Lean Manufacturing Factory Tour

Lean manufacturing factory tour:.

I personally love the way that Paul Akers has taken his company FastCap and transformed it into a world class organization by implementing simple and easy lean manufacturing principles. Paul has not done anything fancy or complicated! He has taken the basic lean manufacturing principles and applied them to help improve the way he and his employees do business, each and every day.

Here is a short video that will demonstrate the power of lean manufacturing principles when they applied with passion to embrace change and the discipline to see it through.

Leave a Comment Cancel reply

You must be logged in to post a comment.

- Privacy Overview

- Strictly Necessary Cookies

- Cookie Policy

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

More information about our Cookie Policy

- Skip to primary navigation

- Skip to main content

- Skip to footer

OpEx Learning Resources

Lean Six Sigma Articles, Guides, Insights, and more!

Videos on Lean Manufacturing, Six Sigma, Operations and Supply Chain. These videos are meant to be instructive and educational, showing the reader virtual factory tours and other educational items related to the practice of Lean, Six Sigma, and efficient and effective application and Operations best practices.

By OpEx Learning Team , Last Updated September 20, 2020

[VIDEO] Amazon UK Fulfillment Center Virtual Tour

One of the most impressive operating companies is Amazon and how they fulfill orders and ship to their customers. Their processes are considered

By OpEx Learning Team , Last Updated January 28, 2019

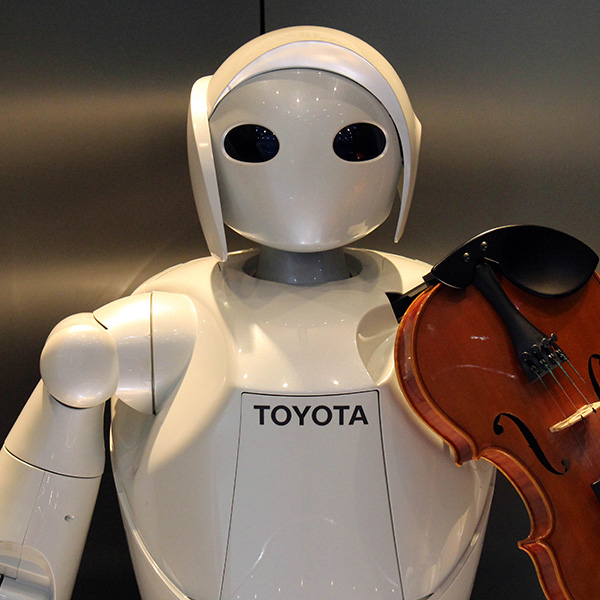

[VIDEO] The Developments That Inspired TPS

What were the historical events that led to the birth of the Toyota Production System (TPS)? Tracing the history back to Eli Whitney and the concept

[VIDEO] Applying Kaizen at Home

Everyone is searching for the magical formula or 'guru' to help them find perfection in their personal lives. Type in "self-help" in your browser, hit

By OpEx Learning Team , Last Updated January 8, 2019

[VIDEO] The Five Principles of Lean

The cornerstone of any organization is based on efficiency and value to the customer. A lean thinking organization uses five simple principles to

By OpEx Learning Team , Last Updated December 17, 2018

[VIDEO] The Tale of the Seven Wastes

The elimination of waste in processes is one of the most effective ways to increase the profitability of any business. Processes either add value or

By OpEx Learning Team , Last Updated December 10, 2018

[VIDEO] Lean Thinking Principles

Lean was born out of manufacturing practices, but in recent times, has transformed the world of knowledge work and management. It encourages the

By OpEx Learning Team , Last Updated December 3, 2018

[VIDEO] Improving Operating Room Efficiency with Lean Six Sigma

The operating room (OR) is a resource intensive and costly unit in every hospital. Finding ways to maximize their efficiency is crucial to ensuring

[VIDEO] Let the Music Play with Gibson Guitars!

For more than 100 years, Gibson guitars have defined the sounds of musicians and fans. They are the most iconic brand of guitars in the world. Gibson

By OpEx Learning Team , Last Updated November 12, 2018

[VIDEO] Building the Boeing 787 Dreamliner

The Boeing 787 is reinventing the way we imagine air travel. This aircraft is setting the standard in both range and performance, enabling airlines to

- Go to page 1

- Go to page 2

- Go to page 3

- Interim pages omitted …

- Go to page 13

- Go to Next Page »

- Automation Supply Chain

- Continuous Improvement

- Last Mile \ Delivery

- Logistics Training and Resources

- Manufacturing

- Procurement/Negotiations

- Supply Chain

- Warehouse/Fulfillment

- Artificial Intelligence

- Entrepreneur

- Robots & Drones

- Self-Driving Vehicles

- *SCM Social Media Channels

- SCT Discussion

JavaScript has been disabled on your browser. The website might not work properly unless you enable it.

Lean manufacturing - lean factory tour – fastcap.

Lean factory tour – Toyota and Shanghai

- Lean / TPS (Kaizen)

- Aichi Around the world

- 6 people ~ 30 people

- 9 Days 11 Days

TOYOTA and Shanghai – Lean factory tour –

Let’s take in the highlights of Japan factory and China on this 9 day tour from Aichi to Shanghai. Countries : 4 nights in Japan and 4 nights in China. 11-day tour can also be arranged. Starts : Aichi Ends : Shanghai Visit city : Nagoya,Toyota,Kyoto,Shanghai

About This tour Visit factories in Aichi. (Toyota’s and suppliers’ factories) Experience Japan culture. (Go to Kyoto.) Visit Shanghai companies or factories you are interested in. Experience Chinese culture. (Short trip from Shanghai)

Recommended for people like this

Have wanting to visit companies in Japan and China. Have planning to hold an incentive tour.

Tour Remarks

Cancellation Policy

- 20days to 8 days before the start date of travel: Cancellation fee 20%

- 7days to 2 days before the start date of travel: Cancellation fee 30%

- The day before the start date of travel: Cancellation fee 40%

- On the day of the start date of travel: Cancellation fee 50%

- After the start of the trip or without notice: Cancellation fee 100%

Click here for the booking and inquiry about the tour.

If you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30 Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Dates & Price

Tour Code: W01-9d

Welcome to Japan!!

We will pick you up at Airport on arrival. Check in Hotel and Dinner. Overnight: Nagoya | Dinner

Factory tour

There are many factories worth visiting in and around Aichi Prefecture. Visit charter buses and charter jumbo taxis with efficient interpreters.

About The Deming Prize The jp-expert factory tour prefers to visit factories of Deming Prize winning companies. The Deming Prize is the one of the highest awards on TQM (Total Quality Management) in the world. The Deming Prize that is given to organizations, has exerted an immeasurable influence on the development of quality control/management in Japan. You will be able to learn the basics of quality management (TQM) in Japan, especially in the automotive industry. A high level of TQM and TPS is the company’s strength not only for set manufacturers but also for its suppliers. (Of course, you can learn from companies other than the automotive industry.)

Overnight: Nagoya | Breakfast and lunch Dinner

We visit two factories and places to visit in one day.

Overnight: Nagoya | Breakfast and lunch

Sightseeing in Kyoto

Kyoto Sightseeing-Arrange your wishes.

Examples of tourist destinations:

- Fushimi Inari

- Japanese green tea ceremony

- Japanese Sake tour

- Experience Katana and Zen

- Gion walking tour

Overnight: Nagoya or Osaka or Kyoto | Breakfast and lunch

Go to China!!

Departure from Chubu Centrair International Airport or Kansai International Airport.

The flight from Osaka to Shanghai is about 3 hours.

Overnight: Shanghai | Breakfast and lunch Dinner

Visit Company

We are happy if we can offer your business opportunities. Please tell us the company you visited and the place you visited. We will arrange it.

About our group company in China Our group company, Kenping Company, is located in Zhejiang Province, China. Kenpei Company provides manufacturing consulting services and employee education services. In particular, there are many business partners in Shanghai and Zhejiang Province, and many companies come to Japan through Jp-expert to learn Japanese technology and ideas from those regions.

We arrange two places to visit in one day.

Overnight: Shanghai | Breakfast and lunch

Experience Chinese culture

Shanghai is a big city. Trip to a place where you can feel the old China near Shanghai.

Return home

We will send you to the departure airport.

Please purchase your own air ticket including between Japan and China. Travel costs, accommodation costs, lunch costs and interpreting costs in Japan and China are included.

Welcome to Japan

Facoty tour.

Sightseeing Kyoto

Free time in Kyoto or Osaka

Please spend a good day.

Overnight: Osaka or Kyoto | Breakfast

Visit company

Sightseeing China

Free time in china.

Airport Pickup

We can arrange transportation from airport to your hotel. Please check the items on the transportation option in the booking or inquiring page.

Upgrade Hotel

If you wish to upgrade, change to Japanese-style Ryokan, or add a hotel. Please inform us at the time of booking or inquiring.

Destination

Aichi Prefecture where there is Toyota city famous for Toyota. It is located between Tokyo and Osaka, has a large international airport and a Shinkansen station, and is very convenient for transportation. And Aichi Prefecture is adjacent to 4 prefectures. (Mie, Gifu, Nagano, Shizuoka) For sightseeing, Toyota Motor's Museum, Atsuta Jingu Shrine, Tokugawa Art Museum, Nagoya Castle, and Inuyama Castle are popular.

A great experience of visiting companies

We was able to visit a company that is expanding globally. It was a very valuable experience and learning for the students and me. We are very happy with the tour arrangement.

Popular Posts

TPS training in Aichi // April 15 (Mon), 2024

Tps training in aichi // february 19 (mon), 2024, tps training and factory tour in aichi // january 22 (mon), 2024, our company.

Our company is a travel agency operated by a consulting company mainly for manufacturers. We can introduce companies with Japan proud true high technologies that ordinary travel agencies cannot.

Please feel free to contact us.

Experienced consultants

TPS training center Toyota production system

Reliable Business Background

Accept customers from all over the world

- Agriculture & Food Industry

- Culture & Education

- Environment

- Exhibitions

- Medical & Elderly Care

- Construction industry

- Seminar Training

Destinations

- Around the world

News Topics

“konichiwa” – from the land of rising sun.

We received an improvement column from our Indian partner Faisal Shaikh. For over 15 years, he has been c…

- Product Videos (sortable)

- Videos en español

- Lean Videos

- Lean Videos (Sortable)

- FastCap Tour Recommended Videos

- 2 Second Lean Videos by Chapter

- Banish Sloppiness Videos by Chapter

- Lean Health Videos by Chapter

- Lean Life Videos by Chapter

- Lean Travel Videos by Chapter

- FastCap Shopping

- FastCap Forum

- FastCap.com

- Paul’s Bio

- Paul’s Bookshelf

Take a Lean Tour of FastCap

Are you interested in Lean Manufacturing? Well take a trip to the shop floor and see a lean factory tour at FastCap in Ferndale, Washington. Paul Akers is the founder and president of FastCap, based in Bellingham, WA. FastCap is an international product development company founded in 1997 with over 2000 distributors worldwide. A prolific inventor, Paul holds US and international patents. FastCap, launches approximately 20 new innovative products per year and has won business of the year multiple times. Paul and his wife, Leanne, have built FastCap from their garage into a multi-million dollar company. At its core, FastCap is a Lean company, determined to continuously improve everything, everyday. Our products reflect the idea that things can be improved and the best ideas come from the shop floor.

I would love to setup a lean tour for my team. Can I have some information for that?

Because we are inundated with tour requests from around the world, we have established tour requirements (see below). We have very large companies tour FastCap (e.g., Boeing, Toyota, Bombardier, the U.S. Navy, etc.) and every one of them have to meet these requirements. Other companies will charge $1000 a person for a similar tour. We don’t charge, but we do judge the seriousness of your lean efforts before we accept you for our tour. The tour is not for the curious…it is for people who seriously want to learn Lean and have made a commitment to take what they learn and implement it. We only have so much time for facility tours, so we have to be very careful how we use it. We now limit ourselves to 8 tours a year.

We are not teaching how to do Lean, we are teaching how to build a Lean culture. With so much demand to learn, we had to come up with a Lean way to reach as many people as possible, so I took my video camera and Razor scooter and 4 hours of time and produced this video https://youtu.be/jYby_HczyDA (over 105,00 views). No film crew, no professionals, just me and my people . It was simple, fast and easy. It is not perfect! Perfection is for people who want to tell you all the reasons they can’t get things done.

Another important video for you to watch is my talk to the LCI group in San Francisco a few years back call Lean Is Simple https://youtu.be/gPUmY8WnnpU (over 143,000 views). It is an hour and a half presentation.

We have 1,500 videos (with over 3 million views ) that are free and go into details on many Lean subjects. Click here to go directly to our Lean Video Library http://www.fastcap.com/estore/pc/viewContent.asp?idpage=88 or go directly to our YouTube Channels: FastCap https://www.youtube.com/user/fastcaptv & Paul Akers https://www.youtube.com/user/PaulAAkers .

There are so many companies around the world that are doing a fantastic job of building a Lean culture. I interviewed the leaders of some of those companies at the MAPP conference in Indiana. Click here to watch the Lean Roundtable https://youtu.be/E9Na_YMKdvE > (over 1,900 views).

Below are videos from 6 companies building a Lean culture: Walters & Wolf http://www.waltersandwolf.com/ > – Hauling the Mail Video https://youtu.be/B2VemLCV8i0 & Where is Shop B Video https://youtu.be/cqojZ-3aCKI Xylem Design http://www.xylemdesign.com/ – Xylem Design Tour Video https://youtu.be/6IUywb_O2KU Klime-Ezee http://www.klime-ezee.com/ – One Year Lean Update Video https://youtu.be/NDZ1Cmhy3eE Yellotools http://yellotools.us/splash-page.html – Breaking Down a Process Video https://youtu.be/QA1ddcXfqM0 Viking Plastics http://www.vikingplastics.com/ – Seal Feeder Improvement Video https://youtu.be/Wc-J7Gm4W7g Omniduct http://omniduct.com/ Weekly Video Blog Video https://vimeo.com/user19812081/review/94993907/c709799f72

We have also built a Lean Hub http://paulakers.net/lean-hub , which provides contact information for a Lean organization by location. Many of them provide tours (they have their own criteria).

FastCap Tour Requirements: CEO must attend. We understand that some organizations are huge and it is not likely that the CEO would attend the tour, however, you should know that we have had companies with 70,000 employees globally and the president, as well as the board members, have attended the tour. We have made a few exceptions to this stipulation, but only if we are convinced that the leader s attending have the power to build a Lean culture successfully. Attendees must read my book, 2 Second Lean http://paulakers.net/2sl (digital/audio versions available at no costs). Attendees must watch at least 10 of our Lean videos in advance of your FastCap tour. Attendees must be committed to transform ing to a Lean culture and company within 1 year or your FastCap tour. Your organization must make 50 improvement videos (before/after) prior to your FastCap tour. Your organization must set up a public YouTube channel to share lean videos with the world. Your organization must allow other businesses to tour your facility within 1 year of your FastCap tour. Your organization is highly encouraged to participate in the Lean Hub http://paulakers.net/lean-hub . Attendees must have a Skype interview with me for final approval. With this interview, I will be able to determine your sincerity. In lieu of this, each member attending can make a 60 second video telling me why they want to tour FastCap and what they expect to get out of it. You can post these videos your YouTube channel, make them unlisted, and send me the links.

If you can meet the above criteria these, please send me with the names/contact information of all attendees (indicate the primary contact).

Tour details and prep work: We start at 7:00 a.m.sharp and end around 9:00 a.m. We work in a manufacturing facility so warm clothes on cold days are encouraged; our plant is usually around 64 degrees. The first thing you will do on the tour is clean our bathrooms. This teaches humility, and demonstrates effective processes…two of the cornerstones of Lean. Attendees should come with one clear goal of what they want to achieve. Please watch these videos http://www.fastcap.com/estore/pc/viewContent.asp?idpage=115 so you will all have a good point of reference to maximize your visit. You can also visit my website http://paulakers.net/ where you will find many more videos and resources that you can use as training tools for your team.

Why FastCap gives lean tours?: We have benefited so much from learning the Toyota Production System…this is our way of giving back. Toyota taught us from their 50 years of experience, so we are paying it forward. We want others to receive the same benefits we have in building a strong business climate in America. We get better at Lean when we teach it. It is rewarding and we feel very satisfied when others want to see and experience what we are doing to build a Lean culture.

Common questions people ask after the tour: How do I start lean? Identify what bugs you and fix it. Learn to see waste; it is everywhere…seen easily by looking in the mirror. Make one small change or 2 second improvement every day for the rest of your life. Create a Lean bathroom and let it spread from there to the rest of your organization.

Can I learn this without consultants and spending lots of money?: First of all, Lean is easy. Approach it with this mind set and you will succeed. Stop making excuses why you can’t do it (i.e., my boss doesn’t get it, my wife doesn’t get it, etc.) If you make excuses, you will never learn or experience Lean. Change yourself, change your family, change your street, change your city, and change the world. Experience a Lean culture by touring Lean companies like FastCap. Become part of the Lean Hub http://paulakers.net/lean-hub. Get connected. We are all here to help one another. Experience it first, see the benefits with your own eyes, then begin to read and learn about it. Watch all the Lean videos FastCap provides and use them as training tools in your company. Subscribe http://bit.ly/FastCap-Subscribe to my weekly emails: 2 Second Lean…a brief video regarding Lean; and The American Innovator…a show about my travels and Lean adventures. Read The Toyota Way http://paulakers.net/lean-resources/pauls-bookshelf (select Business from the right sidebar). Read 2 Second Lean http://paulakers.net/2sl.

Leave a Reply

Name (required)

Mail (will not be published) (required)

XHTML: You can use these tags: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>

Recent Posts

- Staples will never be a problem again!

- Need a temporary drawer pull solution?

- Applying edge banding with FastCap Products

- Never have torn pants from your tape measure again!

- Want the latest security tool for any roll up truck?

Paul Akers Links

Fastcap information.

You are using an outdated browser. Please upgrade your browser to improve your experience.

FREE Shipping at $100 *UPS Ground in the contiguous U.S.A.

Lean Manufacturing – Lean Factory Tour – FastCap

In this video, it is possible to do a virtual tour of a Lean Factory.

Fastcap is a Lean Factory that shows on Youtube a lot of Lean Applications. See now.

Session expired

Please log in again. The login page will open in a new tab. After logging in you can close it and return to this page.

Lean Events and Training / Events / Lean Leadership Learning Tour

Lean Leadership Learning Tour

Go, see, ask why, and show respect to revolutionize your company's future..

October 16, 2024 - October 18, 2024 ET

Louisville, Kentucky and Princeton, Indiana

Why you should attend

Learn the secrets of lean manufacturing, a journey fraught with challenges, false starts, and stops. Gain insights into proper leadership, commitment, and development required for success.

$5,500 includes two nights hotel, all meals, and transportation during tour

Seats are limited.

Go and See, Ask Why, and Show Respect

The Lean Enterprise Institute has joined forces with Toyota to offer an exclusive and private learning experience, taking you behind the scenes at both Toyota Motor Manufacturing and GE Appliances. The aim of this partnership is to provide valuable insights into the world of lean manufacturing and the principles that drive success.

In just three short days, gain insights into:

- The Leadership Role: Understand the critical role of leadership in driving lean success.

- Success and Failure Modes: Learn from both successes and failures to avoid common pitfalls.

- Technical Tools and Management Requirements: Discover the essential tools and management practices for achieving success.

- TPS as a Business Strategy: See how TPS is not just an operational component but an overarching business strategy.

Embark on a Journey with Inspiring Companies

Who Should Attend

All levels of management from CEOs, Presidents, Vice-President, to Continuous Improvement and Op Ex managers.

We recommend attending with at least one other person from your organization. With a learning partner, you’ll be able to compare and discuss how the learning-tour companies’ practices might apply to your company.

Cancel l ation Policy

You can cancel your registration for this learning tour four weeks before the tour start date for a full refund. A cancellation occurring within two to four weeks of the tour dates will be subject to 50% of your registration fee. A cancellation occurring within two weeks of the tour will not be refunded. To cancel, please call LEI at (617) 871-2900 or email [email protected] .

Agenda Overview

Josh Howell

President and Executive Team Leader Lean Enterprise Institute

Joshua Howell is president and executive team leader at the Lean Enterprise Institute (LEI). For over a decade, he has supported individuals and organizations with lean transformations for improved business performance. As a coach, he helps people become lean thinkers and practitioners through experiential learning, believing such an approach can lead to enterprise-wide improvement. Regular e-letters […]

Download the agenda for the October 2024 Lean Leadership Learning Tour

Testimonials

“What a great week of learning! I am very energized to get back to our Gemba. Appreciate everything LEI did to give us the best Lean learning experience anyone could have. Everyday was filled with great learning. John’s wrap up teaching at the end was priceless. I would highly recommend the tour to anyone pursuing TPS.”

Greg Lobsiger President, Loren’s BodyShop, Inc.

“I was so impressed. One of the most positive takeaways was interacting with people from different industries; people that I normally wouldn’t have interacted with. I really enjoyed the [Toyota] plant tour. Probably the most impactful time for me was in the huddle room; seeing where the plant president stands every morning at 8.30.”

David Mannix, Senior Director, performance excellence, Alliance Radiology

“The training team from LEI was nothing short of amazing. I was completely impressed with the professionalism, knowledge. Helpful nature of this team. Thank you for hosting this. I will go back to Elkay as a much better lean thinker.”

Rorrie Kramer Assembly Supervisor, Elkay

Related Events

June 04, 2024 | Coach-Led Online Course

Management Systems

June 10, 2024 | Coach-Led Online Course and Oakland University in Rochester, Michigan

Managing to Learn

June 12, 2024 | Morgantown, PA

Building a Lean Operating and Management System

Subscribe to get the very best of lean thinking delivered right to your inbox, privacy overview.

Kentucky Tour

Kentucky toyota tour and workshop with mike hoseus.

Are you curious to see how Lean is practiced at the company that helped create it? The Iowa Lean Consortium’s Kentucky Lean Tour will explore the best practices in Lean leadership by taking ILC members on an in-depth walking tour of the largest Toyota plant in the world.

This event will be led by Mike Hoseus , executive director of the Center of Quality People & Organizations and co-author of the book Toyota Culture . Participants will be granted unparalleled access to the factory floor of Toyota’s largest plant. You’ll get a first-hand view of Toyota’s culture of continuous improvement and leadership development programs, and you’ll create a tangible action plan on how to take your own Lean program to the next level.

Registration for this November 16-18, 2021 event also includes a tour of Woodford Reserve Bourbon Distillery, it does not include transportation to Kentucky or hotel accommodations. This event is for ILC members only.

We are hoping this can happen in 2021 – waiting for confirmation from Toyota.

Let’s Connect

- Upcoming Events

- Continuous Improvement Cohort

- Lean Basics Online Course

- Lean Learning Hour

- Member List

- ILC Membership Map

- ILC E-news Sign Up

- Member Log In

- Work & Careers

- Life & Arts

Become an FT subscriber

Try unlimited access Only $1 for 4 weeks

Then $75 per month. Complete digital access to quality FT journalism on any device. Cancel anytime during your trial.

- Global news & analysis

- Expert opinion

- Special features

- FirstFT newsletter

- Videos & Podcasts

- Android & iOS app

- FT Edit app

- 10 gift articles per month

Explore more offers.

Standard digital.

- FT Digital Edition

Premium Digital

Print + premium digital, weekend print + standard digital, weekend print + premium digital.

Essential digital access to quality FT journalism on any device. Pay a year upfront and save 20%.

- Global news & analysis

- Exclusive FT analysis

- FT App on Android & iOS

- FirstFT: the day's biggest stories

- 20+ curated newsletters

- Follow topics & set alerts with myFT

- FT Videos & Podcasts

- 20 monthly gift articles to share

- Lex: FT's flagship investment column

- 15+ Premium newsletters by leading experts

- FT Digital Edition: our digitised print edition

- Weekday Print Edition

- Videos & Podcasts

- Premium newsletters

- 10 additional gift articles per month

- FT Weekend Print delivery

- Everything in Standard Digital

- Everything in Premium Digital

Complete digital access to quality FT journalism with expert analysis from industry leaders. Pay a year upfront and save 20%.

- 10 monthly gift articles to share

- Everything in Print

Terms & Conditions apply

Explore our full range of subscriptions.

Why the ft.

See why over a million readers pay to read the Financial Times.

International Edition

- Our Clients

- Client Testimonials

- Our Partners

- #AskSensei Lecture Summaries

- In the Press

- Privacy Policy

- Lean Mining

- Lean Training Course & Certification Program

- Kaizen Training Programs

- Online Lean Training Courses

- Events Calendar

- #AskSensei Webinar

- Lean Japan Tour

- Japanese Business Etiquette

- Managing Multicultural Teams

- Past Events

- Lean Training Testimonials

- Lean Mission Testimonials

- OTRS Case Study – Toyota Boshoku

- OTRS Case Study – Kubota Corporation

- OTRS Case Study – Marugo Rubber

- OTRS Case Study – SUNAQUA TOTO

- OTRS Case Study – Nichirin

- OTRS Case Study – Nippon Express

- OTRS Case Study – Takenaka

- OTRS Case Study – Rejoice Company

- OTRS Case Study – Yachiyo

- Time Study App – Mobile OTRS

Subaru – Factory Tour

Subaru corporation (formerly known as fuji heavy industries) is one of japan’s globally renowned car manufacturers. aside from the automotive manufacturing business, they also have an aerospace business and make aircraft and structural components which represents almost five percent of their revenue..

Corporate Information

- Company : Subaru Corporation

- Foundation : 1953

- Location : Headquartered in Tokyo

- Main Business : Automotive and aerospace manufacturing

Subaru Corporation – Lean Characteristics

Labor effectiveness, one-piece flow production.

Subaru operates two final assembly plants very close to each other in Ota City in Gunma, Japan, and one in Indiana, USA. It produces over one million vehicles from these three facilities per annum with approximately 70% produced in Japan and 30% produced in the USA. Despite this, only 20 percent of their revenue was generated within Japan – meaning their export strategy is key to their success.

The tour will take us through the press, body (weld) and final assembly shops. This is an impressive plant for its labor effectiveness in final assembly (high value-add), its level of automation in the body shop, and the pure size of the press shop.

There is a one-day buffer of parts between the press shop and body shop due to the lot production method used in the press shop, but everything after that is one-piece flow production through the support of its network of component suppliers.

Amazing Tour. Great experience to see and share with Japanese managers. I learned a lot about their culture, their way to think, to work and to improve by themselves. Great moments during training and after work. Thanks a lot. We will return back home with a new eye and mindset. read more

I was a part of the November 2013 Lean Japan Tour and would highly recommend it for anyone who is serious about Lean Manufacturing. Ben and Paul are well organised and have put together a great tour. The tour is very enjoyable and a great insight into Lean manufacturing. I have come back with a… read more

I thoroughly enjoyed my time on the November 2013 tour. I learned so much about Japanese culture and TPS. Despite coming from the IT industry, I was able to gain valuable insights on the philosophy and principles of Lean that I can apply in my industry. Ben and Paul are top-notch guides. Their wealth of… read more

As I have had a previous unpleasant experience with lean training, I was worried about how much I could gain from this tour. At the end of this magnificent experience I can confirm that Shinka Management has exceeded my expectations. They are so organized, dedicated, helpful and generous. The tour was based on very-well known… read more

The Lean Japan Tour was the best lean management experience I have had. I wish I had done this earlier, so I could have done some things differently. One learns that some aspects of lean that one thought one knew, really have a different dimension to them. It helps to see lean management where it… read more

Paul Smith and the team at Shinka Management, in particular Eri Dennis, did an incredible job planning and leading our tailored Japan Study Tour in March 2024. Our team of construction and training professionals learnt and more importantly experienced so much about lean management and Japanese construction, manufacturing and factory practices. Without the expertise and… read more

The Shinka Management Lean Japan Tour is a professional development program run several times annually. The program includes a mix of lean and kaizen seminars, hands-on lean training and visits to several benchmark lean companies. For further information and program dates, see the lean tour overview page.

Tour Inquiries

Interested in joining us in Japan? For additional information prior to registration please fill in the form provided or contact us .

The above form is for inquiries related to the Lean Japan Tour program, Shinka Management consulting and training services, and lean manufacturing software products. Shinka Management does not represent Subaru. For Subaru-related product and service inquiries, please contact Subaru directly.

Park of Culture and Leisure - All You Need to Know BEFORE You Go (2024)

- (0.92 km) Elektrostal Hotel

- (1.60 km) Yakor Hotel

- (2.10 km) Hotel Djaz

- (2.25 km) Mini Hotel Banifatsiy

- (2.32 km) MTM Hostel Elektrostal

- (0.11 km) Teremok

- (0.34 km) Coffee Shop Usy Teodora Glagoleva

- (0.40 km) Mazhor

- (0.48 km) Tashir Pizza

- (0.50 km) Ermitazh

IMAGES

VIDEO

COMMENTS

(Get More LEAN at) https://paulakers.net/Are you interested in Lean Manufacturing? Well take a trip to the shop floor and see a lean factory tour at FastCap...

Join podcast producer, Matt Thompson as he goes behind the scenes at Seating Matters factory to see how they've successfully implemented lean in their cultur...

The lean manufacturing tour includes an intensive week of factory visits, senior management discussions, training in a Toyota Group lean training facility and Japanese cultural experiences. We look after you from the moment you touch-down in Nagoya, providing train transfers and private bus transport, first-class accommodation and meals ...

(Get More LEAN at) https://paulakers.net/Paul Akers provides the requirements for a tour of FastCap and also provides an updated tour of FastCap. Check out ...

Toyota Factory Tour - Lean Characteristics TPS, Jidoka, Just-In-Time Production. Toyota is the home of the Toyota Production System (TPS). The lean manufacturing movement is based around the management principles, tools and culture that Toyota has been developing for over 60 years.. Supported by the two key pillars of Jidoka (a Japanese word that can be translated as "automation with a ...

Lean Manufacturing Factory Tour: I personally love the way that Paul Akers has taken his company FastCap and transformed it into a world class organization by implementing simple and easy lean manufacturing principles. Paul has not done anything fancy or complicated! He has taken the basic lean manufacturing principles and applied them to help ...

Videos. Videos on Lean Manufacturing, Six Sigma, Operations and Supply Chain. These videos are meant to be instructive and educational, showing the reader virtual factory tours and other educational items related to the practice of Lean, Six Sigma, and efficient and effective application and Operations best practices.

The Lean Japan Tour was an educational and exciting experience. The Shinka Management team with its impeccable all-round service ensured that the head and heart were free and open the whole time to be able to collect the many impressions. The factory tours, in connection with getting to know the country and culture, have expanded… read more

A lean factory tour is a visit to a manufacturing facility that has implemented lean manufacturing principles. During a lean factory tour, visitors can observe the different elements of the lean manufacturing system in action and learn how they contribute to the overall efficiency of the facility. FastCap is a company that specializes in ...

Are you interested in Lean Manufacturing? Well take a trip to the shop floor and see a lean factory tour at FastCap in Ferndale, Washington. Paul Akers is the founder and president of FastCap, based in Bellingham, WA. FastCap is an international product development company founded in 1997 with over 2000 distributors worldwide.

TOYOTA and Shanghai - Lean factory tour -. Let's take in the highlights of Japan factory and China on this 9 day tour from Aichi to Shanghai. Countries : 4 nights in Japan and 4 nights in China. 11-day tour can also be arranged. Visit factories in Aichi. (Toyota's and suppliers' factories)

Take a Lean Tour of FastCap. by Paul on Tuesday, June 10th, 2014. Are you interested in Lean Manufacturing? Well take a trip to the shop floor and see a lean factory tour at FastCap in Ferndale, Washington. Paul Akers is the founder and president of FastCap, based in Bellingham, WA. FastCap is an international product development company ...

Lean Videos. Take a Tour of FastCap. FastCap Tour 2.0. Morning Meeting 1. Morning Meeting 2. Lean Is Simple. 2020 Best Improvements. 2019 Best Improvements. 2018 Best Improvements.

Lean Manufacturing - Lean Factory Tour - FastCap. 7,557 views. 1 min read. In this video, it is possible to do a virtual tour of a Lean Factory. Fastcap is a Lean Factory that shows on Youtube a lot of Lean Applications. See now. Fastcap. In this video, it is possible to do a virtual tour of a Lean Factory. Fastcap is a Lean Factory that ...

A one week educational and cultural Lean tour to Japan to observe first- hand, how Lean thinking and practices have elevated Japanese companies to world-class status in operational excellence. ... "I loved the balance of the factory tours, culture and team building activities. I'm so inspired and eager to get back and share and teach my ...

Dates. October 16, 2024 - October 18, 2024 ET. Location. Louisville, Kentucky and Princeton, Indiana. Why you should attend. Learn the secrets of lean manufacturing, a journey fraught with challenges, false starts, and stops. Gain insights into proper leadership, commitment, and development required for success. Cost.

The Iowa Lean Consortium's Kentucky Lean Tour will explore the best practices in Lean leadership by taking ILC members on an in-depth walking tour of the largest Toyota plant in the world. This event will be led by Mike Hoseus, executive director of the Center of Quality People & Organizations and co-author of the book Toyota Culture.

7.55 am Team Morning Meeting. 8.30 am Inventory walkthrough. 9.00 am Practical Demonstrations. 10:00 am Q & A Session. 11.15 am Tour Ends. The key to getting Lean to take root in your organisation is to create a culture of continuous improvement where every single person in the organisation is committed to small daily incremental improvements.

The heavy impact from disruption at a lowly plastic component contractor shows how vulnerable Toyota's lean manufacturing philosophy has made it. The business is tightly integrated with more ...

Elektrostal , lit: Electric and Сталь , lit: Steel) is a city in Moscow Oblast, Russia, located 58 kilometers east of Moscow. Population: 155,196 ; 146,294 ...

The Shinka Management Lean Japan Tour is a professional development program run several times annually. The program includes a mix of lean and kaizen seminars, hands-on lean training and visits to several benchmark lean companies. For further information and program dates, see the lean tour overview page.

Elektrostal metallurgical factory; Elektrostal chemical-mechanical factory; Elektrostal Heavy Engineering Works, JSC is a designer and manufacturer of equipment for producing seamless hot-rolled, cold-rolled and welded steel materials and metallurgical equipment.

Most Recent: Reviews ordered by most recent publish date in descending order. Detailed Reviews: Reviews ordered by recency and descriptiveness of user-identified themes such as waiting time, length of visit, general tips, and location information.

Elektrostal is a city in Moscow Oblast, Russia, located 58 kilometers east of Moscow. Elektrostal has about 158,000 residents. Mapcarta, the open map.