- Woodward Manuals

- Control Unit

- Installation and operation manual

Woodward QuickTrip Installation And Operation Manual

- page of 69 Go / 69

Table of Contents

Troubleshooting, warnings and notices, electrostatic discharge awareness, regulatory compliance, chapter 1. general information.

- Introduction

- Construction

- Figure 1-1. Quicktrip, Key Features

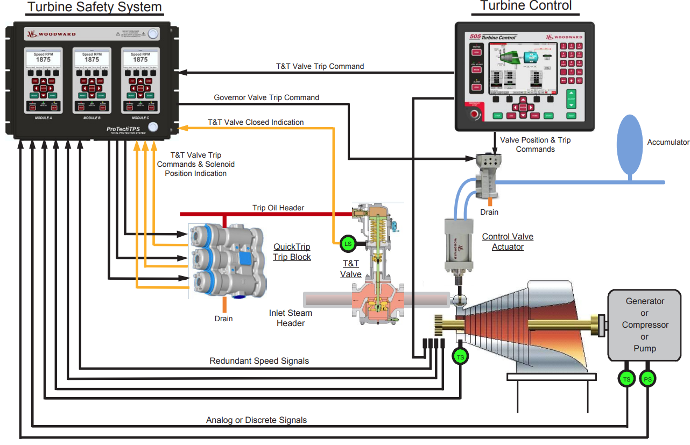

- Figure 1-2. Application Example

- Figure 1-3. Ordering Example

Chapter 2. Specifications

- Physical and Performance Specifications

- Environmental Specifications

- Electrical Specifications

- Hydraulic Specifications

- Figure 2-1. Quicktrip CV Vs Time Curve

- Figure 2-2. Quicktrip Steady State Leakage (50 °C Hydraulic Oil)

- Functional Block Diagram

- Figure 2-3. Quicktrip Steady State Leakage (70 °C Hydraulic Oil)

- Figure 2-4. Functional Block Diagram

- Hydraulic Schematic

- Figure 2-5. Hydraulic Schematic

- Outline Dimensions and Installation Features

- Figure 2-6A. Quicktrip Outline Dimensions

- Figure 2-6B. Quicktrip Outline Dimensions

- Figure 2-6C. Quicktrip Outline Dimensions

Chapter 3. Installation

- Receiving Instructions

- Unpacking Instructions

- Installation Instructions

- Figure 3-1. Quicktrip Product Installation Interface-Bolting Pattern

- Figure 3-2. Electrical Wiring Diagram

- Figure 3-3. Power Supply Input Connections

- Figure 3-4. Correct Wiring to Power Supply Input

- Figure 3-5. Example of Incorrect Wiring to Power Supply Input

- Figure 3-6. Recommended Wiring Strain Relief

- Figure 3-7. Control Input Connections

- Figure 3-8. Feedback Output Connections

- Figure 3-9. Cover Clamps

Chapter 4. Operation

- Operating Quicktrip

- Valve Position Feedback

- Special Ambient Temperature Considerations

- Figure 4-1. Pressure Test Ports

Chapter 5. Repair and Troubleshooting

- Hardware Replacement

Chapter 6. Safety Management

- Product Variations Certified

- SIL Specifications

- Figure 6-1. TUV Rheinland SIIL Certification Stamp

- Failure Rate Data

- Limitations

- Management of Functional Safety

- Figure 6-2. Response Time

- Restrictions

- Competence of Personnel

- Operation and Maintenance Practice

- Installation and Site Acceptance Testing

- Functional Testing after Initial Installation

- Functional Testing after Changes

- Proof Testing (Full Functional Test)

- Diagnostic Testing (On-Line Test)

Chapter 7. Product Support and Service Options

- Product Support Options

- Product Service Options

- Returning Equipment for Repair

- Replacement Parts

- Engineering Services

- Contacting Woodward's Support Organization

- R Equirements

- Table A-1. Installation and Commissioning Checklist

- D Eclarations

Advertisement

Quick Links

- 1 Operating Quicktrip

- Download this manual

- CHAPTER 5. REPAIR AND TROUBLESHOOTING 42

- Troubleshooting 45

Related Manuals for Woodward QuickTrip

Summary of Contents for Woodward QuickTrip

- Page 1 Released Product Manual 26815 (Revision E, 4/2017) Original Instructions QuickTrip Electro-Hydraulic Trip Block Assembly Installation and Operation Manual...

- Page 2 26455 produced. To verify that you have the latest revision, check manual Customer Publication Cross Reference and Revision Status & Distribution Restrictions, on the publications page of the Woodward website: Revisions www.woodward.com/publications The latest version of most publications is available on the publications page. If your publication is not there, please contact your customer service representative to get the latest copy.

- Page 3 Revisions— A bold, black line alongside the text identifies changes in this publication since the last revision. Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be correct and reliable. However, no responsibility is assumed by Woodward unless otherwise expressly undertaken.

Page 4: Table Of Contents

- Page 5 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly 8. A ......57 HAPTER SSET ANAGEMENT AND EFURBISHMENT CHEDULING ERIOD 9..........................58 HAPTER ..................58 TORAGE EQUIREMENTS ..........................59 PPENDIX ....................... 59 OMMISSIONING HECKLIST ........................61 EVISION ISTORY .......................... 62...

- Page 6 Figure 1-3. Ordering Example ........................12 Figure 2-1. QuickTrip Cv vs Time Curve ..................... 15 Figure 2-2. QuickTrip Steady State Leakage (50 °C hydraulic oil) ............. 16 Figure 2-3. QuickTrip Steady State Leakage (70 °C hydraulic oil) ............. 17 Figure 2-4. Functional Block Diagram ......................17 Figure 2-5.

Page 7: Warnings And Notices

Page 8: electrostatic discharge awareness, page 9: regulatory compliance.

- Page 10 The maximum hydraulic fluid temperature shall not exceed 70°C. Conduit stops must be installed within 45cm (18 inches) of the QuickTrip product in order to meet the Zone 1 classification. The following have a maximum constructional gap (ic) less than that required by Table 2 of EN 60079-1...

- Page 11 QuickTrip Electro-Hydraulic Trip Block Assembly The Temperature Code T4 (135 °C) may be exceeded if QuickTrip is cycled on and off at a frequency exceeding 1 Hz. This is considered a rare malfunction and not part of the intended use of the device.

Page 12: Chapter 1. General Information

- Page 13 Because gas and steam turbines are often used in hazardous locations where flammable gases may be present, the QuickTrip is designed to be mounted next to the turbine and is certified for use in Zone-1 or Zone-2 (Class 1 or Class 2) hazardous locations.

Page 14: Construction

Page 15: figure 1-2. application example.

- Page 16 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Table 1-2. Recommended QuickTrip Spare Part Kits Part Number Spare Kit Description 8923-2142 Solenoid Replacement Kit 8923-2146 Electrical Module Replacement Kit 8923-2147 Return Spring Replacement Kit 8923-2192 Field Repair Tool Kit - (Includes special tools to replace the solenoid, return spring, sight window, top cover, &...

Page 17: Chapter 2. Specifications

Page 18: figure 2-1. quicktrip cv vs time curve, page 19: figure 2-2. quicktrip steady state leakage (50 °c hydraulic oil), page 20: functional block diagram, page 21: hydraulic schematic, page 22: outline dimensions and installation features, page 23: figure 2-6b. quicktrip outline dimensions, page 24: figure 2-6c. quicktrip outline dimensions.

- Page 25 Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly NOTES These general reference outline drawings apply to Woodward QuickTrip only. Consult Woodward for the latest outline drawing. Installation Orientation: Orientation vertical approximately as shown See elsewhere in this manual for other installation recommendations.

Page 26: Chapter 3. Installation

Page 27: installation instructions, page 28: figure 3-1. quicktrip product installation interface-bolting pattern.

- Page 29 The hydraulic supply and drain to the QuickTrip are to be at least 25 mm (1 inch), or larger, tubing capable of flowing up to 908 L/min (240 US gal/min) at 34.5 bar / 500 psig.

Page 30: Figure 3-2. Electrical Wiring Diagram

Page 31: figure 3-3. power supply input connections, page 32: figure 3-4. correct wiring to power supply input, page 33: figure 3-6. recommended wiring strain relief, page 34: figure 3-7. control input connections, page 35: figure 3-8. feedback output connections, page 36: figure 3-9. cover clamps.

- Page 37 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly ELECTRIC SHOCK—To reduce the risk of electric shock, Protective Earth (PE) must be connected to the termination point on the top of the unit next to the label with the symbol. The conductor providing the connection must have a properly sized ring lug and wire gauge larger than or equal to 4 mm²...

Page 38: Chapter 4. Operation

- Page 39 (Ex. 5 sec). This configuration is optional, but may provide early warning for a QuickTrip module that fails to energize to a run state (valve fails to close) when commanded to do so. Refer to ProTechTPS manual 26501V2, Chapters 9 and 11 for additional information.

Page 40: Valve Position Feedback

Page 41: special ambient temperature considerations, page 42: chapter 5. repair and troubleshooting, page 43: hardware replacement.

- Page 44 2. If QuickTrip is in a trip state, as indicated by a red LED as viewed through the sight glass, QuickTrip may be energized to close by activating the ProTechTPS interposing relay to initiate a run state. This may be done by pressing the RESET button on the front panel of the ProTechTPS (see the ProTechTPS product manual if module does not reset when the RESET button is pressed).

Page 45: Troubleshooting

- Page 46 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Be prepared to make an emergency shutdown of the turbine, or other type of prime mover, to protect against runaway or overspeed with possible personal injury, loss of life, or property damage.

- Page 47 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Table 7-1. QuickTrip Troubleshooting Guide General Faults Problem Cause Remedy Check power source and connections Input Power below specified limit (Chapter 2: Electrical Specifications). Ensure turbine is running and speed sensors Speed sensor logic solver is in a...

- Page 48 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Table 7-1. QuickTrip Troubleshooting Guide (continued) Power supply is not turned on or wiring is not connected Check power source and connections (Chapter 2: Electrical Specifications). Power supply voltage or current are...

- Page 49 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Table 7-1. QuickTrip Troubleshooting Guide (continued) Check all wiring between trip terminals on Wiring not connected properly electronics module and logic solver Verify that all speed sensors and logic solver Valve is in a run state...

Page 50: Chapter 6. Safety Management

Page 51: failure rate data, page 52: limitations, page 53: restrictions.

- Page 54 1. The following procedure should be followed for each QuickTrip module (A, B and C) 2. Ensure power is connected to one or both power inputs on QuickTrip module (terminals 1 & 2 and 3 & 3. Verify that one or both blue LED’s on the QuickTrip electronics module are lit indicating that either a single power supply or two redundant power supplies are connected and turned on.

Page 55: Diagnostic Testing (On-Line Test)

Page 56: chapter 7. product support and service options, page 57: returning equipment for repair, page 58: replacement parts, page 59: technical assistance, page 60: period, page 61: r equirements, page 62: table a-1. installation and commissioning checklist.

- Page 63 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Table A-1. Installation and Commissioning Checklist (Continued) Category Parameter Specification This Installation Wiring: Trip #1 NO TB2, Terminal 7 Wiring: Trip #1 COM TB2, Terminal 8 Wiring: Trip #2 NO TB2, Terminal 9...

- Page 64 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Revision History Changes in Revision E— • Changed Item number references in Table 1-1 and Figure 1-3 • Changed ground lug torque value in the Unit Grounding section in Chapter 3 Changes in Revision D—...

Page 65: D Eclarations

- Page 66 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Woodward...

- Page 67 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Woodward...

- Page 68 Released Manual 26815 QuickTrip Electro-Hydraulic Trip Block Assembly Woodward...

- Page 69 Email and Website—www.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world. Complete address / phone / fax / email information for all locations is available on our website.

Rename the bookmark

Delete bookmark, delete from my manuals, upload manual.

VALVE-ASSEMBLY, QUICKTRIP

The QuickTrip trip block assembly

is designed for use in steam, gas, and hydro turbine shutdown systems for quick and reliable dumping of the turbine’s trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive steam turbines that use lowpressure (5–25 bar / 73–363 psi) hydraulic trip oil headers.

Electro-hydraulic Trip Block Assembly

Variants Overview Table

- Type Ordinary Location NA Div 1, ATEX/IECEx Zone 1 NA Div 2, ATEX/IECEx Zone 2 NA Div 1, GOST Zone 1 NA Div 2, GOST Zone 2

Questa combinazione non esiste.

Termini e condizioni

Dirt-tolerant design

No orifices to plug

25 lb rotary chip shear force

Self-cleaning valve design

Fast trip times

< 50 ms solenoid action

Increased reliability

2-out-of-3 voting design o Repairable online

No single-point failure

Testable online

Safety certified for use in IEC61508 SIL-3 systems

API-670 Compliant

Local & remote position indications

Local—LEDs o Remote—Relays

Compact size

Certified for hazardous locations

CSA Class I, Div. 1 & 2

ATEX Zone1 & 2

IECEx Zone1 & 2

OR WAIT null SECS

- Do Not Sell My Personal Information

- Privacy Policy

© 2024 MJH Life Sciences ™ and Turbomachinery Magazine . All rights reserved.

Advances in turbine overspeed safety systems

The horsepower of micro-processors has grown dramatically over the past five years, enabling smaller devices such as loop controllers, transducers and auxiliary plant devices to perform more intelligent operations than their predecessors. As a result, turbine safety systems and overspeed protection devices can now monitor multiple turbine parameters simultaneously, as well as monitor and test the response times of the entire turbine shutdown system.

In light of these advances, the American Petroleum Institute (API) has added new overspeed system response time requirements to the 5th edition of its API 670 standard. By adhering to this standard, users and insurance companies can validate turbine safety system performance online as well as off-line.

The latest wave of API 670 compliant protection devices issue an alarm if the safety system response to a turbine trip is too long to adequately protect personnel, units or driven unit load. This encompasses sensors, logic solver, interposing relays, hydraulic trip block assembly, trip-oil header and trip valves.

Diagnostic tests to validate performance

System-level diagnostic tests allow most of a turbine shutdown system to be tested while the turbine is online, and the entire system to be tested when the turbine is off-line. The devices are programmed to undergo routine tests by switching a frequency generator into one of the voting kernel sections, and then monitored. The response time is logged, except for the final actor (turbine shutdown valve). Such diagnostic tests are used to validate the performance/response of the logic solver, any interposing relays and the trip solenoids.

System proof tests are performed during scheduled turbine downtime events to validate the performance of the complete overspeed safety system including the trip-oil headers and the final actor. In case of possible overspeed, safety devices are expected to sense and respond within 20 to40 milliseconds. API 670 requires a response of 40 milliseconds or faster depending on the calculated turbine acceleration rate and overall turbine trip system response time.

Tracking overspeed levels

If a safety system senses only rotor speed, it will issue only a turbine trip command once the programmed overspeed trip level is exceeded. This, however, does not take into account how fast the turbine rotor is accelerating when it reaches its overspeed trip level, resulting in the rotor possibly overshooting the OEMs overspeed trip point by an unsafe margin.

The latest generation systems track acceleration rates and can respond in milliseconds. Over speeding and over acceleration directly affects the life of equipment by inducing excessive stress on rotor blades, generator windings and compressor wheels.

Rich Kamphaus is the Steam Turbine and Compressor Market Manager at Woodward. He can be reached at: +1.970.498.3388 or +1.97.-21.-3733 or [email protected] .

Related Content:

- Power Generation

- Authorizations

- SCN – Service Company Network

- Automation & Electrical Support

- On-Site/In-Situ

- Duap Fuel Injection Systems

- Mechanical Services

- Ultrasonic Inspection

- Turbocharger Sales & Support

- Turbocharger Repair & Maintenance

- Turbochargers Spares Parts

- Turbocharger Retrofit Solutions

- Filtration & Separation

- Safety & Monitoring Systems

- Compressor, Coolers & Deck Equipment

- Control Systems

- Schaller Automation – Oil Mist Detectors

- Marine Electrical Services

- Vessel Re-Power

- Marine Mechanical Services

- Marine Diesel Engine Propulsion Systems

- Marine Engine Dealer Map

- Governor Exchanges and Remanufactured Sales

- Catalyst Maintenance Services

- Maintenance and System Health Review

- Turbine Fuel Valve Repairs

- Control System Integration

- Control Modernization & Retrofit

- Life Cycle Support

- Technical Support

- Control System Service

- Installation & Commissioning

- Mechanical Designs

- Vibration Monitoring Systems and Analysis Services

- Daihatsu Diesel

- MAN Energy Solutions

- S.E.M.T. Pielstick

- YANMAR Marine

- Hyundai HiMSEN

- Mitsui Two-Stroke Engines

- KBB Turbochargers

- MET Turbocharger

- GEA Westfalia Separators

- Hatlapa Compressors

- GEA – Heat Exchangers

- CM Technologies

- ZF Marine Propulsion Systems

- Gas Engine Products

- Gas Turbine Products

- Power Management Products

- Compressor Surge Controls

New Woodward Products

- Diesel Engine Products

- Steam Turbine Products

- Hydro Control Systems

- Dual-Fuel & Bi-Fuel Systems

- DCL QUICK-LID Catalysts and Silencers

- Continuous Catalyst Monitoring System (CPMS)

- DCL MINE-X Catalysts

- DCL Diesel Particulate Filters

- Heat Exchangers

- Selective Catalyst Reduction (SCR) Systems

- Catalyst Replacement Elements

- Siloxane Removal Technology (SRT)

- KRAL Fuel Measurement

- Speed Monitoring

- Vibration Monitoring Systems

- Dynalco Meters & Sensors

- Schaller Oil Mist Detectors

- MSHS HMI and SCADA Systems

- Schaller ACCOMOS®

- Horner Automation

- Auto-Maskin

- Ingersoll Rand Air Starters

- TDI Air Starters

- Retrofit and Adapter Kits

- AVRs & Excitation Systems

- Engine Spare Parts

- Reconditioned Components

- Descriptions

- Schedule 2024

- Custom Training

- Registration

- Request Form

- News & Events

- Bergen Engines

- Hedemora Turbochargers

- Vestas Aircoil – Heat Exchangers/Charge Air Coolers

- SEG Protection Relays

Innovative products for cleaner, more efficient, and more reliable performance. Learn more about Woodward’s new control systems for power generation, oil and gas, and industrial markets.

Woodward has been providing reliable control and safety solutions for the global industrial market since 1870. It is the leader in the design and manufacture of control and safety systems and components for rotating and reciprocating equipment including turbines, engines and compressors.

easYgen-600/800

- Designed for automatic or manual start/stop of diesel/gas generator sets

- Equipped with engine ECU interface to electronic engines

- Multiple feature packages:

easYgen-1600/1800

- Designed for automatic mains failure and changeover applications

- Equipped with comprehensive engine, generator, and utility protection

- Multiple feature packages: easYgen-1600: Compact to minimize footprint easYgen-1800: Advanced with market leading features to give your genset a competitive edge

conversion kit

Woodward offers a wide variety of controllers for the synchronization and load share market. Our basic controllers provide standard features for parallel or load share applications which are easy to set up and use. The easy drop-in replacement kit will save time during installation and for quick retrofits. Included in the kit is the pre-wired DSLC-2 or MSCL-2 mounted on an aluminum chassis that is the exact size as the DSLC or MSLC. Wiring locations are close to the original, minimizing extra terminal blocks and wiring.

- Integrated operator control panel / HMI

- Simple to install and operate

- Ethernet and CANopen expandable I/O

- Bulkhead and panel mount models available

- Rated for Zone-II based hazardous locations

- Integrated alarm/trip logging

easYgen 3400-3500XT Genset Control for Complex Breaker Applications

- Drop-in replacement for previous generation easYgen-3000 Series controls

- Numerous inputs and outputs plus modular software structure.

- Controls up to 32 gensets connected in a network with automatic sequencing.

- Simple or complex paralleling: stand-by, AMF, peak shaving, import-export, cogeneration or distributed generation, isolated, island, mains and multiple unit mains parallel operations.

- Available without display in a rugged metal housing.

Large Engine Control Module (LECM) — Single-Module Approach

- The LECM single-box system can be built up with interlocking modules into an engine-mountable assembly to manage and control gas, diesel, or dual fuel engines.

- The engine-mounted module controls all aspects of the engine’s operation: speed and load control, air/fuel ratio control, ignition or injector control, misfire and knock detection, air/gas/exhaust flow control, the engine’s start and stop routines, including monitoring and engine-protection-related alarms associated with each function, as well as on-board data logging and communications.

- Modules for electronic control components and their software can be mixed and matched to address different applications; all use the same software interface.

- Each module has its own microprocessor, runs its own software routines and shares information in a real-time manner, making the entire system act as one fully integrated control.

505 Digital Control for Steam Turbines

- Operates industrial steam turbines of all sizes and applications.

- Includes specifically designed algorithms and logic to start, stop, control, and protect industrial steam turbines or turbo-expanders, driving generators, compressors, pumps, or industrial fans.

- Special PID-to-PID logic allows stable control during normal turbine operation and bumpless control mode transfers during plant upsets, minimizing process over- or undershoot conditions.

- Field-configurable with integrated graphical operator control panel

505XT Digital Control for Steam Turbines

- For single valve, or single extraction/admission industrial steam turbines.

- Certified for hazardous locations – packaged in an industrial hardened enclosure for mounting within a system control panel in a plant control room or next to the turbine.

- Includes turbine protection functions to ensure the turbine or its driven load is not ouperated outside of its designed limits.

- Ideal for controlling turbine speed, turbine load, turbine extraction header pressure, turbine inlet header pressure, exhaust header pressure, or tie-line power.

QuickTrip Integrated Trip Block Assembly

- Safety certified hydraulic trip block assembly for use in industrial steam turbine shutdown systems.

- 2-out-of-3 voting design certified for use in IEC61508 SIL-3 systems.

- For mechanical-drive or generator-drive steam turbines that use low pressure hydraulic trip oil headers.

- Ideal for critical steam turbine applications requiring turbine up-time and availability.

Redundant CPC–DX Current–To–Pressure Converter – Dual Transfer

- Hydraulic pressure control skid for positioning single–acting steam turbine valve servos in critical applications.

- Redundant CPC skid includes two CPC-II units configured in a master/slave configuration, where the master unit controls output pressure, and the slave unit tracks master unit operation, and bumplessly takes control of output pressure should there be a failure with the master unit.

- Ideal steam turbine valve control for applications requiring a high level of system reliability and availability.

- Single hydraulic assembly provides all the isolation and support benefits of fully segmented current-to-pressure converters.

VariStroke Linear Actuator

- Linear electro-hydraulic actuator provides the force to operate steam turbine control valves or valve racks on mechanical-drive or generator drive steam turbines.

- Uses a low-pressure hydraulic oil source (typically turbine lube oil) to provide its output shaft force.

- Dirt-tolerant design; variable/configurable shaft stroke lengths; fast slew rates/times.

- Precise position control.

Ready to serve you

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Estamos disponible para servirle Instalaciones de servicio completo en el Sureste; Costa Noroeste, y El Golfo. Además una red de agentes en América Latina y el Caribe.

Please complete the form below. Non-Emergency Requests Only.

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!

The text on this page has been made available under the Creative Commons Attribution-ShareAlike License and Creative Commons Licenses

Trans-Siberian Railway Prices

- Trans-Siberian Railway Tickets

- Trans-Siberian Railway Ticket Booking

- Trans-Siberian Railway Car Classes

- Travel Procedure

- Trans-Siberian Railway Route

- Guides & Gadgets

Home » Prices and Trans-Siberian Tickets » Trans-Siberian Railway Prices

Ticket prices for the Trans-Siberian Railway also depend on the current ruble exchange rate.

Is the Trans-Siberian Railway expensive?

Before starting on your Trans-Siberian Railway adventure you naturally want to know what the entire trip will cost. Although this sounds like a simple question, it is pretty difficult to answer. The Trans-Siberian Railway price of travel depends on the following factors:

- Which travel class do I want to use? The price for a first class ticket is about three times the price of a 3rd class ticket

- Am I willing to buy the tickets myself and assume responsibility for the organisation of the trip?

- How many stopovers do I want to make? The more breaks, the higher the total price.

- What sort of accommodation do I want? Will it be a luxury hotel or will a hostel dormitory be sufficient?

- What tours and excursions would I like to go on?

- What is the current exchange rate for rubles?

Basically, everything from a luxury to a budget holiday is available. If you buy yourself a 3rd Class nonstop ticket at the counter, a few hundred Euros will cover the price. All you will experience is a week on the Trans-Siberian train and will see nothing of the cities on the way. There is, however, any amount of room for upward expansion. Everyone makes different choices about which aspects they are willing to spend money on. I personally prefer to save money on accommodation and railcar class, visit as many cities and do as many trips as possible. To enable better classification of your travel expenses I have contrasted two typical traveler types. In the third column you can calculate the total cost of your own journey on the Trans-Siberian Railway. Please keep in mind that these are only rough estimations and not exact prices.

The all-in costs seem fairly high at first. However, they cover everything and it is quite a long journey taking four weeks. Many people forget to consider that when looking at the list. We should also deduct the running costs for food and leisure at home. I think most visitors to this page will classify themselves somewhere between the two categories, that is around the € 2,000 – € 2,500 range. When comparing these prices with other travel packages, you get the impression that it is hardly worthwhile travelling individually on the Trans-Siberian Railway. Please keep in mind that most packages last no more than 14 days and you are herded like cattle through the most beautiful locations.

If you spend less time on the Trans-Siberian Railway you will, of course, pay less. I chose this particular travel length because I prefer not to do things by halves. If you fulfill your dream of travelling on the Trans-Siberian Railway, enjoy it and don’t rush things. But it’s up to you, of course. Try playing around with the form a bit to find the appropriate price for your trip.

- Trans-Siberian Railway Tickets »

IMAGES

VIDEO

COMMENTS

General Information Introduction The QuickTrip trip block assembly is designed for use in gas or steam turbine shutdown systems for quick and reliable dumping of the turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive gas or steam turbines that use low-pressure (up to 34.5 ...

hydraulic trip oil headers. The QuickTrip's fault tolerant design makes it ideal for critical steam turbine applications, where turbine up-time and availability are essential. This trip block assembly's 2-out-of-3 voting design provides users with a very high level of system reliability as well as compliance with industry standard API-670 ...

The QuickTrip trip block assembly is designed for use in gas or steam turbine shutdown systems for quick and reliable dumping of the turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive gas or steam turbines that use low-pressure (up to 34.5 bar / 500 psi) hydraulic trip oil ...

The QuickTrip trip block assembly is designed for use in steam, gas, and hydro turbine shutdown systems for quick and reliable dumping of the turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive steam turbines that use low pressure (5-25 bar / 73-363 psi) hydraulic trip oil ...

The QuickTrip trip block assembly is designed for use in steam, gas, and hydro turbine shutdown systems for quick and reliable dumping of the turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive steam turbines that use lowpressure (5-25 bar / 73-363 psi) hydraulic trip ...

Case in point, For LSTG MI the trip header pressure (ETS) switch is not a trip, however it does select "valves closed" to return the electronic "governor" to a restart condition. the trip header pressure is not used to open the TV, but to signal a hydraulic relay internal to the actuator to quickly close it. the same trip headed is also used by ...

Applications. The QuickTrip trip block assembly is designed for use in steam, gas, and hydro turbine shutdown systems for quick and reliable dumping of the turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive steam turbines that use lowpressure (5-25 bar / 73-363 psi ...

This encompasses sensors, logic solver, interposing relays, hydraulic trip block assembly, trip-oil header and trip valves. Diagnostic tests to validate performance. System-level diagnostic tests allow most of a turbine shutdown system to be tested while the turbine is online, and the entire system to be tested when the turbine is off-line. ...

Safety certified hydraulic trip block assembly for use in industrial steam turbine shutdown systems. 2-out-of-3 voting design certified for use in IEC61508 SIL-3 systems. For mechanical-drive or generator-drive steam turbines that use low pressure hydraulic trip oil headers.

At the specified trip point, this weight makes physical contact with a lever that releases the trip oil header, which directly moves a trip bolt and/or a hydraulic circuit to activate stop valves to close. Because the contact with the lever occurs over a relatively limited angle, there is a maximum trip response time of 15 ms (i.e. 0.015 sec).

In addition to our standard services, Grand Russia offers tours packages to Moscow and St Petersburg. You cannot resist our Two Hearts of Russia (7 Days &6 Nights), Golden Moscow (4 Days &3 Nights), Sochi (3 Days & 2 Nights), Golden Ring (1 Day & 2 Days), and many more. As a leading travel agency specializing in the tour to Russia and Former ...

dumping of the turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive steam turbines that use low-pressure (5-25 bar / 73-363 psi) hydraulic trip oil headers. The QuickTrip's fault tolerant design makes it ideal for

Exchange Rate Moscow. Use the currency below to calculate the current exchange rate for the city of Moscow. The currency used in Moscow is the Russian Ruble. Moscow is the capital of Russia. If you are traveling to Moscow, you will need to exchange your currency for the Russian Ruble. You may exchange your money for the Russian Ruble at most ...

Before starting on your Trans-Siberian Railway adventure you naturally want to know what the entire trip will cost. Although this sounds like a simple question, it is pretty difficult to answer. The Trans-Siberian Railway price of travel depends on the following factors: Which travel class do I want to use?

Customers may receive deliveries on a "will call" basis, which allows them to determine when the oil is delivered, and how much oil they need by calling us and requesting a delivery. Automatic Delivery The most convenient and cost effective way to buy home heating oil. By choosing Plociniak Fuel Services Daily Low Rate Automatic Plan, you ...

turbine's trip oil header. This integrated trip block assembly is intended for use on mechanical-drive or generator-drive steam turbines that use low-pressure (5-25 bar / 73-363 psi) hydraulic trip oil headers. The QuickTrip's fault tolerant design makes it ideal for critical steam turbine applications, where