The Ten Stages of Building Cruise Ships

From steel-cutting to maritime traditions

It feels like a new ship is being launched every other month currently, and to be honest, you would be right.

The cruise industry is undergoing explosive growth right now and the thirst for bigger, better and more exciting ships has never been so great!

The Initial Order

Everything starts with an order. Although shipyards around the world are pretty busy, we’re not quite at a stage yet where rival cruise lines are buying construction slots “just in case” then selling them as airlines do with planes.

Generally, a shipyard will have several ships being built at the same time, all in various different stages and many ships placed in their order books as either confirmed or as ‘an option’ – which allows the cruise line to cancel or postpone the build if necessary.

It is at this stage that the cruise line will announce they’ve placed an order for a new ship and it is usually around 3-4 years away. No name or any details is given at this stage, just the tonnage, possible class of ship (for example a sister ship or a brand new design) and usually the passenger capacity.

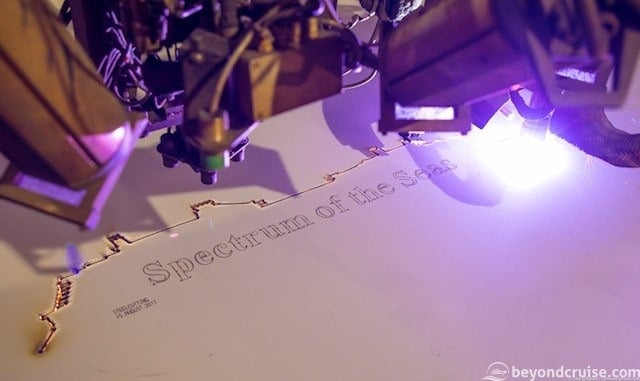

The Steel-Cutting Ceremony

By the time we get to the steel-cutting ceremony, the cruise line is starting to generate some press about their new ship. At this point, the ship is usually given a name publicly, although in some instances she may still only have a build number which is referenced on her hull. The first steel is cut in front of senior management from the cruise line, the shipyard and the press. What you’ll actually see doesn’t really resemble anything but laser-cut steel at this point!

This process continues for months as the shipyard creates lots of pieces of steel all cut into different shapes and sizes which are then welded together to make sections or ‘blocks’.

The Keel-Laying Ceremony

The next important part of building a ship is the laying of the keel. The keel is the lowest (or bottom) of any ship and will be part of the first block that is lowered by massive cranes into the dry dock or basin as it is sometimes called.

At this point, there is usually a coin laying ceremony . Specially commissioned gold coins are laid in the keel block to symbolise good luck. Sometimes they are welded in and at other times, they are just placed in and then retrieved later on and then used in a mast stepping ceremony, where the coins are welded under the bottom of the main ship’s mast. These days cruise ships don’t have a mast like sailing ships and therefore they are placed under or attached to the very bottom of the radar mast and left on display.

The coin ceremony is carried out by the Godmother ( Madrina ) of the ship. The Godmother at this point isn’t the same as the official Godmother that will name the ship when she is finished, instead, it may be someone important from the cruise line or occasionally two people, one from the shipyard and another from the cruise line.

The keel is then laid with exact precision, usually using GPS coordinates which are accurate to the centimetre. We now have (part) of the bottom of the new cruise ship!

As modern ships are now built by block (like Lego!), there is an ongoing process in the shipyard. Engineers will construct new blocks in one area of the shipyard whilst in another area large cranes will lower completed blocks into the dry dock and more engineers will weld together the large sections. These sections can commonly weigh in at 150 tonnes or more with ease.

Eventually, you end up with something on the outside looking like a cruise ship. Although the inside is generally bare at this point apart from structural things like decks and staircases. Temporary lifts will be fitted at the side of the ship and large equipment and more steel will be either lifted or craned onto the ship. From the outside, your ship will look a familiar shape, but her paintwork will be patchy in places and she may not have any glass or outdoor facilities fitted yet.

As the months progress the ship has her azipods fitted (propellers fitted to large shafts which can rotate 360 degrees allowing the ship to move in any direction) and she is now pretty much waterproof, at least from below.

The Float Out

The Float Out is a large milestone in any ship’s build. At this point, there are 100s of workers working on every area of the ship, sometimes in rolling 24/7 shifts depending on how quick the cruise line wants their ship and how many ships the shipyard has on their order books!

By now, cabins – which are usually made in a factory nearby and prefabricated are literally craned or lifted onto the ship and then slotted in next to each other like jigsaw pieces. The plumbing and wiring are connected to each cabin or “pod” and it is ready to go – just needing bedding and other small furniture items adding!

The ship gets to a point where it is ready to be moved out of the dry dock for the first time. Press are gathered, cruise line management, workers who have helped build the ship and even some local dignitaries may also attend. There is a speech, generally by the Chief Engineer and he gives thanks to the builders and talks about the milestones they completed and then the shipyard and cruise line representatives also give speeches.

Then, the Godmother (still not the official one that will name it!) will smash a bottle of champagne over the bow of the ship and everyone will gather at the rear of the ship as the dry dock is flooded for the first time.

Depending where the ship is being built, other maritime traditions may also take place – commonly a sample of the first water to touch the ship’s hull is collected and kept in a sealed bottle (called an ampoule) . It is then presented to the Captain of the ship who will have it on display in his office near the Bridge.

Now the ship is floated out it will be moved to another part of the shipyard for the rest of the fit-out.

The fit-out can usually take months and the ship is usually alongside in the shipyard whilst the next ship to be built is being put together in the drydock. The shipyard operates like a game of chess as ships move in and out of the drydock area and alongside to maximise productivity.

The Sea Trials

The ship still isn’t complete, glass and various other parts might be visibly missing from the ship. But it is now time to test the ship at sea. Commonly sea trials last from a day to several depending on how complex the ship is, especially if it is a new class. The ship will be loaded with the crew, shipyard officials and also representatives from the insurance companies and also people like the British MCA (Maritime & Coast Agency) who will certify the ship as seaworthy.

The ship will perform various manoeuvres including seeing how quick she can stop, a compass swing (to calibrate the ship’s compasses) and the crew will also get used to how she handles at different speeds. No two cruise ships are generally the same, especially when technology changes at such a fast pace, a ship built just a year later may benefit from better hull design or more efficient engines.

After the sea trials, the ship is brought back alongside or even into a drydock again whilst her internal fit out is completed and her hull and the rest of her external paintwork is completed.

The Handover Ceremony

At the handover ceremony, senior representatives from the shipyard, the cruise line and the press are in attendance. At this point, the ship looks like a ship you could board tomorrow – however, it is probably empty of supplies and the majority of the crew will be flying in from all around the world to join the ship for the very first time.

The ship will load some basic supplies and may set sail to its homeport or wherever the naming ceremony is taking place.

The Shakedown Voyage

This voyage is nothing like a cruise you would want to experience! During this voyage, which may last anywhere from 1-7 days the ship will relocate from the shipyard to its new homeport for the season or where it will be named.

The shakedown voyage will possibly include a full ship. Certainly, all crew will be on board, learning everything about their new workplaces. The passenger cabins may also be occupied with workmen from the shipyard installing and carrying out finishing touches around the ship. Additionally, marketing staff will join the ship at this point and take all those lovely photos and videos of the ship whilst everything is looking brand new and is free of passengers!

The Inaugural Voyage

Not all cruise lines do this, but some do sell a pre-maiden voyage if the ship is looking like it will be completed earlier than expected.

The inaugural voyage is sometimes for members of the media and travel agents only. It can last anything from 1-3 nights and sometimes it might not even be a full voyage but could just be alongside in the homeport whilst invited guests come to visit and tour the ship.

The Christening Ceremony

This ceremony is the final milestone in the ship going to sea and starting its life with paying passengers. A large naming ceremony is very popular, with representatives from the cruise line, shipyard, cruise industry and the media all in attendance. Depending on the cruise line the Godmother might be someone who is famous, Royalty or tradition. It might even be someone who won a competition!

The Godmother blesses the ship and smashes a bottle of champagne across her bow. The tradition goes if the bottle doesn’t break on the first time, it is bad luck!

The Maiden Voyage

This is what you all have been waiting for, right? The ship is now ready for paying passengers to enjoy the very first voyage on the ship – in restaurants that haven’t been eaten in and beds that haven’t been slept in! The Maiden Voyage is usually quite special and may actually be a repositioning voyage rather than a normal itinerary. The cruise line may choose to give everyone who travels special commemorative gifts to mark the maiden voyage. This can sometimes be drawn out to a Maiden Season as the ship visits new ports for the very first time on each cruise.

After this, the ship will keep on performing cruises day-in-day-out, without stopping until her next dry dock. Legally the ship must undergo a dry dock for a full hull inspection every five years, at that point cruise lines usually refurbish carpets, cabin materials and sometimes reconfigure bars or restaurants depending on the current trends. Sometimes some ships may perform a dry dock period sooner if the cruise line wants to increase the number of cabins or facilities onboard.

We hope you enjoyed this article about building cruise ships – if you want to see more of what we do, then Like our Facebook page , Follow us on Twitter or Instagram and come and join our Cruise Fans group !

Similar Posts

P&O Iona Introduces New Style of Accommodation

Bookings for MSC Grandiosa now open!

MSC Preziosa Live (2022) – Day 1 Southampton

Cunard World Cruise 2016: Queen Elizabeth itinerary

Harmony of the Seas: The Ultimate Abyss slide in detail

Day 7 – Malaga, Spain

- Credit cards

- View all credit cards

- Banking guide

- Loans guide

- Insurance guide

- Personal finance

- View all personal finance

- Small business

- Small business guide

- View all taxes

You’re our first priority. Every time.

We believe everyone should be able to make financial decisions with confidence. And while our site doesn’t feature every company or financial product available on the market, we’re proud that the guidance we offer, the information we provide and the tools we create are objective, independent, straightforward — and free.

So how do we make money? Our partners compensate us. This may influence which products we review and write about (and where those products appear on the site), but it in no way affects our recommendations or advice, which are grounded in thousands of hours of research. Our partners cannot pay us to guarantee favorable reviews of their products or services. Here is a list of our partners .

How a New Cruise Ship Is Built

Many or all of the products featured here are from our partners who compensate us. This influences which products we write about and where and how the product appears on a page. However, this does not influence our evaluations. Our opinions are our own. Here is a list of our partners and here's how we make money .

Cruise ship construction is an enormous undertaking that involves thousands of decisions and logistical planning protocols that must be precisely set and coordinated in just the right order.

Watching a ship come together is a fascinating process, and I was able to witness it firsthand in Saint-Nazaire, France, where the Celebrity Apex was being built as the second in a series of five Celebrity Edge ships at the Chantiers de l’Atlantique shipyard.

The scope of building a ship

The ship is actually built in stages, often in different locations before being put together like a jigsaw puzzle or a game of Legos. It comes together as the result of 1,000 key steps, 200,000 different tasks, and the involvement of 500 subcontractors and suppliers. According to shipyard officials, each shipyard completes the process a bit differently.

For the Celebrity Apex, it has taken one year to go from having its first pieces of steel cut and prepared to seeing the final touches added before its March 2020 delivery to Celebrity Cruises.

More than 1.5 million manpower hours are involved in putting such a large ship together. In fact, the building of the ship begins even while engineering work is still going on; such is the large-scale nature of this process.

3D imagery and virtual reality are used in creating the mockups and models, which allow interior designers to take tours of the ship before it is built. They can decide where to most efficiently install electrical outlets or piping, as well as how the style of the interiors will come to life. No one wants a power outlet on the ceiling!

This process also allows designers to work on various parts of the ship simultaneously instead of needing to have each be ready before another can start.

» Learn more: Does cruise travel fit into your points and miles strategy?

Starting construction

It takes six months to build the outer structure of the ship, which is then stocked with passenger cabins, restaurants, public areas, bathrooms, and hundreds of miles of electrical wires and plumbing pipes.

Large cranes capable of lifting 1,400 tons at a time put each of the pieces together into what we recognize as a cruise ship.

Stacking cabins like Legos

For me, the most surprising element of ship construction was that most of it is actually built elsewhere. The ship as a whole consists of dozens of smaller parts, including cabins, which are each built at an assembly line.

The assembly line includes the installation of almost all passenger amenities — light fixtures, wiring, power outlets, furniture, TVs, beds, bathroom fixtures and even trash cans — so that when cabins are stacked into the ship, their electrical wires and plumbing can be instantly connected to the rest of the vessel. There is little additional work that needs to be done once the cabin is loaded onto the ship.

In fact, more than 3,000 miles of electrical wires come affixed to the cabin; some suites have even more due to their more spacious quarters. Everything must arrive to the ship at the right time and at the right place.

One installed in the ship, each cabin is furnished with decor and amenities in as few as 20 minutes, as staffers pass through installing facilities and cross-check one another's work.

If you think about it, the cabins must come furnished because large items like beds and sofas would not fit through many ship doorways or hallways. Once the cabins are stacked across the previously built hull, the steel sides are wrapped around the vessel. Designers had left cutouts where the windows and balconies belong.

Altogether, more than 40 individual blocks and 500 panels — each constructed off-site — are eventually integrated into the ship’s frame, which composes 250,000 steel parts representing 25,000 tons of steel.

» Learn more: Our family vacation: A Mexican cruise for 5

Wood, weight and 'wow factor'

Wood is not allowed in the construction of the ship because it can easily burn. Those walls in your room might be covered by wallpaper and artwork, but they are actually made from metal and steel.

The weight of the ship must be balanced and optimized, with a focus on keeping the center of gravity low to the waterline. Celebrity Cruises has a team that manages the weight of everything aboard the ship. Once designers choose what they want to install on the ship, a separate team of engineers gets involved to see if there are more lightweight options to use.

It is a balancing act to reduce weight while also maintaining the overall design aesthetic and “wow factor” of the ship.

Heavier materials are less efficient at the top of the ship; no one wants a top-heavy ocean liner. Thus, the Celebrity Apex uses a more eco-friendly material that looks just like glass for the transparent atrium in the Solarium — though it weighs only 1% of what glass would weigh. Other materials like lightweight carbon fiber help offset the weight of steel and fuel tanks.

Even the smallest details like room and public area signage is examined by a variety of teams from lawyers to marketing experts. To convey important messages, the cruise line wants to be informative without being stern.

For example, small placards by toilets in cabin bathrooms say, “Excuse me, only toilet paper please.” Throwing anything else into these vacuum toilets can cause plumbing stopups.

» Learn more: Should you insure your cruise?

What’s new on board

Adding new amenities for passengers can sometimes pose challenges for designers. New features like the Magic Carpet (also aboard sister ship the Celebrity Edge), required plenty of additional planning.

This cantilevered deck ascends the side of the ship between decks 2 and 16, allowing guests to dine or gather with panoramic views while more comfortably boarding smaller tender boats to go ashore when needed. It essentially is an external elevator on the side of the ship.

In the trilevel Grand Plaza area, the Martini Bar features over 700 LED lights in crystallized lenses designed to dance in coordinated fashion for dramatic effect. If lined up on the ground, these lights would span more than half a mile.

A Spa Thermal Suite adds eight different therapeutic experiences like a salt room, massaging Rainfall Water Therapy room, Iyashi Dome sauna (said to cleanse and detoxify the body), and new treatment tables. It also features the first F45 fitness classes at sea as well as a Kerastase Institute beauty salon.

Each of these elements requires significant plumbing and wiring design, which is different from the systematic approach found in cabins and must be integrated into the overall maze of pipes on the ship. The spa’s design, especially, requires unique setups for plumbing and piping.

A 23-foot 4K LED screen curving around the main theater stage is fitted with laser projectors for wraparound lighting during stage shows.

And Eden, a combined dining and lounge space, features a canopy of leaves, which are more than decorative — they shield the view of electronic equipment and lighting.

» Learn more: I survived a cruise — and you can too

The bottom line

On this ship, I found everything seemed to fit together with precision and often served to function both for internal use and passenger appreciation.

The next time you travel aboard a new cruise ship, look closely to appreciate the myriad details that came together to create it.

Photos courtesy of Celebrity Cruises and Ramsey Qubein.

How to maximize your rewards

You want a travel credit card that prioritizes what’s important to you. Here are our picks for the best travel credit cards of 2024 , including those best for:

Flexibility, point transfers and a large bonus: Chase Sapphire Preferred® Card

No annual fee: Bank of America® Travel Rewards credit card

Flat-rate travel rewards: Capital One Venture Rewards Credit Card

Bonus travel rewards and high-end perks: Chase Sapphire Reserve®

Luxury perks: The Platinum Card® from American Express

Business travelers: Ink Business Preferred® Credit Card

Planning a trip? Check out these articles for more inspiration and advice: Find the best travel credit card for you How to get the best deal on your next cruise Your money-saving guide to vacations

on Chase's website

1x-5x 5x on travel purchased through Chase Travel℠, 3x on dining, select streaming services and online groceries, 2x on all other travel purchases, 1x on all other purchases.

60,000 Earn 60,000 bonus points after you spend $4,000 on purchases in the first 3 months from account opening. That's $750 when you redeem through Chase Travel℠.

on Bank of America's website

1.5x-2x Earn unlimited 2 points for every $1 spent on travel and dining purchases and unlimited 1.5 points for every $1 spent on all other purchases.

60,000 Receive 60,000 online bonus points - a $600 value - after you make at least $4,000 in purchases in the first 90 days of account opening.

- CruiseMapper

- Cruise news

- Cruise Industry

- How are Cruise Ships Built? Discover the Construction...

How are Cruise Ships Built? Discover the Construction & Engineering Behind these Treasures of the Sea

Have you at any point gazed at a huge cruise ship and considered how it was able to remain above water? Many cruise ships constantly travel to Alaska and Hawaii during the summer. During the winter, an abundance of cruises are available to go to Mexico, the Caribbean, and other locations in the South Pacific. Considering the continuous growth & development of the cruise sector, the several types of materials & metals required for assembling the ships, we thought it's worth taking a deeper dive here into the full construction involved.

The Components used for Construction of Cruise Ships

Every one of the heaviest sections of the ship like the powerplants, engines, ballast, water, and fuel tanks are kept at the lower part, 20% from the bottom of the ship in order to ensure the ship remains upright. Ideally, underneath the waterline which is used to make sure the ship remains steady and reduces the center of gravity. The 80% left over part of a regular cruise ship is created to be employed by passengers, which is light and open as it can be.

Looking higher up the cruise ship, you will realize that it gets more open and lighter in weight which is aimed at limiting the weight. The pool is only an exception. Apart from being extremely heavy, you can only get the best view at the top which makes the swimming pool located there.

The materials are properly chosen and are also based upon your location in the vessel. Close to the upper part of the ship, the prominent selections are high durable steel and aluminum. This provides the best available strength-to-weight ratio. Carbon fibers and fiber strengthened plastics are now been tested on more recent vessels as these materials are quite new and pretty uncommon. Getting a little lower, hotter rolled steels would be found. The crucial features here are heavyweight and durability which allows designers to employ thicker materials in this section.

The part that requires more strength, usually very complicated and developed first is the hull. It has the shape of a massive metal tube with several supports and leak-proof rooms inside it. This is vital because several stresses are exerted by the ocean on ships. Tubes are part of the shapes that have the most mechanical strength in the world but it gets weaker when holes are drilled into it like it is required for doors. This makes the door locations to be planned properly which is then strengthened by the structural support.

The massive structure is then fitted at the top after the completion of the hull. But this massive structure spaces of the entire cabin and activity area remains open. The cabin and other components are assembled in a contained environment that is not on the ship just like a car. After the construction of these flat-packed spaces, they are then integrated into the massive structure and installed like the plugging in a huge LEGO.

Several facades are present in many of the rooms looking into the ship. Considering those attractive sheets of surfaces of wood and marble, they are actually artificial wood on light, durable and frames of metal or thin stony sheets. Stainless steel and ceramics are also very common since they are very durable, cost-effective and incombustible.

Crucial Ship Rigging Equipment

Rigging is an important component of ship employment. Riggers set up ships’ parts & equipment for transports by the crane, hoists or other material handling equipment.

When considering ship rigging tools, you’ll be majorly getting involved with hooks, eye straps, swivels, pulleys, and other devices. Even though many of these materials are quite simple and modest. An effective rigging task can only be achieved with all these tools working collectively.

In regards to lifting tools, you typically would be looking at chokers, hooks, halyards, eye straps, connectors, blocks, swivels and many more. Each of these small devices plays a major part in pulling off a rigging job.

Other components such as the ropes and dynamometers are also very crucial when performing rigging and lifting tasks.

The demand for guy wire or wire rope in the marine industry is numerous whether during the start of the construction process of the ship or when harboring the ship at the docks. Heavy strains, pressure and loads are usually involved irrespective of what the wire ropes will be used for. A thin rope can obviously not be able to harbor a ship at the docks. Lifting materials are usually developed to carry out numerous tasks that involve heavy pressure and strain which makes it a top choice for the marine industry.

During the start of a marine procedure, the wire ropes are also employed to build the ships since it is usually employed with cranes when performing lifting tasks in the engineering and construction industry. Ships developed with solid and enormous materials and the best equipment that can help to move them around in a building site is by using wire ropes.

Apart from the lowering and lifting jobs carried out when building a vessel, cranes found in the docks and on the ships are also beneficial when transferring cargos. Concerning the point mentioned above, the best choice for transferring heavy loads is still the rope.

The components are as well beneficial in securing vessels at the docks. The weight of the ships is without any doubt very heavy and one of the tools that can position them securely without floating off is the rope.

The ready-made strategy is usually not far-fetched however, the monstrosity of the scale makes the construction of a heavy ship an enormous task. The construction process incorporates many years of preparation and design procedure along with millions in cost of materials and workers. Ships that are as enormous as the Quantum of the sea with a construction cost of about $1.6 billion. However, in the end, a beautiful transportation masterpiece arises that can be appreciated for years to come.

Building Cruise Ships: The Ultimate Guide

Since the introduction of the world’s first bona-fide cruise ship Prinzessin Victoria Luise in 1901, cruising has developed into a multi-billion-dollar industry.

There are currently over 320 cruise ships sailing worldwide, which represents only a tiny fraction of the estimated 99,800 cargo ships around the world.

2018 was the busiest year ever for the cruise market. An incredible 26.5 million passengers were carried across all the world’s cruise ships. Shortly after this, numbers plummeted due to the pandemic, but cruise lines are recovering. Many companies downsized their fleets in order to cut costs, selling off older and smaller vessels in favour of larger vessels capable of carrying more passengers.

While cruise ships have a fairly long lifespan – usually at least 25 years – there is a steady need to replace old ships and expand fleets, so shipyards still do good business in building new cruise ships.

Where are most ships built?

According to Statista , there are an estimated 283 shipyards around the world. Asia rules the world when it comes to shipbuilding. South Korea is the leading nation in shipbuilding by tonnage produced, closely followed by China and then Japan. These three nations are responsible for over 80% of new ships by tonnage.

Incredibly, of the 283 shipyards producing merchant ships, there are only four shipyards in the world capable of building modern cruise ships .

Fincantieri is the largest shipbuilder in Europe, and the fourth largest shipbuilder in the world. Arguably the leading shipyard for building cruise ships, Fincantieri is responsible for the construction of one third of the world’s cruise ship fleet.

STX Europe has operated under a number of different names, and now builds cruise ships solely in France. The world’s largest cruise ship by gross tonnage, Wonder of the Seas , was completed in their Saint-Nazaire shipyard in January 2022. In the past, STX Europe operated a yard in Finland which constructed ships for Royal Caribbean, TUI Cruises, Viking Line, and others.

Meyer Werft is a German shipbuilding company which has been owned by the Meyer family for seven generations. Their German yards are home to the largest roofed dry docks in the world. Unusually, due to the inland location of Meyer Werft’s shipyard in Papenburg, ships built there must make a 36-kilometre voyage up river Ems to reach open sea once launched. In 2014, Meyer Werft purchased a majority share of STX Europe’s Finnish shipyard.

Mitsubishi Heavy Industries is located in Japan and its Nagasaki shipyard has the smallest output of cruise ships among the four shipbuilders. In 2016, Mitsubishi announced that due to huge losses sustained on previous orders, it would no longer be taking orders for massive passenger ships, instead limiting itself to small and midsize cruise ships.

Cruise companies do not necessarily stick with the same shipyard to build all of their ships. They will opt for the yard which can offer them the best deal in both price and availability. Princess Cruises, for example, have had ships built by Fincantieri, STX Europe, and Mitsubishi.

How to build a cruise ship: a timeline

All cruise companies will have succession plans for each of their ships. These plans may be influenced by market trends and the success of the business, but they will have a general idea of when they intend to order new ships.

Once a company has decided that it wants to build a new cruise ship, it will begin the planning stage around 3-4 years before the ship’s intended launch date. This involves drawing up a rough design of the proposed vessel, with general details such as size, number of passengers, and unique features being decided upon.

The company will then open discussions with some or all of Fincantieri, STX Europe, Meyer Werft, and Mitsubishi to get an idea of the availability and rough price of each yard.

The build cost will vary as material costs in shipbuilding can fluctuate quite a lot. Steel, for example, has seen a large surge in price in the last 18 months. Even the location of the shipyard can incur extra costs – Mitsubishi attributes some of its past losses on building large cruise ships on the fact that it had to import so many parts from Europe to meet European passengers’ preferences.

You may find it surprising how quickly a cruise ship can be built. Considering their size and the attention to detail required in their interior design and finishes, it seems remarkable that a cruise ship can be fully constructed, launched, and ready for passengers in under 12 months . This is achieved by incredible efficiency in the build process.

Approximately 18 months before the planned launch date, the steel cutting ceremony takes place. Although called a ‘ceremony’, this is typically a low-key affair. At the ceremony, the very first plates of steel that will be used in the ship’s construction are cut into shape. After this point, it takes around six months for all of the ship’s steel to be cut into the correct size and shape, ready to be assembled.

Approximately 1 year before the planned launch date, the keel laying ceremony takes place. This is the first major ceremony in a ship’s life and will be attended by executives from the cruise company and the shipyard because this officially marks the exciting first day of the building project after many years of planning.

Traditionally, a keel laying ceremony involved the literal laying of the actual keel – the central piece of timber which made up the backbone of the vessel. In modern ship construction, vessels are built in many small sections which are fabricated and then transported to the dry dock to be welded together, so nowadays the keel laying ceremony will usually consist of the first prefabricated section being placed into the dry dock.

One major part of a cruise ship’s keel laying ceremony is the placing of the coin under the mast . This is the continuation of an ancient ceremony which is believed to date back to Ancient Greece, where the coin was intended to pay the ferryman Charon across the River Styx should the ship sink. These coins are usually placed where they will be visible to passengers, so if you are ever on a cruise ship have a look for it!

You may have noticed that there are a fair few ceremonies involved in the building of a ship. Considering the superstitious and traditional nature of seafaring, it’s not surprising that these ceremonies are still happening today.

After the keel laying ceremony, the ship’s construction really begins. Prefabricated sections of the ship’s hull and superstructure are constructed in yards away from the dry dock before being lifted into place on the keel blocks in the dock and then being welded together, one layer at a time.

As the decks are built up, essentially machinery is also installed. The engines and machinery in cruise ships’ engine rooms are absolutely massive, and this is the easiest way to get them into the belly of the ship, before decks are added above them.

One very important aspect of cruise ships is not installed until the shell of the entire ship is completed, however – the cabins .

All cruise ship cabins are constructed as individual units off-site. Carpet is laid, wardrobes, beds and tables added, and plumbing and wiring installed. Each cabin is in a self-contained metal box, which is crafted to specific measurements so that the cabins all sit flush to one another once installed.

Once constructed, each individual cabin is craned into place and slots into position, its magnetic walls helping it to sit firmly in place.

Once the shell of the ship is completed, it is time to complete the interior work. Public spaces such as atriums, theatres, and restaurants are all fitted out with their equipment before the focus turns to perfecting the aesthetics of the ship’s interior.

Once the exoskeleton of the ship is finished and all cabins are in place, the outside of the ship is painted and the ship’s name is added to the transom and to each side of the bow. Each cruise line has its own colour scheme for the outside of its ships, with AIDA, Norwegian Cruise Line, Cunard, and Holland America Line ships all being immediately recognisable simply from their exterior paintwork.

It is well known that most cruise ships are painted mostly white above the waterline. If you’d like to find out why, check out our video:

You may have noticed that all merchant ships, not just cruise ships, are painted a different colour below the waterline. Check out our video below to learn how using different paint below the waterline can save shipping companies millions of dollars over the lifetime of a ship:

External machinery such as rudders and propellers are also installed at this stage. There are many different types of propulsion used by cruise ships, and they all work in different ways. The fuel efficiency, manoeuvrability, and speed of a cruise ship can vary depending on which type of propulsion she has installed. To learn more about the different types of propulsion that a cruise ship can have, check out our article: Do Ships Have A Reverse Gear?

After over 130,000 hours of planning and 2,000,000 working hours in the shipyard (according to Fincantieri ), the ship will be ready to be put into the water for the first time. This is known as the launching ceremony .

In the past, this would be combined with the naming ceremony of the ship. However, cruise companies like to be able to stage these naming ceremonies in their preferred location for marketing and PR purposes, so it is more common for these ceremonies to be staged separately.

Once she is floated, she will undergo sea trials .

Sea trials involve up to three days of intense testing of the ship. Insurers, executives, surveyors, and essential navigational and engineering crew will all be onboard the ship as her manoeuvrability is tested to the limit.

The data collected from these sea trials will be collated and used to create a wheelhouse poster displaying the manoeuvring capabilities of the ship, including crash stop time and distance and turning circle at various speeds and rudder angles.

Once sea trials are complete, the ship’s first crew will come onboard and begin an intense period of familiarising themselves with the ship, drills, and training. If the ship has an identical sister ship already in the fleet, it is common for officers who are familiar with the sister ship to be assigned to the new ship to expedite the learning and training process.

Once the crew are all fully familiarised and the ship has been fully inspected and audited by its Flag State, it will sail to its home port for the biggest ceremony of all – the naming ceremony .

A cruise ship’s naming ceremony is a high-profile affair featuring celebrities, executives from the cruise company and shipyard, journalists, and often royalty. It is a long-standing naval tradition – not restricted to cruise ships – for a godmother to be appointed to the ship.

The ship’s godmother is responsible for smashing a bottle of champagne against the ship’s hull, which is said to bring good luck to the ship and those who sail on her. Conversely, it is said to bring bad luck to a ship if the champagne bottle does not smash on the first attempt.

Of course, that’s just a superstition. By the way, the bottle did not smash during the Costa Concordia’s naming ceremony…

Ships and their godmothers

A wide range of women have been asked to be godmothers to cruise ships in the past. Famous godmothers include Queen Elizabeth II (Queen Mary 2, Queen Elizabeth), Helen Mirren (Ventura), Julie Andrews (Crystal Serenity), and Sophia Loren (eight different MSC ships).

It is not always celebrities who are chosen to be godmothers to cruise ships, however. Some companies have used the title of godmother to honour women who have accomplished great things or who have overcome incredible hardships.

For example, Royal Caribbean chose Katherine Louise Calder to be godmother to the Freedom of the Seas . Katherine had fostered over 400 children with additional needs over three decades, and is certainly deserving of her recognition.

How do cruise ships last so long?

Because they are constantly in the public eye, cruise ships receive a lot more care and attention than most other merchant ships. They have a much higher budget for maintenance and paintwork, and they also go to dry dock more often than cargo ships.

Passenger ships are legally required to dry dock two times every 5 years, with a maximum period of 36 months between dry docks. It is a general rule that ships carrying passengers must adhere to the strictest legislation regarding their architecture, safety, stability, and maintenance.

In dry dock, the ship will undergo essential maintenance that is not possible with passengers onboard, some of which can only be done while the ship is out of the water.

Some of the major dry dock jobs include stripping all of the anti-foul paint off the hull and re-painting it. This not only makes the ship look better, but it also improves fuel efficiency by removing any marine life that had called the ship’s hull home.

Maintenance of major equipment such as the rudder and propeller shafts is undertaken. Anchors are paid out and their chains are re-painted and checked for corrosion. The condition of all the ship’s tanks is also inspected.

With proper planning and maintenance, regular dry docks can extend a cruise ship’s life beyond three decades. As long as the champagne bottle smashes on the first attempt…

A Look into New Ship Building Methods

Building cruise ships is a massive undertaking. Years of planning and design are carried out even before construction begins, and the movement from factory to dry-dock and launch is another rigorous step. It takes approximately 2 years from start to finish, but it can take longer or less depending on the size of the ship.

Designing A Cruise Ship

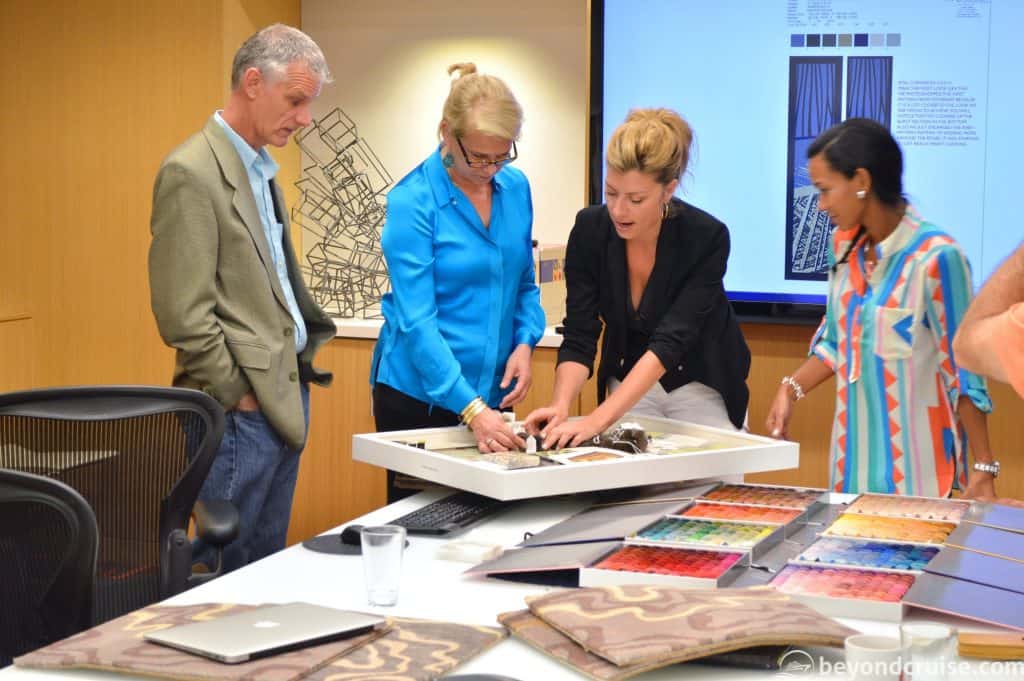

The cruise lines hire a design firm to come up with the latest concepts ranging from restaurants to staterooms and innovative public spaces. The vessel’s interior design must match the demographics and embrace the company’s market segment.

The design firms are involved in every facet of the design process, including typography on signage, elevator buttons, carpets and furniture – most of which is custom designed and produced for a specific ship. Cabins and public areas are designed with a standard service life of 30 years; interiors must stand the test of time and changing trends. Staterooms must be highly functional being as light as possible to help save fuel.

Each cruise line looks to find their own unique spot in the market, driven not only by price and product, but by style and functionality to create the experiences offered onboard. Cruise lines are pushing the envelope by the day, and it all starts with a blank piece of paper under the eye of a designer.

Building A Cruise Ship

We know cruise ships are built in shipyards. But what exactly is a shipyard?

At the shipyard, you’ll find large cranes to position each part of the ship into place, machinery to prepare and secure the hull, dry docks, painting facilities, equipment to weld portions of the ship together and slipways that allow for completed portions to be floated in the water. The largest shipyards in the world include Fincantieri in Italy, Meyer Werft in Germany and STX Europe with locations in Finland and France.

The ships are not built entirely on site, c ertain pieces are built off-site and brought to the shipyard to be added to the growing vessel. For example, while the shipyard constructs the hull, the passenger cabins are prefabricated in the workshop before being fitted on the ship like giant Lego pieces. In fact, much of the ship, including steel hull plates are constructed in a modular approach. Modular methods are used out of necessity as well as convenience.

The hull first takes shape on land before the rest of the ship’s pieces and parts are placed on top. To validate the hull’s structure, dams unleash torrents of water in a controlled factory-test environment before the entire ship is eventually pushed into a real body of water.

Fun Fact …. Cruise ships are built upside down in separate sections. Why? Because it’s easier for builders to weld each plate of steel in a downward direction, rather than upwards with their backs facing the ground.

Access Cruise is a Miami based cruise marketing and sales consulting group, specializing in product and business development within the cruise industry.

Recent Posts

- Vacation Blues Episode 31 – Hardangerfjord, Norway – The Queen of the Norwegian Fjords

- Vacation Blues Episode 30 – Flåm, Norway

- Vacation Blues Episode 29 – Gothenburg, Sweden

- Vacation Blues Episode 28 – A Coruña, Spain

- Vacation Blues Episode 27 – Vigo, Spain

- Vacation Blues Episode 26 – Arendal, Norway

- Vacation Blues Episode 25 – Isle of Man

- Vacation Blues Episode 24 – Dover, England

- Vacation Blues Episode 23 – Aberdeen, Scotland

- Vacation Blues Episode 22 – Lisbon, Portugal

- Cruise News

Exclusive: Behind the Scenes Construction Photos of Princess’ Groundbreaking New Ship

Doug Parker

- March 11, 2023

I just got back from Fincantieri shipyard in Malfacone, Italy, where Princess Cruises’ latest ship, Sun Princess , is coming together… one weld at a time.

When completed, the 175,500 gross registered ton ship will be the largest vessel in the Princess fleet. And while she still has a long way to go, some of the signature elements one expects from the line can already be spotted in these photos.

Other elements, including many which will be unique to Sun Princess , aren’t yet in evidence.

Years In the Making

Building a cruise ship is a complex and time-consuming process that requires years of planning, designing and, eventually, construction. Just ask Richard Parker, director of newbuilds for Princess Cruises. Parker — no relation, by the way — said he’s been waiting six years to see Sun Princess come together.

While Princess Cruises is a division of Carnival Corporation, and this ship will be powered by LNG, it is not — as some have assumed — an Excel-class ship like those built by Carnival Cruise Line, Costa Cruises, and P&O Cruises. Rather, this Sphere-class ship was designed from the ground up as a collaboration between Princess and Italian shipbuilder Fincantieri.

Building a Cruise Ship

From the initial concept to the final launch, every aspect of a cruise ship’s construction must be carefully considered and executed. It’s also something of a balancing act, as form and function need to co-exist. Safety is obviously the top priority, but other factors such as how each element fits both literally (in a construction sense) and figuratively (in the overall vision of the designers) must be taken into consideration.

Once the design is finalized, the actual construction of the ship gets underway, beginning with the laying of the keel — aka the bottom of the ship— in place. Once the most basic of steps have been completed, assembling the various components and systems of the vessel — including the hull, engines, propulsion system, electrical wiring, and pipes — can begin.

To visit a shipyard during the process is to witness the very definition of “organized chaos.” To the casual observer, it seems impossible to believe that the pile of pipes to your left and wiring to your right will become essential to the operation of the vessel.

Yet nothing is left to chance as each individual element eventually becomes part of the larger whole that is taking shape.

After the ship’s structural components and systems are in place, the interior fitting and outfitting phase begins. This is when the ship begins looking more like what passengers expect to see. Furniture is brought in, and previously empty spaces morph into dining rooms and theaters and staterooms.

In early March, Sun Princess was floated out from the dry dock (where it was built) and taken to the wet dock (where it’ll be finished).

What Makes This Ship Different?

Given the massive amount of money a line invests into each new ship, it won’t surprise you to learn that they do a great deal of marketing in order to determine what guests want. And while that’s a never-ending process that helps them decide everything from itineraries to carpet designs, it starts long before a ship is even designed.

Based on feedback from guests, here are some of the ways in which Sun Princess will differ from the line’s previous offerings.

1. The World Marketplace Buffet — which on other Princess ships is located on the upper pool deck — will here be moved down to deck nine, which will allow guests to enter from one of the open promenade areas.

2. The Princess Arena has the ability to be configured in three different ways: What’s known as the “end-stage” (as in traditional theaters); in-the-round (with the stage in the center and guests surrounding on all sides); and the proscenium setup (which is more in line with a classic opera house).

3. Sun Princess will have one of the first casino spaces at sea to feature an air purification system pumping 100 percent clean air onto the gaming floor. It’ll also feel very roomy with high ceilings.

4. The main dining room will span decks six, seven, and eight. And in another first, each level will offer a slightly different dining experience as well as level of formality. The space will also have floor-to-ceiling windows offering wake views and lots of natural light.

5. The Dome — a literal glass dome perched atop the ship — will feature indoor/outdoor pools and, at night, transform into a South Beach-inspired entertainment venue.

6. The Wake View Terrace — sitting at the back of the ship, as one might expect — will be a resort-like patio that extends over the aft end of the ship with an infinity pool, bar, and entertainment offerings.

7. There will be new categories of staterooms and 100 adjoining cabins. The cabana staterooms come with access to a private patio, along with cove balconies on deck six.

8. Every stateroom will now have a sitting couch, multiple USB outlets, and showers with glass doors as well as a shaving bar for the ladies. Also announced was eliminating the walk-in closet and using closet storage like most cruise ships have when you walk in. “By eliminating the walk-in closet, we were able to add more usable square footage to the stateroom,” Parker said.

9. A move towards a ship-within-a-ship concept of sorts. Guests in the Signature Collection staterooms will have a dedicated restaurant, lounge, and amenities. These features will not, however, be in a separate space with keycard-access (as with NCL’s The Haven or MSC’s Yacht Club).

For instance, the Signature Collection dedicated dining room will be located off one of the promenades. Guests will also have access to their own sun deck, which is an extension of the pay-for-use sanctuary space.

Looking Ahead to 2024

Although a great deal of information was shared with us during the tour, some details were not revealed… including venues that have not yet been announced.

For example, there’s a mysterious black door found on deck eight, behind which a unique experience supposedly will be found. (Perhaps an old-time “speakeasy” at sea? Only time will tell… )

When Sun Princess debuts next February, she’ll spend her inaugural season in the Mediterranean before repositioning to Port Everglades (Fort Lauderdale) in the fall.

As the ship enters her final stages of construction, more photos and details will no doubt be forthcoming.

Until then, all we can do is wait to see what else Princess Cruises has in store for us aboard this innovative, groundbreaking ship.

Recent Posts

Sun princess christened in barcelona by hannah waddingham, princess cruises [photos], construction starts for royal caribbean’s private beach club in nassau, princess introduces new sanctuary collection on sun princess and star princess, norwegian’s next cruise ship floated out at shipyard, share this post, related posts.

![cruise ship on top of building Sun Princess Christened in Barcelona by Hannah Waddingham, Princess Cruises [PHOTOS]](https://cruiseradio.net/wp-content/uploads/2024/04/Sun-Princess-Christening-6-300x169.jpg)

MSC and Mercy Ships To Build State-of-the-Art Hospital Vessel

New Consumer Law Mandates Clear Pricing for Cruise Lines

Bringing you 15 years of cruise industry experience. Cruise Radio prioritizes well-balanced cruise news coverage and accurate reporting, paired with ship reviews and tips.

Quick links

Cruise Radio, LLC © Copyright 2009-2024 | Website Designed By Insider Perks, Inc

How much does it cost to build a cruise ship?

Today's cruise ships are akin to floating resorts, so it's perhaps not surprising that building a ship can get pricey.

The newest vessels often feature multiple decks with numerous restaurants and bars, entertainment venues, various types of cabin configurations and every attraction you can imagine (such as roller coasters, zip lines and ice skating rinks). The price tag could be astronomical.

The cost of building a cruise ship can vary due to many factors, some of which include ship size, amenities, technology and design. If you're curious just how much money a cruise line needs to construct a new ship, here's everything you need to know.

For more cruise guides, news and tips, sign up for TPG's cruise newsletter .

On average, modern cruise ships cost between $500 million to over $900 million to build.

Cruise ship costs were much different back in the day. When the Titanic entered service in 1912, the 3,300-passenger ship was the world's largest and cost $7.5 million to build (almost $239 million by today's standards).

While we might think of the Titanic as a cruise ship, it was technically classified as an ocean liner. While its main purpose was transporting passengers across the Atlantic, it also carried mail and products. However, it was designed to offer passengers comfort and luxurious sea travel, making it similar to today's cruise ship experience.

Mardi Gras , the first ship in Carnival Cruise Line 's fleet, cost $5 million to renovate and carried 1,248 passengers when it launched in 1972. (The ship was the refurbished Empress of Canada, originally constructed in 1961.)

Carnival's cruise ships have certainly evolved over the years. The line's new Mardi Gras debuted in 2020, showcasing a seemingly endless list of attractions, including the first roller coaster at sea called BOLT: Ultimate Sea Coaster . The cost to build the 6,500-passenger ship was around $950 million.

Why do cruise ships cost so much to build?

Many components factor into cruise ship construction costs. The bigger the ship and the more passengers it holds, the more money it will cost to build. Also, the number of cabins and suites, as well as onboard features like restaurants, bars, spas, pools and ship attractions (water park, climbing walls, sports areas and the like) add to the final cost.

Additionally, new ships often employ cutting-edge technology and engineering, and cruise lines must pay for the teams of experts needed to turn design dreams into reality. The type of materials used can also drive up the cost, especially if sustainable or ultra-high-end products are used.

Where are cruise ships built?

The shipyards that build most modern-day cruise ships include the Meyer Werft shipyard in Germany, the Chantiers de l'Atlantique shipyard in France, the Meyer Turku shipyard in Finland and several Fincantieri shipyards in Italy.

At the shipyard, cruise ships are built in a special dry dock. The dry dock is an open dock area that's been drained. When construction is complete, the ship is launched into the water using a float-out technique — shipyard workers flood the dock with seawater, and the ship floats out. Interior work will continue even as the ship takes to the water for sea trials.

What is the most expensive cruise ship?

Size doesn't always matter when it comes to shipbuilding expenses. Ponant Cruises ' 245-passenger Le Commandant Charcot reportedly cost $430 million for a ship with just 123 rooms. Launched in 2021, the vessel is the first expedition cruise ship capable of reaching the North Pole.

Related: The most epic cruise ever? What it's like traveling to the North Pole on a luxury icebreaker

Royal Caribbean corners the market for building expensive cruise ships. Allure of the Seas , which debuted in 2010, is currently the world's most expensive cruise ship. It was constructed at the STX Europe Turku shipyard in Finland for a cost of around $1.43 billion.

The 18-deck, 8,454-passenger ship was the second vessel in the line's groundbreaking Oasis Class series. It's one of the world's largest. The ship is chock-full of amusements — multiple dining and drinking venues, a zip line, the FlowRider surf simulator, an ice skating rink and an AquaTheater.

Wonder of the Seas , the line's newest ship, is the second-most-expensive ship at a construction cost of approximately $1.35 billion. Built at the Chantiers de l'Atlantique shipyard in Saint-Naizaire, France, the 6,988-passenger vessel, which debuted in 2022, currently holds the title of the world's largest ship. As you can imagine, it also holds a dizzying array of diversions. Additionally, it's the first Oasis Class ship to feature a dedicated neighborhood of exclusive amenities for suite guests.

Set to debut in early 2024, Icon of the Seas might overtake the top spot in the list of most expensive cruise ships to build — just as it will surpass Wonder of the Seas as the largest cruise ship in the world.

Icon is Royal Caribbean's first ship in the line's all-new Icon Class, so its design and style will differ from previous vessels. The 7,600-passenger, 20-deck-tall ship will also be around 6% larger and about 10 feet longer than Wonder of the Seas. Early estimates have the construction cost at $2 billion.

Refurbishing older ships vs. building new ones

While it's more cost-effective to refurbish an older ship than to build a new one from the ground up, those enhancements don't come cheap. Sometimes, the renovations require a complete overhaul, including changing the ship's layout and adding cabins, restaurants and attractions.

For example, 17 years after it launched, Royal Caribbean's Navigator of the Seas received a glow-up in 2019 at a cost of $115 million. Improvements included everything from new furniture, carpeting and upholstery to expanded onboard amenities, entertainment and cabins.

Bottom line

The next time you board a cruise ship teeming with every diversion you can imagine, think about how much it cost to build that floating megaresort. It might give you new appreciation for just how much the cruise line has invested to create your ideal vacation at sea.

Planning a cruise? Start with these stories:

- The 5 most desirable cabin locations on any cruise ship

- A beginners guide to picking a cruise line

- The 8 worst cabin locations on any cruise ship

- The ultimate guide to what to pack for a cruise

- A quick guide to the most popular cruise lines

- 21 tips and tricks that will make your cruise go smoothly

- Top ways cruisers waste money

- The ultimate guide to choosing a cruise ship cabin

This Is Where Cruise Ships Are Built

by Contractor | Nov 12, 2020 | resources , Travel Tips | 0 comments

Over 21 million travelers take a cruise on an annual basis. With so many people taking cruises , it may make you curious about where these massive ships are being built, how they are being built, what it costs to build them, and finally, how they get to the water.

The three countries that produce the largest quantity of cruise ships are Italy, Germany, and South Korea. A cruise ship is built in a shipyard. Most shipyards are located on a tidal river or the ocean. There are other shipyards around the world, but these are the most prominent.

Cruise shipbuilding has evolved immensely since 1900 when the first of its kind was built. Modern technology and luxuries have made seeing the world via cruise ship an extremely popular way to travel. More than 25 million people will travel via cruise ship each year. In this article, we’re going to explore more about the amazing cruise shipbuilding process.

Where Cruise Ships Are Built

Cruise ships are built in a shipyard, not to be confused with a dockyard. The main difference between the two is that a shipyard is where ships are actually built .

A dockyard is more of a storage facility or place for repairing ships and other water vessels. There are only four shipbuilding companies in the world that are large enough to produce a cruise ship.

The Top Ship Builders

The top four shipbuilders are:

- Fincantieri (Italy)

- Meyer-Werft (Germany)

- STX-Europe (South Korea, Brazil, Finland, France, Norway, and Romania)

- Mitsubishi Heavy Industries (Japan)

Fincantieri

Established around 1790, Fincantieri has been building ships for almost 230 years.

The first cruise ship ever built was in the year 1900. It was called “Prinzessin Victoria Luise” and was approximately 400 feet long and 50 feet wide. The first voyage was in 1905. The vessel held around 1,500 passengers. The Prinzessin Victoria Luise did not have a very long life because it ran aground in 1906 and could not be repaired.

Meyer-Werft

Established around 1795, Meyer-Werft has been a leading competitor in the ship building business. This German-based company’s first cruise ship was built in 1986 and was named the “Homeric,” which they re-named a few years later, the “Westerdam.”

It has a length of approximately 800 feet and 95 feet long and can carry a little more than 1,700 passengers.

In 2006 Aker Yards and Alstrom shipbuilding companies decided to come together, and thus, STX-Europe was formed to wind up creating high-quality, world-class, luxury cruise ships.

Since its inception, STX has grown to be one of the world’s top builders. Their classy, modern design, luxury, and comfort give the guest a fabulous place to relax and see the world.

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries was established around the late 1800s and has been producing many different kinds of large ships since.

Due to financial losses in 2006, they discontinued making passenger cruise ships. They are still in operation today, but their primary focus is on cargo ships and naval ships for different countries.

NOT Made In The USA

You may have read through this list and realized that the United States of America is not on the list of where cruise ships are built. The main reason for this is because, in 1920, there was an act of legislation passed referred to as “The Merchant Marine Act,” also known as “The Jones Act.”

Senator Wesley Jones was the creator of this act, and it was primarily put into place to protect the merchant mariners and their jobs. Another reason the United States does not build cruise ships is because it is very costly to build them and requires highly skilled, experienced builders from other countries to help construct them, raising the cost of production.

How Cruise Ships Are Built

On average, it takes about a year and a half to build a cruise ship.

By now, you are probably wondering how they can build such a large ship in dry dock and how on earth do they get into the water?

The second part of that question is easy.

As stated earlier, shipyards are built on tidal rivers or directly next to the ocean to allow for easy entry and access to the water.

Putting the Ship Puzzle Together

Most cruise ships are built in sections or pieces.

The cabins are usually built off location in a factory and brought to the shipyard when they’re ready. When the cabins arrive at the shipyard, a crane and giant magnet are used to install and fit them into the ship

The ship goes together like a set of children’s connecting blocks. The hull of the ship is the first part to be built. It takes extremely large cranes and equipment to put it together.

It is first constructed on dry land and then given multiple water tests. The builders can test it on dry land or in the water, depending on their needs.

How Long Does It Take?

The length of time it takes to build a cruise ship can vary greatly depending on the ship’s size. On average, it takes about a year and a half to build a cruise ship. Some smaller cruise ships may not take that long, but the larger luxury ships can take over two years.

Materials Used in the Building Process

We have discussed how a cruise ship is made and how long it takes to build, but what materials are used to build them? The short answer is a combination of lightweight metals and super strong steel are used, which reduces the ship’s overall weight and helps with balance.

Reducing the ship’s weight also reduces the amount of fuel used, and in return, reduces the emissions, which lessens the ship’s effect on the environment.

The cabins’ interiors are made with high-quality fabric, finishes, and designs to emulate the feeling of being in a 5-star hotel.

Who Builds For Which Cruise Lines?

You may be wondering which shipbuilding company builds for each cruise line.

Some cruise lines use multiple builders; however, the cruise lines listed below are examples of the exclusive builders for certain lines:

- Fincantieri (Disney Cruise Lines and Holland America)

- STX-Europe (Royal Caribbean, Carnival, and Princess Lines)

- Meyer-Werft (Norwegian Cruise Lines and Viking Ocean Cruises)

Interesting Cruise Ship Facts

- In France, “Harmony of the Seas” was built by over five-hundred-thousand builders and had an extensive team of world-class designers to decorate and style the entire ship to make you feel like you are in a 5-star hotel.

- In Norway, a luxury cruise ship named “The World” was built with around 160 apartments and is owned cooperatively by its passengers who live on it full time.

- An Australian billionaire named Clive Palmer has privately funded the making of a replica of the original Titanic. It is named the Titanic II and is expected to launch in 2022. The Titanic II will not be built by any of the above-mentioned shipyards; instead, it will be built in China at, Jingling shipyard.

- South Korea, Japan, and China are the largest shipbuilding countries; however, European shipbuilders are still on top of the market for cruise ships, yachts, and military vessels.

Cruising to the Dock

Although cruise ships are not built in The United States of America, there are many shipyards along our beautiful coasts that do allow tours of their facilities.

If you ever get the chance to tour a shipyard, it’s well worth your time. It is a very cool experience that you will never forget. Standing next to the massive cranes and ships that are being built, you will feel like the tiniest being on earth. Crowley Shipping and Logistics in Jacksonville, Florida, will not disappoint if you take time for a visit. It gives you insight into how things are made and transported globally.

( https://www.cruisecritic.com/articles.cfm?ID=3929 )

( https://www.worldatlas.com/articles/the-largest-cruise-ships-ever-built.html )

( https://cruisedeals.expert/how-much-does-a-cruise-ship-cost-to-build/# )

( https://www.thedailymeal.com/travel/20-crazy-facts-about-cruise-ships )

( https://www.crowley.com/ )

( https://www.quora.com/Why-are-cruise-ships-not-built-in-the-United-States )

( https://www.jonesactlaw.com/faqs/what-is-the-merchant-marine-act-of-1920/ )

( https://www.cruise1st.co.uk/blog/cruise-ships/how-are-cruise-ships-built/#whobuildscruiseships )

( https://www.kickassfacts.com/25-interesting-facts-about-cruise-ships/ )

( https://titanicll.wordpress.com/the-jinling-shipyard-what-do-we-know/#:~:text=Right%20from%20the%20outset%20of,built%20in%20China%27s%20Jingling%20shipyard .)

(statista.com/6558/cruise-shipbuilding-industry-worldwide/

Related Posts:

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Privacy Overview

- Things to Do

- Restaurants

- Vacation Rentals

- Travel Stories

- Rental Cars

- Add a Place

- Travel Forum

- Travelers' Choice

- Help Center

A 'Ship' on Top of Buildings - Sands Skypark Observation Deck

- Asia

- Singapore

- Singapore - Things to Do

- Sands Skypark Observation Deck

A 'Ship' on Top of Buildings

We went to the highest floor where we were only allowed to visit Kudeta. it was understandable since we were not staying in MBS hotel. The view was amazing. 2 hours with the dollars spent was worth the money

Boat shape restaurant on the top of building is glamours all round the year and its an identity of Singapore..Must visit for anyone.

Placed in the top of Marina Bay Sands hotel, its main attraction is the pool. There is an amazing infinity edge that seems to end in the sky. It is located 57 floors above the ground and from inside the pool you can enjoy a beautiful view of Singapore. There is also the restaurant "Sky on 57" where the Chef Justin Quek offers a mix of Asian and French cuisine. Do not miss.

The view is excellent from the deck, you must see it! The cost of entry is SGD 23 per person, then you end up on the 56th floor. You can go up one floor to 57th outside on the deck. You can see the Gardens by the Bay, the Formula 1 racetracks, the Singapore Flyer and a floating soccer ground as well. After coming down, pay a short visit to the Casino on the ground floor. The rotunda is awesome in there!

From a far one marvels at the engineering ability to build these three towers then join them together on top with large boat design and to incorporate a skypark for the public to view Singapore. In saying that we were disappointed with the actual viewing area set aside for public viewing. One is confined to the pointed part of the skypark the rest is reserved for hotel guest and apartment owners. We paid and went up late afternoon along with hundreds of other people to view the lights and laser show. The show is much better viewed at ground level facing the building rather then standing on top of the skypark. Then after the show finished there is a long wait for the lifts to take you back down. When visiting Singapore and you have time by all means go up to the skypark but I think there is a lot better places to visit before hand then the skypark.

This is worth either the $22 or buying a cocktail in one of the bars up on top. Great views and like being on top of the world. There are 2 bars and a swimming pool up there and if you are a guest at the hotel there is a viewing terrace as well. I loved it and enjoyed my cocktail too

Cruise News and Updates

The costly investment of building cruise ships: a closer look.

Table of Contents

Key Takeaways

- Building a cruise ship is a significant investment, with costs ranging from $300 million to over $1 billion.

- The construction process takes 12 to 18 months and involves thousands of crew members.

- Refurbishing a ship is a cheaper alternative to building a new one, costing millions.

- Operating a cruise ship requires significant expenses, including crew salaries and fuel costs.

The Financial Aspect

Construction Process

Operating and maintenance costs, frequently asked questions, how long does it take to design a cruise ship before the construction process begins, what are some common challenges faced during the construction of a cruise ship, how often do cruise ships undergo refurbishments, what are some key factors that influence the operating costs of a cruise ship, how do cruise lines prioritize innovation in ship design and features.

Alfons is the visionary leader and driving force behind Voyager Info’s success. As the Editor in Chief, he brings a wealth of experience and an unwavering passion for travel to the helm of our cruise-centric platform.

With a lifelong fascination for exploring new horizons, Alfons discovered his love for the ocean and cruising at a young age. From sailing across pristine Caribbean waters to embarking on daring expeditions to far-flung destinations, he has amassed a treasure trove of first-hand experiences in the world of cruising.

The Evolution Of Cruise Ship Size: From Icon Of The Seas To Mega-Ships

Why Florida Residents Get Cruise Discounts: Proximity, Residency Offers, And Strategic Moves

Alfons is the visionary leader and driving force behind Voyager Info’s success. As the Editor in Chief, he brings a wealth of experience and an unwavering passion for travel to the helm of our cruise-centric platform. With a lifelong fascination for exploring new horizons, Alfons discovered his love for the ocean and cruising at a young age. From sailing across pristine Caribbean waters to embarking on daring expeditions to far-flung destinations, he has amassed a treasure trove of first-hand experiences in the world of cruising.

You may like

Customizable omelets, breakfast potatoes, muesli yogurt, fresh fruit, and assorted breads: a breakfast buffet delight.

- Customizable omelets and breakfast potatoes offer a personalized and delicious breakfast option

- Muesli yogurt and fresh fruit provide a healthy and energizing start to the morning

- Assorted breads add a touch of indulgence and variety to the breakfast buffet

- The breakfast buffet offers a wide range of choices with unique flavors and textures.

The Ultimate Omelet Experience

A Crispy and Flavorful Potato Medley

Energize your morning with muesli yogurt.

Fresh and Vibrant Fruit Selections

Indulge in a bread basket extravaganza.

- Soft and buttery dinner rolls, perfect for spreading with a pat of creamy butter.

- Flaky and buttery croissants, with their delicate layers and golden exterior.

- Crusty and rustic baguettes, ideal for tearing apart and savoring with a smear of homemade jam.

- Sweet and sticky cinnamon rolls, oozing with gooey caramel and fragrant spices.

- Savory and hearty cornbread muffins, with their golden crust and fluffy interior.

Customizing Your Perfect Omelet

Exploring the world of breakfast potatoes, the delightful crunch of muesli yogurt, savoring the sweetness of fresh fruit, what are the different types of bread and pastries offered in the assortment, are there any vegetarian options available for the omelet station, can the breakfast potatoes be made gluten-free, is there a limit to the number of ingredients that can be added to the omelet, are there any vegan options available for the yogurt in the muesli yogurt dish.

Meet Asra, a talented and adventurous writer who infuses her passion for exploration into every word she writes. Asra’s love for storytelling and her insatiable curiosity about the world make her an invaluable asset to the Voyager Info team.

From a young age, Asra was drawn to the power of words and their ability to transport readers to far-off lands and magical realms. Her fascination with travel and cultures from around the globe fueled her desire to become a travel writer, and she set out on a journey to turn her dreams into reality.

Demystifying Royal Caribbean Gratuities: Your Guide to Costs and Etiquette

- Royal Caribbean charges a daily gratuity to every passenger, regardless of age, which is distributed to passenger-focused crew members.

- The gratuity rates are $16.00 per person, per day for most guest rooms and $18.50 per person, per day for guests in suites.

- Guests have the option to prepay gratuities before the cruise to avoid potential rate increases and eliminate extra charges on the ship.

- While the gratuity amount is typically automatic and not easily changed, reductions may be reasonable for poor service or major issues, which can be discussed at Guest Services.

Understanding the Daily Gratuities Charge

Who Must Pay Gratuities on Royal Caribbean?

Breaking down the costs: how much are gratuities.

- For most guest rooms, the daily gratuity charge is $16.00 per person, per day.

- Guests staying in suites are charged $18.50 per person, per day.

Payment Options: How to Pay Gratuities

Can i change the amount paid dealing with service issues.

Navigating Gratuities Etiquette on Royal Caribbean

Are gratuities on royal caribbean mandatory, can i choose not to pay gratuities on royal caribbean, how are gratuities distributed among the crew members, are there any exceptions to the daily gratuity charge, are gratuities included in the price of specialty restaurant meals, drinks, and spa services, cruise news: costa toscana, no-sail order, barcelona port, and industry impact.

- Costa Toscana is the newest ship in the Costa Cruises fleet, and it was christened in the port of Barcelona.

- The no-sail order has been extended, causing significant financial losses for cruise lines, trip rescheduling for passengers, and job uncertainties for crew members.

- Barcelona is a popular cruise port, offering attractions and contributing to the local economy through cruise tourism.

- The cruise industry is working on implementing health and safety protocols to address the impact of the no-sail order.

Costa Toscana: The Newest Addition to Costa Cruises Fleet

No-sail order extension: impact on cruise industry, barcelona port: a hub for cruise ships, costa toscana christening ceremony: a celebration in barcelona, financial losses: the toll of the no-sail order, passenger troubles: rescheduling and cancellations, job uncertainties: crew members in the cruise industry, implementing health and safety protocols: industry efforts.

- Enhanced cleaning and disinfection procedures throughout the ships.

- Mandatory pre-boarding health screenings for passengers and crew.

- Social distancing measures in public areas, including reduced capacity.

- Improved ventilation systems to enhance air quality onboard.

- Regular testing and monitoring of both passengers and crew for early detection of any potential health issues.

Barcelona’s Attractions: A Delight for Cruise Passengers