Government agencies communicate via .gov.sg websites (e.g. go.gov.sg/open) . Trusted website s

Look for a lock ( ) or https:// as an added precaution. Share sensitive information only on official, secure websites.

Turning Waste to Energy: TuasOne Waste to Energy Plant Tour

More tours are available under Clean & Green Experiences! Please visit http://cgs.gov.sg/experiences

How does Singapore deal with the huge volume of waste we generate every day? Learn how Singapore’s efficient waste disposable system reduces solid waste by 90% and powers the country at the same time.

Date: 11, 25 July, 2:30 – 4:30 pm Admission: Free (registration required) Venue: Shuttle bus from Jurong East MRT Organiser: National Environment Agency

Get an exclusive behind-the-scenes look at how the TuasOne Waste to Energy Plant incinerates 3,600 tonnes of waste and generates 120 megawatts of electricity daily. The energy generated from incineration is enough to meet the electricity demand of 240,000 4-room HDB flats!

Participants must be 13 years old and above. This facility is not accessible by wheelchair.

- Modular concept

- Testimonials

- Technological competence

- Waste management

- European view

- Plant visits

- MERIT benefit

- Legal information

- Data Protection

- Whistleblower Policy

Good service begins with the very first contact

Would you like further information regarding our product and service portfolio? Or would you like an individual offer? We’re here to help. Please fill in all the sections marked with an asterisk * and then click on 'send form'.

How would you like us to contact you?

The personal information provided by you will only be used by us to contact you. This data shall in particular not be published. For further information please read our Privacy & Cookies page

REMEX GmbH Am Fallhammer 1 40221 Düsseldorf Germany T +49 211 17160-0 F +49 211 17160-420 Email

- REMEX Processing

Visits of recycling facilities for incinerator bottom ash

The following videos provide information that makes the recycling of mineral materials from waste incineration more easily understood. As this is a relevant waste stream in many countries, industry professionals, stakeholders and the public should be able to gain a better understanding of the opportunities that our technology offers. Interested parties or delegations that would like to see a plant in live operation can send us a message applying for a plant visit.

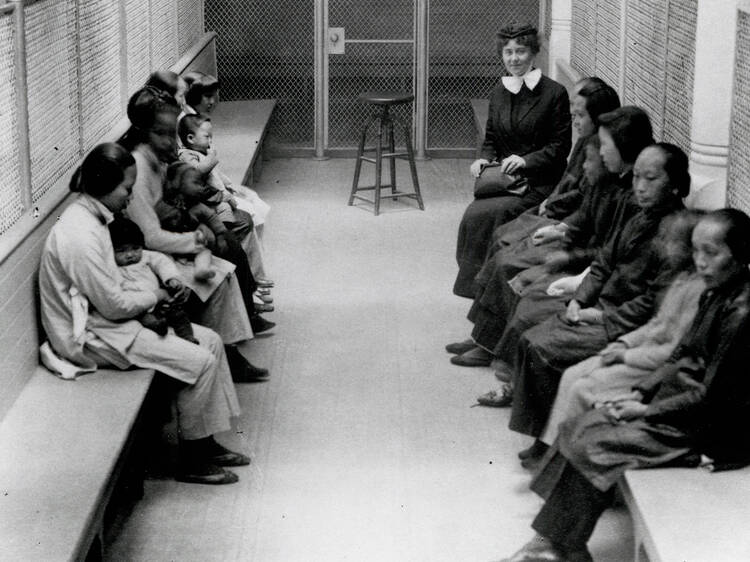

Michael Stoll introduces the Singapore plant

In Singapore, REMEX operates one of the most modern recycling facilities for the processing of municipal solid waste incinerator bottom ash and recovery of metals.

Michael Stoll: "Today I am proud to introduce Singapore’s first metal recovery plant for incinerator bottom ash. This milestone marks a pivotal step within Singapore’s long-term strategy to ensure a full recovery for residues from solid waste incineration. This facility is the first of its kind in Asia. It is a result of a successful collaboration of the NEA of Singapore and REMEX."

Venkat Patnaik: "The moment the contract was awarded to us in 2014, we were faced with two challenges: Space constraints on 1.2 hectares and a tight timeline. The goal was to create a highly efficient plant by maximising the resources available to us. We began construction in October 2014 and within eight months we have exactly achieved what we want. The metal recovery process reduces more than ten percent of the volume of the bottom ash that is sent to landfill, effectively extending its life."

Speaker: At the REMEX 1.4 hectares purpose built facility, incinerator bottom as or IBA is received daily at our ash receiving hall where it is stored and dried. Then fed into the input feeder for processing.

Once at the first station, the bar sizer screens the fresh IBA and removes any material bigger than 150 mm. And the excavator’s magnetic attachment eliminates all bulky ferrous material.

Back on a conveyer belt, fractions of ferrous metals are separated into metal bays by overbelt electro-magnets. Then at the flip-flow, IBA is sieved into various granular fractions and channelled onto the equipment.

On reaching the advanced recovery, a high-speed rotor isolates the lighter material onto a conveyor which transports it to the discharge hoppers. While the heavier fractions are channelled for the flip-flow for sieving and then to the eddy-current separators for separations.

At the eddy-current separators, non-ferrous material is separated from the IBA as it passes over a high-speeding rotating magnet below the conveyor where out of a total of eight eddy-currents, three are arranged in a cascading configuration for efficient recovery of small and non-ferrous metals.

At the last station, the manual hand-picking station, a team handpicks stainless steel and any remaining ferrous and non-ferrous material to ensure most of the metals are recovered.

Finally, the processed IBA is transported to the discharge hoppers that automatically load the ash-tipping trucks for transfer to the Tuas Marine Transfer Station.

And the recovered metals are loaded into containers for delivery to customers around the world.

Processing more than 600,000 tonnes of IBA a year, recovering up to 90% of ferrous and non-ferrous metals, REMEX helps reduce landfilling rate. And REMEX metal-free IBA can be treated for various applications, making possible zero IBA to the landfill.

REMEX Minerals – your partner in working for the future.

Five plants in less than three minutes

Waste materials of today are important resources for tomorrow – provided they undergo professional treatment. As a specialist in the recovery of raw materials from mineral waste, REMEX is one of the internationally sought-after service providers in the fields of mineral waste management , secondary aggregates , underground stowage , remediation services and landfill operation .

REMEX’s core international activities include the processing of municipal solid waste incinerator bottom ash. In this specialist field, the company operates numerous plants of different categories. In Germany, the Netherlands and Singapore, for example, the group operates production facilities with an annual capacity of up to 700,000 tons.

With direct access to ports, a broad road and rail network and proximity to industrial and waste incineration plants, REMEX has secured a distinct competitive advantage.

With the technologies we develop, we provide customers at home and abroad with the right concepts for high-quality mineral recycling.

During processing, we extract valuable ferrous and non-ferrous metals from the ash. The remaining mineral fraction forms the basis for the production of high-quality secondary construction materials, which are used, for example, in road construction, earthworks or concrete products. Our technological expertise is therefore an indispensable element of a functioning circular economy.

IBA washing plant HEROS

A detailed illustration of the operation and processes of the washing plant located on the premises of REMEX's Dutch subsidiary HEROS in Sluiskil. The incinerator bottom ash (IBA) is treated in a hydromechanical two-stage process.

In the Netherlands, REMEX owns one of the biggest plants in Europe for the processing of incinerator bottom ash stemming from energy-from-waste plants. On an area of about 45 ha, the company’s subsidiary HEROS is responsible for the operation of the facility.

Incinerator bottom ash or IBA is first treated in the main processing unit where minerals are separated from metals and organic impurities before entering an extended installation which includes, among other technical processes, numerous additional eddy-current separators and screening processes. The remaining ash forms the base material for the additional hydro-mechanical treatment.

Washing incinerator bottom ash mainly serves to improve the environmental characteristics of IBA. The plant that we see here at the HEROS location has been especially designed to fulfil the requirements of the Dutch Green Deal. It is optimised to meet the mineral specifications of the Dutch market and focuses on the production of hydro-cleaned bottom ash of the fraction size 0 to 14 mm.

The washing of IBA at the Sluiskil plant consists of a two-step process with the aim to produce a purified material in the form of sustainable secondary aggregates. An added benefit of the process is the additional recovery of valuable heavy metals.

At the centre of the hydro-mechanical technology are two washing drums arranged in sequence. The incinerator bottom ash is cleaned with water intensively in these large drums, releasing sludge and organic material from the sand and gravel fraction. The sludge is later landfilled and the organic matter returned to the incineration plant.

After leaving the washing drum, the coarse material bigger than 2 mm is separated from the sand using sieving technology. The fractions are sprayed with water via various drainage screens to remove as many contaminants as possible.

Following this, the fraction smaller 0.063 mm is separated from the sand by means of a cyclone. The remaining sludge is passed on to the sedimentation tank for further treatment and water recycling; it is later disposed of as sludge cake.

The screened and washed material sized 2 to 14 mm is also being drained. Together with the fine ash fraction, the material is then stored before it is ready for the second hydro-mechanical treatment process.

After leaving the second washing drum and screening process, the material sized 2 to 14 mm is passed on to an extra technology called jig. The coarse IBA – which still contains valuable heavy non-ferrous metals – is swirled around in water by a pulsating waterflow. The metals sink faster than the ash and collect at the bottom of the jig from which they are discharged through an adjustable weir. The remaining mineral fraction is passed on to the mixing drum. Here, it is merged in a fixed ratio with the grain size of up to 2 mm. The final result is hydro-cleaned IBA granulate 0 to 14 mm.

Water required in the operation of the plant is collected at all stages during the process. It passes through several water clarification installations, including a sedimentation tank with flocculant as clarifying agent. After physical and chemical treatment, the cleansed water is returned to the production process - thus reducing fresh water consumption to a minimum.

The metals recovered during the washing process include copper, zinc, lead, stainless steel and small amounts of gold and silver - valuable non-ferrous metals which are sold to smelting and metal processing companies. Using recycled metals such as these in metal production means a lower carbon footprint, reducing the emission of greenhouse gases in metal production.

As for the final minerals, the washed material quality enables the full reuse of incinerator bottom ash in high-end applications. Our group of companies markets these aggregates under the brand name GRANOVA. A strict quality control process makes sure that all required environmental and structural standards are met.

The main applications for IBA with hydro-cleaned qualities are:

- Road construction,

- Earthworks,

- Asphalt production and

- Concrete products

As part of ongoing research projects the use of IBA in applications such as bricks, ceramics or cement is under development.

Metal recycling plant Singapore

REMEX operates its own metal treatment plant directly adjacent to the IBA processing plant in Singapore. The facility has a capacity of 200 tons per day and is used to dry and purify iron scrap.

HEROS working for the future

The Dutch company film of the recycling expert for mineral waste HEROS Sluiskil B.V. The company is a 100% subsidiary of REMEX GmbH.

Legal information Data Protection Whistleblower Policy Sitemap

Drop us a line

Would you like to find out more about career prospects at REMEX? Then visit the REMONDIS Group's career portal

- Sustainability

- Latest News

- News Reports

- Documentaries & Shows

- TV Schedule

- CNA938 Live

- Radio Schedule

- Singapore Parliament

- Mental Health

- Interactives

- Entertainment

- Style & Beauty

- Experiences

- Remarkable Living

- Send us a news tip

- Events & Partnerships

- Business Blueprint

- Health Matters

- The Asian Traveller

Trending Topics

Follow our news, recent searches, crunching up refrigerators, tvs and more: a look at singapore’s first fully automated recycling plant for home appliances, advertisement.

Ang Hwee Min

SINGAPORE: A spent refrigerator inches up a long conveyor belt, into the mouth of a towering machine that starts up with a huge groan.

In a matter of minutes, the refrigerator that weighs almost 100kg folds and bends, gets crushed and is turned to dust. The machine then separates what comes out into foam, plastic and ferrous or non-ferrous metals.

This is Singapore's only fully automated recycling plant for large household appliances, located at Tuas View Square.

Run by EWR2, the plant processes used appliances like washing machines and dryers. The recycling facility also accepts and processes other e-waste like computers, desktops and TV screens.

“The main components, we recover quite a lot of metals. We have copper, we have aluminium, we also have plastics,” the facility’s managing director Jonson Lai told reporters on Tuesday (Jul 13) during a visit to the EWR2 facility.

Here, about 95 per cent of the materials from large home appliances can be recovered and about 80 per cent can be recycled, he added.

READ: Nationwide e-waste management system to start in Singapore on Jul 1

There were more than 20 spent refrigerators sitting in front of the huge machine waiting for their turn with it. Plastic parts that have been stripped from their refrigerator shells sit in large bins next to them.

Before they enter the large home appliance recycling plant, another machine extracts the refrigerant from the end-of-life refrigerators. Workers also use another machine to cut open the refrigerator compressor motors to retrieve the copper coils inside.

The plant started operations in March, and has processed more than 1,000 tonnes of e-waste so far, said Mr Lai. This includes about 500 tonnes of large home appliances.

“For incoming goods, like refrigerators, when they come in, some of them are really very dirty and smelly. Some of them even have rotted food inside. So these are things we need to clean up before we can recycle them,” he added.

Singapore generates more than 60,000 tonnes of e-waste, or electrical and electronic waste, every year, and this is expected to increase, said the National Environment Agency (NEA).

READ: Singapore's e-waste collection and disposal scheme: What you need to know

The agency launched the Extended Producer Responsibility scheme for e-waste on Jul 1, making producers responsible for managing the end-of-life disposal of electrical and electronic products they supply to the Singapore market.

Regulated products include infocomm technology equipment, large appliances, light bulbs and tubes, batteries and solar photovoltaic panels.

“With the recently launched Extended Producer Responsibility scheme for e-waste, regulated products that reach their end-of-life will need to be sent for proper treatment and recycling,” said Senior Minister of State for the Ministry of Sustainability and the Environment Amy Khor, who was at the visit.

“This will protect the environment and public health from hazardous substances and also ensure that the precious materials, as well as working components within the e-waste, can be recovered and reused.”

Large household appliances like air conditioning units, washing machines and refrigerators are “typically more challenging” to recycle than other types of e-waste, said Dr Khor.

“And this is because the recycling process for LHAs (large household appliances) requires highly specialised tools and machinery. And the recovered components are typically of lower value,” she added.

On top of the recycling plant for large household appliances, EWR2 also has a printed circuit board (PCB) processing plant that can take 300kg of boards at a time.

Some appliances like CPUs or computer and LED screens have to be taken apart first by hand because they contain some hazardous materials.

Most PCBs they receive first go into a component dismantling machine, which uses friction and heat to knock off or melt the separate parts attached to the board.

The parts that drop off are sent to the precious metal recovery plant on the third floor of the facility, and metals like gold, silver and palladium are extracted using acids. There are also wastewater and acid treatment plants to support the precious metal recovery plant.

What remains of the PCBs is processed in the processing plant, separated into metals and plastic.

READ: Singapore unveils Green Plan 2030, outlines green targets for next 10 years

The facility also houses a laboratory and a material testing room, which test the purity of the precious metals recycled in the plant.

A manual large household appliance recycling plant would usually need about 10 to 15 people to operate, but since EWR2’s plant is fully automated, it needs only three to four people on site to operate it, said Mr Lai.

Pre-sorting the appliances still “takes some time”, but he estimates that the fully automated plant only needs 20 to 30 per cent of the man-hours needed by a manual recycling plant.

When the volume of e-waste they receive grows, Mr Lai hopes to expand the facility’s operations.

“Presently in Singapore, not many people automate their equipment to do recycling of e-waste, and we’re doing this for household appliances because there is a need to do so, and there is volume,” said Mr Lai.

“In Singapore, there are many tonnes of refrigerators that need to be processed. With automation, we can cut short the manpower and increase the volume (that we can process).”

Related Topics

Also worth reading, this browser is no longer supported.

We know it's a hassle to switch browsers but we want your experience with CNA to be fast, secure and the best it can possibly be.

To continue, upgrade to a supported browser or, for the finest experience, download the mobile app.

Upgraded but still having issues? Contact us

Awesome, you're subscribed!

Thanks for subscribing! Look out for your first newsletter in your inbox soon!

The best of Singapore for free.

Sign up for our email to enjoy Singapore without spending a thing (as well as some options when you’re feeling flush).

Déjà vu! We already have this email. Try another?

By entering your email address you agree to our Terms of Use and Privacy Policy and consent to receive emails from Time Out about news, events, offers and partner promotions.

Love the mag?

Our newsletter hand-delivers the best bits to your inbox. Sign up to unlock our digital magazines and also receive the latest news, events, offers and partner promotions.

- Things to Do

- Food & Drink

- Shopping & Style

- Coca-Cola Foodmarks

- Music & Nightlife

- Restaurants & Cafes

- Los Angeles

Get us in your inbox

🙌 Awesome, you're subscribed!

From trash to treasure: Singapore's first plastic maker community is changing the recycling game

What does it truly mean to recycle? We speak to Paul Lee from Plastify to gain more insights.

It is no newsflash that plastic has imposed a big issue on the environment, with almost 900 million kilogrammes of plastic discarded every year in Singapore alone. And humans aren’t the only species affected. With the infiltration of plastics in the ocean, hundreds of marine species are prone to ingestion, suffocation and entanglement which could eventually lead to death. Plastics can also disintegrate into small particles – microplastics – and find their way into our food chain, the air we breathe, and the water we drink.

But what does it truly mean to recycle? For most of us, dropping our trash off at the big blue bin might be it, but the truth is, it doesn’t end there. There's a lot that goes behind the scenes of recycling that is invisible to us. That’s where Plastify Singapore comes in, Singapore's foremost community-based plastic maker space that aims to increase awareness on plastic recycling and its process. Founded two years ago, this initiative leads beach clean-ups, maker workshops, educational talks and hands-on opportunities at their workshop space. They start by educating individuals about the nature of plastics and subsequently showcasing the techniques utilised to decompose plastic waste, which is then transformed into practical everyday items. Till date, they have gathered more than 500 volunteers and have made over 1,000 products – such as coasters, earrings, carabiners – out of recycled plastics.

Paul Lee, director of Plastify Singapore, explains, “Many people don’t know that there are actually seven different types of plastics – Type 1 (PET), Type 2 (HDPE), and so on and so forth. Even the regional environmental teams in corporations may not know this, so there’s really a lot to educate on.

“We make most of our products from Type 2 where we have your bottle caps, shampoo and conditioner bottles. We have also worked with Pedro shoes to recycle shoe bags and are currently pitching to Adidas. And also fun fact, Styrofoam – which falls under Type 6 – is the most environmentally friendly plastic because it uses the least energy and resources to make.”

Our vision is to be a hub for plastic recycling and education. So, if they have questions about anything with regards to plastics, or are looking to create products by recycling, they can come to us.

Most of the plastics at Plastify are donated by caf és, retailers and various individuals. “The support from the community is fantastic. We get a lot of plastics. People trust us as we are very transparent. Our vision is to be a hub for plastic recycling and education. So, if they have questions about anything with regards to plastics, or are looking to create products by recycling, they can come to us,” says Paul.

The plastics collected are being sorted, cleaned, and then shredded. The plastic shreds are then deposited into their injectors which are made from scratch based on a modified open sourced blueprint (what!) to melt and then squeezed out into a mould of one’s choice to create products.

Plastify also provides educational workshops and presentations to schools, aimed at fostering a deeper understanding of and appreciation for sustainability. During these sessions, students can also participate in the making process using Plastify's portable injectors brought along for the workshops.

“Kids know about recycling, just that their knowledge is not very in-depth. There’s still a lot to teach. They think that recycling is just putting waste into a bin, but it is actually both the collection and the transformation of waste into a product. You can’t claim you’ve been recycling until you’ve transformed something. That’s what we want people – both old and young – to realise,” shares the 30-year-old.

This is in line with the Ministry of Education (MOE)’s Singapore Green Plan 2030 (SGP30) where schools are playing an active role in integrating environmental sustainability into the students’ curriculum to prepare them for the green economy. Plastify believes in educating – especially from a young age – to understand the full picture of what goes behind the sustainable label.

“There is a lot of greenwashing going on. A lot of sustainability talk. For example, a lot of corporations give out free tote bags that are supposedly biodegradable. However once you imprint it, it’s not anymore. What’s the point then? And when it comes to something being biodegradable, you need the right facilities and conditions for it. You don’t expect them to biodegrade naturally in grasslands here as it is something that Singapore does not have,” Paul says.

Another thing that he highlights is the concept of circularity, which is when products or services are repurposed in a way that enables it to re-enter a new cycle of life or supply chain.

“I want people to be more educated on plastic types. Before you throw something away, think of the process after. Consume more consciously. Think twice when buying something. Be a minimalist, or rather also a maximalist. What I mean by that is minimal in a way to consume things consciously, and maximal in a way whereby you make full use of an item you purchased.”

In his day-to-day life, he also practises bringing along his own utensils, bags, bottles, and whatnot.

And if I can, I would like to debunk the myth that plastic is bad. Plastic has uses. Actually, it uses the least resources as compared to paper, for example. So, choose the plastic bag option if you were to only use it once.

As Singapore’s largest community plastic maker space, friends and like-minded people come together with a single goal – to close the plastic loop. Ultimately, the guys over at Plastify believe that recycling can be both fun and accessible. And that not all plastics are bad.

“I want people to know there’s an outlet for waste. After all, waste is just a misplaced resource. And if I can, I would like to debunk the myth that plastic is bad. Plastic has uses. Actually, it uses the least resources as compared to paper, for example. So, choose the plastic bag option if you were to only use it once,” Paul says.

“It helps to find something you enjoy while being sustainable. For me, creating the coasters gives me the freedom to be creative. So for anyone who wants to practise sustainability, I suggest first identifying what you like to do as a person that can be inline with it,” Davniel, a regular volunteer at Plastify, adds.

Plastify has several new plans in the works which are expected to bring about more innovative products and programmes in the near future. If you would like to be part of the movement, reach out here for workshops, volunteering opportunities, and more.

View this post on Instagram A post shared by Time Out Singapore (@timeoutsg)

An email you’ll actually love

More to explore

Upcoming theatre and dance performances in Singapore

The best art exhibitions in Singapore

The best music concerts and festivals in Singapore

[image] [title]

Discover Time Out original video

An email you'll actually love

- Press office

- Investor relations

- Work for Time Out

- Editorial guidelines

- Privacy notice

- Do not sell my information

- Cookie policy

- Accessibility statement

- Terms of use

- Modern slavery statement

- Manage cookies

- Sign up to newsletter

- Advertising

- Express Advertising

- Time Out Market

Time Out products

- Time Out Worldwide

Time Out magazine

- Print edition

- Digital edition

The Straits Times

- International

- Print Edition

- news with benefits

- SPH Rewards

- STClassifieds

- Berita Harian

- Hardwarezone

- Shin Min Daily News

- SRX Property

- Tamil Murasu

- The Business Times

- The New Paper

- Lianhe Zaobao

- Advertise with us

New research centre and future recycling plant mark S'pore's first attempt at recycling used textiles

SINGAPORE - A pilot textile recycling plant will open in Singapore as early as 2024, as part of an overall investment into Singaporean textile recycling capacities.

Part of these investments include a new textile recycling research centre that opened on Thursday (Aug 4).

The new research centre and eventual recycling plant - which would produce new fabrics and materials from used fabrics, such as old clothes - mark Singapore's first attempt at recycling used textiles, beyond reusing them.

Research from the centre will be piloted at the nation's first textile recycling plant, which will recycle 8,760 tonnes of fabric waste per year at full capacity. This is equivalent to the weight of 58.4 million T-shirts.

The new research centre in Nanyang Technological University (NTU) comes from a $6 million investment from Royal Golden Eagle (RGE), a global resources-based manufacturing group and the world’s largest producer of viscose.

RGE executive director Perry Lim said there is an urgent need to begin recycling textile waste in Singapore, as he said the Republic produced 189,000 tonnes of textile waste last year, from sources like discarded clothing, linens and bags.

Mr Lim said: "Currently, only 4 per cent of textiles are being (repurposed) and are either given to lower-income families or exported to other countries."

Furthermore, after the clothing has completely deteriorated in quality, it is ultimately thrown away and wasted.

Therefore, Mr Lim said it is important to develop new and better ways of recycling textiles into higher-quality materials to increase the lifespan of raw materials such as cotton.

However, recycling fabric waste has many challenges, said Professor Hu Xiao from the NTU School of Materials Science and Engineering, one of which is the separation of combination fibres used frequently in clothing - such as the cotton-polyester blend.

Prof Hu, who co-leads the new RGE-NTU Sustainable Textile Research Centre, said: "These blended fibres are actually a weave of cotton and polyester fibres twisted in a very thin diameter."

He added that separating them mechanically would be too complicated and also make the constituent fibres unusable.

But he said the centre aims to overcome this difficulty by dissolving such fibres chemically to retrieve their base materials.

In the case of the cotton-polyester blend, these would be cellulose - found in the walls of plant cells - and recovered polyester, which is a kind of plastic.

Prof Hu said the cellulose would then be converted into viscose, which is made primarily of cellulose, and recovered polyester could be used in a myriad of things, such as clothes and adhesives.

Presently, Prof Hu said the chemical process developed at the centre can break down a textile made of cotton-polyester blend into its base materials in under two hours.

The centre, which is also led by Dr Jaroslav Stavik, head of RGE R&D, will also search for ways to strip dye from fabrics without using toxic chemicals like bleach, among others, to make the fabric recycling process less environmentally harmful and cheaper.

Although there are presently textile recycling efforts in the United States, Europe and Asia, Prof Hu said most of these centres focused on repurposing the fabrics with some slight chemical treatment.

He added that many of these efforts are by start-ups which can lack expertise and scale.

Prof Hu said: "This collaboration between NTU and RGE is really the first of its kind."

Join ST's WhatsApp Channel and get the latest news and must-reads.

- Environmental issues

Read 3 articles and stand to win rewards

Spin the wheel now

NEWater Visitor Centre Tour Booking

With effect from 29 Aug 2022, mask wearing while at the NEWater Visitor Centre will be optional.

Pre-requisites for the successful completion of the e-service

You should have the following information ready before you begin:

Contact Person and Organisation Particulars

Number of Participants and Age Range

Estimated time of completing the e-Service

You will need approximately 10 minutes to complete this booking.

Estimated processing time (offline processing may be required)

You will be notified of the outcome of your booking within 10 minutes.

All the information you provide is securely maintained and kept strictly confidential. We do not, and will not, disclose your information to others without your prior permission.

BACK TO TOP

Southeast Asia’s First Battery Recycling Facility in Singapore

Southeast asia’s first battery recycling facility to recover precious metals from batteries opens in singapore, singapore, 24 march 2021 — e-waste recycling giant tes officially opened its multimillion-dollar, state-of-the-art facility today to recycle lithium batteries in singapore. known as tes b, the plant is the first of its kind in southeast asia and has the daily capacity to recycle up to 14 tonnes or the equivalent of 280,000 lithium-ion smartphone batteries. the facility uses a combination of mechanic equipment and hydrometallurgical processes to recover precious metals such as nickel, lithium, and cobalt. partially powered by a 1mwh 2nd life energy storage system (ess) that is fed by 350kwh of rooftop solar panels, it is the most sustainable battery recycling solution of its kind..

Ms Grace Fu, Singapore’s Minister for Sustainability and the Environment, officiated the facility’s opening this afternoon, together with Dr Amy Khor, Senior Minister of State for Sustainability and the Environment. Ms Fu was joined via video link by TES’s Chief Executive Officer Gary Steele, Chairman Terence Ng, and Navis Capital Senior Partner Jean-Christophe Marti. Senior government officials, including the National Environment Agency (NEA) and Singapore Economic Development Board (EDB), industry partners, and clients were also present during the launch ceremony. TES’s proprietary battery recycling technology closes the loop on the take-make-dispose model widely used in lithium battery manufacturing and disposal chains. The recovery rate of precious metals exceeds 90% and yields a purity level of almost 99%. Thus, the metals TES recovers from lithium batteries are commercially ready for fresh battery production. The plant achieves this success via the use of shredders and separation equipment that convert the batteries into black mass, followed by a chemical treatment process that extracts precious metals including lithium and cobalt. These closed loop processes are environmentally friendly, as they do not release secondary contaminants like heavy metals or volatile organic compounds into the atmosphere. TES B was named project of the year by the Singapore Business Review’s Technology Excellence Awards 2020 and was recognised by the Reuters Responsible Business Awards 2020 in the Sustainability Innovation Award category.

Gary Steele, TES’s CEO, said: “The opening of the TES B recycling facility in Singapore today marks one of the biggest milestones in our vision of becoming a global sustainability leader. Looking ahead, the battery space is potentially facing raw material commodity shortages stemming from the exponential proliferation of Internet of Things devices, electric vehicles, and mobility devices. These real-world challenges need real-world solutions. Working in close partnership with the EDB (Singapore Economic Development Board) and the NEA (National Environment Agency) has enabled TES to develop an innovative battery recycling solution that further cements Singapore as being at the centre of the future circular economy.”

Jean-Christophe Marti, Navis Capital’s Senior Partner, said: “As a majority shareholder since 2013, Navis is excited at the rapid growth of TES and will continue to support investments in sustainable innovations. Advanced Battery Recycling is at the heart of this strategy to develop a global sustainability leader.” Mr Luke Goh, NEA’s CEO, said: “The TES B recycling facility is integral to the Extended Producer Responsibility Scheme’s ecosystem for the management of e-waste. The facility will help build up capacity for the recycling of lithium-ion batteries in Singapore and allow the recovery of precious materials, contributing towards the circular economy. Such facilities support Singapore’s move towards phasing out internal combustion engine vehicles in favour of cleaner vehicles, such as EVs, for better public health and to mitigate climate change. This will bring us closer to our goal of being a zero-waste nation.” Mr Chng Kai Fong, Managing Director of the EDB, said: “We are proud that TES has chosen Singapore to site its first closed-loop battery recycling facility in the world, reflecting the company’s confidence in Singapore as a trusted location for business to capture opportunities in sustainability. As Singapore scales electric vehicle adoption and solar deployment, TES B and TES’s efforts in second-life energy storage systems will contribute to our battery recycling and energy management ecosystem, which will support Singapore’s sustainability agenda and create new and exciting job opportunities for Singapore.” Besides bringing innovative recycling processes to Southeast Asia, TES also announced that it is working with strategic partners to introduce ESS offerings and scalable turnkey solutions using retired electric vehicle batteries for various commercial and residential energy needs in the secondary market. ESS uses a network of optimally connected, second-life battery cells to store electricity and is a viable power alternative for green energy plants, remote mining power, and base transmit stations, among other applications.

LARGE CALL TO ACTION MESSAGE

See how tes can help you today.

Related resources

SINGAPORE (May 16, 2023) – TES's IT asset disposition (ITAD) services have been making a...

The Higher Colleges of Technology in Abu Dhabi, United Arab Emirates, hosted the 2022...

Continuing with the growth already seen in the Asia-Pacific and Europe, the Las Vegas...

- Items Items

- Freecycling Freecycling

- Resources Resources

- Shops Shops

- Meet the Team

All Articles

Donation Drives

First glass recycling plant set up in Singapore

Feb 1, 2023.

- A new local plant has been setup to turn used glass into an industrial abrasive called Abrablast

- Abrablast is used for sandblasting in industrial settings (eg paint and rust removal)

- Glass dust produced not suitable as an abrasive may also have uses in construction (no details given, probably still exploratory). This dust constitutes ~20% of the total glass weight.

- Production of Abrablast requires no heat: the glass is simply crushed

- Likewise no colour separation is needed

- Glass is sourced from Public Waste Collectors

- Plant capacity is up to 12,000 tons annually.

- Current production is ~ 3,500 tons/year

- In 2021, Singapore produced 74,000 tons of glass waste

- Abraclean is based in Jurong not far from Tuas.

Abraclean has opened Singapore's first recycling plant for glass waste, which can transform it into new products and reduce the amount of glass being sent to Semakau landfill. The 16,000 sq m facility, which has a processing capacity of 5 tonnes of glass waste per hour, can handle up to 12,000 tonnes annually. The recycled glass will be used to make Abrablast, a patented abrasive that removes coatings such as rust and paint from metal surfaces in industrial settings.

Since its launch in 2021, the plant has aimed to recycle 3,500 tonnes of glass waste by March 2024, with 80% being transformed into Abrablast. The remaining 20% of glass dust is also utilized, being utilized in the production of lightweight bricks and construction materials.

Unlike typical recycling facilities that require glass to be sorted by color before processing, Abrablast production does not require segregation. Additionally, the plant can produce the product without melting the glass, as it crushes it instead.

- Because glass cannot be incinerated (it melts at a temperature far higher than our waste to energy plants), 100% of glass mass that is not recycled or exported ends up in Semakau

- Glass is heavy and expensive to transport so domestic solutions to glass waste are preferable to export

- Strictly speaking this is not “recycling” (ie breaking old glass down to make new glass) - it is more akin to upcycling/downcycling

- Sand made from glass has very different physical properties compared to sand from beaches.

- Many people have asked why we don't just turn old bottles into sand for construction: but these physical differences mean that glass sand is not usually fit for purpose.

- The top question that arises here is: Do they only recycle soda lime glass or are other types of glass suitable? Soda lime is the glass you get in bottles and jars and the only type currently accepted in blue bins. It's almost guaranteed is that they cannot use other types of glass (they need to rely on consistent physical properties of the input) like Pyrex. However the ST uses a photo of waste glass that does not looks more like sheet glass than soda lime s so there is a question mark here. If they are in fact using glass from construction (eg old windows) then it means that consumers still do not have a good local solution to recycle their waste glass.

Source: The Straits Times

Want to keep up with Singapore's Zero-Waste happenings?

Sign up for Recyclopedia News here. Get the latest info on new donation drives, recycling initiatives, zero-waste news, and the occasional life-hack for living lighter. No spam. You can unsubscribe any time. See a past issue here .

Related Items

Glass Bottles & Jars

Related resources.

P&R Resource Management

Things you've suggested

Thanks for your suggestions!

Government agencies communicate via .gov.sg websites (e.g. go.gov.sg/open) . Trusted website s

Look for a lock ( ) or https:// as an added precaution. Share sensitive information only on official, secure websites.

Launch of the Plastics Recycling Association of Singapore - Ms Grace Fu

Speech by ms grace fu, minister for sustainability and the environment, at the launch of the plastics recycling association of singapore on 17 august 2021.

Er Edwin Khew, President of Plastics Recycling Association, Singapore

Ladies and Gentlemen

1 A very good afternoon to all. It is my pleasure to join you for the launch of the Plastics Recycling Association of Singapore, or PRAS.

The problem of rising waste

2 With rising consumption and a prevalent throw-away culture, countries are now facing a global waste crisis. A World Bank Report has estimated that global waste generation will grow by 70 per cent to 3.4 billion tonnes by 2050, unless urgent action is taken.

3 One of the drivers of this significant growth in waste generation is the use of single-use plastics. The UN Environment Programme estimated that half of all plastics produced is designed to be used once and then discarded. Much of the plastic waste ends up in landfills, where it may never decompose. It is a significant threat to our planetary and oceanic environment.

4 In Singapore, the amount of waste generated locally has increased sevenfold over the past 40 years. Our only landfill, the Semakau Landfill, will run out of space by 2035, based on the current waste disposal rate, even with incineration.

5 Plastic waste is also one of our largest waste streams. In 2020, we generated 868,000 tonnes of plastic waste, and only 4 per cent is recycled.

Our shift to zero waste and circularity

6 It is clear we need a paradigm shift - to move from a linear approach of take, make and throw, to a circular one where waste becomes resource and is reused over and over again. And we need to move fast.

7 The Government has taken major steps to catalyse Singapore’s transition to a circular economy. We launched the Zero Waste Masterplan in 2019 to lay out our vision and strategies.

a. The Masterplan sets out a target to reduce the amount of waste going to our landfill by 30 per cent by 2030. Under the Singapore Green Plan 2030, we will frontload our efforts to achieve a 20 per cent reduction by 2026.

b. We aim to achieve a 70 per cent overall recycling rate by 2030, through various measures to improve both the domestic and non-domestic recycling rate.

8 We introduced the landmark Resource Sustainability Act in 2019 to put in place an Extended Producer Responsibility, or EPR, framework for our three priority waste streams: electrical and electronic waste, or e-waste for short; food waste; and packaging waste, which includes plastics.

a. The EPR mandates producers and suppliers of regulated products to be responsible for the collection and proper treatment of their products at end-of-life. This ensures that products are properly collected for treatment and disposal, with safe handling and extraction of valuable resources.

b. An example of the EPR framework can be seen in Singapore’s first nationwide e-waste management system which started last month. Under this new initiative, regulated consumer e-waste is collected across Singapore for proper treatment and recycling on behalf of the producers.

9 We are investing heavily in sustainable infrastructure to close resource loops and meet Singapore’s long-term waste treatment needs.

10 The Tuas Nexus Integrated Waste Management Facility, or IWMF, will be Singapore’s first integrated facility to treat incinerable waste, source-segregated food waste, and dewatered sludge. Its automated Materials Recovery Facility will consolidate and sort all recyclables collected under the National Recycling Programme, to achieve higher recovery yields and boost our recycling. The co-location of the IWMF with PUB’s Tuas Water Reclamation Plant will derive synergies from the water-energy-waste nexus, resulting in improved energy and resource recovery, land savings, as well as carbon savings of more than 200,000 tonnes annually.

11 I am happy to announce that the IWMF will be the first infrastructure project by a Statutory Board to be financed through green bonds. NEA has established a S$3 billion Multicurrency Medium Term Note Programme and a Green Bond Framework. Proceeds from the issuance of Notes will be used to finance sustainable infrastructure projects, including the IWMF. NEA’s issuance of green bonds will help develop green finance solutions and markets, supporting Singapore’s vision to become a leading centre for green finance. This is a major milestone to catalyse the flow of capital towards sustainable development, and green our economy as part of the Green Plan.

Businesses play a key role

12 Singapore cannot achieve a circular economy by the Government’s efforts alone. We need to forge active and meaningful partnerships with all stakeholders, especially the business community, for which the circular economy presents many new opportunities.

13 As we transit towards a low-carbon future, organisations are beginning to rethink their business models – such as by embracing circularity in product design, recovering resources from products at their end-of-life, or undertaking lifecycle assessments to green supply chains.

14 Consumers are also demanding greener and more sustainable products and services. Many businesses are reviewing plastic packaging and setting targets to scale up the use of recycled plastics in their production processes. For example, German company Henkel has committed to use 100 per cent recyclable or reusable packaging, and at least 30 per cent of recycled plastics in all its plastic packaging, for its consumer products by 2025. Sportswear company Puma has also set targets to increase recycled polyester use for its apparel to 75 per cent, and reduce production waste to landfill by 50 per cent, by 2025.

PRAS – A synergistic partnership to close the plastics loop

15 The setting up of the PRAS in Singapore is timely. The PRAS brings together stakeholders from industry and research – including waste management companies, chemical producers, Institutes of Higher Learning and government agencies – to exchange knowledge and best practices on plastic waste management and recycling. The aim is to deepen Singapore’s capability in plastics recycling.

16 Let me share three areas of opportunities that the PRAS can harness.

17 First, in developing and expanding our recycling capabilities for plastic waste. Singapore will implement a beverage containers return scheme as the first phase of EPR for packaging waste. Producers, such as beverage companies, will be accountable for the collection and recycling of their beverage bottles. Consumers will get a refund when they return the empty beverage containers at designated return points. The scheme will aggregate a relatively clean source of plastic waste, such as PET plastic beverage bottles, to provide a steady stream of feedstock for the local recycling industry.

18 A PET bottle recycling facility in Singapore will be one way for PRAS to strengthen our local capability in recycling PET bottles. Such a facility will create economic value and green jobs locally. It will also bring expertise in areas such as precision engineering, manufacturing of recycling equipment and plastic recycling processes.

19 Second, in collaborating with our research and development (R&D) ecosystem, PRAS can explore new solutions in plastic waste recycling. Our researchers are making progress in minimising plastic waste footprint under our Research, Innovation, and Enterprise (RIE) plans. For example, a team from A*STAR’s Institute of Chemical and Engineering Sciences is developing a solution to recover PE and PET layers in multi-layered films; while a team from Temasek Polytechnic’s Centre for Urban Sustainability is looking at processing mixed plastic waste into ingredients for building and construction applications. By participating in the translation of our R&D efforts to real world applications through test-bedding and commercialisation, PRAS can gain the knowledge and skills to develop cutting-edge solutions to address global plastic waste challenges.

20 Third, to seek opportunities to bring about circular economy beyond Singapore. The need for plastic recycling solution is rising across the world. Singapore is certainly not alone in recognising the need for a circular approach when using our resources. Malaysia has outlined a roadmap towards zero single-use plastics, and is developing a Circular Economy Roadmap to combat plastic waste. Indonesia also seeks to adopt a circular economy approach towards sustainable growth and development. There is opportunity for us to collaborate with regional partners through bodies like the PRAS to accelerate the shift towards plastics circularity in our region.

21 Let me conclude. Once again, we welcome the formation of PRAS and would like to congratulate PRAS on your successful launch. While plastics is a critical component in our manufacturing and logistical processes, its impact on the environment cannot be ignored. The current Business-As-Usual mode cannot continue. The world is urgently in need of sustainable solutions to plastic waste. I urge all stakeholders to put in serious efforts to look for better solutions for a better world. Thank you.

- CGS Experiences

- Eco Schools

- Community and the Environment

- Workshops & Activities

- Sponsors & Supporting Partners

- Clean Public Toilets

- Environment and Us

- Downloadable Resources

- Say YES to Waste Less

- Recycle Right

- Pre-school Educational Resource Materials and Programmes

- School Programmes

- CGS 2021 Launch

- CGS 2020 Launch

- Learning Journeys

- ES Workforce Day 2020

- Volunteer Roles

- Volunteer Journey

- Year of Public Hygiene

- NEA YES Leaders Programme

- Hungry for Change Challenge

- YCLP-NEA YES Edition

- Youth Sustainability Film Prog

- Zero Waste Testbed Initiative

- Sustainable Cities Challenge

- Volunteer Opportunities

- Social Media

- Educational Resource Materials

New! You can personalise your feed. Try it now

Study underway for Singapore’s first plastic bottle recycling plant, which could recycle 150 million bottles a year

Advertisement.

SINGAPORE — A study is being done on whether Singapore should have its first recycling facility dedicated to plastic bottles only, a move that its proponents say would greatly boost the recycling rate for these bottles.

In Singapore, there is no facility that recovers contaminated plastics from domestic waste, and domestic waste makes up about 52 per cent of the total waste disposed here.

- A study is being done by the newly established Plastics Recycling Association of Singapore

- This is to see if Singapore can have its first recycling facility for plastic bottles

- It is working alongside the National Environment Agency and a German engineering firm on this

- It also plans to build a centre of excellence to share research on plastic recycling with the region

- The aim is to raise the plastic recycling rate to 30 per cent in five years and 70 per cent in the next decade

The idea is being mooted by the Plastics Recycling Association of Singapore, a new organisation that was launched on Tuesday (Aug 17).

The association aims to increase the rate of recycling plastic waste here, as well as to support the Singapore Green Plan 2030 , a government initiative to advance the sustainability agenda.

The association's vice-president Joachim Ihrcke told TODAY that the polyethylene terephthalate (PET) bottle-to-bottle recycling plant it is hoping to build and run by the end of 2023 will recycle an estimated 150 million plastic bottles a year — or 30 per cent of the 500 million PET plastic bottles discarded in Singapore yearly.

At the moment, the recycling rate is 4 per cent for plastic bottles.

The association said in a press statement that when it comes to the recycling of plastics, the present rate of 4 per cent is the lowest here among other waste streams such as metal and paper.

PET is a plastic that is commonly used to make bottles and food containers. These plastics need to be identified, sorted and segregated. After that, they have to go through mechanical recycling and chemical recycling.

The National Environment Agency (NEA) previously said that there is no facility here that recovers contaminated plastics from domestic waste, and that domestic waste makes up about 52 per cent of the total waste disposed in Singapore.

However, the new generation PET recycling plant that the Plastics Recycling Association of Singapore envisions would require “substantial investments”, it said in its statement.

It is thus working with German engineering firm HTP GmbH & Co KG to conduct a feasibility study to ascertain the cost, design and technology behind the project, among other details.

Mr Ihrcke hopes that the results of the study will attract investors to support the project. He is looking to secure enough funding for it by the middle of next year.

“We are confident that when the results of the feasibility study comes out, it will prove that this is not only a project that is feasible but also will be a project that is profitable,” he said.

“And with that profitability, I think we will find it relatively easy to attract investors.”

Mr Ihrcke added that the cost of the project will still be contingent on the results of the study, but that he expects it to amount to an eight-digit sum.

The location of the facility has not been firmed up either and is also pending the results of the feasibility study.

REGIONAL CENTRE FOR PLASTIC RECYCLING RESEARCH

At its launch on Tuesday, the Plastics Recycling Association of Singapore also announced plans to set up a Plastics Recycling Centre of Excellence, which will develop recycling solutions for the region.

The centre signed several agreements with various partners such as universities and research facilities, including the Norwegian University of Science and Technology in Norway and the Centre for Biocomposites and Biomaterials Processing at the University of Toronto in Canada, to tap their expertise and knowledge in plastic recycling.

The association added that the centre will be fully functional only when the planned PET bottle-to-bottle recycling plant is operational.

“Then, we can oblige the participants in the plastic recycling plant to also come into the centre of excellence and be prepared to share their know-how,” Mr Ihrcke said.

Mr Edwin Khew, president of the association, said that through these initiatives, the association will “move the recycling needle” of plastic waste from 4 per cent to 30 per cent in the next five years, and then up to 70 per cent in the next 10 years.

“We hope to achieve (this) with recycling technologies and new plastic technologies that we will be introducing into Singapore,” he said.

‘PARADIGM SHIFT’ NEEDED

Att the launch of the Plastics Recycling Association of Singapore was Ms Grace Fu, Minister for Sustainability and the Environment, who noted the challenges of recycling plastics in Singapore.

“It is clear we need a paradigm shift,” she said. “To move from a linear approach of 'take, make and throw', to a circular one where waste becomes a resource and is reused over and over again.”

She said that the PET bottle recycling facility would not only strengthen Singapore’s capability in recycling PET bottles, but also create more jobs here.

In the meantime, she said that the association may tap a new law that will hold producers, such as beverage companies, accountable for the collection and recycling of their beverage bottles.

The law, which will kick in next year, means that consumers will get a refund when they return empty beverage containers at designated return points.

“The scheme will aggregate a relatively clean source of plastic waste, such as PET plastic beverage bottles, to provide a steady stream of feedstock for the local recycling industry,” Ms Fu said.

She also announced that NEA had established a S$3 billion multicurrency medium-term note programme and a green bond framework, and that the proceeds from the issuance of notes will be used to finance sustainable infrastructure projects such as the Tuas Nexus Integrated Waste Management Facility .

Such notes and bonds are financial instruments used to borrow money from investors.

The Tuas Nexus Integrated Waste Management Facility will also be the first infrastructure project by a statutory board to be financed through green bonds.

Related topics

Read more of the latest in

Stay in the know. Anytime. Anywhere.

Subscribe to get daily news updates, insights and must reads delivered straight to your inbox.

By clicking subscribe, I agree for my personal data to be used to send me TODAY newsletters, promotional offers and for research and analysis.

Recent Searches

This browser is no longer supported.

We know it's a hassle to switch browsers but we want your experience with TODAY to be fast, secure and the best it can possibly be.

To continue, upgrade to a supported browser or, for the finest experience, download the mobile app.

Upgraded but still having issues? Contact us

- Work & Careers

- Life & Arts

- Currently reading: How Singapore became Asia’s go-to hub for start-ups

- FT ranking: High-Growth Companies Asia-Pacific 2024

- South Korean virtual reality fishing game reels in 1mn users

- Zypp Electric rides India’s growing EV market to top FT ranking

- Australia’s Commonwealth Bank tie-in gives More Telecom a boost

- Asia-Pacific start-ups adapt to drop in VC funding

- Japan’s start-up spirit awakens

How Singapore became Asia’s go-to hub for start-ups

- How Singapore became Asia’s go-to hub for start-ups on x (opens in a new window)

- How Singapore became Asia’s go-to hub for start-ups on facebook (opens in a new window)

- How Singapore became Asia’s go-to hub for start-ups on linkedin (opens in a new window)

- How Singapore became Asia’s go-to hub for start-ups on whatsapp (opens in a new window)

Mercedes Ruehl in Singapore

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Singapore, despite its modest size and population, is home to more businesses in this year’s ranking of high-growth companies in the Asia-Pacific region than any rival city.

This is not unusual for the city-state of just 6mn people. A trading entrepôt between east and west, the island nation has long been a leading destination for entrepreneurs and investors thanks to its strategic location within south-east Asia, supportive government policies, strong legal frameworks, and a mix of both local and foreign workers.

More recently, this appeal as a base for business has been boosted by Singapore’s neutral status between the US and China, which appeals to companies wishing to protect themselves from geopolitical and supply chain disruptions.

With 93 businesses in the FT’s ranking of high-growth companies in Asia-Pacific , Singapore beat the cities of Seoul and Tokyo — though South Korea and Japan outstripped the nation state on a countrywide basis.

Singapore’s growth companies are varied, too — from such sectors as manufacturing, artificial intelligence, software, commodities and healthcare — underscoring the breadth of businesses that the city can support.

“Singapore is neutral, it is the Switzerland of Asia,” says Dylan Ng, co-founder of Lionsbot, a manufacturer of cleaning robots that is 23rd in the ranking, with a compound annual growth rate (CAGR) of 178 per cent for the period between 2019 and 2022. “This is important with the geopolitical situation globally. There is a big pool of talent, you can deliver to the world and the city has a strong law-abiding reputation,” he adds.

The majority of Lionsbot’s customers are outside Singapore and the company is now focusing on growing in overseas markets, including the US and Europe, after raising $35mn in a series A funding round last year.

But even companies that do not do business in the city-state describe the benefits of having it as a base.

iCare, number 65 on the list this year with a CAGR of 115 per cent, provides access to basic but life-changing appliances — including washing machines, refrigerators and rice cookers — to low-income female factory workers in developing countries, including Laos and Cambodia.

Co-founder Pablo Alonso Caprile, who is based in Cambodia, says having the group’s base in Singapore gives a “layer of safety”.

“The benefits are multilateral. It simplifies paperwork and reporting, while high reporting and accounting standards allow investors comfort,” he says. iCare has its headquarters in the city state but does not have operations or core employees based there.

Singapore is also a fundraising hub for the region and Caprile says he visits frequently because many of iCare’s investors have a presence in the city-state.

The company has a catalogue of appliances and works with factories to allow workers to buy the items they need and pay back in interest-free instalments.

iCare makes its margins from dealers, rather than charging customers and handles the repayments directly with the factories.

“We have been running this successfully since 2015, well before ‘buy now, pay later’ was a household name,” Caprile points out.

Skrya, another Singapore-based company at number 10 in the ranking, also gets most of its revenue from outside the city-state. Skrya helps clients, such as automobile parts companies, to recycle materials including palladium, rhodium and platinum via an app, Catalopedia, which uses AI and 3D to determine the best pricing.

“We are trying to do an old type of business — recycling — in a modern way, with apps and tech,” explains Sivakumar Avadiar, chief executive officer for the five-year-old group.

Skrya, which is profitable, has a number of facilities and a team of roughly 10 employees in Singapore. But it is planning to grow internationally this year, opening a new plant in India, which could add another $30mn-$40mn in revenue, Avadiar says.

Singapore is neutral, it is the Switzerland of Asia Dylan Ng, co-founder, Lionsbot

Singapore’s stable reputation , and the ease of setting up a company there, made it the best choice as a base, he adds. However, he has found the cost of running a business in the city has gone up in recent years.

A survey of business sentiment by the Singapore Business Federation in January found that the increase in business costs is the top challenge companies are navigating, especially the cost of manpower.

Even for tech start-ups, such as X0PA AI — a software company that uses artificial intelligence and automation to help clients hire employees better and faster — the environment has been tougher.

“The market had a massive correction in the past few years,” says founder Nina Suri. “We had to correct ourselves and take a step back to focus on more sustainable growth.”

X0PA AI is fundraising now, via a second series A round. Suri says the company expects to break even this quarter and hopes to turn a profit by the end of 2024.

Singapore is X0PA AI’s largest market but the company is now focusing on growing in Europe, the Middle East and Africa, as well as the US.

Suri divides her time between Singapore and London but says Singapore’s ecosystem, which includes resources, talent and government support, such as grants, made it a “no brainer” to be X0PA AI’s base.

“But, for a business like ours you can’t survive and grow enough in just Singapore,” she says. “The government understands that and we got a grant to expand into overseas markets including the United Arab Emirates and the UK.”

However, despite the number of Singapore companies on this year’s list looking to expand beyond the city-state, there are still plenty that see opportunities in its small domestic market.

Doctor Anywhere, which started life as a primary care tele-health start-up, is now growing rapidly offline. For example, it recently started operating a health screening and imaging diagnostics facility. The business is ranked 55th on this year’s list with a CAGR of 124 per cent.

“Our underlying business comes from the region but many people come here for top healthcare,” says Wai Mun Lim, co-founder.

“We are building out our business in the city before replicating many of our services in other countries we operate in the region, including Malaysia and the Philippines. When you tell anyone a business is from Singapore, it means you are legitimate.”

Promoted Content

Explore the series.

Follow the topics in this article

- Tech start-ups Add to myFT

- Asia-Pacific companies Add to myFT

- Technology Add to myFT

- Singapore Add to myFT

- Mercedes Ruehl Add to myFT

International Edition

Virtual Field Trips

Take your students on a virtual field trip of how a recycling center and a modern landfill works. These videos are designed to inform specific lessons in 3rd-5th grade, 6th-8th grade and 9th-12th grade, but can also be used outside of those lessons to take your students on a journey through the process!

3rd-5th Grade

Recycling center video tour.

Take your students on a virtual field trip of a modern recycling center. A network of highly trained specialists and sophisticated, automated equipment doing the jobs of sorting, packing, and shipping recyclable materials.

- Required for 3rd-5th / Lesson 2

- Recommended for 3rd-5th / Lesson 3

Download: Low-Res (88.09 MB) | High-Res

Modern Landfill Video Tour

When we don’t recycle, materials go to a landfill, but a modern landfill isn’t what you might think. Take your students on a virtual field trip of everything from landfill construction and planning to gas-to-energy and environmental compliance.

- Recommended for 3rd-5th / Lesson 2

Download: Low-Res (62.21 MB) | High-Res

6th-8th Grade

- Required for 6th-8th / Lesson 2

- Required for 6th-8th / Lesson 3

Download: Low-Res (188.67 MB) | High-Res

Download: Low-Res (202.94 MB) | High-Res

9th-12th Grade

- Required for 9th-12th / Lesson 1

- Required for 9th-12th / Lesson 2

- Required for 9th-12th / Lesson 3

These Terms and Conditions (“Terms”) govern your access to and use of http://recyclingsimplified.com, including any microsites or mobile versions of the site or microsites (collectively the “Website”) operated by Republic Services, Inc. (“Republic Services”). Your access to or use of the Website constitutes your acceptance of these Terms and results in a binding agreement between you and Republic Services. Each time you download Available Materials (as defined below) from the Website, you are acknowledging and agreeing to be bound by these Terms, as they may be modified from time to time. If you are accessing this Website on behalf of your company, you represent and warrant that you have the authority to bind your Company and to accept these Terms on your company’s behalf.

Republic Services’ Property

COPYRIGHT: All content included on this Website, such as HTML code, scripts, text, graphics, logos, button icons, images, video, downloadable content, and audio (collectively, “Materials”), is Republic Services’ property or the property of Republic Services’ content suppliers and protected by United States and international copyright laws. All software used on this site is Republic Services’ property or the property of Republic Services’ service provider or its suppliers and protected by United States and international copyright laws.

TRADEMARKS: Republic Services retains all rights regarding its trademarks, service marks, trade names, brand names, logos and trade dress (individually and collectively hereafter “Marks”). These Marks and all associated logos or images are registered and/or common law trademarks and are protected by U.S. and international laws and treaties. Use of Republic Services’ Property

LIMITED LICENSE: Republic Services grants to you a non-exclusive, non-transferable, royalty free, revocable, limited license to download, reproduce, use, display and distribute any Marks and Materials available through this Website that Republic Services has enabled for user download (“Available Content”) for the sole purpose of non-commercial educational use, including customer education. You may not use the Available Content for any other purpose without the prior written consent of Republic Services. All Available Content must be used solely in the form in which it was made available on the Website, unless otherwise approved in writing by Republic Services. You may not modify, alter or adapt the Available Content nor use any Available Content in combination with any other trademark or service mark without prior written consent. Any unauthorized use terminates your limited license, and we may revoke this limited license at any time for any or no reason. All rights not expressly granted to you hereunder are reserved by Republic Services.

ADDITIONAL RESTRICTIONS: Republic Services reserves the right to object to any use of its Marks or Materials, and you agree that, upon being notified of such objection, you will take prompt action to cease or modify your use of the Marks or Materials in accordance with Republic Services’ direction. You agree that you will not dispute or contest, directly or indirectly, or do or cause to be done any act which in any way contests, impairs or tends to impair, Republic Services’ exclusive rights in and to the Marks and Materials or the validity thereof, and you will not assist others in doing so. Additionally, Republic Services reserves the right to remove Available Materials from the Website, at any time and without notice to you.

SPECIAL NOTICE: Republic Services has a no-tolerance policy regarding the use of our Marks or names in metatags and/or hidden text. Specifically, the use of our Marks or names in metatag keywords is trademark infringement, and the use of our Marks or names in page text, metatags, and/or hidden text for purposes of gaining higher rankings from search engines is unfair competition. You may not, without our express written consent, do any of the following: (a) link to any web page of this Website; (b) use any meta tags or any other “hidden text” utilizing our Marks or names; or (c) frame, inline link or utilize other similar techniques to associate or juxtapose any of our Marks or other Materials with advertisements and/or other information not originating from this Website.

Miscellaneous

DISCLAIMER OF WARRANTIES: THIS WEBSITE AND ALL INFORMATION, CONTENT, MATERIALS AND SERVICES INCLUDED ON OR OTHERWISE MADE AVAILABLE TO YOU THROUGH THIS WEBSITE ARE PROVIDED ON AN “AS IS” AND “AS AVAILABLE” BASIS. REPUBLIC SERVICES MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO THE OPERATION OF THIS SITE OR THE INFORMATION, CONTENT, MATERIALS OR SERVICES INCLUDED ON OR OTHERWISE MADE AVAILABLE TO YOU THROUGH THIS SITE. YOU EXPRESSLY AGREE THAT YOUR USE OF THIS WEBSITE AND THE MATERIALS MADE AVAILABLE ON IT ARE AT YOUR SOLE RISK. WE DO NOT WARRANT THAT THIS WEBSITE, OR THE INFORMATION, CONTENT, MATERIALS OR SERVICES INCLUDED ON OR OTHERWISE MADE AVAILABLE TO YOU THROUGH THIS WEBSITE, ARE FREE OF VIRUSES OR OTHER HARMFUL COMPONENTS.

LIMITATION OF LIABILITY: IN NO EVENT WILL WE BE LIABLE TO YOU FOR ANY DAMAGES OF ANY KIND ARISING FROM THE USE OF THIS WEBSITE OR FROM ANY INFORMATION, CONTENT, MATERIALS OR SERVICES INCLUDED ON OR OTHERWISE MADE AVAILABLE TO YOU THROUGH THIS WEBSITE, INCLUDING, BUT NOT LIMITED TO, DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, AND CONSEQUENTIAL DAMAGES, LOST PROFITS OR REVENUES, COSTS OF REPLACEMENT, BUSINESS INTERRUPTIONS, LOSS OF DATA OR DAMAGES RESULTING FROM USE OF OR RELIANCE ON THE INFORMATION PRESENT, EVEN IF REPUBLIC SERVICES IS EXPRESSLY ADVISED ABOUT THE POSSIBILITY OF SUCH DAMAGES.

DISPUTES: Any dispute between you and Republic Services concerning this Website or the Materials located on this Website shall be submitted to final and binding arbitration as the sole and exclusive remedy for such controversy or dispute, provided, however that Republic Services may commence action against you in a court of law for infringement of Republic Services’ intellectual property rights. BY AGREEING TO ARBITRATE, EACH PARTY IS GIVING UP ITS RIGHT TO GO TO COURT AND HAVE ANY DISPUTE HEARD BY A JUDGE OR JURY. Any claim required to be submitted to arbitration shall be made by filing a demand for arbitration within one (1) year following the occurrence first giving rise to the claim. The right and duty of the parties to resolve disputes by arbitration shall be administered exclusively by JAMS pursuant to its Comprehensive Arbitration Rules and Procedures then in effect. The decision and award of the arbitrator shall be final and binding and the award so rendered may be entered in any court having jurisdiction thereof. The arbitration shall be held and the award shall be deemed to be made in Maricopa County, Arizona, United States of America, or such other place agreed to by the parties. Each party shall bear all of its own costs of arbitration, except that the fees of the arbitrator shall be divided equally between the parties. The arbitrator shall have no authority to amend or modify these Terms or to award punitive or exemplary damages, and the award may be enforced by judgment in a United States Court of Law.

SEVERABILITY: If any provision in these Terms shall be deemed invalid, void, or for any reason unenforceable, that provision shall be deemed severable and shall not affect the validity and enforceability of any remaining provisions.

APPLICABLE LAW: You agree that the laws of the State of Arizona, United States of America, without regard to principles of conflict of laws, will govern these Terms and any dispute of any sort that might arise between us.

CHANGES TO TERMS: Republic Services reserves the right to change these Terms at any time, and in its sole discretion, by making modified Terms available via the Website. Your use of the Website after any such changes to these Terms are made available will constitute your acceptance of those changes.

I accept the terms and conditions.

You are using an outdated browser. Please upgrade your browser to improve your experience.

- Get the app:

- Android

- iPhone

- 3R Programmes and Resources

- The National Environment Agency

- Our Services

- Waste Management

National Recycling Programme

- Where to Recycle E-Waste

- National Voluntary Partnership for E-Waste Recycling

- Extended Producer Responsibility (EPR) System for E-waste Management System

- Food Waste Management Strategies

- Food Distribution Organisations, Local Recycling Facilities and Suppliers

- Food Waste Valorisation

- Food Resource Valorisation Awards

- Packaging Partnership Programme

- Recycling / Collection Points

- Types of Recyclables and Recycling Processes

- 3R Guidebooks

- Reducing Our Use of Disposables

- Zero Waste Manager Course

- Waste Collection Systems

- Tuas Marine Transfer Station

- Waste-To-Energy Incineration Plants

- Sarimbun Recycling Park

- Integrated Waste Management Facility

- Solid Waste Management Infrastructure

- General Waste Disposal Facility

- Illegal Dumping

- Disposal of Bulky Items, Garden Waste and Dead Pets

- Mandatory Waste Reporting

- Waste Statistics and Overall Recycling

- Reverse Vending Machines

- Mandatory Packaging Reporting

- Donation, Resale and Repair Channels

- Beverage Container Return Scheme

- Disposable Carrier Bag Charge

Public waste collection sectors

Collection system

The NRP adopts a collection system in which paper, plastic, glass and metal recyclables are deposited into the same blue recycling bin for collection by the PWCs. To find out what can be recycled, please check out Bloobin’s Recycling Guide for his advice on the common list of recyclables or the Recycling Search Engine .