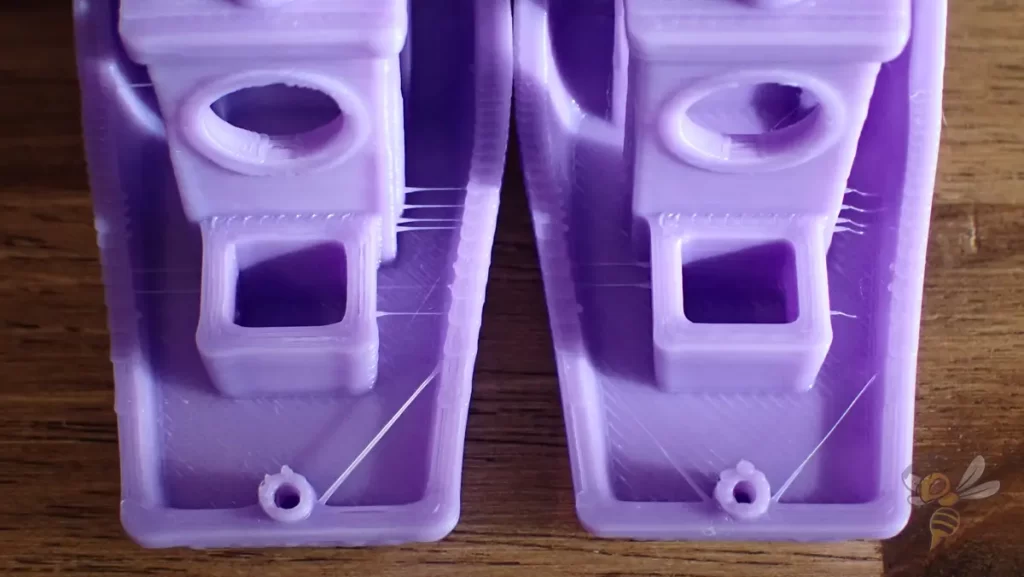

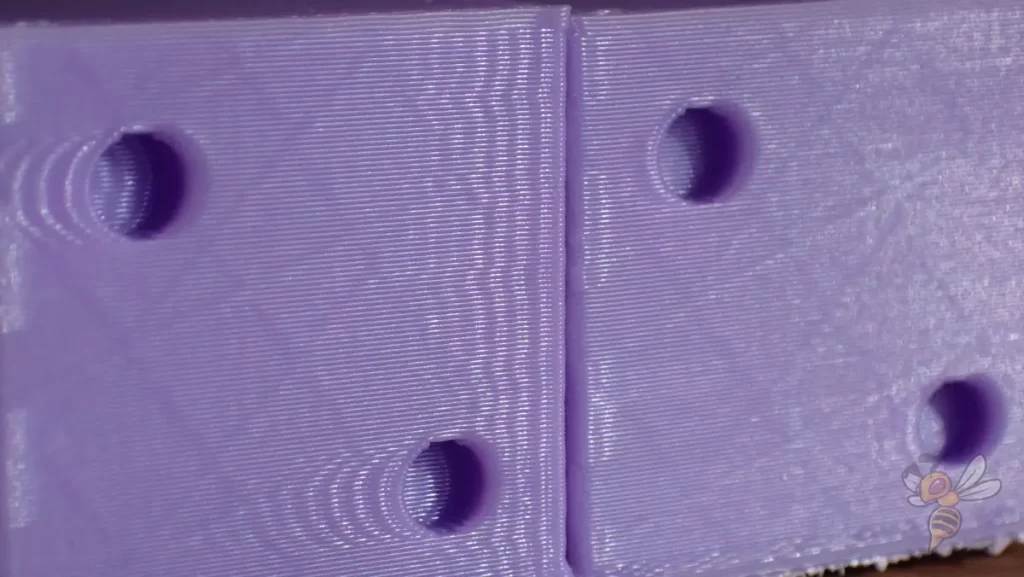

To determine the optimal travel speed for your printer, print out a test print at various travel speeds, starting at 100 mm/s and adjusting by 5-mm/s increments. Keep bumping up the speed if the surface quality is acceptable, and decrease if print quality suffers. Look out for defects like misaligned layers, as pictured above.

Retraction Speed

Retraction speed adjusts how fast the printer pulls filament back before travel moves. This setting is critical for reducing stringing and improving print quality. Too slow, and you may be left with unsightly strings and blobs on your prints. Too fast, and you may experience the symptoms of filament grinding , which also include stringing and blobbing.

To determine the optimal retraction speed for your printer, print out retraction speed test at various retraction speeds, starting at 25 mm/s and adjusting by 5-mm/s increments. Look out for web or tree-like strings stretching between the spikes on the model. The perfect retraction speed should be the highest value that minimizes these artifacts without jeopardizing filament flow.

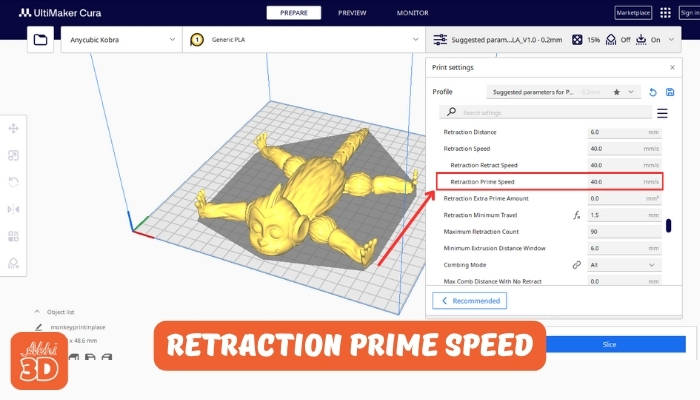

To better refine retraction speed, this setting is commonly split into two more secondary settings :

- Retract speed: This setting adjusts how fast the retract (the actual pulling back of the filament) occurs. This is usually the same as your overall retraction speed, and tuning it follows the same process.

- Prime speed: This setting adjusts how fast the filament is reinserted after the initial retract, in preparation for further printing. Increasing this speed will result in reduced print times and less blobbing due to extended exposure of the plastic to heat. Increasing it too much, however, may also result in insufficient heating of the freshly-reinserted filament before printing resumes. For most users, keeping this the same as the general retraction speed setting should work well.

Shells, Infill, & Layer Height

Your 3D printer’s speed isn’t determined only by “speed” specifically. It’s also significantly affected by how much plastic, and in what thickness, each layer of the 3D print is extruded. These settings are incredibly detailed, so we’ll only go through general information about how each affects print speed. For more, we have specific guides to 3D printing shells , infill , and layer height .

- Shells: The shells setting indicates how many perimeters of plastic are extruded to form the outline of your part. Increasing the shell count increases part strength, but also print times.

- Infill: Infill is the internal structure generated to save material when printing the interior of 3D prints. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. A higher infill density will increase part strength but also print time.

- Layer height : Layer height has a significant impact on how fast your prints come out. The greater your layer height, the thicker each layer of your 3D print is, and thus the quicker your print is completed. Adjust this based on how much fine detail your print requires.

Continue reading

- 3D Designs For 3D Printer

- 3D Printing Design Service

3D Printing Guides

- FDM 3D Printer

- 3D Printing Technology

- PLA Filament

- All Popular Filament Types

- PLA+ Filament

- ABS Filament

- PETG Filament

- ASA Filament

- Nylon Filament

- Carbon Fiber Filament

- Resin 3D Printer

- Resin Liquid

- Infill – Complete Guide

- All Infill Pattern Types

- Strongest Infill Pattern

- Fastest Infill Pattern

- Gyroid Infill

- Rectilinear Infill

- Honeycomb Infill

- 100 Infill In 3d Printing – Solid And Robust 3D Print

- 0 Infill In 3D Printing – Hollow 3D Print | Without Infill

- Bed Leveling

- Auto Bed Leveling

- All Build Plate Adhesion Types

- Brim vs Skirt vs Raft

- G-Code File

- How to Open STL File in Blender – Explained Step by Step

- How To Export STL File From Blender For 3D Printing

- Travel Speed

Travel Speed For Print Head in 3D Printing

In 3D printing technology, managing travel speed for print head is crucial for achieving high-quality prints. When the print head travels, it can sometimes leave behind strings of filament , a phenomenon known as stringing. This can affect the overall quality and look of the 3D-printed object.

So here in this article, we will cover everything about Travel Speed and its recommended settings.

Now, let’s talk about travel speed first.

Table Of Contents

What is Travel Speed in 3D Printing?

What is retraction in 3d printing, travel speed setting in cura 3d slicer:, recommended travel speed in cura:, travel speed faq (frequently asked questions):.

The travel speed in 3D printing is a crucial aspect that often goes unnoticed. It refers to the speed at which the print head moves when not extruding any material. This is a non-print move, meaning the printer is transitioning from one area of the design to another without laying down any filament .

The travel speed can significantly impact the quality of your 3D print. If set too high, it can lead to stringing or oozing, as the filament may not have enough time to cool and solidify before the print head moves. On the other hand, if the travel speed is too low, it can result in a longer print time and potential defects in the print due to prolonged heat exposure.

Let’s have a look at what’s retraction. Another very important term to understand.

Retraction is a feature that pulls the filament back from the nozzle and moves it to a new location. This process helps to prevent oozing or stringing, which are common issues in 3D printing where excess filament leaks out of the nozzle and creates unwanted lines or blobs on the print. By using retraction, you can ensure a cleaner and more precise print.

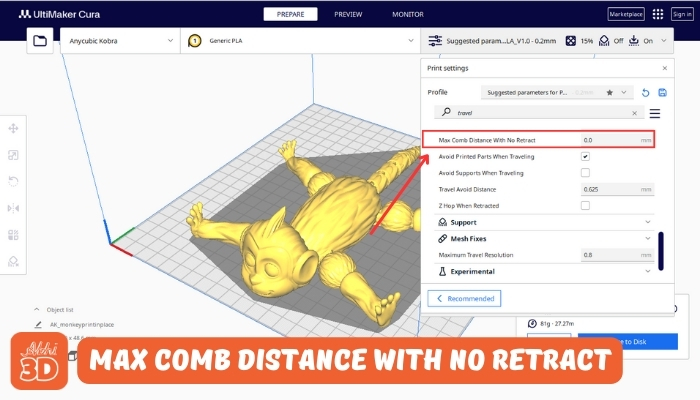

Travel settings in Cura refer to the configuration options that control the movement of the print head during non-printing phases, such as moving between print layers or during retraction. These settings can significantly impact the quality of your 3D prints and help prevent issues like stringing and layer separation.

In Cura, there are several settings related to travel speed that you can adjust to optimize your 3D prints. Let’s understand each travel settings one by one.

1. Combing Mode:

Let’s talk about “Combing Mode.” This setting is like your GPS, guiding the print head’s movement within the parts. It has three options: Off, All, and Not in Skin. When it’s off, the print head moves in straight lines, regardless of the model’s boundaries. The ‘All’ option ensures the print head stays within the model’s boundaries, reducing the risk of stringing. ‘Not in Skin’ is a balance between the two, avoiding visible parts of the print (the skin) but moving freely within infill areas.

2. Max Comb Distance with No Retract:

Max Comb Distance with No Retract is a feature in Cura that sets the maximum distance the print head can travel without retraction. It’s a balancing act between print quality and speed, optimising your 3D printing process.

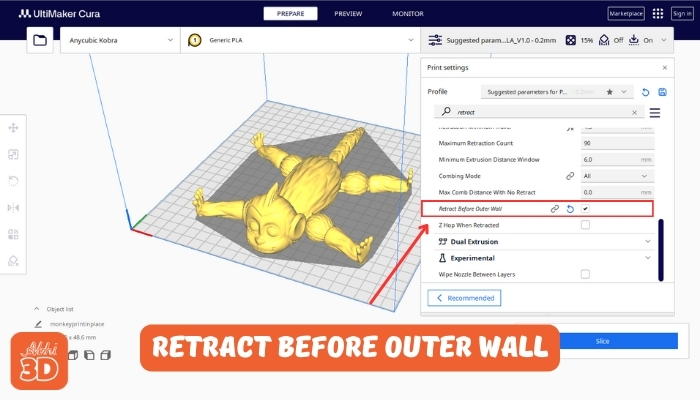

3. Retract Before Outer Wall:

Retract Before Outer Wall setting pulls back the filament before the printer starts working on the outer wall. This helps to reduce any potential oozing and results in a cleaner, more precise print.

4. Avoid Printed Part When Travelling:

Avoid Printed Parts When Travelling ensure the print head maneuvers around already printed sections, minimizing the risk of damage or displacement.

5. Retraction Setting:

It pulls the filament back when the print head moves between parts, reducing stringing. You can adjust the retraction distance (how far the filament is pulled back) and retraction speed (how fast it’s pulled back).

6. Retraction Minimum Travel:

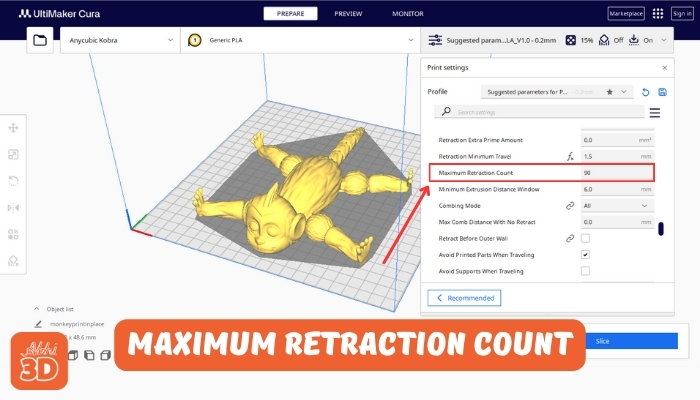

Retraction Minimum Travel setting determines the minimum distance the print head should travel before a retraction is triggered. This helps to reduce stringing and improve print quality.

7. Maximum Retraction Count:

This setting limits the number of times the filament can retract within a specified distance, helping to prevent filament grinding and other issues.

8. Retraction Prime Speed:

Retraction Prime Speed controls the speed at which the filament is pushed back after a retraction, ensuring smooth and precise printing.

9. Z Hop Setting:

When enabled, the print head lifts slightly when it travels, reducing the chance of it knocking into and damaging the print.

10. Z Hop When Retracted:

Z Hop When Retracted is a 3D printing setting that slightly lifts the print head during retraction, reducing the risk of scraping or damaging the print.

11. Z Hop Only Over Printed Part:

Z Hop Only Over Printed Parts ensures the print head only lifts (or ‘hops’) when moving over already printed areas.

12. Z Hop Height:

Z Hop Height dictates the vertical distance the print head lifts during a Z hop, optimising print quality.

Now, onto the recommended settings. Generally, a good starting point for your travel speed in Cura is around 100 mm/s. This moderate speed allows for efficient printing without compromising on quality.

However, this isn’t a one-size-fits-all solution. Depending on your printer’s capabilities and the complexity of the model you’re printing, you might need to adjust this speed.

If you’re noticing stringing or oozing in your prints, it could be a sign that your travel speed is too slow. In this case, try gradually increasing the speed. On the other hand, if your printer is struggling to keep up or the movements seem jerky, you might need to reduce the travel speed.

- Was this post helpful?

- Next →

Recommended Posts For You

How to update bambu studio to new version, how to update your prusaslicer software to latest version, how to update your cura 3d slicing software in 6 simple steps, leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

3D Designs For 3D Printing

© Abhi 3D | Terms | Privacy Policy | Cancellation

Sharing is Awesome, Gratitude!

- ReshareOnInstagram

Let’s Design Your

How It Works?

- Kindly email [email protected] with your requirement.

- If what you require, is not in the list above, just tell me what you’d like me to make instead. I take custom orders of any kind.

- I will reply within 48 business hours about the details of the project and the cost.

- If you stay outside India, I will send you a PayPal Invoice. Upon clearing the invoice, you will be asked to send 2-3 photos of the person/pet to my email [email protected] (For people residing within India, other modes of payment can be arranged) The project will be completed within 15-20 business days depending on the nature of the project. All my work is sent across digitally. If you have any other questions, please feel free to ask in the form on the right. I’m more than happy to answer them.

- Kindly email [email protected] with your requirement. If what you require, is not in the list above, just tell me what you’d like me to make instead. I take custom orders of any kind.

- If you stay outside India, I will send you a PayPal Invoice. Upon clearing the invoice, you will be asked to send 2-3 photos of the person/pet to my email [email protected] (For people residing within India, other modes of payment can be arranged)

- The project will be completed within 15-20 business days depending on the nature of the project. All my work is sent across digitally.

- If you have any other questions, please feel free to ask in the form on the right. I’m more than happy to answer them.

Fill Below Form

You are currently not a premium member, upon cancelling you will lose below premium member benefits:.

Book you 3D design service now

- Convert Plus is all-in-one software to generate more leads & drive more sales with onsite targeting

- Unlimited free downloads

How to Speed Up 3D Printing for Faster Prints: 9 Easy Tips

Mario De Lio

Last Updated:

March 11, 2024

Disclosure: This post may contain affiliate links. We may receive compensation when you purchase via my links at no cost to you. See our disclosure for more information.

One of the most common challenges faced by 3D printing enthusiasts is the time it takes to complete a print. With some projects taking hours or even days to finish, everyone is looking for ways to increase the speed of 3D printing without compromising on quality.

There are several ways to speed up 3D printing without reducing print quality. Let’s look at some easy tips to 3D print faster, such as adjusting slicer settings, modifying infill patterns, and experimenting with nozzle sizes to help you create a 3D image more quickly.

Table of Contents

How to Speed Up 3D Printing

1. increase print speed in your slicer.

Increasing the print speed is one of the easiest ways to get faster print times. Print speed, typically measured in millimeters per second, dictates how fast the print head moves during extrusion.

It’s best to increase this speed gradually and run a test print to evaluate the impact on print quality. Faster print speeds often reduce the quality of your 3D model as faster speeds create more vibrations and don’t provide as much time for the filament to bond.

Remember that every printer has its limits. You can’t increase print speed indefinitely.

Different filaments also react differently to speed changes, so consider the material you use. For instance, increasing speed can sometimes lead to poor layer adhesion, reduced surface quality, and less accuracy in the print. To strike the right balance, you might want to experiment with varying speeds for different parts of your print, like opting for slower speeds for the outer walls and faster for the infill.

You can also adjust the acceleration and jerk settings, which control the speed at which the print head changes directions.

Tip: Raise the print temperature when you increase print speed to prevent under-extrusion issues. Higher print temperatures allow the filament to melt and extrude faster. I recommended a 5-15 °C temperature increase for every 5-10mm/s increase in print speed.

2. Increase Travel Speed

An often overlooked speed setting is the travel speed. The travel speed is how fast the print head moves when not extruding material. Think about gaps in your print or when you’re printing multiple items.

Increasing the travel speed reduces overall print times.

You’ll notice the most significant time savings when printing objects where the print head spends much time over open spaces. If you’re printing a solid object, such as a vase, this setting won’t impact print times.

The default setting in Cura is 150mm/s, but you can increase it with a 3D printer capable of faster speeds.

Faster travel speeds also reduce stringing in your 3D prints, as there’s less time for the filament to ooze out of the nozzle during movements.

The biggest drawback is that faster travel speeds increase the chance of the hot end crashing into parts of your print.

Enable Z hop, which raises the nozzle during travel, preventing collisions with printed objects. You can also enable Combing, which adjusts the travel path to avoid collisions. We prefer Z hop over combing as the modified path is longer, increasing print times. In comparison, Z hop does not affect the print speed.

3. Increase Layer Height

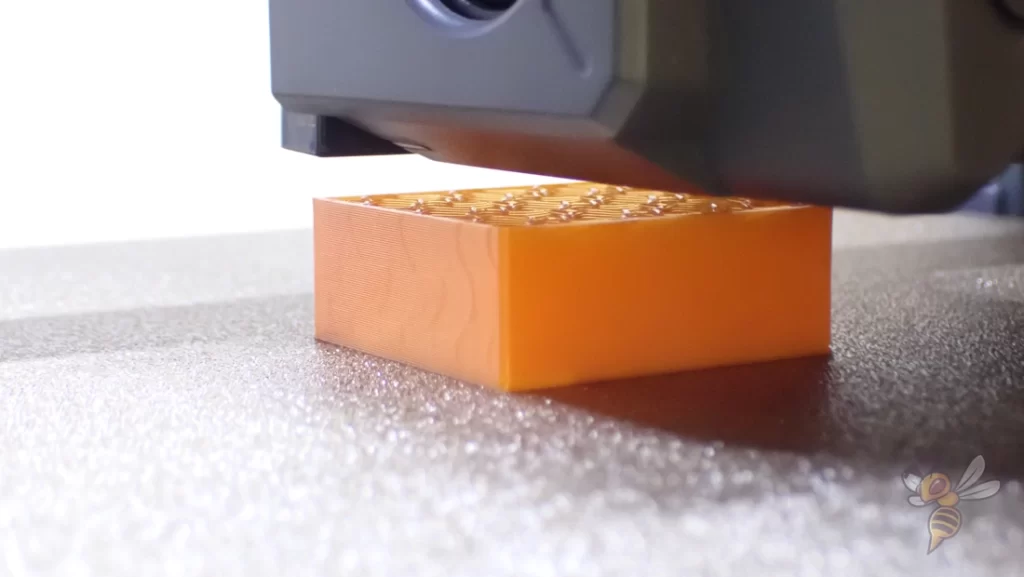

Increasing the layer height is the best way to reduce print times. However, increasing the layer height reduces the print quality of your 3D model.

Layer height is often referred to as the print resolution .

Increasing layer height is particularly effective for larger, less detailed objects. However, it’s essential to be aware of the trade-off involved: a thicker layer height can reduce the level of detail and smoothness of the print’s surface, making layer lines more visible.

You can increase the layer height to 80% of the nozzle diameter.

You can print with a standard 0.4mm nozzle with a maximum 0.32mm layer height . With a wider nozzle diameter of 0.6mm, you can print at a much larger layer height of 0.48 mm.

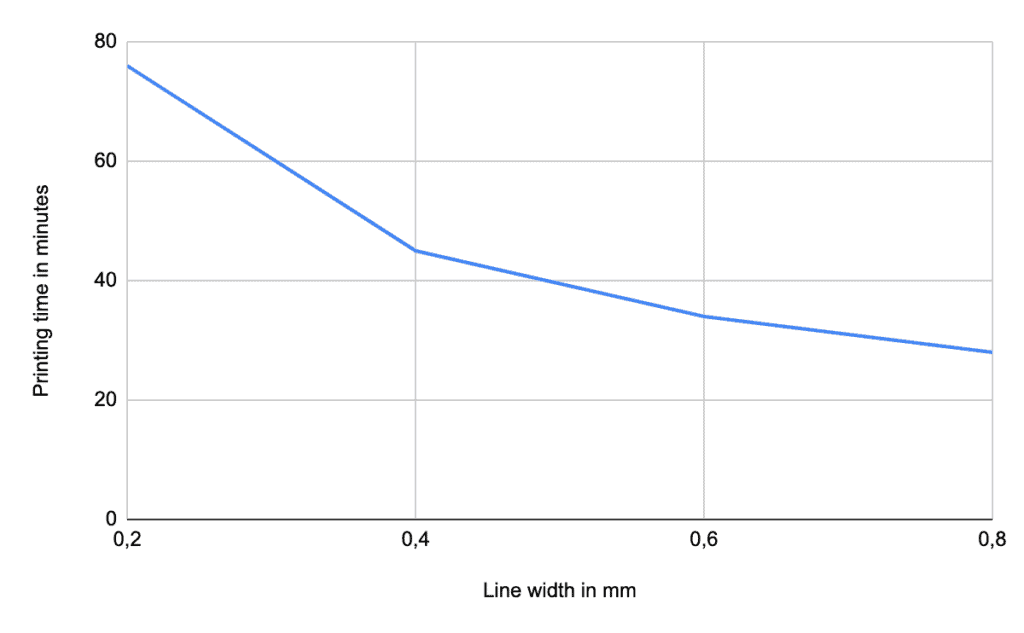

4. Use a Wider Nozzle

Using a wider nozzle diameter is an effective way to increase the speed of 3D printing. Wider nozzles allow for a higher filament extrusion rate and larger layer heights.

Most 3D printers have a 0.4 mm nozzle. However, you can upgrade to a larger 0.6mm or 0.8mm nozzle diameter to increase 3D printing speeds.

However, larger nozzle diameters reduce the level of detail in prints, making them less suitable for high-precision or intricately detailed objects.

When switching to a wider nozzle, adjustments in the slicing software, such as recalibrating the extrusion rate, layer height, and printing temperature, are necessary.

Wider nozzles are especially beneficial for larger prints where fine detail is not a priority. I often use a wide nozzle diameter when printing large cosplay props because I know they will be sanded and painted, so layer resolution isn’t necessary.

5. Decrease Infill Density

Decreasing the infill density of a 3D print is a strategic approach to significantly reducing print times. Infill density refers to the amount of material used to fill the inside of a print. Lowering the infill density reduces the amount of filament required .

You can choose an infill density between 0% and 100%. An 0% infill produces a hollow object that is quickest to 3D print, while an infill density of 100% creates a solid object.

When you decrease the infill density, less material is used to fill the interior of your print. This reduction means the printer has less material to extrude inside the object, directly decreasing the print time.

However, it’s essential to balance the infill density with the structural requirements of the print. Lower infill densities make the 3D printed object lighter and use less material, which is cost-effective but also makes the final object less sturdy and more prone to damage or breaking, especially under stress.

Here’s a general guideline for selecting the best infill density for your 3D print :

- Decorative prints (0-15%) : Ideal for lightweight miniatures, display models, and objects that don’t need much structural integrity.

- Standard prints (15-30%) : A good choice for objects requiring more strength but not needing to be solid or too heavy.

- Durable prints (30-50%) : Suitable for functional parts that undergo moderate repeated stress, where tensile strength and durability are important factors.

- Functional prints (50-100%) : Best for solid functional items and components that must withstand significant forces. Remember that a 100% infill might reduce flexibility in certain models.

Decreasing infill densities is best suited for objects where internal strength is not a primary concern, such as decorative items or parts that don’t bear a load.

6. Choose a Faster Infill Pattern

Changing the infill pattern is another technique to optimize print times in 3D printing. The infill pattern is the shape of the internal structure of a print.

Infill patterns vary in complexity and design. Different patterns impact the finished product’s printing speed and structural integrity.

Lines and zig-zag patterns are among the simplest and fastest to print . These patterns involve straightforward, continuous movements of the print head, allowing for a more efficient printing process with fewer stops and starts. These infill patterns can be printed quickly due to their simplicity and the reduced need for complex movements or retractions of the print head.

However, the simplicity of lines and zig-zags comes with a trade-off regarding structural support. These patterns are not as strong as more complex infill designs like grid, honeycomb, or triangular patterns. The straight-line nature of these infills can lead to weaknesses, especially under torsional or bending forces. Faster printing infill patterns are best for decorative items that don’t require structural strength.

A more intricate infill pattern might be necessary for objects that require more strength, albeit at the expense of longer print times.

7. Lower Wall Thickness

Decreasing the wall thickness in 3D printing, or shell thickness, is the number of solid layers forming the sides of a print, is a straightforward way to improve 3D printing speed.

When you reduce the wall thickness, there are fewer perimeter layers to lay down. The reduction in filament translates to faster 3d printing.

However, lower wall thickness reduces a print’s strength and quality. Thinner walls are less robust, making the print more susceptible to damage under physical stress.

Additionally, with thinner walls, the infill pattern might be more visible, potentially affecting the print’s aesthetic appeal.

8. Remove or Reduce Supports

Adjusting the support settings is a strategic way to reduce the time required to complete a 3D print. Supports are essential for printing overhangs and bridging gaps, but they can also add significantly to print time and material usage.

By optimizing your support material settings in the slicer program, you can minimize the amount of support used, thereby speeding up the printing process.

- Selective Support Placement: Instead of using the default setting, which often adds supports everywhere, opt for selective placement. You can selectively place supports where they are absolutely necessary, such as under extreme overhangs or large bridges. This method does take some skill, as you need to understand which parts of your print require support.

- Reducing Support Density: Decreasing the density of the support structures reduces print time as less filament is required. Higher-density supports are stronger but take longer to print and use more material.

- Using Support Patterns Efficiently: Choose support patterns that are quick to print and easy to remove. For instance, a zig-zag or line pattern can print faster and be less dense than a grid pattern, which helps reduce overall printing time.

- Adjusting Support Overhang Angle: Increase the overhang angle for support generation. By default, many slicers generate supports for overhangs greater than 45 degrees. If your material and printer settings allow, increasing this angle means less support material, speeding up the print. You can often get away with 60 degrees or more if your 3D printer is calibrated correctly.

Optimizing support settings involves ensuring adequate support for overhangs and minimizing unnecessary support structures. This balance is critical to reducing both print time and material usage.

By selectively placing supports, adjusting their density and pattern, and fine-tuning overhang angles and distances, you can significantly speed up your 3D printing process while maintaining the integrity and appearance of your prints.

As a bonus, with less material, supports are easier to remove and have less of an impact on the surface of your print.

You can also use Cura’s tree supports or Prusa Slicer’s organic supports, which use less filament than traditional support structures.

9. Print Multiple Objects at Once

Printing multiple objects at once in 3D printing can lead to significant time savings, often reducing the total print time by up to 50%. This efficiency gain is achieved because the printer works on several prints simultaneously rather than completing them individually.

And that doesn’t include the time it takes to remove the previous print, preheat the hot end, and level the print bed between prints.

When you print multiple items together, the printer’s head moves from one object to the next in a single layer before advancing to the next layer. This process continues layer by layer until all objects are completed.

I’ve found the most significant time savings when printing on multi-color printers. For example, when I print on my Bambu Lab P1P , there’s a significant time delay between color changes. But when I print multiple objects at once, the printer prints one color before moving to the next, reducing the amount of color changes.

However, there are some considerations to keep in mind. Printing multiple objects simultaneously can increase the risk of print failures affecting all objects on the build plate. Additionally, if one object fails, it can potentially interfere with or damage the other models being printed.

Therefore, it’s essential to ensure the bed is properly leveled and the objects adequately spaced to allow smooth movement between the print head.

When printing multiple items, ensure no overlap between support structures or bed adhesion layers, like rafts, brims, and skirts.

Ready to Improve Your Results?

Dive deep into the world of 3D printing with our exclusive newsletter. Get insider tips, hands-on reviews, and the latest news to improve your 3D printing.

Trending now

Your cart is empty

Estimated total.