Cruise Ship Engine Room (Everything You Want to Know)

Disclosure: This post may contain affiliate links. We may receive compensation when you purchase via my links at no cost to you. See my disclosure for more information.

Cruise ships require a lot of power to sail and operate. The cruise ship engine room is both mysterious and fascinating because it’s hidden from passengers.

Passenger ships have come a long way from sails and steam engines. Modern cruise ships use diesel-electric engines, while newer cruise ships are moving towards more environmentally friendly solutions like liquified natural gas.

Here’s everything you need to know about a cruise ship’s engine room.

Table of Contents

Where is the Cruise Ship Engine Room?

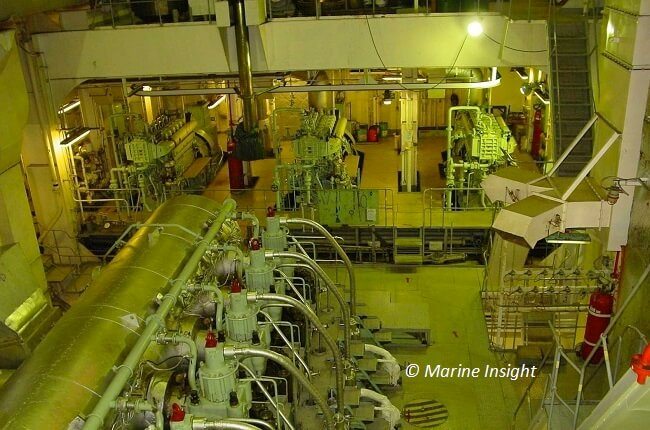

The engine rooms on cruise ships are located on the lower decks, between the midship and the aft. The engines aren’t quite at the back of the vessel but closer to midship.

There are several reasons for keeping the cruise ship engine room away from passenger areas.

- Stability : Placing the engines and heavy equipment below sea level helps keep the ship stable and prevents cruise ships from tipping over .

- Noise : Engine rooms are extremely noisy. Naval engineers compensate by incorporating sound reduction features and noise dampeners. However, the sound and vibration wouldn’t be pleasant for cruise ship passengers.

- Security : The engine room spaces are in crew-only areas for safety and security purposes.

Most of the heavy machinery on a cruise ship is located on the lower decks, just above the keel. The positioning of the engine room, other machines, and technical equipment give the massive vessels a lower center of gravity.

Although you might envision the engine room as a massive open room running the ship’s length, the lower decks are divided into several water-tight compartments. One compartment may house the cruise ship water fresh water systems , another for the main engines, and another for the air conditioning.

The division of the engine room into separate compartments is for safety. Dividing the engine room into different containers makes it easier for the ship to contain the damage if there’s a fire or leak in the hull.

Cruise ship fuel tanks are also on the lower decks, but they are kept separate from the main engines.

Crew members can monitor the ship’s systems from the engine control room. From the operation control center, crew members monitor the ship’s systems and act as a central area for maintaining the technical equipment on the cruise ship.

Every piece of equipment can be monitored from the engine control room to ensure the cruise ship runs smoothly.

The room is monitored 24/7 by watchkeeping teams. Each crew member is assigned specific machinery. For example, one person may be responsible for the freshwater generators and water pumps and another for the fuel oil systems.

How Big is a Cruise Ship Engine?

A cruise ship engine room spans several decks and holds the ship’s engines, fuel tanks, water systems, generators, control room, engine workshop, air conditioning, and other essential navigation systems.

Modern diesel-powered cruise ships have between four to six medium-speed (500 revolutions per minute) engines . Each engine can generate upwards of 25,000 horsepower or nearly 18.5 megawatts.

The engines on a cruise ship can be up to 45 feet long, 27 feet high, and weigh up to 275 tons .

These massive engines can propel cruise ships at an average speed of 18-22 knots .

Cruise Ship Engine Technology

Cruise ship engine technology has evolved from wind and sails to newer liquified natural gas technology.

We’ll cover some of the most popular technologies used by cruise ships.

Steam Engines

When the cruise industry began in the mid-1800s, vessels were propelled by steam engines.

Steam engines had boilers that used wood for fuel. Later steam engines used coal.

The boiler produced steam which created pressure in a pressurized system. The pressure moved pistons which drove the propeller shaft.

The Titanic was powered by two huge triple-expansion steam engines and a small propeller. ( Source )

Diesel Engine s

Diesel engines propel most modern ships. Cruise ships may have four to six medium-speed (500 rpm) engines producing 8-10MW each .

Diesel engines work on the same concept as steam engines. Rather than steam, the ignition of diesel fuel pushes the pistons up and down, turning the crankshaft attached to the propeller shaft.

Many of today’s diesel-engine cruise ships also employ a shaft generator to generate electricity for shipboard services, like lighting.

A shaft generator converts the circular motion of the propeller shaft into electricity. However, shaft generators only operate when the ship is moving. And can’t generate electricity while docked in port.

Diesel-Electric Cruise Ship Engines

Almost all new diesel-powered cruise ships use diesel-electric engines.

The engines work the same as a traditional diesel engine, but rather than connecting to the propeller shaft – diesel-electric engines connect directly to large generators .

A diesel-electric engine has one job, generating electricity.

The electricity produced by the engine is used to power the ship’s propellers.

These engines provide greater efficiency than traditional diesel engines.

While connected to a generator, the engines can run at their most efficient settings regardless of the travel speed . Whether the ship is sailing at 10 or 20 knots, the engines can operate a peak efficiency.

Diesel-electric engines are popular because of their ease of control, low noise, minimal vibration, and relatively compact size compared to other forms of propulsion.

Marine vessels that run on diesel power must carry exhaust-treatment systems and catalytic-reduction equipment to reduce the environmental impact of the ship.

Gas-Turbine Power System

Royal Caribbean Group was the first company to experiment with gas-turbine systems.

Compared to diesel engines, gas turbines offer several advantages, including:

- Lower environmental impact.

- More reliable.

- Take up less space.

- Gas engines require a smaller maintenance crew and less inventory.

The heat generated from the engine is recovered and used to produce electricity for other onboard systems, such as air conditioning and water heating.

Despite their advantages, gas propulsion is not widely used in the cruise industry. Gas-powered ships are faster, but most cruise ships don’t travel faster than 22-25 knots .

Diesel engines have greater fuel efficiency at slower speeds , and the high gas price compared to diesel makes them more costly to operate.

LNG Powered Ships

Many new cruise ships are propelled by liquified natural gas (LNG).

LNG is the cleanest fossil fuel currently produced. According to Cruise Critic , LNG-powered cruise ships can “reportedly reduce sulfur emissions by as much as 99 percent and nitrogen oxide emissions by up to 85 percent.” LNG can reduce carbon emissions by up to 20 percent .

The special engines of LNG-powered cruise ships use natural gas cooled to approximately -260°F. Once cooled, the liquid form of natural gas is about 600 times denser than natural gas , making it easier to transport.

Carnival Cruise Line announced the first LNG-powered vessels in 2015, using a “dual fuel” design. The ships can burn both liquified natural gas and marine fuel, reducing the required fuel storage space.

AIDAprima became the world’s first LNG-powered cruise ship on her debut in 2016.

Natural gas is purer, cleaner, more efficient, and cheaper than other fossil fuels . But it’s a relatively new technology, and not all ports have the facilities for refueling LNG-powered ships.

Because natural gas burns cleaner than other fossil fuels, the engines require less maintenance. But LNG has a lower fuel density than diesel, so LNG vessels need fuel tanks that are twice the size.

Emergency Generators

Every cruise ship has an emergency generator to maintain vital electrical power in case of engine failure.

The emergency generators are located away from the main engine room, usually on a higher deck. Their location isolates them from catastrophic damage in the engine room (for example, a fire).

The generators can operate critical navigation systems, emergency lights, and other vital equipment. But emergency generators can’t power the ship .

Larger ships may have multiple emergency generators. But due to the size constraints, they can’t produce the same power as the main engines and cannot propel the ship.

What happens if the generator fails?

Cruise ships have several redundant systems to ensure the safety and security of passengers. If the generators fail to work during an emergency, cruise ships have an emergency battery backup to power the most critical systems for up to 24 hours .

Shore-to-Ship Power Supply

Despite innovations in engine technology, cruise ships produce a lot of pollution.

To further reduce ships’ environmental impact, many cruise ships can connect to the cruise port’s power grid , known as “shore-to-ship power” or “cold ironing.”

In the past, cruise ships kept their engines running while docked to generate electricity for shipwide services.

But most of the energy produced by the ship’s engines goes towards powering the propellers, and running the engines while docked created massive energy waste.

Some cruise ships used smaller generators to power the hotel and amusement functions. The smaller generators allow cruise ships to shut off the main engines in port, reducing pollution.

Modern cruise ships are equipped with systems to “plug in” to the local power grid. Even some older cruise ships are being retrofitted to allow for shore-to-ship power.

Not all cruise ports have facilities to enable shore-to-ship energy. But many larger cruise ports have dockside electrical hookups that allow cruise ships to shut off their engines and run on the city’s electrical grid. The technology reduces harmful emissions by up to 95% while ships are docked .

Considering how much time cruise ships spend docked at port, it significantly reduces sulfur and carbon emissions.

How Loud is the Engine Room of a Cruise Ship?

A cruise ship engine room is incredibly noisy, exceeding 173 decibels . At this noise level, the noise in an engine room can cause immediate damage to your hearing without proper ear protection.

For reference, a gunshot is 130 decibels.

Engine rooms have insulation and sound-reducing technology, so it’s not as noisy. To prevent hearing damage, crew members must wear hearing protection when entering the multi-story engine room.

But guests don’t have to be concerned about the noise.

Thanks to the insulation and sound dampening, you’ll only hear a slight “purr” if you’re near the engine room.

You may feel the engine’s vibration if your cabin is on the lower decks, near the aft . On most ships, the noise isn’t enough to cause any annoyance or trouble sleeping.

But if you’re a light sleeper, accommodations near the engine room are among the worst cabins on a cruise ship .

Where are the Fuel Tanks?

The fuel tanks are located below the passenger decks , near the engine room. The fuel is stored in double bottom tanks.

How Much Fuel Can a Cruise Ship Hold?

A large cruise ship of 1,100 feet in length can hold between 1 to 2 million gallons of fuel .

It’s enough to power the cruise ship for up to two weeks of sailing without refueling.

Are There Cabins Near the Engine Room?

Newer cruise ships have a large gap between the cruise ship engine room and passenger cabins to minimize noise and vibrations.

However, you may still find cabins reasonably close to the engine room.

If you book a cabin near the engine room, you can expect to hear some noise and feel the vibrations caused by the engines . However, cruise ships use sound-dampening technology and insulation to minimize noise pollution.

The engines are typically cheaper because most passengers avoid booking cabins next to the engine room.

Cabins near the cruise ship engine room aren’t noisy enough to cause annoyance or sleeping issues.

If anything, the vibrations caused by the engines are more likely to cause annoyance over the sound of the engine .

How Much Fuel Do Cruise Ships Use?

It takes a lot of fuel to power a cruise ship.

The average cruise ship uses around 18.3 gallons of fuel per minute or 1100 gallons per hour . ( Source )

Marcello De Lio

Leave a Reply Cancel Reply

Your email address will not be published. Required fields are marked *

Name *

Email *

Add Comment *

Save my name, email, and website in this browser for the next time I comment.

Post Comment

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Trending now

The Shipyard

For Those Who Love Ships

- Cruise Ships

How Cruise Ships Work (Part 3): The Bridge and the Engine Room

It’s like back in the days when we were little children. Grandpaw’s almost mystical tool shed was strictly off limits, but we were just dying to have a peek, weren’t we? Now that we are all grown up, Grandpaw’s gadgets are old news, but there is still a place or two on a cruise ship that remains like a pie in the sky for all of us obsessed by ships.

It’s the heart of the matter, it’s where it all happens, it’s the real deal. And if you are anything like me, you would gladly give away a day at the spa, a dessert buffet and even two, or the latest Marvel flick in the movie theater, just to spend a precious hour down in the noisy engine room of your favorite cruise ship. But life being proverbially unfair, modern cruise lines rarely allow their passengers to enter the bridge or the engine rooms of their ships, unless the visit is part of a specially organized guided tour. Some cruise ships have a window from which passengers can observe what’s going on in the bridge, but only if they promise not to disturb the officers. Which is really hard, when you badly want to touch everything…

So until the next time someone lets me out of sight and I make my umptieth attempt at trespassing to the engine room, let’s have a quick virtual tour of a cruise ship’s most forbidden and exciting parts.

The bridge is the brain of the ship. It is from there that the captain and his officers command and maneuver the ship, keep watch for other vessels or potential hazards, and navigate through the oceans.

For twenty-four hours each day, the bridge is occupied by two Deck Officers and two Able Seamen, traditionally in four-hour shifts. The main job of the Officer of the Watch is to monitor the ship’s systems and surroundings, and to ensure that everything is running safely and smoothly. During extreme weather, docking, or other special cases, the Captain of the ship is also present on the bridge to guide the deck officers.

The term “bridge” comes from the time of the paddle steamers, where a bridge was built above the two paddle houses that used to hold the paddle wheels. This way the skipper could observe both wheels, while moving freely between the two and giving out commands. On today’s cruise ships, the bridge is usually on the upper deck in the forward part of the ship and extends over the sides of the superstructure, allowing deck officers a view to the sides of the ship as well as down to the waterline. The side extensions are called bridge wings and often have a glass flooring for better visibility.

The bridge houses a number of important nautical devices and information systems for command and navigation of the ship.

Satellite Navigation

The signals emitted by special navigation satellites are picked up by the cruise ship through a special antenna. On board, a computer converts these signals into the exact position of the ship at a given time. On large ships, the position indicator is constantly recorded in a so-called electronic nautical chart.

Satellites also enable automatic positioning systems on modern cruise ships. The positioning system is controlled from the bridge and it uses GPS to ensure that the ship stays at a defined location. When the captain defines a position where the ship needs to remain for a while without anchoring, the system automatically maintains the ship in position by using the bow and stern thrusters.

Modern cruise ships carry a gyro compass and a magnetic compass. The gyro compass consists of a fast-rotating disk, usually positioned in a gimbal. It is a non-magnetic compass oriented parallel to the axis of rotation of the earth and thus indicates the north-south direction.

The gyro compass is more accurate and reliable than the magnetic compass and is therefore the primary reference point for steering the ship. The magnetic compass on board is more prone to inaccuracies and it serves only as back-up.

The word radar stands for Radio Detection And Ranging. Radars are devices that allow us to locate distant objects from a given location, regardless of visibility and weather conditions. The radar emits electromagnetic waves to an object, then receives back the reflected echoes from that object, and interprets them based on distances and angles. These interpretations enable us to determine where an object lies, and in some cases even what its contours look like. In the shipping industry, radars are used for monitoring traffic in ports and coastal regions, for collision protection, for collecting weather data, and for navigation.

Speed logs are devices that measure the speed of the ship. There are two main types of speed logs: Doppler logs and electromagnetic logs.

The Doppler logs send out underwater sound signals. When the sound wave reaches the sea floor, it gets reflected and then returns to the receiver of the log. Due to the movement of the ship relative to the seabed, a Doppler effect occurs and is evaluated by the device. As long as the sound waves can reach the bottom of the sea and return to the receiver, the Doppler log measures the distance travelled over ground. However, if it is no longer possible to use the seabed as a reference, the device uses particles suspended in the water, such as plankton and minerals, to measure travel through the water.

The electromagnetic logs create an electromagnetic field in the water around the ship, with the aid of a small alternating current and a transducer. A voltage proportional to the speed of the ship is generated in the water and is picked up by special sensors, which then transfer the information to an electronic device for interpretation. From the electronic device, the speed is then transmitted onto the displays in the bridge.

Echo Sounder

Cruise ships also have an echo sounder, a device used for the electro-acoustic measurement of water depths (sounding). The depth is determined by measuring the time between the emission of a sound impulse (water sound) and the arrival of the sound waves reflected from the bottom of the sea. The main purpose of echo sounders in cruise ships is safe navigation through waters.

Electronic Chart Display and Information System

The Electronic Chart Display and Information System (ECDIS) is a console, built into the bridge of modern cruise ships, which incorporates the main engine safety system, fire control system, monitoring and control system, power management system, propulsion control system and navigation and maneuvering system. The ECDIS allows for navigation of the ship without the need of traditional paper charts. Navigation can be done manually, automatically, or through the Navigation and Command System (NACOS).

The NACOS is the main software used to coordinate all factors that need to be taken into consideration, in order to navigate and maneuver the ship safely. The console is composed of a number of displays showing information from the radars and compasses, data about the course of the ship and planned maneuvers, the current status of the pitch of the thrusters, the speed of the ship, and anything else concerning the steering of the ship. An intelligent autopilot tracks changes in the behavior of the ship through navigational sensors. If the ship drifts off its course due to strong winds, for example, the system automatically responds to correct the change by sending signals straight to the engine room. Once the signal is received by the engines, the rudder or thrusters of the ship are activated and move to the position given by the system. The displays on the bridge show both the angle of the rudder or thrusters, as well as the rate and the radius of the maneuver in progress.

The Engine Room

The engine room is the heart of a cruise ship. It is here that pistons hammer and crankshafts turn to propel the ship forward. It is the loud and oily place where the Chief Engineer and his team work around the clock to ensure that everything is running smoothly. It is the engine room of the ship that allows for the luxuries of air-conditioning, electricity, and plumbing on board cruise ships.

In future articles we will have the chance to explore the contents of the engine room in all the excruciating detail that they deserve, so to all the techies out there – I’ve got you covered. Just stay tuned.

Most larger ships have more than one engine room to house their machinery. The arrangement of the engine room can vary depending on the type, design, and size of the ship. For stability reasons, the engine machinery is typically placed as low as possible in the ship’s bowels and often takes up several decks in height. The machine rooms are split into watertight compartments, each housing different machinery.

Today’s cruise ships operate on diesel or diesel-electric engines. Their operating principle does not differ much from the old days of coal steamers, except for the medium used to generate power. While back in the day ocean liners used steam to move the engine’s pistons, modern cruise ships use diesel fuel. Today’s diesel engines are composed of the engine unit itself, gearboxes, shafts and generators. Some ships also have shaft generators which create electricity from the turning movement of the propeller shaft. The electricity is then used in the cabins, on deck and in the kitchens.

The latest generation of cruise ships are equipped with diesel electric engines. Instead of the more traditional engine-shaft-propeller arrangement, in this case the engines are connected to generators to create electricity. The generators power electric motors, and the electric motors move the propellers.

Aside from the engines and generators, the machinery that occupies the engine rooms includes pumps and heat exchangers for engine cooling, stabilizer fins and their motors, as well as the ship’s bow thruster system.

Since all of the equipment in the engine room is highly dependent on electricity, modern cruise ships also have back-up generators, usually located outside the main engine room, to protect them in case of fire. While these generators cannot produce enough power to keep the ship moving, they produce enough to keep some of the vital functions of the ship running, such as powering the emergency lights and the communication and navigation systems. In case the back-up generators fail, cruise ships are also equipped with a back-up battery that allows some of these functions to continue running for short periods of time.

All the machinery in the engine rooms is monitored in the Engine Control Room (ECR). The ECR is a room full of screens, lights, alarms, and switches from where the current operational status of every piece of equipment can be checked.

The main switchboard of the ECR is used to distribute the generated electricity to where it is needed on board. The ERC is also where the engineering team comes together to discuss and plan the safe running of the engine rooms, to take decisions in emergency situations, to consult the technical manuals and drawings of the ship, to restart certain pieces of machinery if necessary, and to maintain communication with the bridge. Communication between the ECR and the bridge is crucial for the safe operation of the ship, especially during docking, moving through shallow waters, maneuvering, and changes in the course or speed of the ship.

This concludes our three-part overview of how a cruise ship functions. Now that we have covered the basics, in future articles we can explore all the specifics to our hearts’ content. As always, don’t hesitate to leave your constructive comments below and feel free to suggest topics you want to know more about – chances are I want to know more about them too!

Stay in touch and I’ll see you next time!

Share this:

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Privacy Overview

This is How Cruise Ships Work

by Contractor | Nov 24, 2020 | resources , Travel Tips | 0 comments

Are you wondering how cruise ships work? Whether you’re planning a trip or just curious about a cruise ship’s technicality or even the logistics, it’s always intriguing to find out how massive ships like work. How does a cruise ship work?

First and foremost, a cruise ship’s heart is in the engine of the vessel. The engine’s design, paired with proper fueling, provides the power for the ship’s mobility and all the entertainment aboard. The ship’s engineering and the logistics of running a cruise company play a role in shaping how a cruise ship works overall

If you are an engineer curious about a ship’s mechanics, this is an article for you. Fortunately, if you’re just a curious traveler wondering how a cruise vessel will shape your next trip, this is also for you, so read on. There is so much to a cruise ship other than the cocktails and fun parks on top. This will be an eye-opening article for all audiences.

How Do Cruise Ships Work

To the ultimate question, “how a cruise ship works,” let’s dive into how it works mechanically. What are the technical and mechanical aspects of a cruise ship? What does an engine do? How does a massive ship provide light, food, entertainment in the middle of an ocean? Is the water safe to drink?

Then, after reviewing how the cruise ship’s mechanics work, the answer to how a cruise ship works logistically can be answered. How do companies make a profit from these vast ships? How do the ships prepare for new passengers?

Technical Aspects of Cruise Ships

The technical aspects are a vital part of a cruise ship, so it will be first visited. Not to state the obvious, but the ship’s heart is shaped by the crew and the engineers that have put many hours and dedication into making a cruise ship work.

This is article will reveal the true hidden layers of what makes it all work starting from ground zero, the heart.

Technical Aspects

If you want one thing in a cruise ship aside from the cocktails and a nice tan, it’s the vessel’s stability and durability. Whether you are traveling through an unexpected storm or cruising on a gentle wave, your cruise ship should be the most stable in all situations.

How are cruise ships stabilized? The general idea for balancing and maintaining buoyancy is distributing the weight throughout the ship correctly, and of course, displacing the right about of water as it moves. So, let’s first talk about one of the most massive machinery onboard, the engine. Where does it sit and how does it run the cruise ship?

Engine Rooms

Where are the engines located? You guessed it, most heavyweights, such as engines, are found as low as possible in the lower decks, ground zero. For most cruise ships, the engines are close to the keel. The structural keel is the most closes to the bottom of the vessel and the ship’s wide hull. It runs the length of the vessel down its centerline and in most ships, you won’t have to go far to find the engine rooms.

Just because it’s placed low in the ship doesn’t mean it doesn’t take a lot of space. For all the ship’s power, the engine rooms can take up several decks high and are generally divided into several compartments. It may not feel like an open massive space, but it is truly the heart of the ship and the design of the rooms and placement are critical.

Usually, the primary concern for most ships is have engines and machinery compartmentalized for safety and avoiding fire hazards. Compartmentalized and labeled rooms make maintenance simpler and enhances safety for unprecedented accidents.

New legislations also support the requirement for compartmentalization. Ships are required to have at least a duplicate of equipment and at least two separate spaces for engines. So, what about these engines? Why are they so important and why do ships need so many of them?

Power and Engines

Just to answer those questions, we’ll have to visit more fundamental questions such as: How do the engines power a giant cruise ship? How does it help the ship propel forward? Are there specific engines that power different parts of the cruise? Out of many questions regarding the engines, the answer starts with the main engines.

The main engines are the engines that produce the majority of the power for the cruise ship to move. Depending on the type of vessel, the main engine connects to different parts of the propelling power. From traditional steamboats, to diesel electric, the engine is the fundamental powerhouse for the entire ship on the sea.

The following table is a general overview of how engines on different types of vessels are connected to the ship’s requirements.

So How Do These Engines Make the Ship Move?

As shown in the table, depending on the vessel type, the engine will provide power to different aspects of the ship. More or less, everything is distributed to operating proportions, but the key mechanics differ from one to another.

Diesel may be something more familiar to what we saw in old movies with steamboats. Even in modern days, we use similar mechanisms, if not labeled the same. The main difference is the source of pressure, which can be the traditional steam, or a fuel ignition.

Whether it is steam (traditional) or fuel ignition, the pressure generated from either push the pistons up and down in the vessel. These pistons connect to crankshafts through gears, which turns the pistons.

The crankshaft connects to the propeller through a long propeller shaft and gears, which further determines its speed in traditional diesel-powered vessels by steam pressure. Generally, the faster the pistons move up and down from the pressure, the quicker the propeller shifts would move.

With modern designs that control the propeller speed, engineers placed the gears in between the propeller and the engines which further enhances efficiency for both engines and propellers.

Again, although the majority of the engine provides electricity to the propeller shaft, electricity must be provided to the rest of the ship for entertainment. Often, options such as a shaft generator offer power to outlets such as lighting the dining and general appliances onboard while in motion.

Diesel-Electric

Diesel-electric is another form of vessels that are found commonly with conventional diesel vessels. Unlike the conventional diesel, diesel-electric engines are connected directly to the generators that provide the electricity for the propellers and main generators.

This electricity also provides direct power for the ship’s lights, appliances, and much more.

Environmentally Friendly Power

On a side note, if the thought of diesel in the ocean disturbs you, there is some good news! Thankfully, more and more environmentally friendly options are appearing for cruise ships. For example, liquified Natural Gas (LNG) is an alternative method for powering ships that burns natural gas for power.

Using natural gas could reduce nitrogen oxide and carbon dioxide emissions significantly! With green-oriented companies, more green cruises have been released in the past few years.

That being said, if you are looking to book a trip, be on the lookout for green cruising opportunities! Onboard, you can also find environmentally conscious crew members and less-waste policies.

Source: CruiseCritic , Windstar Cruises , Green Cruises

Fuel Consumption

So, how does fuel play a part in powering the engine and the cruise ship? Let’s go back and visit what an engine does. An engine generates electricity to the propellers by supplying power the propulsion motors. How do they get the electricity and what makes an engine work? Most likely fuel and ignition (besides the steamboat example from before).

How much Fuel?

In general, a large cruise ship can consume up to 250 tons of fuel a day, which is close to 80,000 gallons a day. For medium size cruise ships, consumption can still range up to 150 tons of fuel a day.

Onboard, a ship may carry up to 1 to 2 million gallons of fuel, depending on the vessel size. Most of the power, which can be close to 85%, goes to the propellers, while the rest goes to keeping the cruise lit and comfortable for the passengers and crew members.

While passengers dine and enjoy their cruise aboard, crew members are constantly maintaining the proper fuel levels and providing proper power for the ship. As for the captain of the ship, he also has several variables to keep in mind to control fuel consumption and safety.

Fuel consumption may vary for several reasons, just like when we are driving our cars (but with more variability). For example, depending on where the wind is hitting the ship, the fuel consumption can go 1 – 5% over the average consumption rate.

Here is a short list of variables that the captain is keeping track of:

- Speed of the cruise

- Sea conditions (vs. sailing direction)

- Weather (including the direction of the wind)

- Size of the ship

- Engine (Gas turbines, diesel-electric, diesel, or electric)

Source: Windstar Cruises , Cruise Mapper

Overall, the fuel, power, and engine, are all functions of making the magic happen. Starting from the design of the engine, to the crewmembers and captain maintaining the fuel and power consumption, a lot of action happens behind the scenes while passengers are onboard during vacation.

Floating and Buoyancy

Now that the ship is powered, how do we ensure that it floats? How do these massive machineries, ice-skating rinks, restaurants, and bars float on water while keeping thousands of passengers safely onboard?

While the cruise ship constantly pushes the water out of its way when moving forward, the water being pushed will try to come back to its place. This displaced water pushes back with a force on the vessel which lets the cruise ship stay afloat.

This is the general idea when engineers designed the hull of the ship. This ratio has to be calculated when designing a ship and has to be correct. If you get a chance to see the hull of most ships, they have a wide U-shape hull at the front to maintain the displacement.

In addition to basic buoyancy principles, an engineer must also consider the ship’s average density. This means that the ship’s general open spaces must be considered on top of the vessel’s average weight, so the vessel remains “less dense” than the ocean’s (usually salty) water. A great example is a rock sinking vs. a beach ball floating on water.

Source: Express

Water Onboard

So the power, fuel, engine, and buoyancy are the fundamentals of the ship. What about the details of the cruise ship such as the water in your shower? Is it salty? Is it fresh? Where and how does that come to your room without running out.

In general, most cruise ships have a steam-evaporation system. Water is pumped and desalinated before going to your room. During this process, your water is distilled and desalinated using a reverse-osmosis system and filtration system.

Distillation and desalination process uses a purification system to take all contents out of the water. This is generally not healthy to drink, so this water is mineralized and chlorinated for taste and safety.

Additionally, some ships have water brought onboard for laundry and other maintenance purposes. Generally speaking, the water onboard available for drinking are tested and checked for purification. If you are ever in doubt, check with a crew member to ensure the water is safe for consumption.

Is the Water Safe?

The answer to your ultimate question is, no, the water you are drinking is not toilet water. Regulated by the Maritime Organization laws, all “toilet water” must be treated and discharged into the ocean at a specific distance from the land. This water is never treated and recycled for passengers to use again.

On a side note, if you feel uncomfortable drinking this water, bottled water will most likely be available onboard for purchase. If you need special water for medical needs, you will most likely be able to bring a few bottles on board by notifying them ahead of time.

Now that we have reviewed how cruise ships work mechanically, let’s dive into the ship’s logistics. How do they work? Who’s working, how is it supplied, and how are they so cheap? Or perhaps, why are they so expensive? All of these questions come down to logistics.

General Logistics

Depending on your opinion and type of cruise you may have signed up for, you may think that your cruise is way under or over-budget. The cruise companies measure these decisions and prices to minimize cost and maximize returns (of course).

For example, cruise ships avoid fines by taking specific lines. They must often save fuel and hiring a knowledgeable captain who can make these decisions and keep passengers aboard safe is essential.

So, what are the different divisions of a cruise vacation? Are some better than others?

Mainstream, Premium, and Luxury

If we broke down cruises into 3 main categories, we could look at the mainstream, premium, and luxury lines of cruise types. You will often see categories within each of these types, but let’s break them down into the major categories for simplicity.

First, we will start with the mainstream cruise lines. These are cruises that are readily available, common, and well-known by the public with reasonable ticket costs.

Generally, these cruises’ primary business is through the onboard casinos, spas, shopping, and drinks. They suit the needs of most passengers. To make maximum profit, companies design these cruises by providing readily available entertainment on board. Most passengers are estimated to use 500$ onboard for their vacation experience.

Onboard, you will find general amenities, restaurants, bars, pubs, nightclubs, shopping, theaters, cinemas, swimming pools, gyms, karaokes, libraries, and even museums! These are great for big parties and are generally the biggest ships at sea.

Examples of Mainstream Cruise Lines that are known as “floating resorts”:

- Carnival Cruise Line

- Royal Caribbean International

- Norwegian Cruise line

- Lindblad Expeditions

- Amawaterways

Mainstream cruises are great for

- Group of friends

Source: NancyandShawnPower , Fodors , and Wind Rose Network

Premium lines are perfect for adults or those that are retiring. The brilliant catch is that many have policies of “no kids allowed,” making it an excellent selling point for adults who need some peace and quiet. These cruises make money upfront by offering more access to ports and offering the serene luxury.

Premium cruises generally have a refined style in comparison to mainstream cruise lines. Activities are more focused on lifestyles. For example, you may find computer classes or a language-learning class. Besides, these ships still offer resort-style pools, game nights, bingo, spas, gyms, and maybe even a jazz night.

The perks for a premium in comparison to the mainstream is the higher quality of cuisine. Usually offering specialty restaurants and quality chefs, the price may be higher, but the overall quality is higher. The rooms at premium cruise lines are also superior, often offering suites and rooms with balconies.

Examples of Premium Cruise Lines

- Princess Cruises

- Celebrity Cruises

- Holland America Line

The popular audience for Premium cruise lines:

- Older Adults

- Sometimes family-oriented

Source: Fodors

Luxury lines are pricier yet offer the best-selling point, fewer people onboard with a luxurious experience from beginning to end. The more expensive tickets provided to only a few hundred passengers make a profit for the company with the much higher ticket prices.

There are abundant space and a deluxe ship that will greet you as a valued guest from beginning to end for the high price. No doubt, one will fall for such an exquisite experience that starts from fine dining of caviar and foie gras to personal service available at one’s fingertips.

Course meals are offered from a full restaurant menu in your stateroom and served with limitless wine. Most interiors are luxurious and elegant, with rooms that are large and overlooking the sea.

Amenities range from gyms, spas, pools, and low-key entertainment. Generally targeting a niche group, most luxury cruise lines do not allow children.

Examples of luxury cruise lines:

- Windstar Cruises

- Paul Gauguin

- Silversea Cruises

- Crystal Cruises

- Oceania Cruises

Source: Cruise Critic

Many corporations own several of these different targets to make the most profit. Additionally, by corporations owning various cruise types, they can also hand down older ships throughout their other brands.

Logistics throughout the year

In addition to managing several types of cruises, there are numerous ways cruises have to operate to maintain their profits and not waste money through resting and selecting the wrong routes.

For example, cruise lines generally have high sales in November through April by Americans. The cold Americans usually take a warm vacation away from winter for a trip to the Caribbean.

What about other times of the year? Staying on seas without business is a considerable loss in revenue and usually unheard of. So, what do they do? They sell repositioning one-way tickets in April!

Generally, towards the end of April, you will start seeing two-week trips from the Caribbean to Europe. Typically, these trips can range from any state on the Eastern Coast of the United States to European countries.

Switching over/Cleaning

When there are one-way trips, there also needs to be exceptional coordination for a short turnaround between trips. When the cruise ships get to the destination, all hotels, theaters, dining, laundromat, and parks are cleaned and reset for the next people to come on board within half a day!

How do they do it?

During night-time, luggage and bags are ready ashore for passengers to check out. Meanwhile, all the trash is dumped, and the trash containments are cleaned, crew members switch, fuels are refilled, and food is refreshed with new inventory.

Remember the 1 to 2 million gallons of fuel to refill? This process, called bunkering, is a whole-team effort and is completed before the ship is ready to travel again.

A small boat, a “barge,” brings fuel to the 400 ports fueling for ships.

- Barge secures to the side of the cruise ship

- Connects a hose between the ship tanks

- Pumps fuel while watching guard

When passengers load off, then the cleaning crew comes to clean the rooms. While the ship is pampering, they complete paperwork from the first trip, fulfill any necessary maintenance, redecorate rooms, and start preparing and cooking food and lunch for the next set of passengers coming on board.

Soon, the ship is reloaded with happy passengers and starts to move again. They make their profits from when the Casinos start, and food is served.

Crew Members

This brings light to the less noticed crew members. The ones that make all the magic happen. Generally, a cruise will have 1 crew for 2 passengers. Most of the crew members are working very long hours for several months.

In general, these crew ships are in their rooms when not on duty and do not get in the passengers’ way. How do cruises afford these crew members and their extended hours of work? The trick is that cruises can register in any country to abide by their labor laws. This is how they keep costs low, but there is a catch to that.

Crews and Destination

So, there is a catch, but it impacts your travel too. Did you ever wonder why cruises took less than expected stops? Not necessarily detours or emergency stops, but maybe a cruise led you to Ensenada or the Tabuaeran. This is due to the Passenger Vessel Services Act of 1886.

Why do cruises take weird detours?

Generally, a cruise ship can register any Labor law, as stated above. This makes it easy for cruise ships to pick a non-American country since it is cheaper and easier to fulfill (for business purposes). Unfortunately, if they choose this option, they must also abide by the Passenger Vessel Services Act of 1886. This act states that “No foreign vessel shall transport passengers between the United States.”

This means that if the cruise ship is registered under another country, they can never directly stop at an American stop if their initial take-off was in the United States. This is why you see stopes in Ensenada, for example.

For example, before Norwegian registered as American, if their cruise trip was to Hawaii from the motherland, they had to stop at Tabuaeran, a small island nearby.

When Norwegian registered as American, this let them bypass the Passenger Vessel Services Act. Unfortunately, this led the crew members’ service fees to rise, which led to higher ticket prices. If you want to watch how the above logistics work, check out this video !

A Cruise Ship Overview

Starting from the engine, fuel, and engineering to the logistics of companies, crewmembers, and governing policies, a cruise ship works in a marvelous way to shape every passengers’ experience abroad.

Thousands of crewmembers across various cruise ships, engineers of several centuries, and many hours of dedicated personnel make a cruise vacation work. Next time you are enjoying a cocktail on deck, remember that there is so much more behind the meaning of your cruise. There are so many parts that worked to make it happen! Enjoy and bon voyage!

Related Posts:

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Privacy Overview

Optimized Cruise Liner Operation with Expert System Simulation and Condition Monitoring

- Cover Story

- Systems Engineering

- Published: 16 March 2018

- Volume 8 , pages 26–33, ( 2018 )

Cite this article

- Hinrich Mohr 1 ,

- Martin Abart 1 ,

- Vasilios Lamaris 1 &

- Robert Strasser 1

89 Accesses

Explore all metrics

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

http://www.cruisemarketwatch.com/growth/

2017 Cruise Industry Outlook by CLIA. https://www.cruising.org

Sala, S.: Energy Efficient Design and Operation of Cruise Vessels. 6 th International Conference Ship Efficiency, Hamburg, September 2017

Google Scholar

Abart, M.; Lamaris, V.; Eder, S.; Teichmann, R.; Mohr, H.; Takanabe, M.; Taya, C.: Benefits of Cylinder Pressure Based Engine Condition Monitoring using Expert Algorithms — Analysis based on 10 years of experiences in the field. International Symposium on Marine Engineering (ISME), Tokyo, October 2017

Mohr, H.; Zabeu, C.; Abart, M.; Koops, I.; Teichmann, R.; Martelli, A.; Salvador, R.; Peñaranda, A.; Ruy, G.: Operational Optimization of Gas Engine Power Plant by integrated Approach of Expert Condition Monitoring and Closed-Loop Engine Control. 10 th Dessau Gas Engine Conference, Dessau, April 2017

Mohr, H.: World's first Dual-Fuel Conversion of High-Performance Diesel Engines for Fred. Olsen Express High-Speed Crafts. European Marine Engineering Conference 2017, Amsterdam, April 2017

Schyr, C.: Modular Test Environment for Autonomous Navigation Systems; Maritime & Naval Test & Development Symposium 2017, Amsterdam, June 2017

Download references

The authors greatly thank Karl-Heinz Fölzer and Dr. Rüdiger Teichmann, both AVL List GmbH, for their support and contribution to this paper.

Author information

Authors and affiliations.

AVL List GmbH, Graz, Austria

Hinrich Mohr ( Key Account Manager and Product Manager System Integration Large Engines ), Martin Abart ( Product Manager Condition Monitoring Systems ), Vasilios Lamaris ( Technical Expert Engine Diagnostic and Field Support ) & Robert Strasser ( Lead Engineer System Simulation )

You can also search for this author in PubMed Google Scholar

Rights and permissions

Reprints and permissions

About this article

Mohr, H., Abart, M., Lamaris, V. et al. Optimized Cruise Liner Operation with Expert System Simulation and Condition Monitoring. MTZ ind 8 , 26–33 (2018). https://doi.org/10.1007/s40353-018-0001-1

Download citation

Published : 16 March 2018

Issue Date : March 2018

DOI : https://doi.org/10.1007/s40353-018-0001-1

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Cruise Lines

- Condition Based Maintenance (CBM)

- Maximum Cylinder Pressure

- Cylinder Balancing

- Find a journal

- Publish with us

- Track your research

How Ship’s Engine Works?

Marine engines on ships are responsible for propulsion of the vessel from one port to another. Whether it’s of a small ship plying in the coastal areas or of a massive one voyaging international waters, a marine engine of either 4-stroke or 2-stroke is fitted onboard ship for the propulsion purpose.

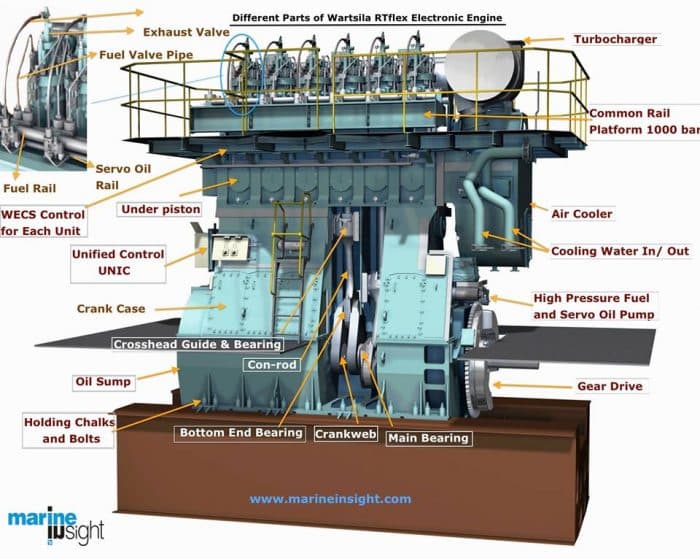

The marine engines are heat engines used for converting heat, which is generated by burning fuel, into useful work, i.e. developing thermal energy and transforming it into mechanical energy. The engines used onboard ships are internal combustion engines (a type), in which, the combustion of fuel takes place inside the engine cylinder and the heat is generated post the combustion process.

Ship Engine Working Principle

As mentioned earlier, IC (Internal combustion) engines are mainly used for marine propulsion and power generation purpose. The working of the marine engine can be explained by the following procedure:

– The fuel is injected at a controlled amount at high pressure

– A mixture of fuel and air is compressed inside the engine cylinder with the help of piston, which results in the explosion of the mixture when pressurized due to compression. As a result, heat is released which increases the pressure of the burning gas

– The sudden increase in the pressure pushes the piston downwards and transmits the transverse motion into the rotary motion of the crankshaft using connecting rod arrangement. The explosion is repeated continuously for maintaining the power output depending upon the type of marine engine and its usage.

Related Read: 14 Terminologies Used for Power of the Ship’s Marine Propulsion Engine

The crankshaft is connected via a flywheel, either to the alternator or to a propeller arrangement for doing the mechanical work. To obtain continuous rotation of the crankshaft the explosion has to be repeated continuously.

Before the next explosion, the used gases are drawn out from the cylinder through an exhaust valve and fresh air is supplied, which helps to push the used gas and also to provide fresh air for next combustion process.

Related Read: Components and Design of Exhaust Gas System

Types of marine diesel engines:

The two basic types of marine diesel engines are –

- 4 stroke engine

- 2 stroke engine

A 4 stroke engine can be installed on the ship to produce electrical power and also to propel the ship (usually in small size vessel). This engine takes 4 cycles to complete the transfer of power from the combustion chamber to the crankshaft.

Related Read: Why 2-stroke Engines are Used More commonly for propulsion than 4-stroke on Ships?

The events taking place in I.C. engine are as follows:

- Suction stroke for taking the fresh air inside the chamber – which is the downward movement of the piston

- Compression stroke to compress the air-fuel mixture – which is an upward movement of the piston

- Power stroke – in which the explosion takes place and the piston is pushed downwards

- Exhaust stroke – which is an upward movement of the piston to draw out used gases

The four events are completed in four strokes of the piston (two revolutions of the crankshaft). An inlet and exhaust valve is fitted on top of the cylinder head to draw in fresh air and to expel the used exhaust gas.

Both, the valves and the fuel pump (which supply fuel to the injector), are operated using camshaft, which is driven by crankshaft using a gear drive. In a four-stroke engine, the camshaft runs at half the speed of the crankshaft. The crankcase is open to the piston liner arrangement, which assists in the lubrication of the liner.

The 2 stroke engines are used for vessel propulsion and are bigger in size as compared to the 4 stroke engines. In this engine, the complete sequence is complete in two cycles i.e.

- Suction and compression stroke – which is the upward movement of the piston to draw fresh air inside and to compress the air-fuel mixture

- Power and exhaust – which is the downward movement of the piston due to an explosion inside the chamber followed by removal of exhaust through the exhaust valve fitted on the top of the cylinder. A stuffing box is used which separates and seals the crankcase against the combustion chamber.

A basic ship engine working video is shown below:

This video shows how a 2 stroke marine engine on ship works-

How and where is ship’s engine made?

If you have seen engines on ships, including small 4 stroke generator engines and also the massive 2 stroke propulsion engines, one thought which must have crossed your mind is how and where these engines were made?

The most famous engine manufacturers, whose engines, are used in ships are:

- MAN Diesel & Turbo (Previously B&W engines) – famous for high, medium and slow speed marine engines

- Wartsila (Previously Sulzer Engines) – famous for high, medium and slow speed marine engines

- Mitsubishi – producing engines for light, medium, and heavy-duty applications

- Rolls Royce – famous for the cruise ship and naval ship engines

- Caterpillar manufactures – for medium speed and high-speed marine diesel engines

Related Read: The Most Popular Marine Propulsion Engines in the Shipping Industry

Wartsila is still the Guinness World Record holder for the largest ship engine ever built.

The Wärtsilä RT-flex96C two-stroke engine fitted with turbocharger holds this record. Manufactured for large container ships , its dimensions are as follows:

Length – 27 metres (88 ft 7 in),

Height- 13.5 metres (44 ft 4 in)

weight > 2,300 tonnes.

Power output~ 84.42 Megawatts (114,800 bhp).

The size of the ship engine varies from ship to ship, type of stroke it has, and its power output. The ship engine can be as high as a 5 story building, and to accommodate it, the ship engine room has to be designed accordingly.

Where are marine engines made?

These marine engines are built at the facilities of the manufacturers. For e.g. MAN Diesel has production facilities in Augsburg, Copenhagen, Frederikshavn, Saint-Nazaire, Shanghai, etc.

Similarly, Wartsila has facilities in Finland, Germany, China etc.

The ship’s engine can also be made in reputed shipyard if there is a contract between the two companies.

The engine is usually made in three different sections (explained below) and depending upon the size of the engine room and access for the installation, it can be fitted in the shipyard either in sections or as an entire assembly.

Related Read: How Massive Main Engines are Fitted in the Ship’s Engine Room?

Material Used For Making Ship Engine

The material used for making the ship’s engine and different ship engine parts are:

Bedplate: The bedplate is the bottom-most portion of the engine which is the base of the engine and accommodates crankshaft bearings and A-frame. For the small engine, a single casting of cast iron is used and for large 2 stroke engines, fabricated cast steel transverse sections with longitudinal girders are used.

Related Read: Important Things To Check In Ship’s Engine Bedplate

A frame: The A-frame, as the name suggests, is similar to the shape of letter ‘A’ and is installed above the bedplate of the engine. It is built separately to carry the crosshead guide and on top, it supports the base of the entablature. The bottom surface of the A-frame is machined for making a mating surface to install on top of the bedplate.

Entablature: The entablature , also known as cylinder block, is made from cast iron and used to accommodate the cooling water and scavenge airspace. Depending upon the size of the engine, the casting can be either for individual or multicylinder (bolted together). The lower portion of the cylinder block is machined to form a mating surface and fastened with the A-frame using fitted bolts.

The other different ship engine parts which are fitted inside the engine are:

Piston, liner, cylinder, connecting rod, crankshaft, camshaft, fuel pump, exhaust valve, etc. and these important parts can be studied in details in our ebook –

Ship engine maintenance

The basic ship engine maintenance comprises of planned maintenance which includes overhauling of important moving and static parts of the combustion chamber.

Following are some of the most common maintenance done on the marine engine:

- Overhauling and measurement of Piston, rings and piston rod

- Overhauling and measurement of the cylinder liner

- Overhauling and measurement of the exhaust valve

- Overhauling and measurement of the stuffing box

- Overhauling and measurement connecting rod and crosshead bearings

- Overhauling and measurement of main bearings

Related Read: Types of Main Bearings of Marine Engines and their Properties

7. Measurement of crankshaft deflection

8. Checks and measurement of fuel pump timing

9. Checks and overhauling of starting air system

The time between overhauling of different parts of the engine is provided by the manufacturer in the engine manual. The maintenance needs to be performed as per the time specified between two overhauling durations, irrespective of issues shown by the engine.

Apart from timely overhauling, the engine ratings and power needs to be checked using digital power indicator. The scavenge space inspection is also done to check the condition of the piston ring, which in turn defines the efficiency of the lubrication system of the cylinder liner.

Marine engines used on ships are some of the most sophisticated and complicated engineering works. Marine engineers are therefore provided special training for operating, maintaining and troubleshooting marine engines on board ships.

You may also like to read:

Things to Consider During Fuel Valve Overhauling

Do you have info to share with us ? Suggest a correction

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

WAIT! Did You Download 12 FREE Maritime eBooks?

- The Inventory

The Largest Piston Engine In The World Makes People Look Shrink-Ray'd

Anyone thinking about swapping a container ship engine into your '86 Celica? Better think again — these things are huge . You'd probably need something with more room, like a Toronado, or if you're thinking of the 25,480L, 14 cylinder Wärtsilä RTA96-C , maybe something even bigger. Like a vacant lot.

Related Content

The RTA96-C (or the newer RTAflex96-C) is a two-stroke, turbocharged diesel engine designed to run at very low speeds. When each cylinder is 1820 liters, you don't really need all that much speed. In fact, the engine runs at a fairly lethargic 22- 102 RPM, though even at those low speeds you're getting 5,608,310 lb-ft of torque and up to 108,920 BHP. Holy crap. That's the sort of power that God's dad's boss's Ultra-Camaro makes.

But the best thing about the RTA96-C engine is the sheer, improbable scale of it, and how it still, fundamentally, looks like the sort of engine's we're all familiar with. That means in photos of people next to the engine or engine parts, our brains want to read these people as victims of a shrink-ray. These pictures always make me do a double-take.

Also remarkable is that this engine gets mentioned in meme-ified screenshots from the Fast and Furious movies:

Now let's all sit back and bask in just how big this thing is. Look at this picture of a bent rod from one of these. Now just contemplate the forces involved with that.

Holy crap, right?

Which cruise brand is best for you? A guide to the most popular lines

Thinking about booking your first cruise? The sheer range of choices can be daunting. There are more than two dozen lines marketing to North Americans — no two alike.

The list of brands includes everything from giant companies such as Royal Caribbean and Carnival Cruise Line, which are household names, to lesser-known small operators such as Windstar Cruises.

Some of the brands — Royal Caribbean, MSC Cruises and Norwegian Cruise Line, in particular — operate massive vessels that are like giant floating resorts with deck-top water parks and other over-the-top amusements . Others specialize in intimate, boutique hotel-style ships.

For more cruise guides, news and tips, sign up for TPG's cruise newsletter.

Some lines, such as Carnival, are aimed at a budget crowd. Others operate vessels that are as luxurious as any upscale resort found on land. A few small luxury players such as Regent Seven Seas Cruises have ships with lavish suites that'll cost you as much as $11,000 a day .

Where should you start your search for the perfect cruise for you? Below, you'll find our quick guide to some of the most popular cruise brands. As you'll see, it's not meant to be an in-depth review of the lines. It's just a short overview — enough to give you a sense of which particular cruise operator might best appeal to you.

Once you've narrowed down the choices to a few brands that you think best fit your style, do a deeper dive into them and their specific ships, their itineraries and home ports and their comparable costs (either on your own or with the help of a cruise-savvy travel agent ). Note that TPG has many guides to individual lines, which you can find by clicking on our cruise line hub pages linked in each segment below.

Related: TPG's ultimate guide to picking a cruise line

With just four ships, each holding fewer than 700 passengers, Azamara is one of the smallest players in the cruise business. But it has a loyal following of travelers who appreciate the upscale ambience of its vessels, the inclusive amenities it offers (including gratuities and alcoholic drinks) and its destination focus.

The line prides itself on offering longer stays in ports, including multi-day visits. Its ships have an intimate, boutique-hotel feel. Pricing is higher than at the big, mass-market lines but not quite as high as you'll find at luxury lines.

Related: 5 things to love about Azamara's newest ship

Carnival Cruise Line

The self-described "fun ship" line is the king of short, affordable, fun-focused cruises from U.S. ports to the Caribbean, the Bahamas, Mexico and beyond.

The choice of roughly one in five cruisers, Carnival Cruise Line' s ships are notoriously lively, flashy and packed with fun features such as water parks with multiple waterslides. Just don't expect anything too fancy .

Related: The ultimate guide to Carnival Cruise Line

Celebrity Cruises

Designed to be a cut above mainstream options such as Carnival while remaining relatively affordable, this Miami-based "premium" line is known for some of the most stylish big ships at sea.

Expect high-end design, cutting-edge art and trendy restaurants. In short, Celebrity aims for sophisticates, not the party crowd (although it's not a luxury product).

Celebrity's four newest ships, Celebrity Edge , Celebrity Apex , Celebrity Beyond and Celebrity Ascent, feature "infinite veranda" cabins that are open to the sea in a way we haven't seen with other ocean ships. They boast a glass wall that opens from the top to create a balcony-like effect.

Crystal Cruises

This much-beloved luxury line recently restarted operations under new owners after shutting down for 18 months. For years, it was considered the ultimate luxury cruise operator, and our take after sailing on Crystal Serenity after its relaunch is that the line is even better than before. Initially, Crystal has returned to operations with just two ships. But it recently announced plans to expand rapidly with four more ships over the next six years.

A storied line with roots that go back to the 1800s, this three-ship brand is perhaps best known for its 2,695-passenger flagship, Queen Mary 2. The ship lives up to its billing as a true ocean liner with semiregular, transatlantic service between Southampton, England, and New York.

Cunard fans love the line's relatively formal vibe (including nightly dress codes) and other nods to ocean liner tradition, including evenings with ballroom dancing. A fourth Cunard ship called Queen Anne is set to debut in 2024.

Related: Why I was wrong about transatlantic cruises

Disney Cruise Line

Meet-and-greets with Disney characters, Disney-themed shows and the most extensive kiddie fun zones on the high seas are just a few of the family-friendly allures of a Disney cruise . If you're a Disney fan, nothing quite compares.

If Disney isn't your thing, well, this probably isn't the line for you. The biggest downside of the brand? As with Disney's parks on land, it doesn't come cheap.

Related: A first-look photo tour of Disney's newest ship, Disney Wish

Holland America

Tradition long has been a touchstone for this storied line, which dates to 1873 and is known for carefully crafted, globe-circling itineraries on midsize ships.

However, Holland America has been shaking things up in recent years with lively new venues such as B.B. King's Blues Club. Couples and retirees are the market for this line. Families with kids might want to look elsewhere.

MSC Cruises

A giant of cruising in Europe, Switzerland-based MSC Cruises is making a big play for North Americans with newer, bigger ships sailing year-round from Florida to the Caribbean and Bahamas. It also offers sailings from New York City.

Like Royal Caribbean and Norwegian, MSC Cruises operates big, resort-like vessels that appeal to a broad audience. Among the highlight of its cruises in North America are stops at its new private island in the Bahamas, the Ocean Cay MSC Marine Reserve .

Norwegian Cruise Line

Multistory waterslides, ropes courses and even go-kart race tracks are among the gee-whiz attractions atop Norwegian Cruise Line 's giant, resort-like ships. The vessels also are packed with eateries, bars, casinos and showrooms.

The brand is known for its entertainment, including big Broadway shows such as "Beetlejuice." If you're looking for a Las Vegas-style resort at sea, this is your line.

Oceania Cruises

Oceania has carved out a niche with relatively small, upscale ships that offer a significant upgrade from mass-market vessels but aren't quite as fancy (or pricey) as luxury offerings.

Its seven ships feature a relaxed, country club-like ambience and inspired dining that appeal to a mostly older crowd.

Itinerary-wise, Oceania is known for destination-intensive voyages that typically are 10 nights or more in length, with some globe-circling trips as long as 180 days.

Related: Take a look at Vista, Oceania's stunning new ship

This France-based line is a specialist in expedition cruising , a type of cruising that involves traveling to remote, hard-to-reach places on small, hardy vessels that carry their own landing craft.

Operating a fast-growing fleet of tough but upscale expedition ships (none carrying more than 264 passengers), Ponant is known for voyages to places like Antarctica and the Arctic.

If you're looking for waterslides and laser tag, this is not the cruise line for you.

Related: This epic Ponant trip will take you to the North Pole

Princess Cruises

Popular with middle-aged couples, retirees and multigenerational families, the "Love Boat" line's ships aren't as flashy (or big, for the most part) as those of Royal Caribbean and Norwegian, and that's just the way its customers like it.

Princess Cruises ' customers also like its wide range of itineraries, including voyages in Asia and Australia, as well as closer-to-home places like the Caribbean. It's long been one of the dominant lines in the Alaska cruise market.

Related: The ultimate guide to Princess Cruises

Regent Seven Seas Cruises

This Miami-based luxury line operates some of the most opulent vessels at sea, including three recently unveiled Explorer-class ships billed as the most expensive luxury vessels ever built on a cost-per-berth basis.

Regent Seven Seas Cruises is particularly known for some of the most over-the-top suites at sea (including some bigger than the average American home ), some of the most inclusive fares in the cruise business and high levels of service. The only catch: You'll pay a pretty penny for it. Rooms on Regent ships start at around $1,000 per person per day and can cost as much as $5,500 per person per day.

Royal Caribbean

For megaresort fans, there's nothing quite like a Royal Caribbean vessel.

The line's biggest ships are more than 20% bigger than almost any others afloat (only MSC Cruises has ships that come close in size) and feature every type of amusement imaginable, from rock climbing walls and surfing pools to Broadway shows and ice skating rinks.

Families, in particular, will love this line, due to all the family-friendly activities and venues on its vessels. Royal Caribbean ships sail everywhere in the world, but the line's heaviest presence is in the Caribbean and Europe.

Related: The ultimate guide to Royal Caribbean

Another leader in luxury cruising, this seven-ship brand offers all-suite vessels, top-notch service and elegant cuisine.

As with other luxury lines, Seabourn offers a wide range of itineraries around the globe. It also recently jumped into more adventurous, expedition-style cruising with two new 264-passenger vessels designed to operate in polar regions such as Antarctica and the Arctic.

Silversea Cruises

Exquisite service, refined dining and well-appointed accommodations are hallmarks of this Monaco-based luxury line with 12 vessels. Silversea Cruises is also known for its industry-leading array of off-the-beaten-path itineraries.

Its growing fleet of small expedition ships will take you everywhere from the Arctic to Papua New Guinea in style.

The Ritz-Carlton Yacht Collection

Fans of upscale hotel chain Ritz-Carlton will feel at home on one of this line's yacht-like vessels. Or, at least, that's the idea.

The cruising arm of Ritz-Carlton has been in operation for just a bit over a year, and the jury still is out on where it ranks in the pantheon of luxury cruise brands. The line notably struggled to get off the ground after years of construction delays for its first and only ship.

Dubbed Evrima, the line's only operating ship is a 298-passenger vessel designed to appeal to Ritz-Carlton regulars with an elegant, residential look. A second, bigger ship called Ilma that's already open for bookings debuts later this year.

Related: The ultimate guide to the Ritz-Carlton Yacht Collection

This fast-growing line has dominated the world of river cruising for North Americans for years, and in the last few years, it's become a significant player in upscale ocean cruising as well. Viking 's 80 river ships operate on just about every major river in the world, and its 10 ocean ships (up from just one in 2015) can be found in a growing number of destinations, too.

Viking is known for impeccably designed vessels with modern Scandinavian interiors and offering unusual, port-intensive itineraries. They also operate with a mostly all-inclusive format, as Viking long has subscribed to a "no nickel-and-diming" philosophy. Just don't bother booking the family. Kids under 18 aren't allowed on Viking.

Related: The ultimate guide to Viking cruises

Virgin Voyages

This relatively new cruise line, backed by Richard Branson's Virgin Group, is reinventing mainstream cruising with a hipper, more inclusive, younger vibe (though not too young; its ships are adults-only). Think tattoo shops, karoake booths and no upcharges for tips or eateries.

Virgin Voyages ' first three ships ( Scarlet Lady , Valiant Lady and Resilient Lady ) have suites by acclaimed designer Tom Dixon. Destinations include the Dominican Republic, Mexico and a private beach club in the Bahamas, as well as parts of Europe and Australia.

Related: I've been on more than 150 cruise ships; here's why I loved my first Virgin sailing

Windstar Cruises

If the idea of sailing on a big ship makes you cringe, small-ship specialist Windstar could be the answer.

Its six vessels carry just 148 to 342 passengers — fewer than fit on a single big-ship lifeboat — and are wonderfully intimate.

Romantic types will love Windstar's three vessels with sails — a relative rarity. Foodies can choose one of the James Beard-themed cruises, which include market tours and cooking demonstrations with a James Beard Award-winning chef.

More guides that will help you plan a cruise:

- The 5 most desirable cabin locations on any cruise ship

- The 8 worst cabin locations on any cruise ship

- 21 tips and tricks that will make your cruise go smoothly

- 15 ways cruisers waste money

- 15 best cruises for people who never want to grow up

- What to pack for your first cruise

- Guide to picking a cruise line

Wolf Street

The engines of the largest container ships in the world, and challenges their manufacturers face, by mc01 • may 28, 2018 • 101 comments, the crankshafts may set the limits., by mc01, a frequent commenter on wolf street :.

Three engine manufacturers have come to dominate the market for the giant low-speed two-stroke diesel engines used in the largest container ships, bulk carriers, and tankers: MAN SE of Germany, Mitsubishi Heavy Industries of Japan, and Wärtsilä of Finland.

Stricter environmental legislation around the world is only part of the increasingly more challenging environment these three firms – and the shipyards and contractors they work with – have to deal with.

The shipping industry does not merely demand cleaner and more fuel-efficient engines, but also engines that will last the design life of the ship (usually 25 years) with only scheduled maintenance and minimal repairs. Several shipowners (led by CMA CGM) are coming to like the single engine/single propeller configuration for its efficiency and reduced running costs – as long as it doesn’t impact cruising speed too much.

Technical solutions range from the use of plates of corrosion-resistant materials such as Inconel (a family of nickel-based super-alloys originally developed for jet engines) welded to the piston crown to using crankcase oil to cool not just the pistons themselves but the rod as well to reduce the likelihood of heat-induced failures.

To give an example of what the shipping industry demands nowadays, Maersk’s Triple-E container ships – the largest container ships in the world with a capacity of over 18,000 twenty-foot-container equivalent units (TEU) – are powered by two MAN two-stroke diesels, each driving its own propeller. Each engine has eight cylinders with an 800 mm bore. The engines are designed to deliver their maximum efficiency at 73 rpm. Their combined power of 59,000 kW allows the monster-ship to cruise at 16 knots.